Electronics ageing test system

A technology for aging testing and electronic products, applied in the direction of control/regulation systems, measuring electronics, measuring devices, etc., can solve problems such as failure to meet aging tests, insufficient test environment and accuracy, and poor versatility, and achieve safety, stability, and trouble-free Running test, system protection function is complete, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

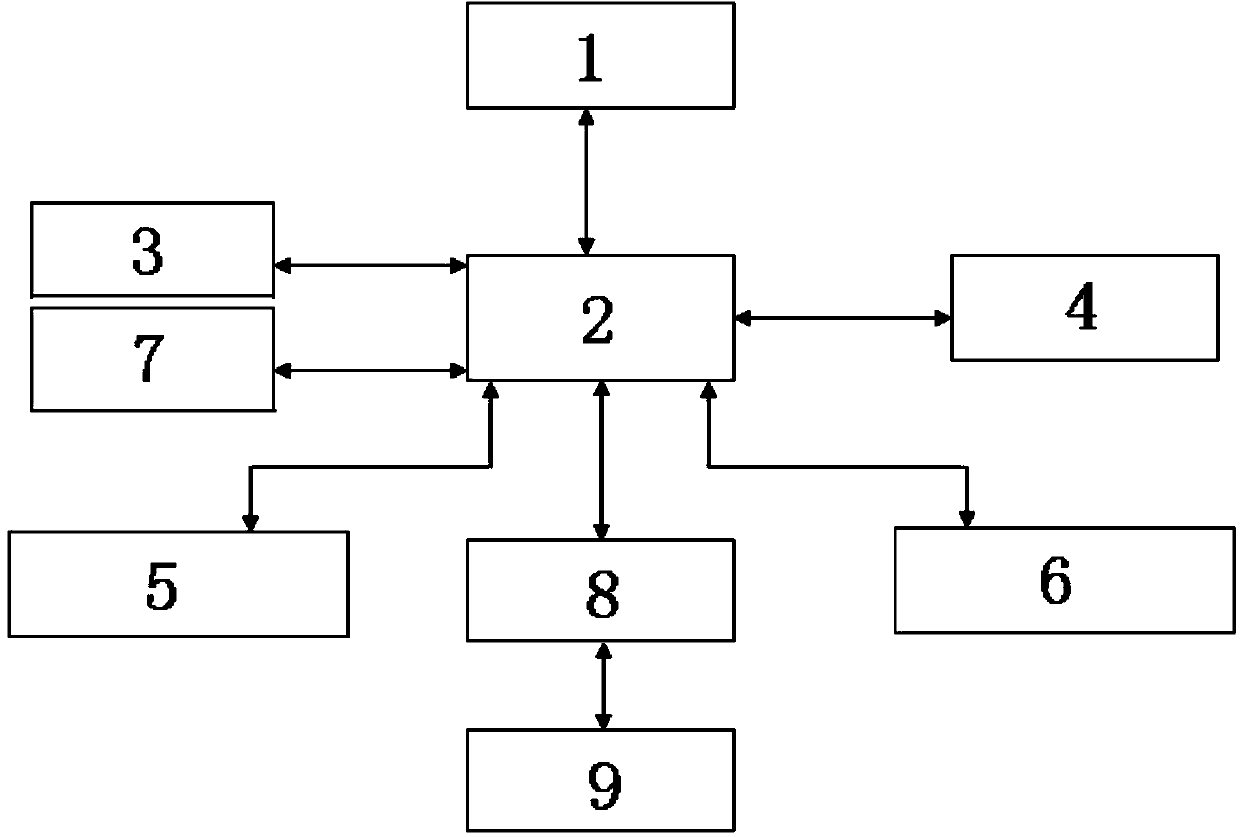

[0015] The present invention includes background system 1 namely computer, PLC module 2, temperature module 3, humidity module 4, temperature adjustment module 5, humidity adjustment module 6, time adjustment module 7, signal source module 8.

[0016] Background system 1 is the monitoring layer. PLC module 2 is the control layer. The temperature module 3, the humidity module 4, the temperature adjustment module 5, the humidity adjustment module 6, the time adjustment module 7, and the signal source module 8 jointly carry out on-site data collection and form the on-site layer.

[0017] Specifically as figure 1 As shown, the present invention controls the PLC module 2 of the background system 1 to connect the temperature module 3, the humidity module 4, the temperature adjustment module 5, the humidity adjustment module 6, and the time adjustment module 7 respectively; the time adjustment module 7 is connected to the product to be tested 9; the signal source After the module 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com