Blast furnace multiple-material preparation system and method in concentrated weighing mode

A kind of material and blast furnace technology, which is applied in the field of multi-material preparation system of blast furnace, can solve the problems of increasing material preparation time, increasing the labor intensity of operators, and unable to guarantee the accuracy of mixing ratio, and improving production efficiency and production quality. Stacking and electrical equipment overload, the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

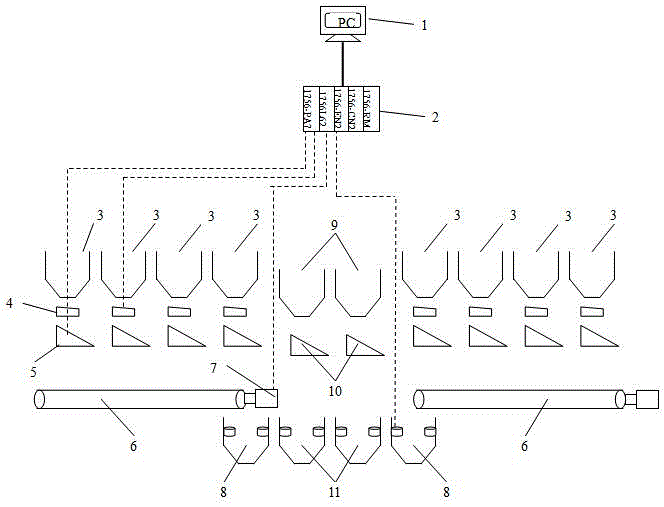

[0026] Such as figure 1 As shown, a blast furnace multi-material preparation system in a centralized weighing mode includes two sets of symmetrical preparation systems. Take the system on the left side of the figure as an example, including a conveyor belt 6, and the upper part of the conveyor belt 6 is along its length There are four ore bins 3 in sequence. Between the ore bin 3 and the conveyor belt 6, there are a feeder 4 and an ore vibrating screen 5 in sequence. The feeder 4 and the ore vibrating screen 5 have the same number as the ore bin 3 For one correspondence, there is a centralized ore weighing hopper 8 below the end of the conveyor belt 6, and a conveyor belt motor 7 is connected to the conveyor belt 6; a coke bin 9 is provided on one side of the end of the conveyor belt 6, and coke bins 9 are sequentially provided below The vibrating screen 10 and the coke centralized weighing hopper 11; the system also includes a host computer 1 and a PLC controller 2. The PLC co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com