Motor rotation speed detection system and method and storage medium

A motor speed and detection system technology, applied in linear/angular velocity measurement, speed/acceleration/shock measurement, measurement device, etc., can solve the problems of calculated speed error, inability to detect motor speed, damage to motor mechanical structure and physical characteristics, etc. , to achieve the effect of improving efficiency and accuracy and eliminating calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

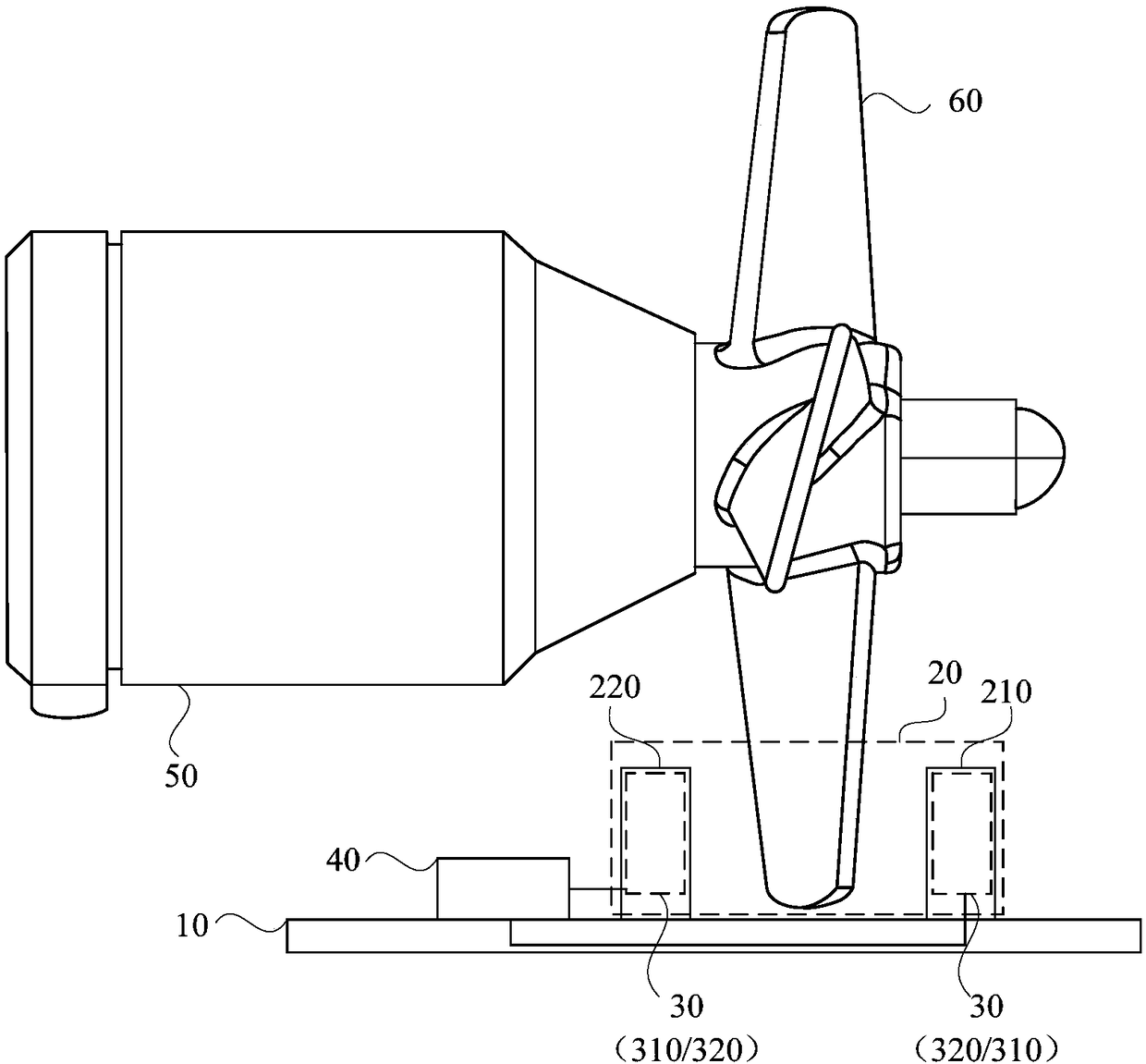

[0023] figure 1 It is a schematic diagram of a motor speed detection system provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the structure of the motor speed detection system includes:

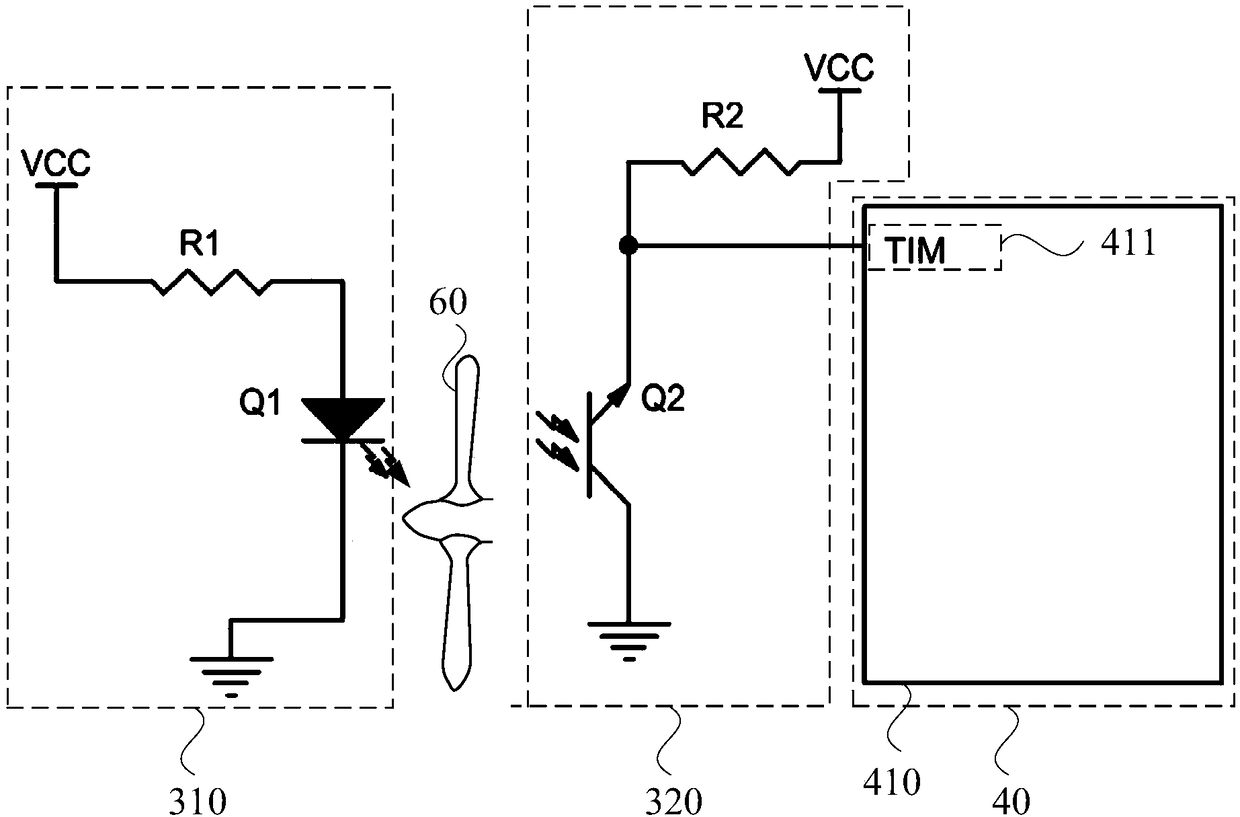

[0024] The motor installation base plate 10, the concave groove 20 arranged on the motor installation base plate 10, the blockage detection sensor assembly 30 and the controller 40 connected to the blockage detection sensor assembly 30; the concave type groove 20 is used to form the propeller blade 60 of the motor to be tested The rotation channel; the blocking detection sensor assembly 30, which is arranged on the side wall of the concave groove 20, is used to detect the propeller blade 60 passing through the concave groove 20, and sends the detection result to the controller 40; the controller 40 is used for According to the received detection results, the rotational speed of the motor 50 to be tested is calculated.

[0025] Wherein, the motor installation ...

Embodiment 2

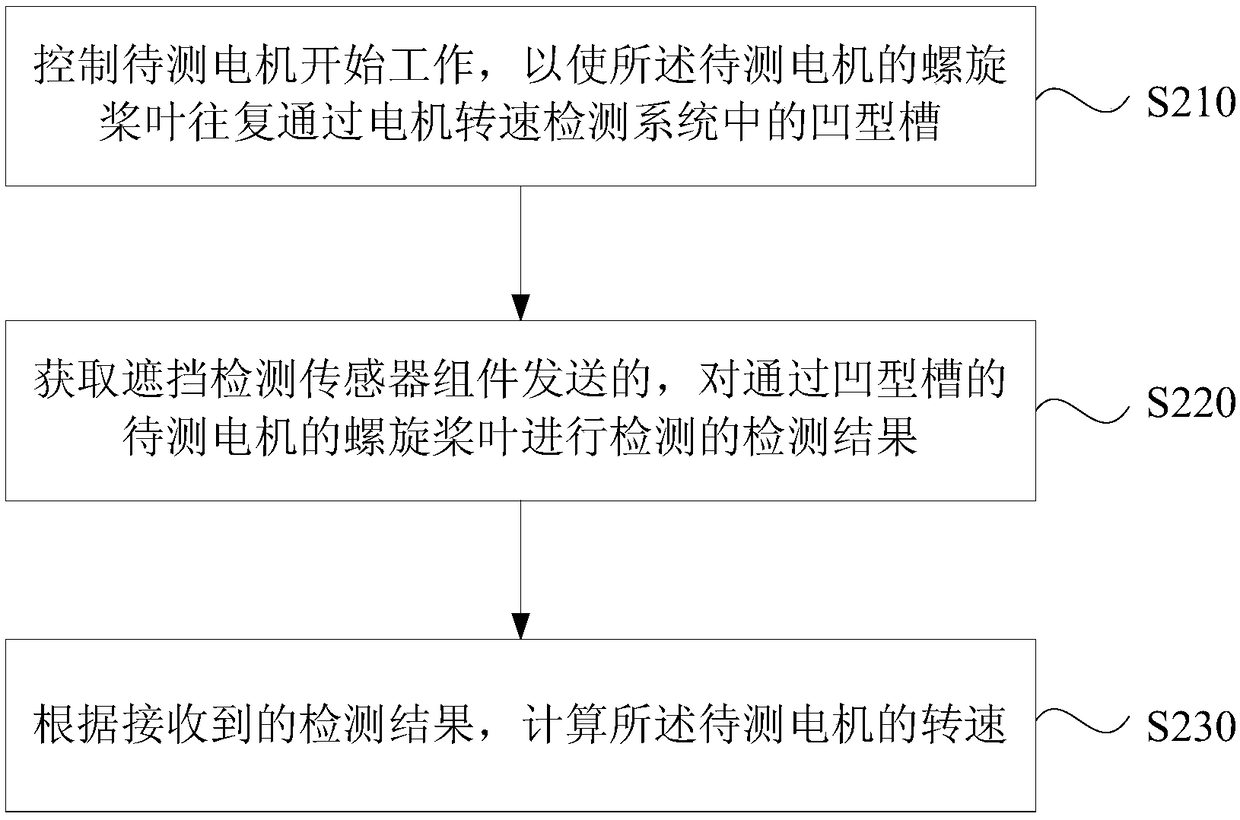

[0036] image 3 It is a flowchart of a motor speed detection method provided in Embodiment 2 of the present invention, which is applicable to the detection of motor speed. The method can be executed by any motor speed detection system described in the embodiment of the present invention. The system can be implemented by software and / or hardware implementations such as image 3 As shown, the method includes the following operations:

[0037] S210. Control the motor to be tested to start working, so that the propeller blade of the motor to be tested reciprocates through the concave groove in the motor speed detection system.

[0038] In the embodiment of the present invention, before detecting the rotational speed of the motor to be tested, the motor to be tested must be controlled to start working so that the propeller blades of the motor to be tested are in a rotating state. The propeller blades of the motor to be tested need to be kept reciprocatingly rotating in the concav...

Embodiment 3

[0050] Figure 4 It is a schematic diagram of a motor speed detection device provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the device includes: a motor control module 510, a result acquisition module 520 and a rotational speed calculation module 530, wherein:

[0051] The motor control module 510 is used to control the motor under test to start working, so that the propeller blade of the motor under test reciprocates through the concave groove in the motor speed detection system;

[0052] The result obtaining module 520 is used to obtain the detection result sent by the occlusion detection sensor assembly to detect the propeller blade of the motor to be tested passing through the concave groove;

[0053] The rotational speed calculation module 530 is configured to calculate the rotational speed of the motor under test according to the received detection result.

[0054] In the technical solution of the embodiment of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com