Method and device for measuring absorbing capacity of organic solvent volatile gas in ion liquid

A technology of organic solvents and ionic liquids, which is applied in the field of devices for measuring the absorption of volatile gases of organic solvents in ionic liquids, and can solve the problems of small amount of analysis and inability to make natural volatilization of organic solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

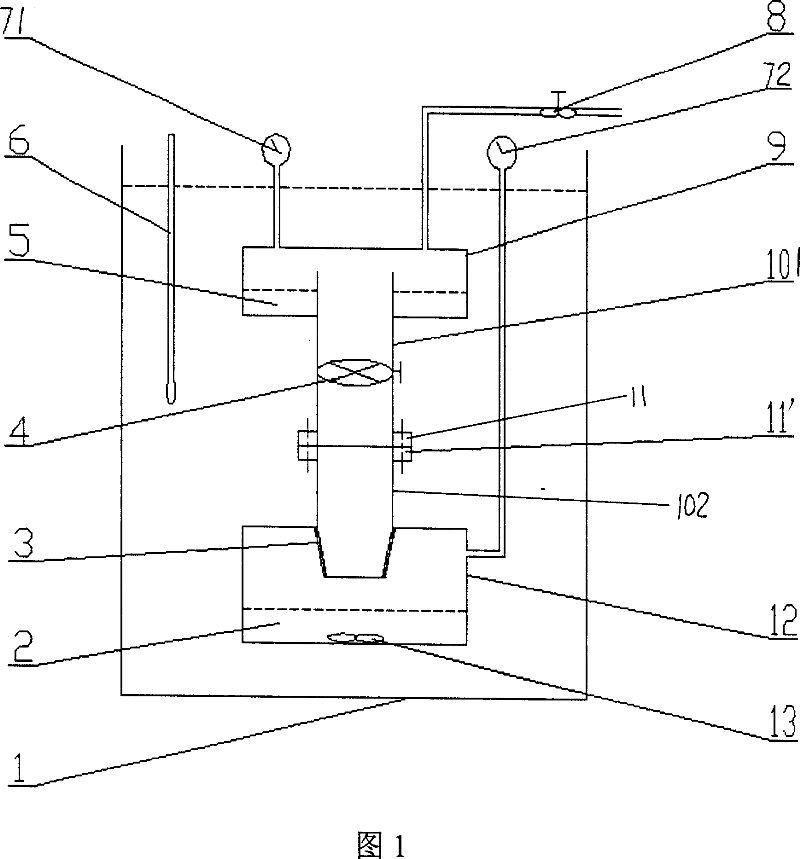

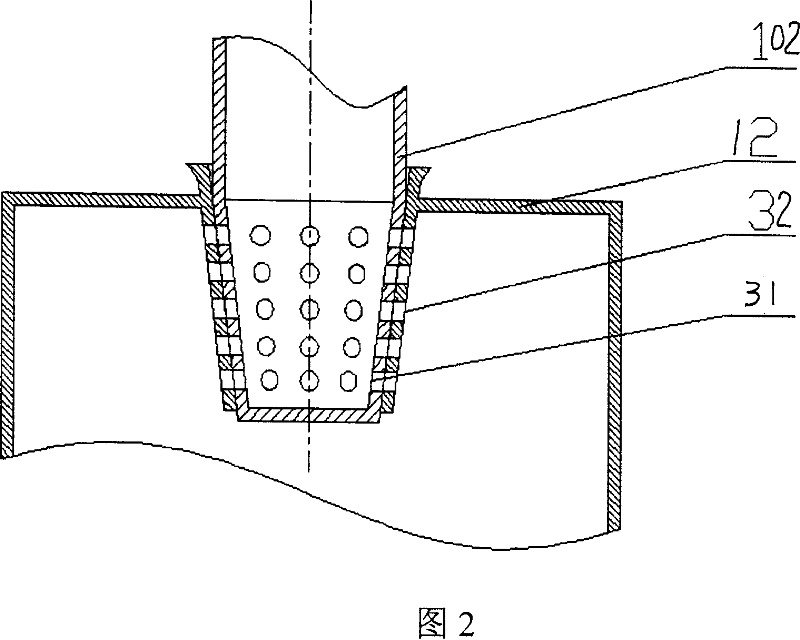

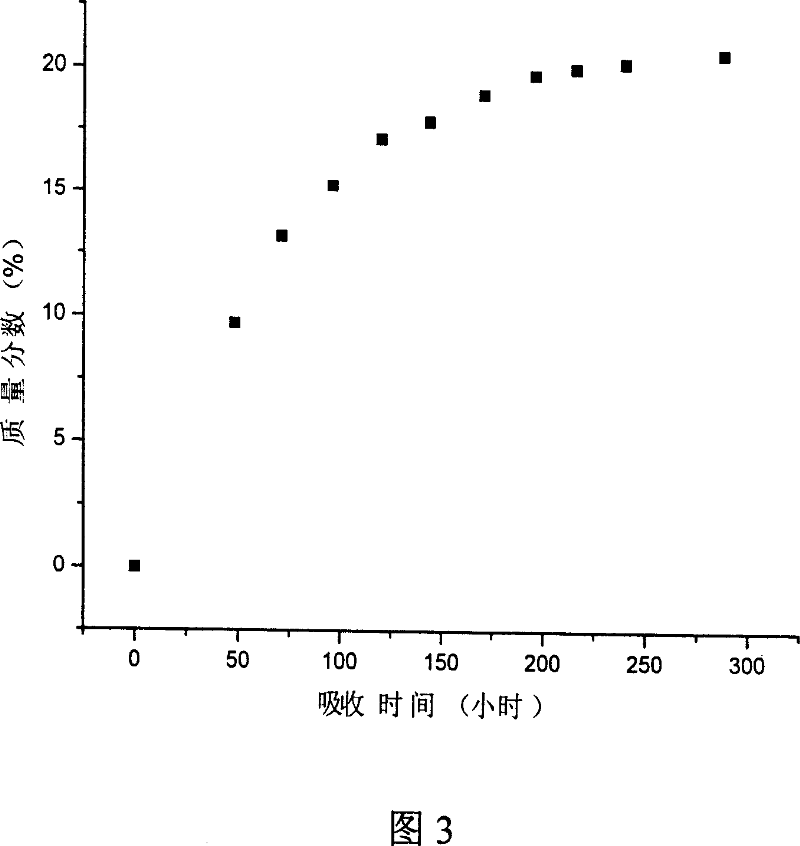

[0061] Embodiment 1, under constant pressure, ionic liquid [bmim] [PF 6 ] Measurement of Absorption of Butyl Acetate Vapor by Absorbent

[0062] 100ml butyl acetate is placed in steam generator 9 among Fig. 1, 35g ionic liquid [bmim][PF 6 ] Placed in the steam absorber 12, connect the steam generator and the absorber through the flanges 11, 11', open the upper and lower connecting valves 4, 3, control the temperature in a water bath constant temperature bath, keep the temperature at 20°C, and vacuumize. The steam absorber and the steam generator are kept in communication, and the organic solvent vapor diffuses into the absorber to be absorbed in the ionic liquid. After a period of time, close the upper and lower connection valves 4, 3, open the flanges 11 and 11 ', and take off the vapor absorber 12 for weighing. Samples were taken and weighed at different times to obtain butyl acetate volatile gas in the ionic liquid [bmim][PF 6 ] in the absorption curve with time. Figure...

Embodiment 2

[0063] Embodiment 2, under constant pressure, ionic liquid [bmim] [PF 6 ] Absorption of n-butanol volatile gas by absorbent

[0064] Put 100ml n-butanol in steam generator 9, 35g ionic liquid [bmim][PF 6 ] Placed in the steam absorber 12, connect the steam generator and the absorber through the flanges 11, 11', open the upper and lower connecting valves 4, 3, control the temperature in a water bath constant temperature bath, keep the temperature at 20°C, and vacuumize. The steam absorber and the steam generator are kept in communication, and the organic solvent vapor diffuses into the absorber to be absorbed in the ionic liquid. After a period of time, close the upper and lower connection valves 4, 3, open the flanges 11 and 11 ', and take off the vapor absorber 12 for weighing. Samples were taken and weighed at different times to obtain the volatile gas of n-butanol in the ionic liquid [bmim][PF 6 ] in the absorption curve with time. Figure 4 shows the volatile gas of n-b...

Embodiment 3

[0065] Embodiment 3, under constant pressure, ionic liquid [bmim] [BF 4 ] Measurement of Absorption of Toluene Vapor by Absorbent

[0066] 100ml of toluene is placed in the steam generator 9 among Fig. 1, 35g of ionic liquid [bmim][BF 4 ] Placed in the steam absorber 12, connect the steam generator and the absorber through the flanges 11, 11', open the upper and lower connecting valves 4, 3, control the temperature in a water bath constant temperature bath, keep the temperature at 20°C, and vacuumize. The steam absorber and the steam generator are kept in communication, and the organic solvent vapor diffuses into the absorber to be absorbed in the ionic liquid. After a period of time, close the upper and lower connection valves 4, 3, open the flanges 11 and 11 ', and take off the vapor absorber 12 for weighing. Samples were taken and weighed at different times to obtain the toluene volatile gas in the ionic liquid [bmim][BF 4 ] in the absorption curve with time. Figure 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com