Weighing system and weighing method for dynamic vehicle box distribution of tandem containers

A container and tandem technology, which is applied in the tandem container vehicle dynamic sub-box weighing system and the weighing field, can solve problems such as inability to limit overweight boxes, inaccurate single box weight, and offset center of gravity, so as to improve shipping efficiency, The effect of safety guarantee and convenient operation of the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (Embodiment 1 weighing system)

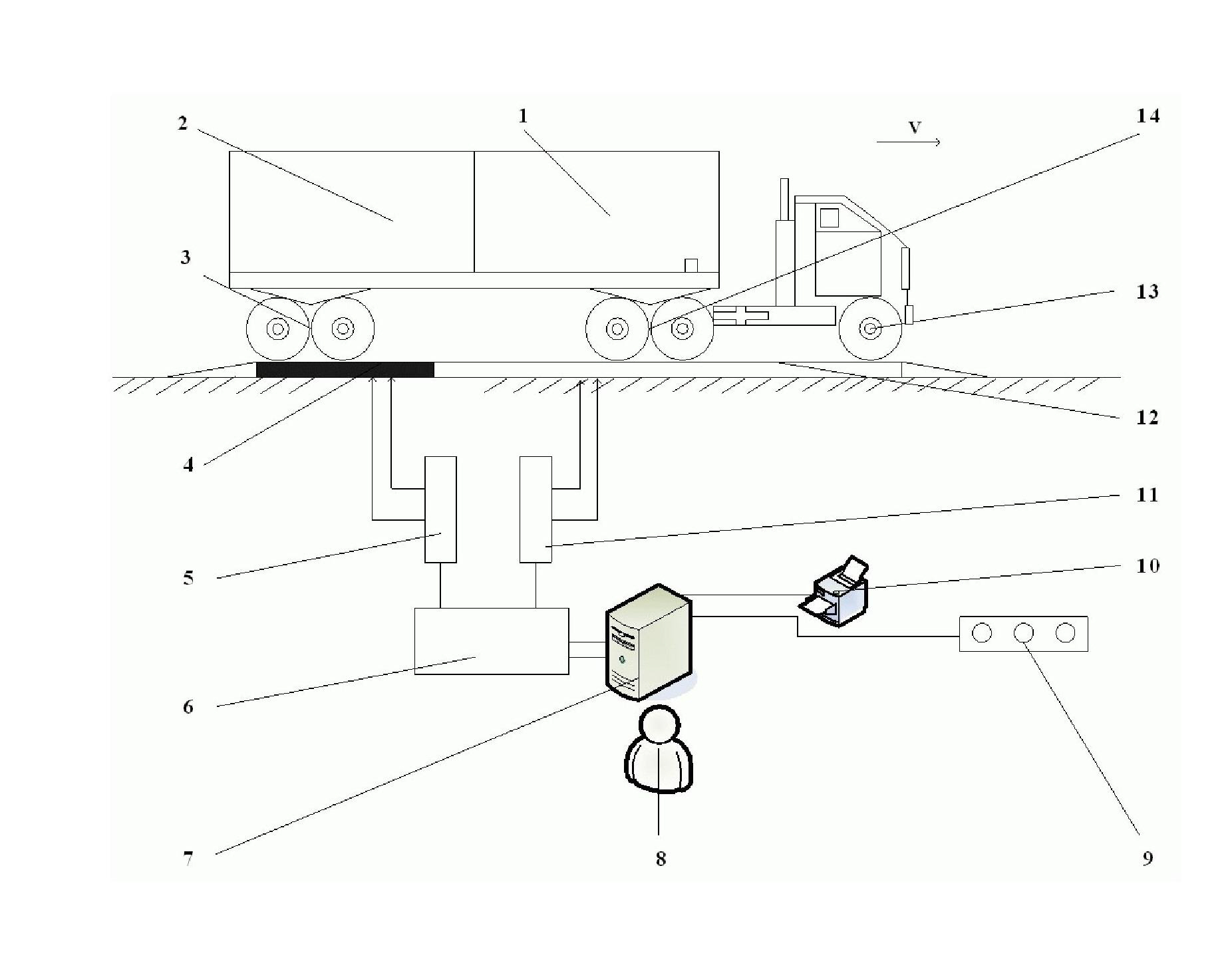

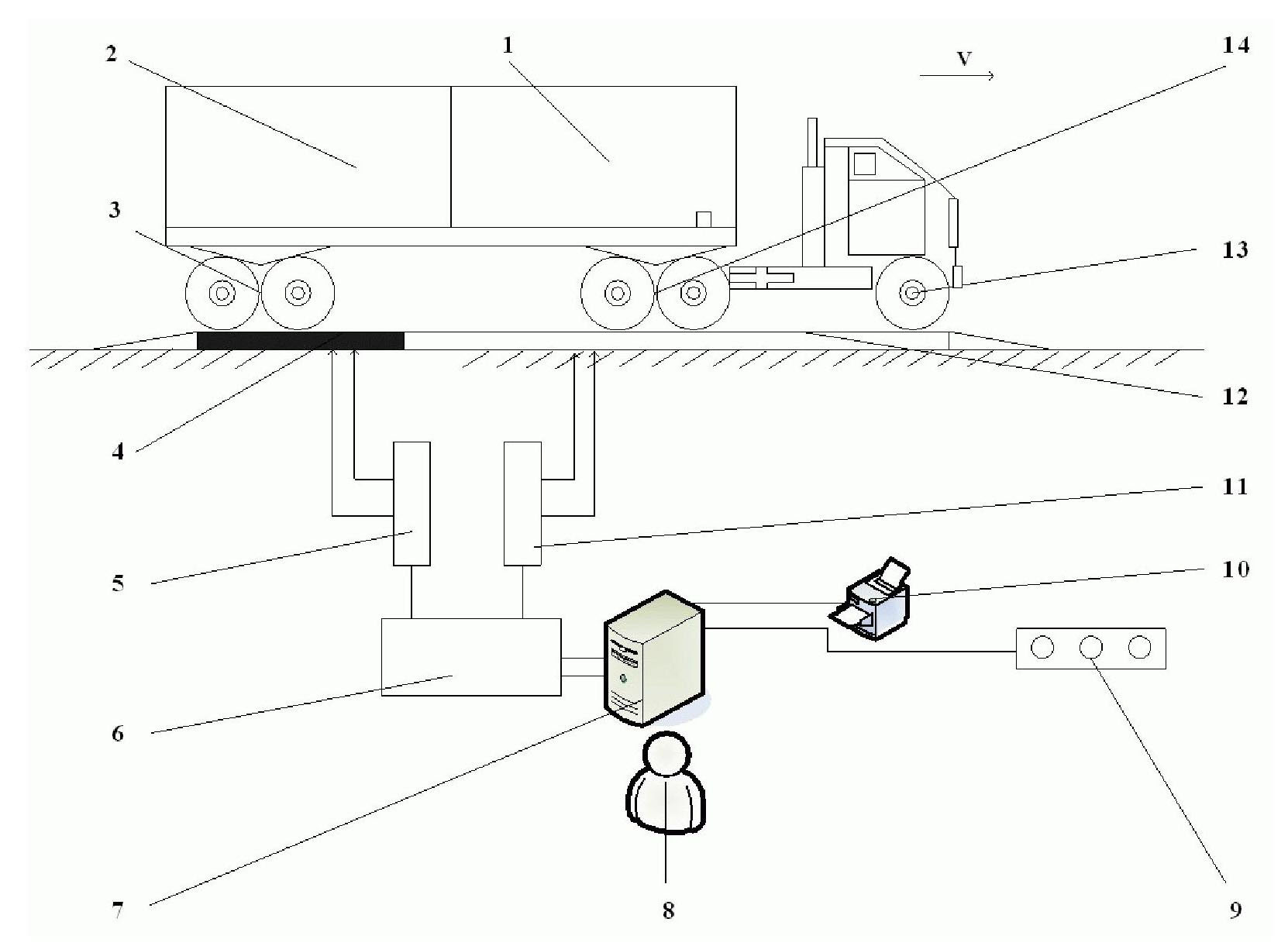

[0029] See figure 2 , the tandem container vehicle dynamic sub-box weighing system of the present embodiment includes a dynamic and dynamic shaft weighing platform 4, a dynamic scale detection instrument 5, a data acquisition device 6, a computer 7, a signal indicator light 9, a printer 10, and a static scale detection Meter 11 and static weighing platform 12. The static weighing platform 12 and the dynamic axis weighing platform 4 are connected in sequence according to the forward direction of the vehicle, and the two are equal in width and are on the same level above the ground; the dynamic weighing instrument 5 and the static weighing instrument 11 are respectively connected to the dynamic axis The weighing platform 4 and the static weighing platform 12 send the data to the data acquisition device 6; the data acquisition device 6 sends the aforementioned data to the computer 7 for analysis and calculation. The signal indicator ligh...

Embodiment 2

[0030] (embodiment 2 weighing method)

[0031] The weighing method of the present embodiment is carried out according to the following steps:

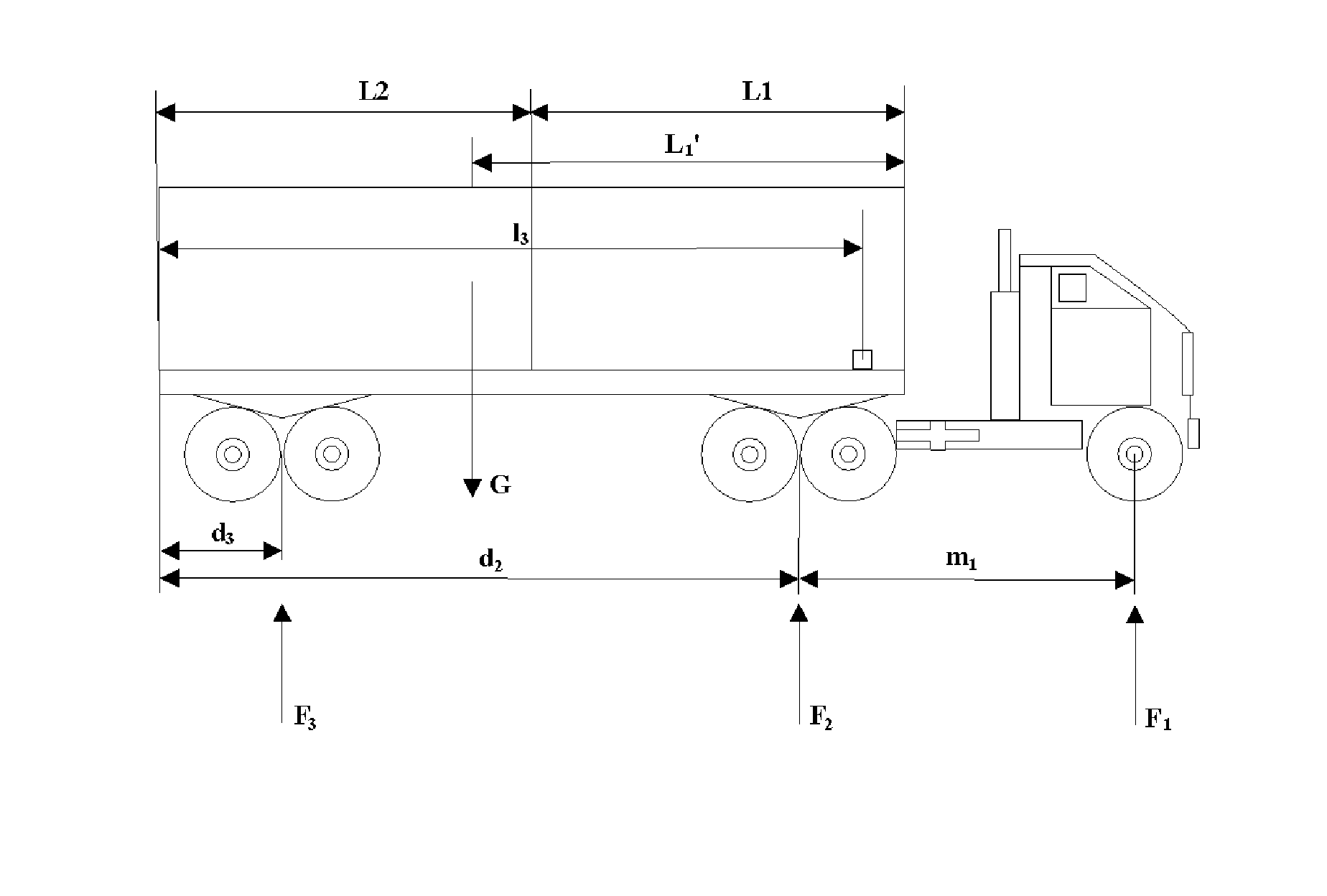

[0032] ① collect vehicle type data and container data, and store the data in computer 7; see figure 1 , the collected vehicle type data includes the distance m between tractor axles 1 , the distance between each axle of the trailer and the rear of the trailer d i , the distance between the center pin and the trailer rear l 3 , the weight of the unloaded tractor T 1 , Weight of unloaded trailer T 2 , Ground pressure F of the unloaded tractor 10 ; The collected container data includes the length L1 of the front container and the length L2 of the rear container.

[0033] ②Mathematical model L of the position of the center of gravity of the container along its length 1 ′, the weight mathematical model G1 of the front container 1, the weight mathematical model G2 of the rear container, and the optimal correction value K of each vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com