Platinum-rhodium thermocouple fine wire material for quick temperature measurement and preparation method thereof

A technology of thermocouples and wire materials, which is applied in the field of precious metal materials, can solve the problems of poor control of strength and flatness, affect the control of steel smelting process, and low yield, so as to improve the yield of preparation, increase the tensile strength and Processability and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the scope of the examples.

[0034] The proportioning of each component of the platinum-rhodium thermocouple micro-wire material used for rapid temperature measurement of embodiments 1 to 3 is shown in Table 1

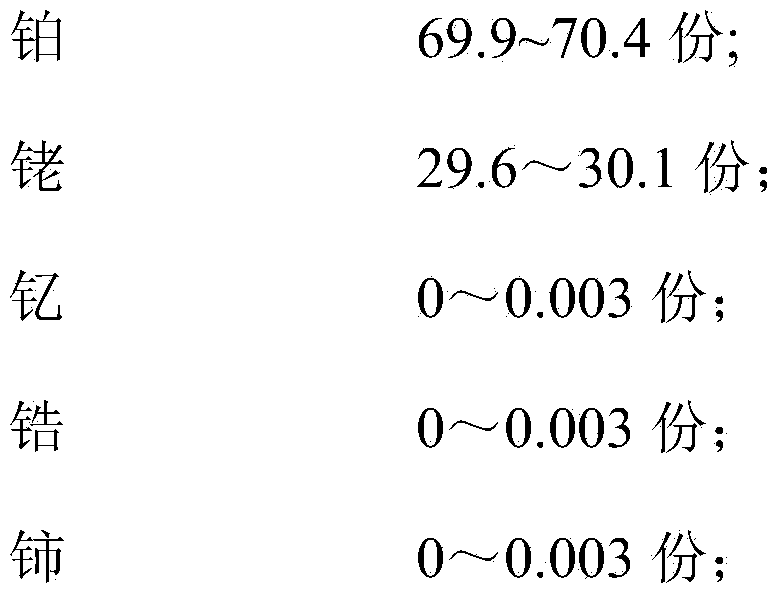

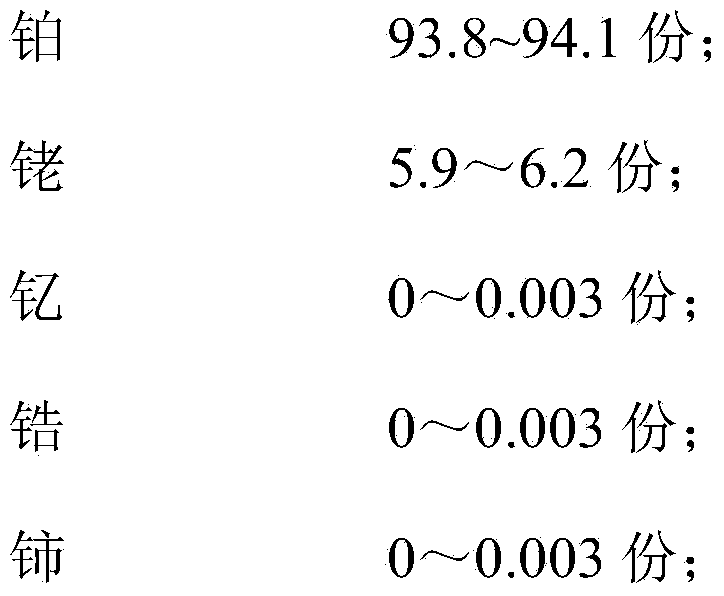

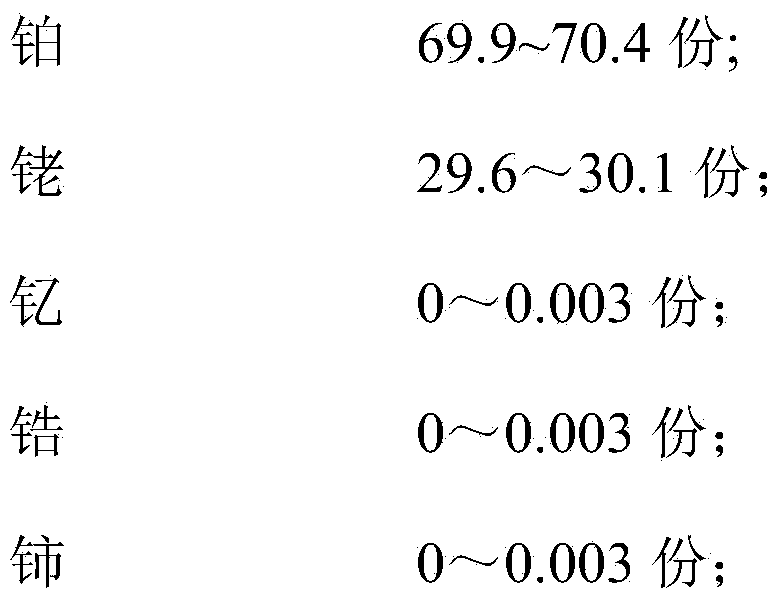

[0035] Table 1 Platinum rhodium 30-platinum rhodium 6 thermocouple material composition list

[0036]

[0037]

[0038] Get each material described in table 1 embodiment 1-3, prepare the platinum-rhodium thermocouple micro-wire material for rapid temperature measurement respectively according to the following method:

[0039] (1), high vacuum intermediate frequency melting:

[0040] The raw materials of each component of the positive electrode prepared in step 1 are placed in a high vacuum intermediate frequency, and the vacuum degree is 1×10 -3 ~1×10 -5 Pa, the melting temperature is 1900-1980°C, and at the same time, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com