Fly ash curing treatment system

A processing system and fly ash solidification technology, applied in the field of fly ash solidification processing system, can solve problems such as decreased weighing accuracy and inability of programs to run automatically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

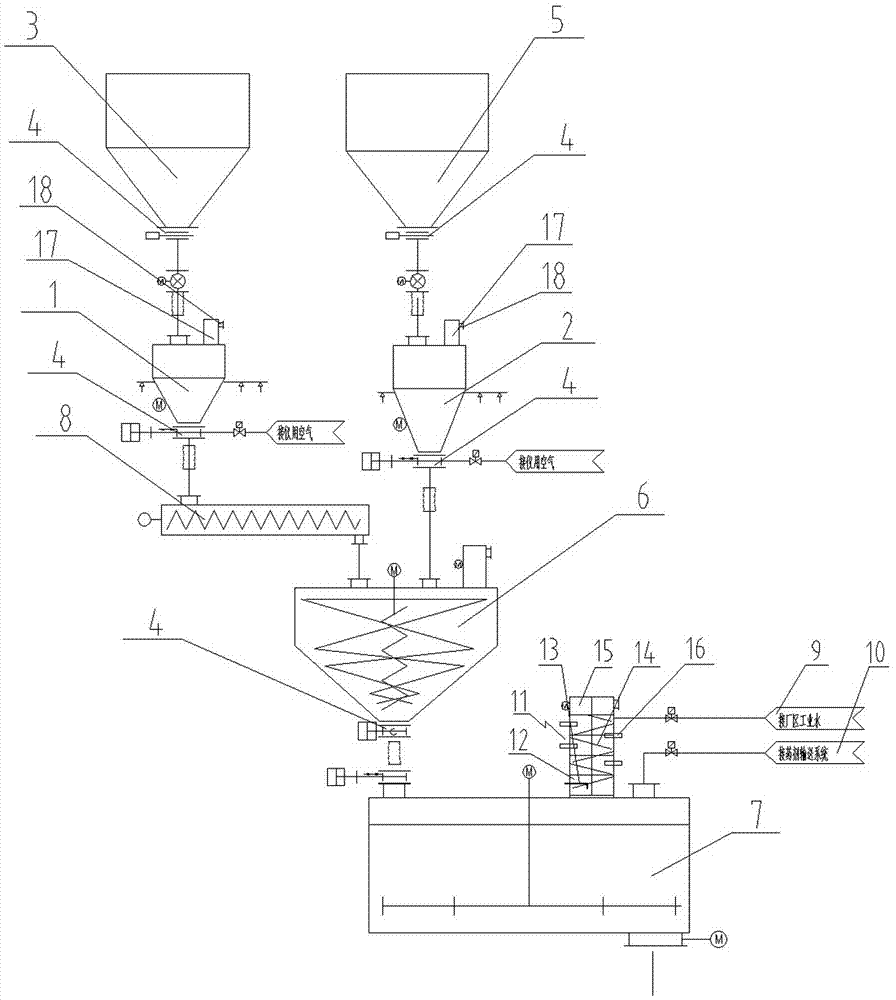

[0010] See figure 1 , a fly ash solidification treatment system, which includes a fly ash weighing bin 1 and a chemical weighing bin 2, the fly ash bin 3 is connected to the fly ash weighing bin 1 through a valve 4, the chemical bin 5 is connected to the chemical weighing bin 2 through a valve 4, and the fly ash The weighing bin 1 and the chemical weighing bin 2 are respectively connected to the spiral mixing agitator 6 through the valve, and the spiral mixing agitator 6 is connected to the planetary agitator 7 through the valve 4, and the fly ash weighing bin, the chemical weighing bin and the planetary agitator 7 are provided with Spiral mixing agitator 6, when the fly ash processed in the spiral mixing agitator 6 is mixed with water in the planetary agitator 7, it can effectively prevent a large amount of dusty water vapor in the planetary agitator 7 from entering the scale body It causes the discharge door of the scale body and the internal hardening of materials, which en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com