Bucket inner wall on-line self-cleaning device of packing scale

A technology of self-cleaning and packaging scales, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low weighing and measurement accuracy of packaging scales, achieve the elimination of low packaging measurement accuracy, improve packaging measurement accuracy, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

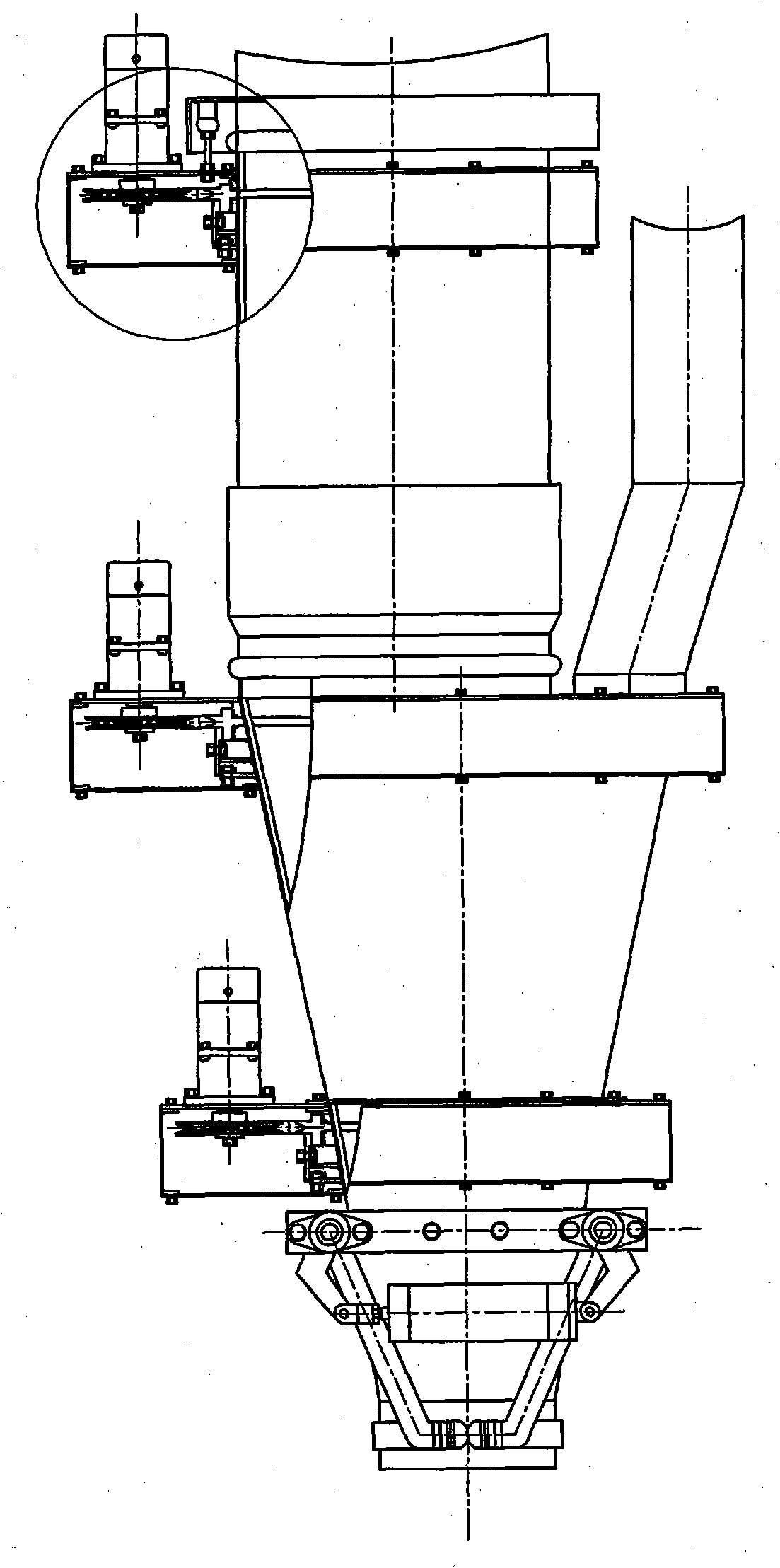

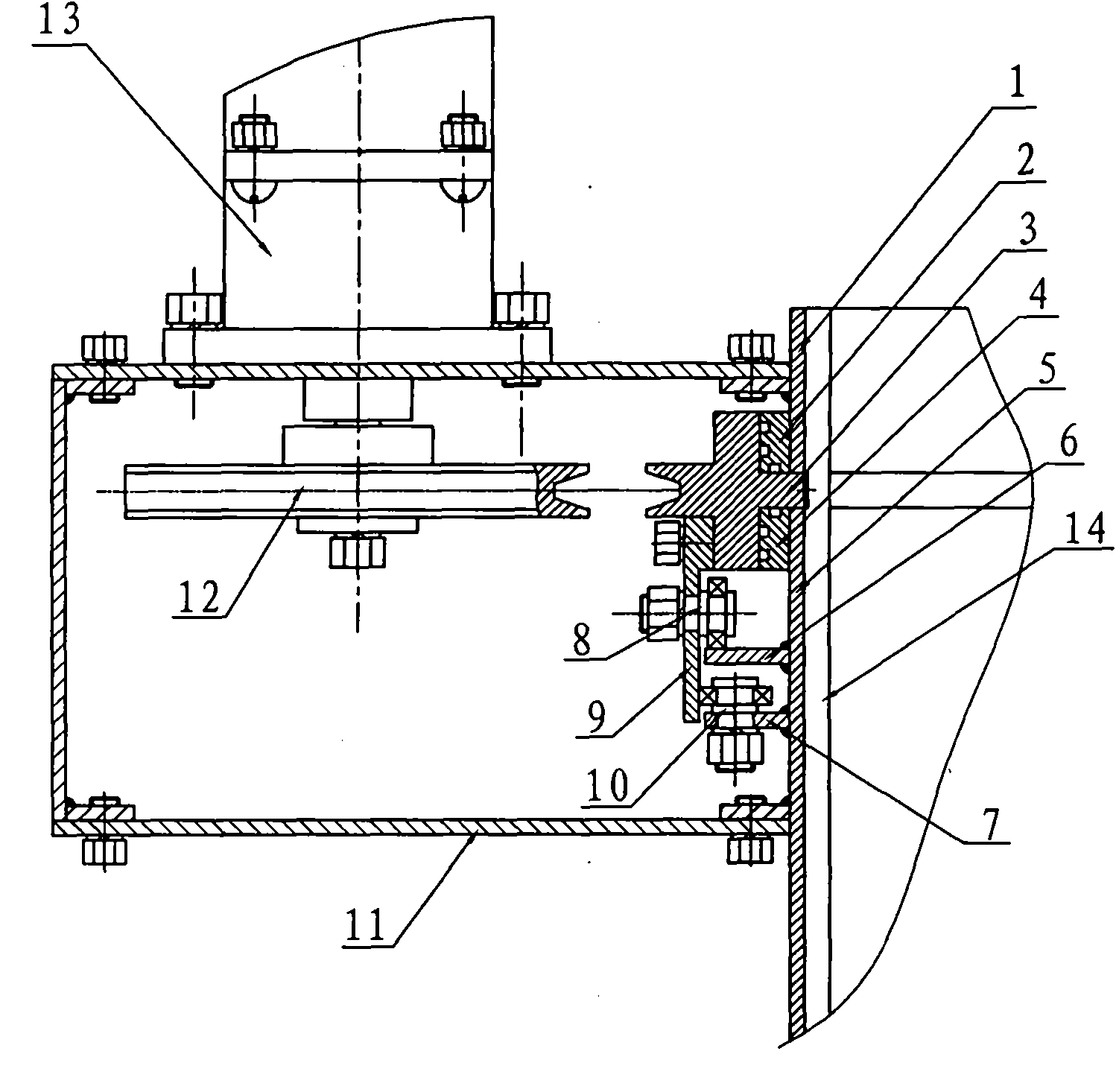

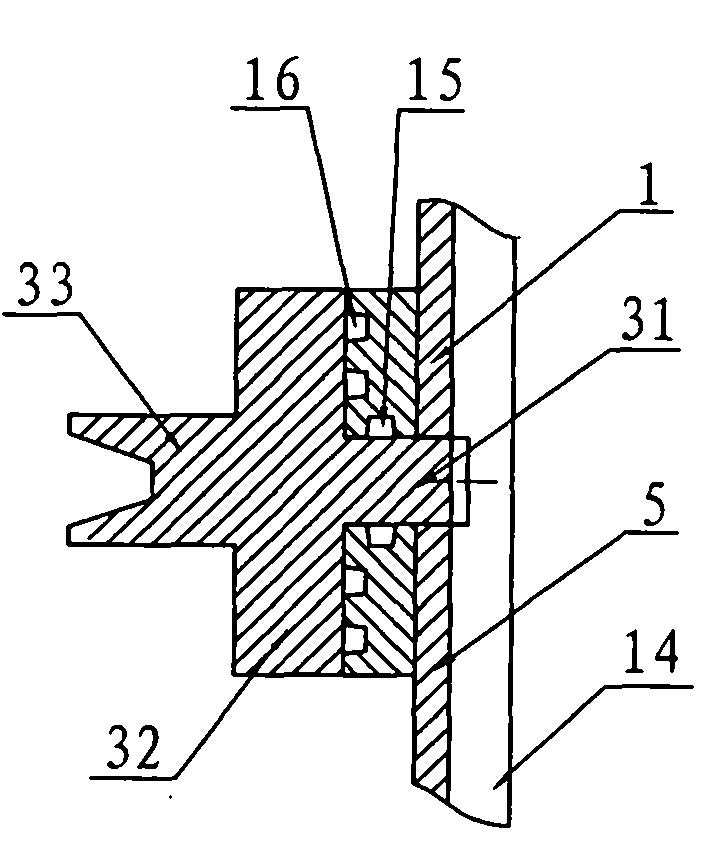

[0019] The online self-cleaning device for the inner wall of the bucket of the packaging scale includes an upper body of the weighing bucket 1, an upper fixed ring 2, a cleaning wheel 3, a lower fixed ring 4, a lower body of the weighing bucket 5, a raceway ring 6, a roller seat ring 7, an axial Scroll wheel 8, radial limit ring 9, radial scroll wheel 10, connection box 11, drive wheel 12, motor 13 and bracket 14, upper fixed ring 2 is fixed on the lower section of the upper body 1 of the weighing bucket, and the lower section of the two The ports are flush; the lower fixed ring 4 is fixed on the upper section of the lower body 5 of the weighing bucket, and the upper ports of the two are flush; the cleaning wheel 3 is composed of an axial inner ring 31, a radial positioning ring 32 and a transmission ring 33. The cleaning wheel 3 The cross-sectional shape is a "ten" shape, and the radial limit ring 9 is fixed on the outer surface of the radial positioning ring 32 of the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com