Method for weighing belt conveyor and weighing device

A belt conveyor and weighing device technology, applied in the field of sensor weighing, can solve the problems of inaccurate weighing and measurement, uneven force on the sensor, etc., and achieve the advantages of overcoming the influence of weighing accuracy, reasonable structure, and low weighing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with embodiment and accompanying drawing.

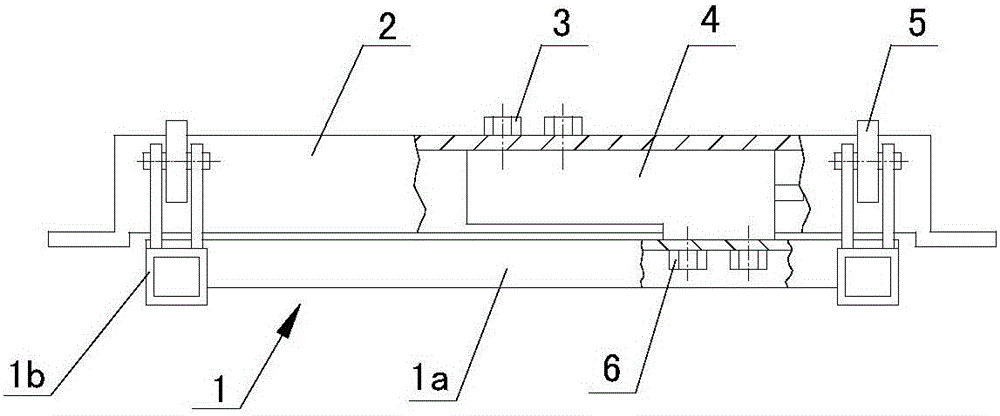

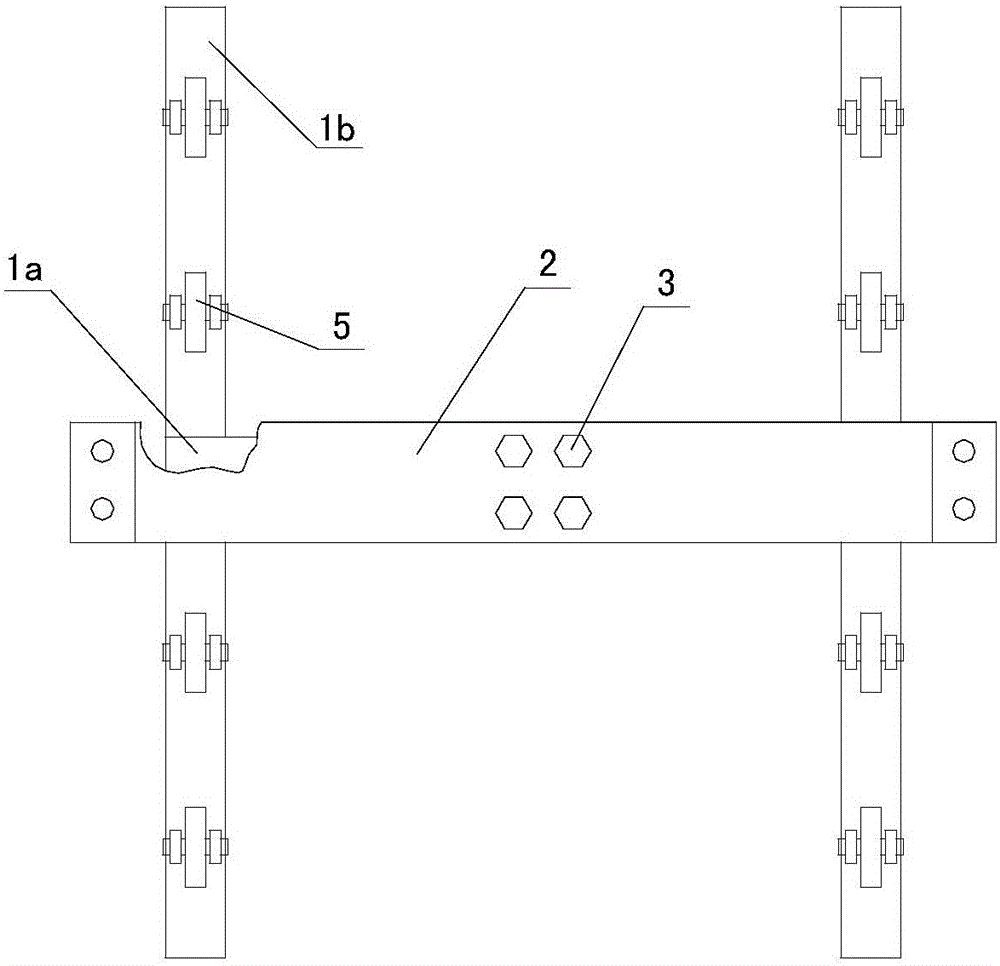

[0015] The weighing method of the belt conveyor provided by the present invention is to divide the weighed area of the belt conveyor into several weighing sections, and the belt of each weighing section is supported by a group of cantilever type load cells. The cantilever type load cell sends the weighing signal obtained to the weighing control instrument, and the weighing control instrument analyzes and processes the weighing signal obtained by each group of cantilever type load cell according to the inclination angle of the belt conveyor, and obtains the belt The cumulative amount of the weight of the material conveyed by the conveyor during a certain period of time.

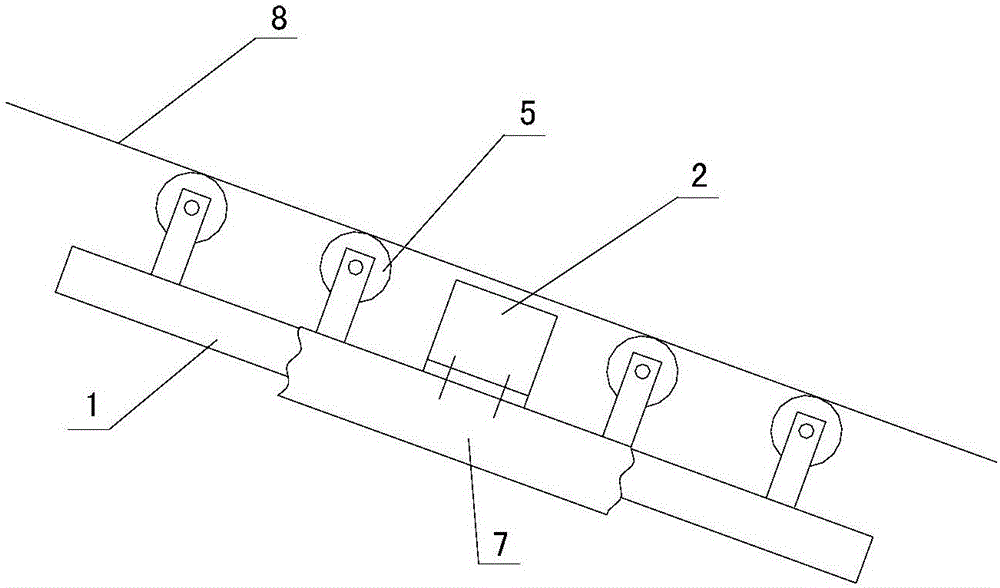

[0016] In this embodiment, in order to reduce the impact of the positive pressure of the material on the belt when the belt conveyor is inclined, the force and strain axis of each cantilever loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com