Auxiliary verification device for hopper scale and implementation method thereof

A technology of calibration device and hopper scale, which is applied in the direction of measuring device, weighing auxiliary equipment, weighing equipment testing/calibration, etc., can solve the problem of poor accuracy calibration, difficulty in full-scale calibration, unstable force, etc. problems, to achieve the effect of improving the implementation process of calibration, fully verifying and rechecking, and ensuring weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

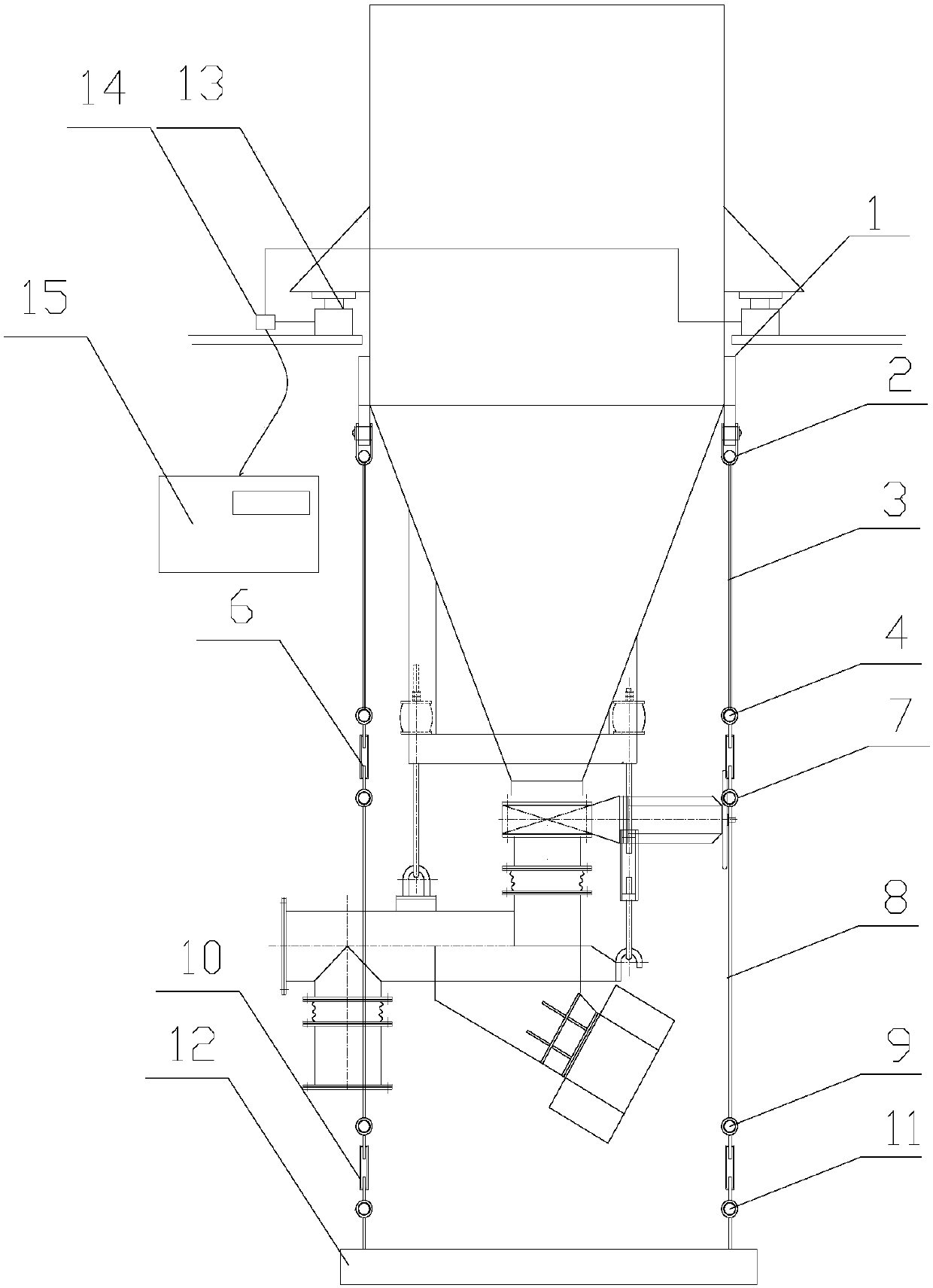

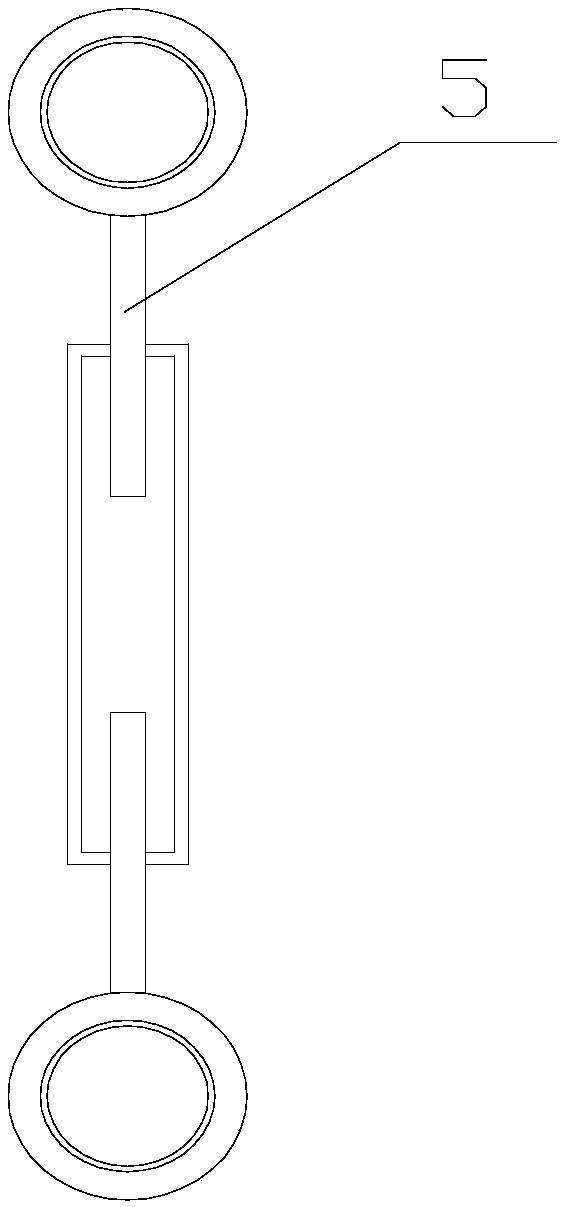

[0034] Such as figure 1 , shown in 2, a kind of hopper scale auxiliary calibration device that the present invention proposes, comprises the hanging plate 1 that is welded on the outside of feed bin symmetrically, specifically fixes at least hanging plate vertically from the storehouse wall of hopper, generally speaking, hanging plate 1 is welded On the outer surface of the cylinder of the hopper, a first lifting lug 2 is fixedly installed under the hanging plate 1, and the first lifting lug 2 is vertically arranged with a first hook 3, and the first hook 3 has hooks at both ends. The middle is a thin round steel structure. A second lifting lug 4 is provided at the lower end of the first hook 3. A screw rod 5 with external threads is provided on the second lifting lug 4. There is a first connecting plate 6, and the two ends of the first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com