Fully-automatic equal-weight powder distribution system

A material distribution system and equal weight technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of high labor intensity, poor quality consistency of refractory bricks, and many labor occupations, so as to control the consistency of finished products, improve mixing efficiency, and save The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

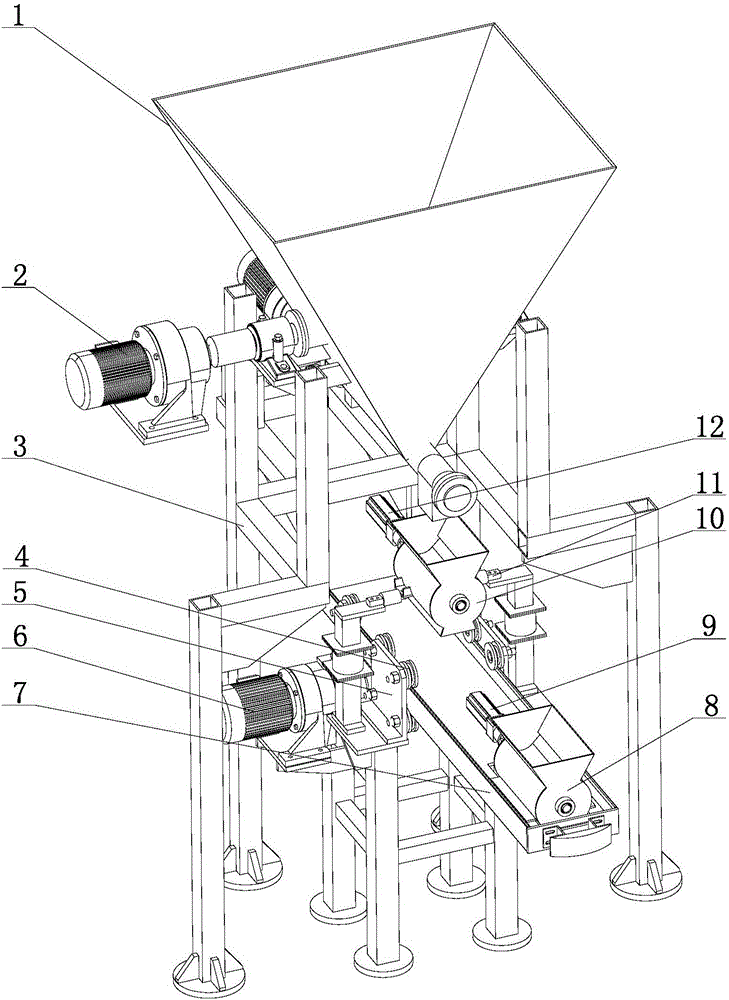

[0025] Such as Figure 1~5 As shown, the powder equal-weight automatic distribution system of the present invention includes a frame 3 and a raw material bin 1 installed on the frame 3 from top to bottom, an automatic weighing bin 10 and a mold distribution bin 8 .

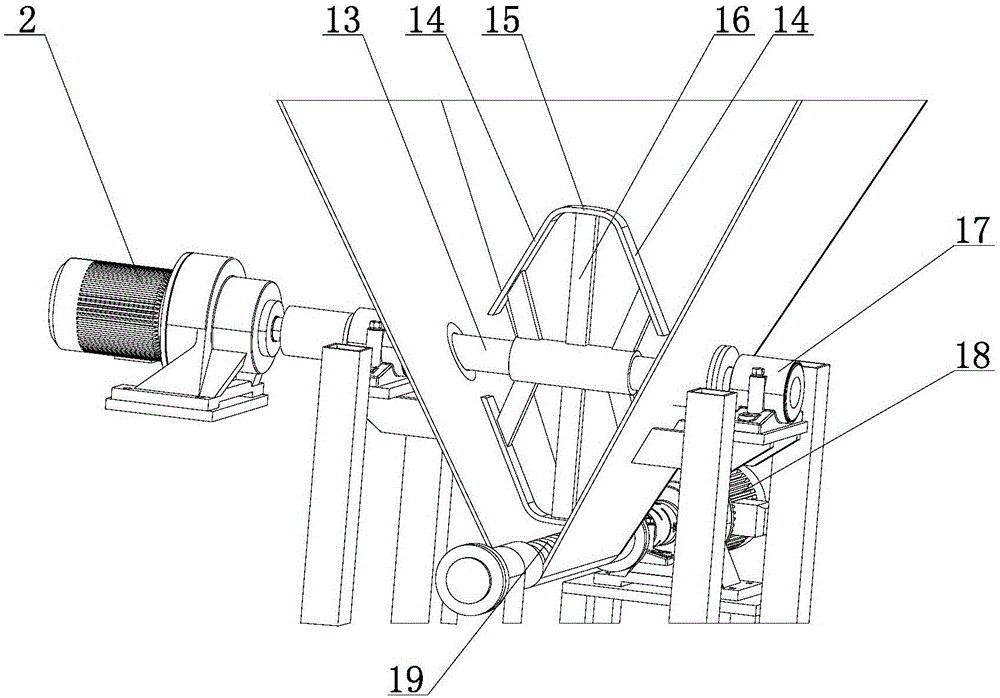

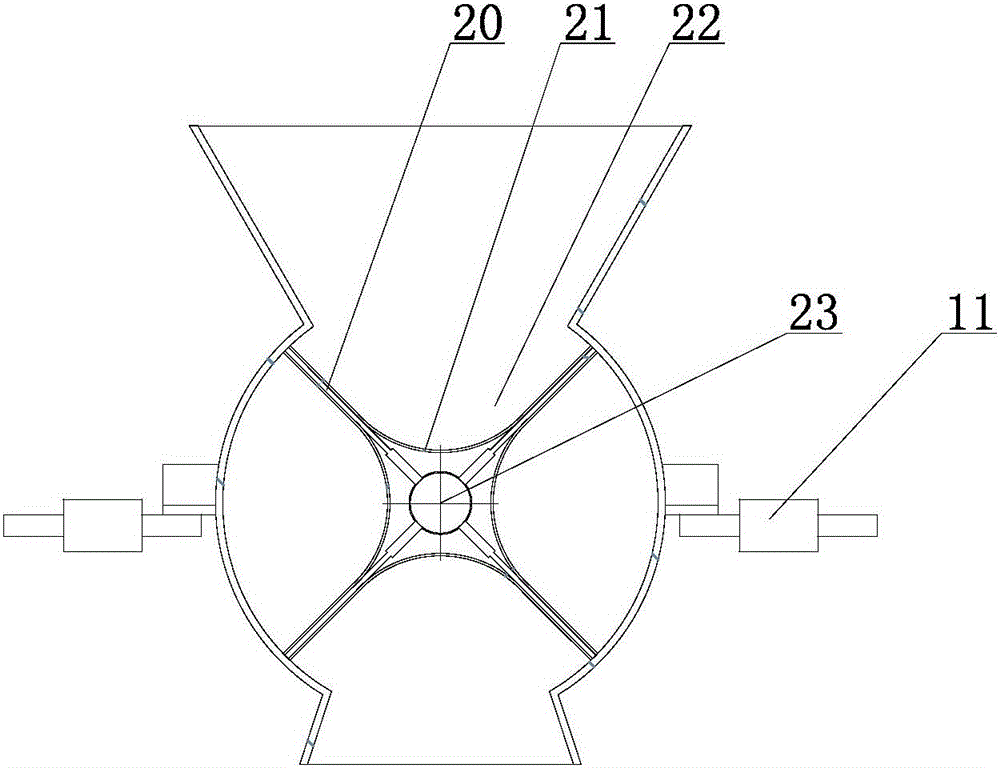

[0026] The raw material silo 1 is a Mitsubishi column whose front and rear ends are isosceles triangles and the apex of the isosceles triangle faces downward; the inner bottom of the raw material silo 1 is provided with a feeding auger 19, and the feeding auger 19 adopts a conventional silo Feeding auger gets final product, and during work, its own deceleration motor 18 drives the screw blade on the screw shaft to rotate, realizes feeding, and the discharge end of feeding auger 19 passes from raw material silo 1 and exits downward; Raw material A powder stirring device is installed in the warehouse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com