Battery capacity correction method based on improved ampere-hour integral method

An ampere-hour integration method and battery capacity technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve problems such as unsuitable lithium batteries, unsolvable batteries, poor linearity, etc., to eliminate calculation errors and avoid errors Cumulative, easily engineered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

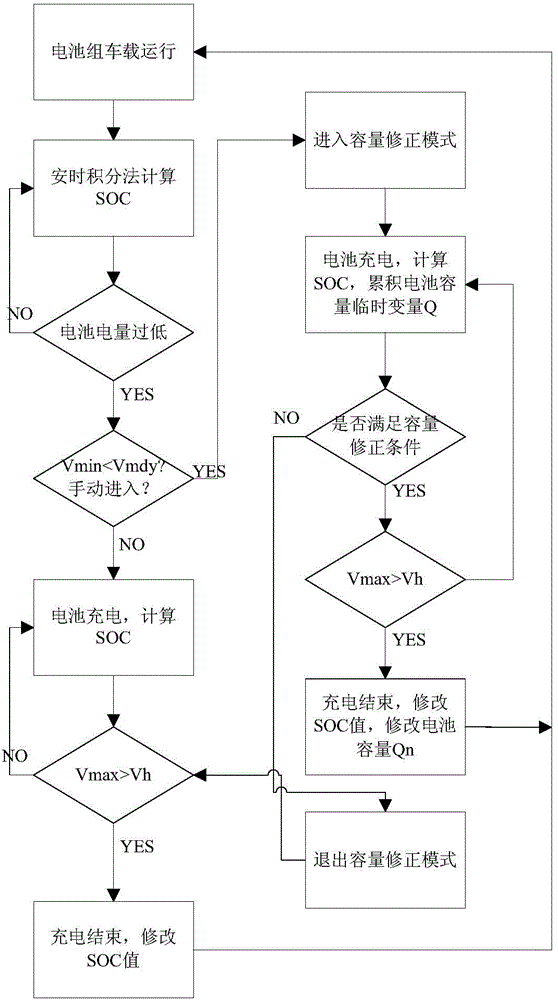

[0047] like figure 1 As shown, a battery capacity correction method based on the improved ampere-hour integration method includes the following steps:

[0048] Step (1): The battery pack runs on the vehicle;

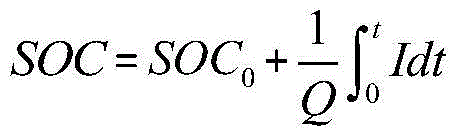

[0049] Step (2): Obtain the battery cell voltage V of the battery pack in real time i , the highest battery voltage V max , minimum battery voltage V min , charge and discharge current I; use the ampere-hour integral method to calculate SOC;

[0050] Step (3): Determine whether the battery power is too low, if yes, enter step (4); if not, return to step (2);

[0051] Step (4): Determine the minimum battery voltage V min Is it lower than the capacity correction mode threshold voltage V mdy , if yes, enter step (5); if no, enter step (6);

[0052] Step (5): Enter capacity correction mode; carry out capacity correction, then exit capacity corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com