Patents

Literature

66results about How to "Reduce negative quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

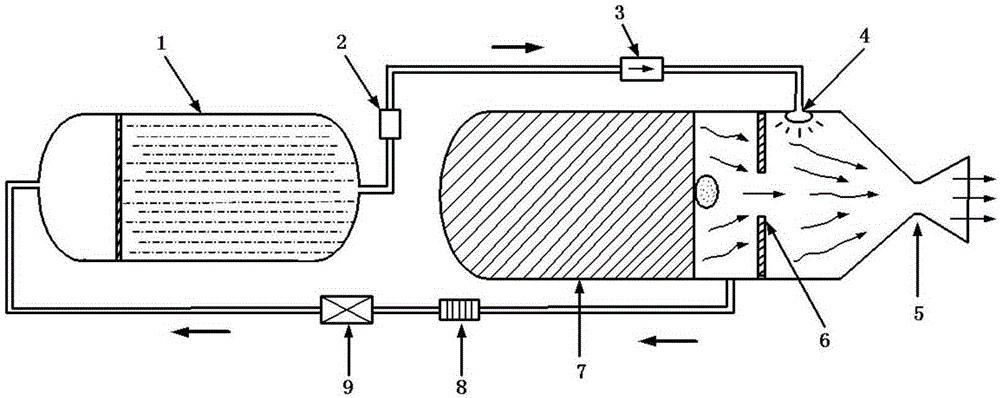

Gas self-pressurization hybrid rocket engine

InactiveCN105156231ASelf boostingSimplify structural complexityRocket engine plantsCombustion chamberEngineering

The invention provides a gas self-pressurization hybrid rocket engine which comprises an oxidizing agent storage box, an oxidizing agent control valve, a check valve, an oxidizing agent injector, a spray pipe, a flow regulating valve, a poor-oxygen gas generator, a filter and a pressure reducer. A sealing piston is arranged in the oxidizing agent storage box. The sealing piston divides an inner cavity of the oxidizing agent storage box into two sealed cavities, an oxidizing agent is placed in one sealed cavity, one end of the poor-oxygen gas generator is a sealed end, the other end of the poor-oxygen gas generator is provided with the spray pipe, a grain is poured at the position of the sealed end, and the flow regulating valve is arranged in a cavity of the poor-oxygen gas generator in which a grain is not poured. The flow regulating valve divides the cavity in which a grain is not poured into two cavities, and the cavity close to the spray pipe is a secondary combustion chamber. According to the gas self-pressurization hybrid rocket engine, self-pressurization can be achieved, and the complexity of an oxidizing agent supply system can be simplified greatly.

Owner:中国航天科技集团公司第四研究院第四十一研究所

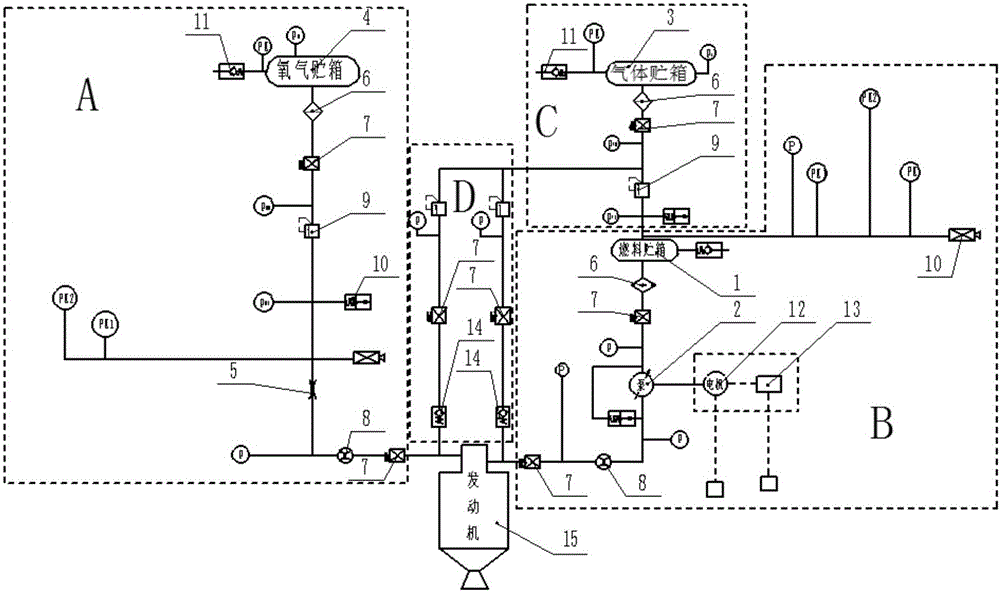

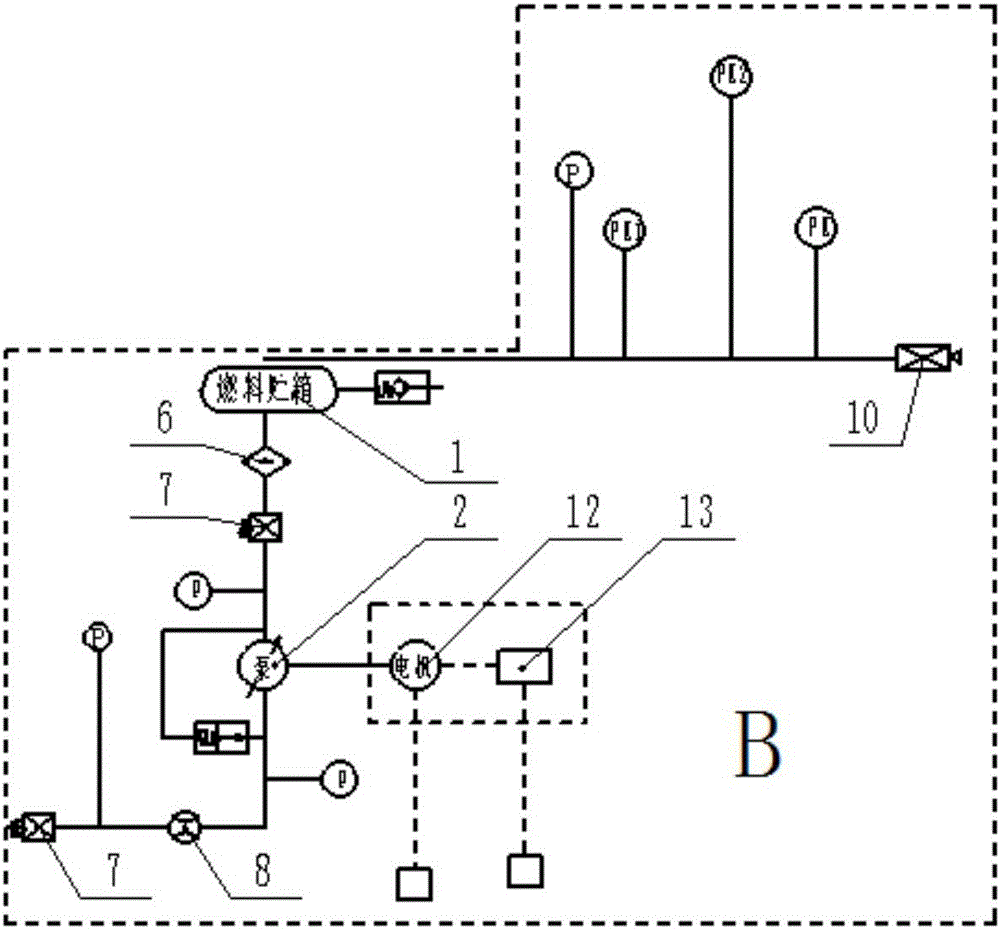

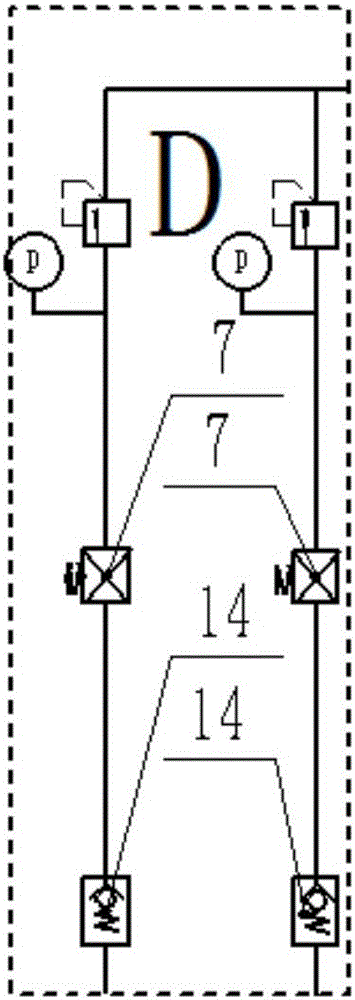

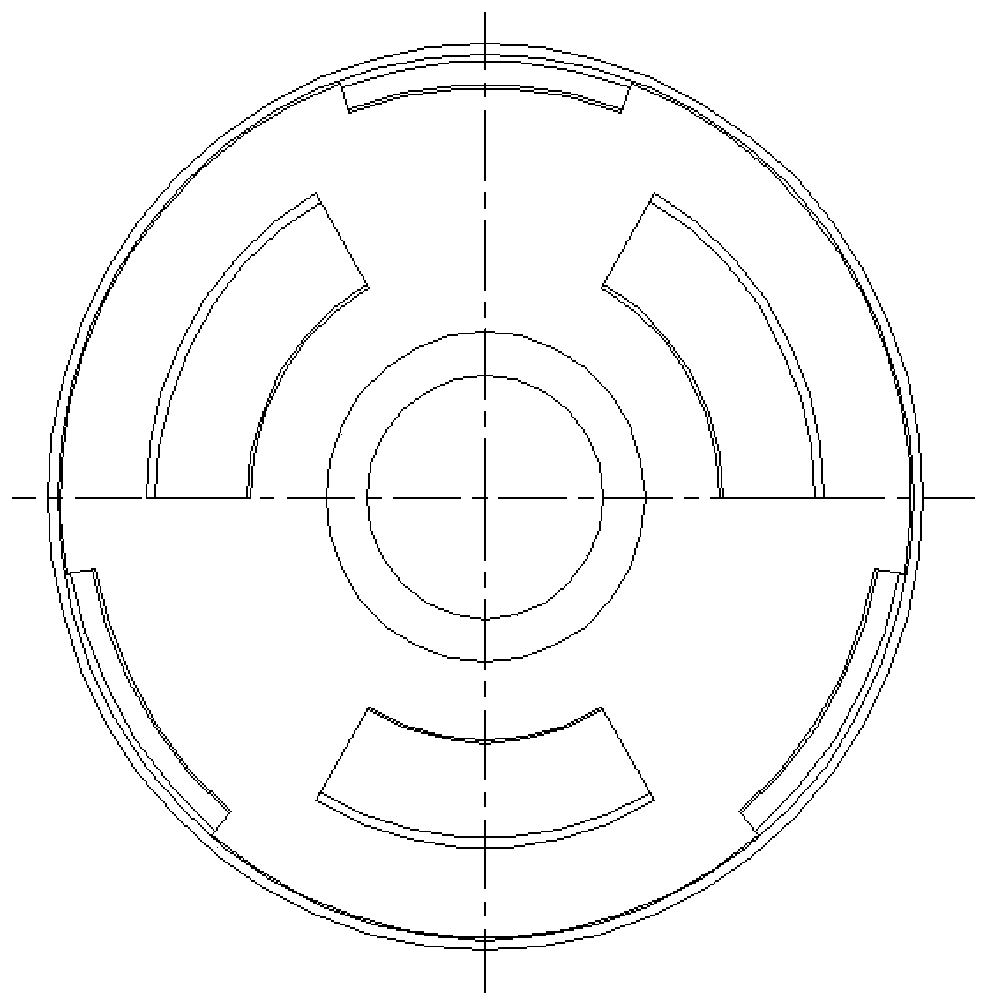

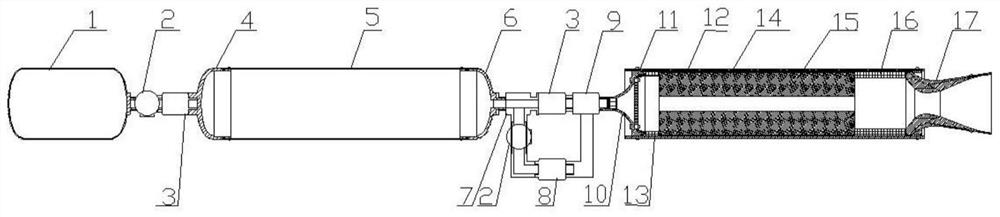

Propellant supply system for RBCC large regulating-ratio liquid-propellant rocket engine

InactiveCN105909424AReduce negative qualityMeet different needsRocket engine plantsFuel supplyOxidizing agent

The invention aims to provide a propellant supply system for an RBCC large regulating-ratio liquid-propellant rocket engine. The system comprises an oxidizing agent supply system, a fuel supply system and a gas blowing-down system, and the systems communicate with the engine respectively, wherein the fuel supply system is also connected to a fuel pressurization system. The fuel supply system comprises a fuel storage tank used to provide fuel to the engine, wherein a fuel flow regulating system used to adjust a flow rate and a mixing rate of a propellant is disposed on an output pipeline of the fuel storage tank; and the fuel flow regulating system comprises a plunger pump, and the plunger pump is connected to a motor drive device used to control actions of the engine. The system solves the problems that an existing propellant supply system cannot be integrated in an RBCC, and the flow rate and the mixing rate of the propellant cannot be adjusted within a large scope simultaneously.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

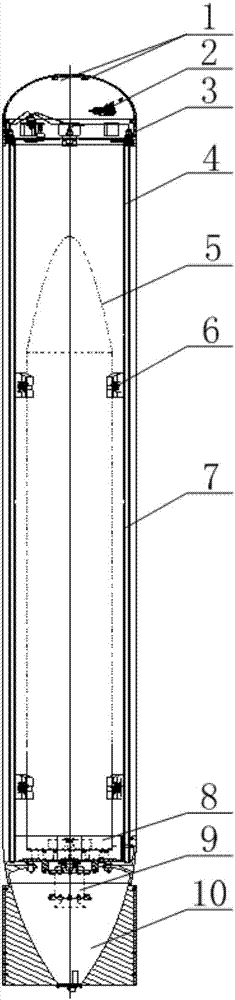

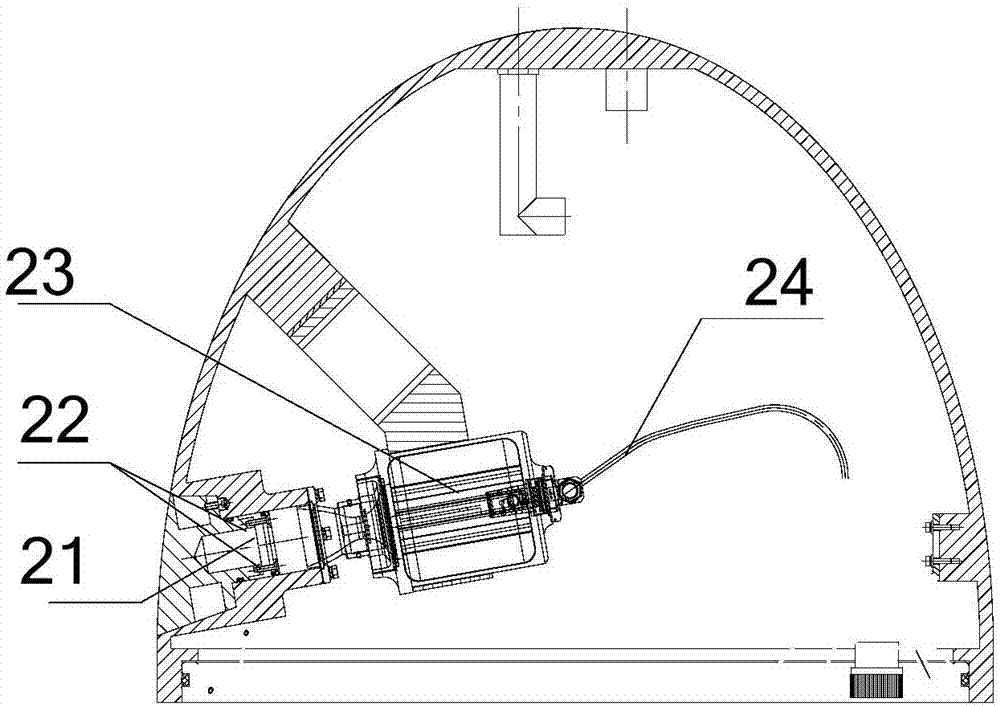

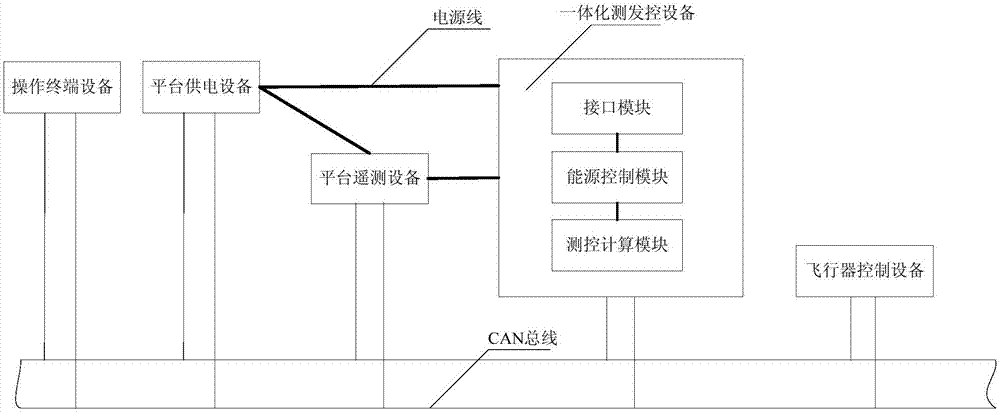

Large-diving-depth underwater unpowered aircraft transmitting system and method

ActiveCN107416226ALow design requirementsImprove portabilityLaunch systemsLaunching/towing gearUnderwaterControl system

The invention discloses a large-diving-depth underwater unpowered aircraft transmitting system and method. The transmitting system comprises an underwater autonomous measuring and control system, a transmitting cylinder with a front cover, a catapult arranged in the transmitting cylinder, and an aircraft arranged in the transmitting cylinder, wherein the transmitting cylinder, the catapult, the aircraft and the measuring and control system integrally adopt an axial deflection design; compared with a mass center, the axial buoyant center is closer to the front cover of the transmitting cylinder; the transmitting system is fixed to an underwater platform, after the transmitting system is separated from the underwater platform, the situation that upward buoyance is greater than the sum of gravity and floating resistance is changed into the situation that the upward buoyance and the sum of the gravity and floating resistance gradually tend to be balanced; the aircraft is fixed on one side of a sealing bottom plate in the transmitting cylinder, and the other side of the sealing bottom plate is connected with the catapult; and after the front cover is opened, the catapult produces thrust to push the aircraft to slide in the direction from the transmitting cylinder to the front cover, and the aircraft slides from the transmitting cylinder. According to the large-diving-depth underwater unpowered aircraft transmitting system disclosed by the invention, the maximum transmitting depth of the transmitting system is not less than 200 meters; and in the transmitting system, the aircraft does not bear water pressure limit directly, so that the aircraft is low in design condition requirements, and high in portability.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

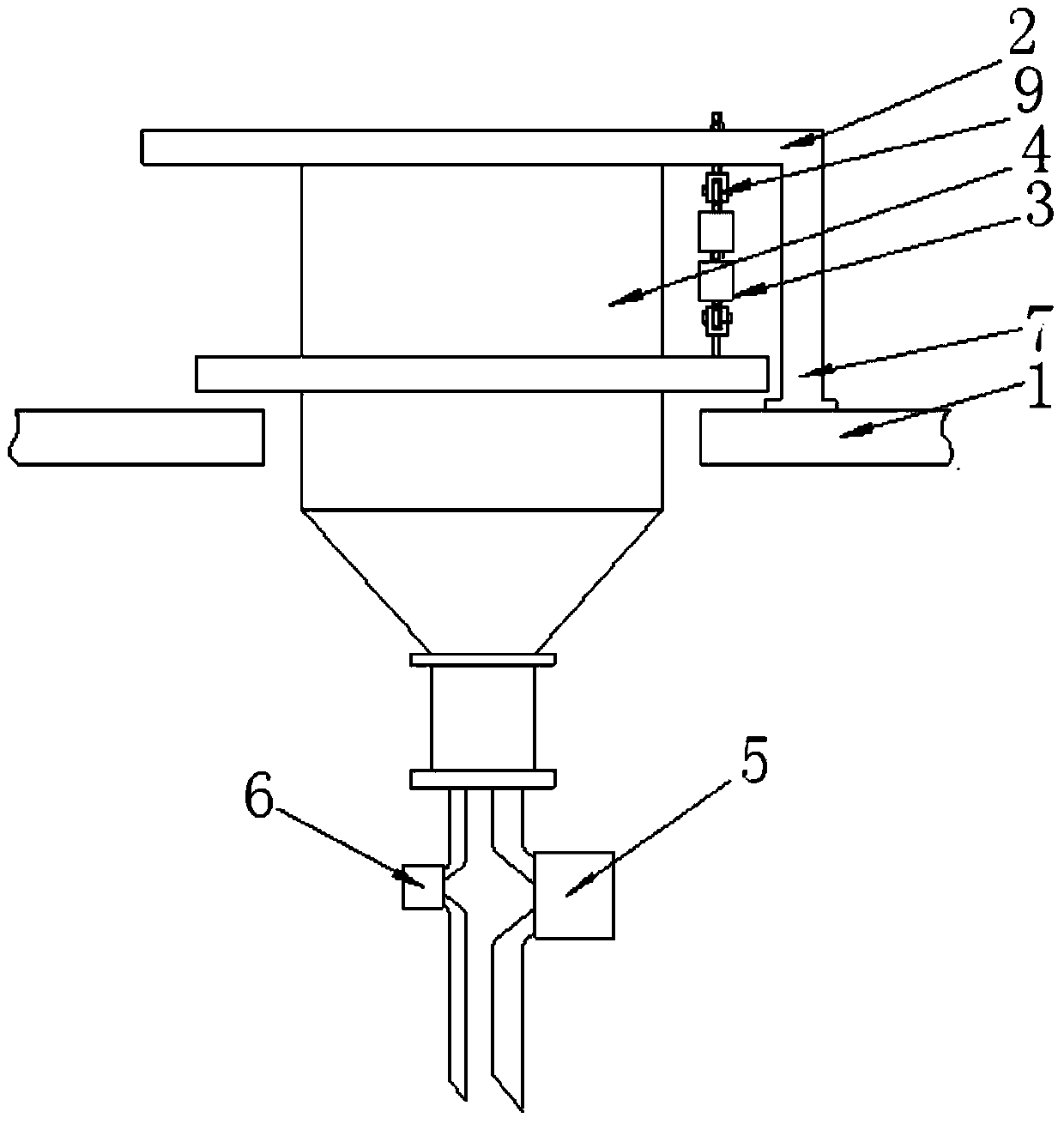

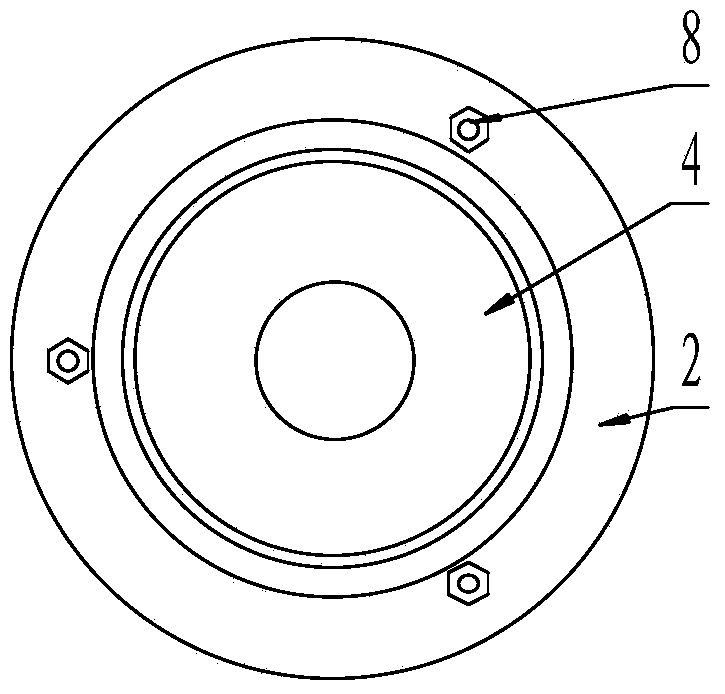

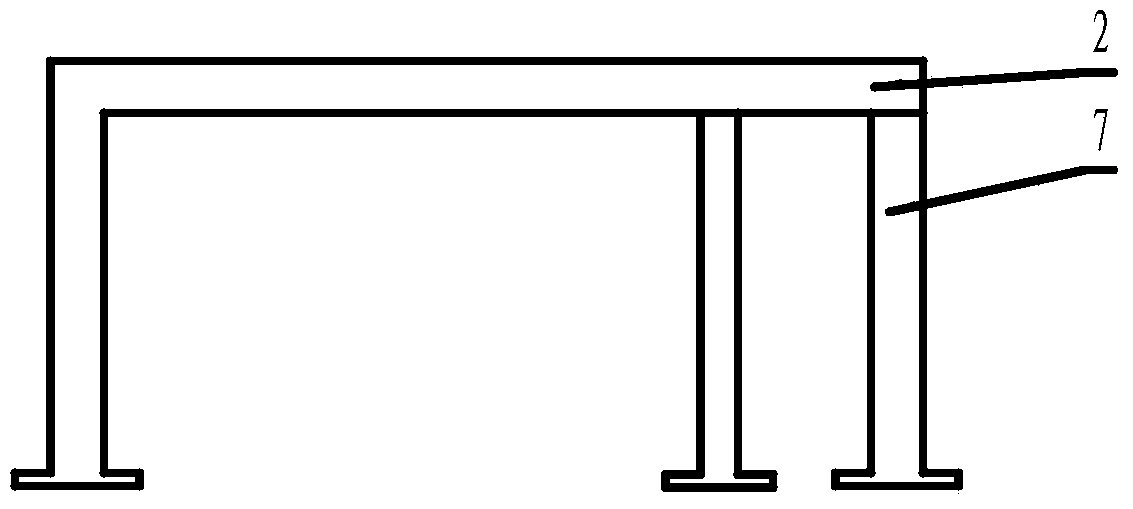

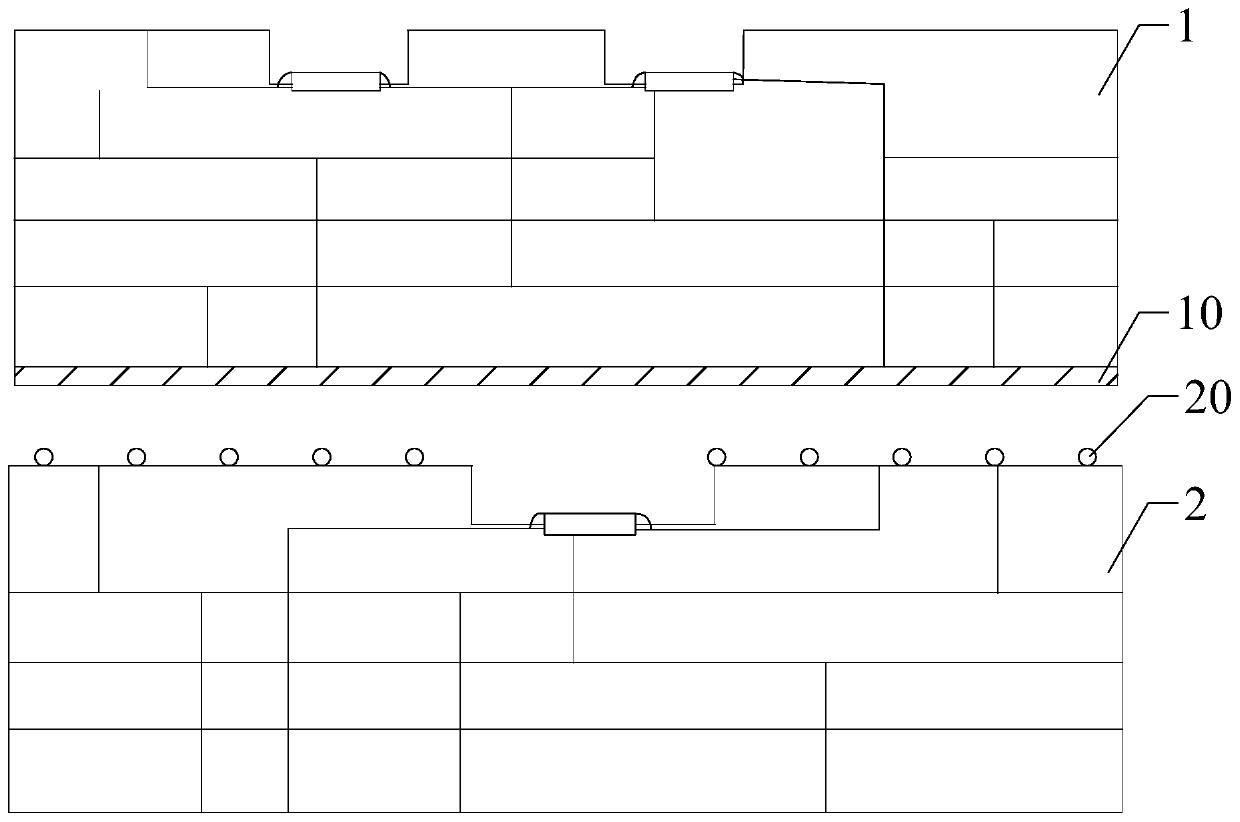

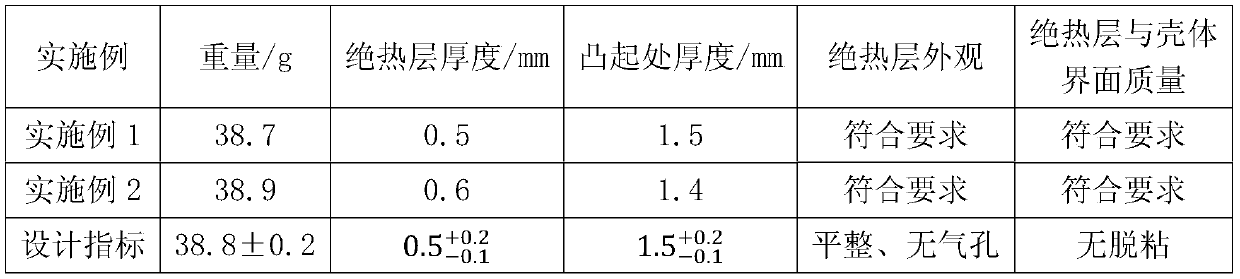

Device for weighing liquid with viscosity being 4mPa.S

InactiveCN103630220AReduce negative qualityImprove reliabilityWeighing apparatus for materials with special property/formEngineeringUltimate tensile strength

The invention relates to a device for weighing liquid with viscosity being 4mPa.S, which comprises a supporting platform, a ring support, three sensor modules, a viscose liquid hopper, a quick release valve and a slow release valve. A panel of the ring support is sleeved on the circumference of an upper end of the viscose liquid hopper, and a clearance is formed between the panel of the ring support and the viscose liquid hopper. Three support rods of the ring support are placed on the supporting platform. The three sensor modules are uniformly distributed on the periphery of the viscose liquid hopper. Upper ends of the three sensor modules are respectively and fixedly connected with the panel of the ring support; and lower ends of the three sensor modules are respectively and fixedly connected with clamping edges of the hopper. The quick release valve and the slow release valve are respectively arranged on a flange plate of a discharge hole of the viscose liquid hopper through pipelines, and are communicated with an inner cavity of the viscose liquid hopper. According to the device, loading of different release valves is controlled through an industrial control computer, the weight of materials is controlled through a manner of weighting by adopting a reduction method, the labor cost is effectively saved, the labor intensity is reduced, the automatic degree of viscose liquid weighing is greatly improved, and the problem of harming occupational health of operating personnel is solved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

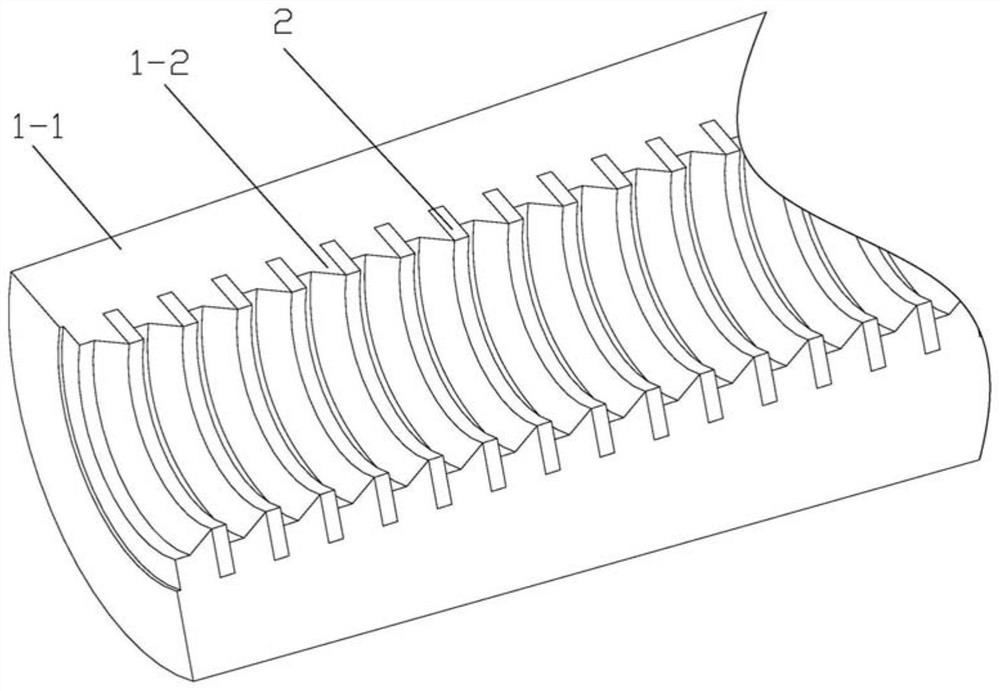

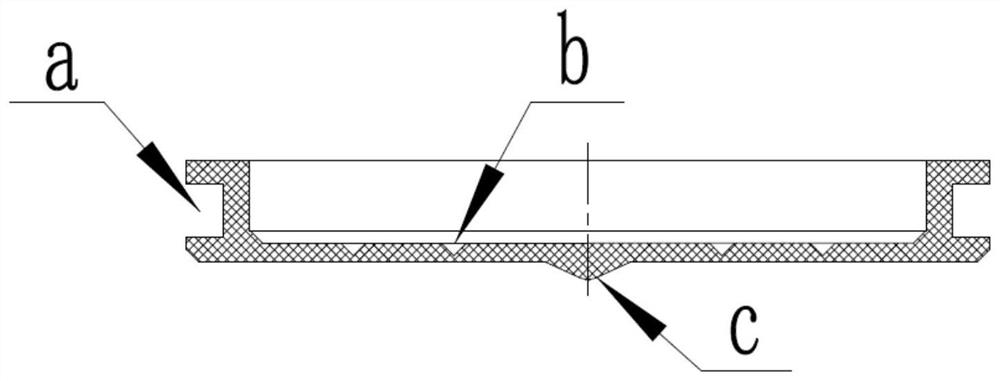

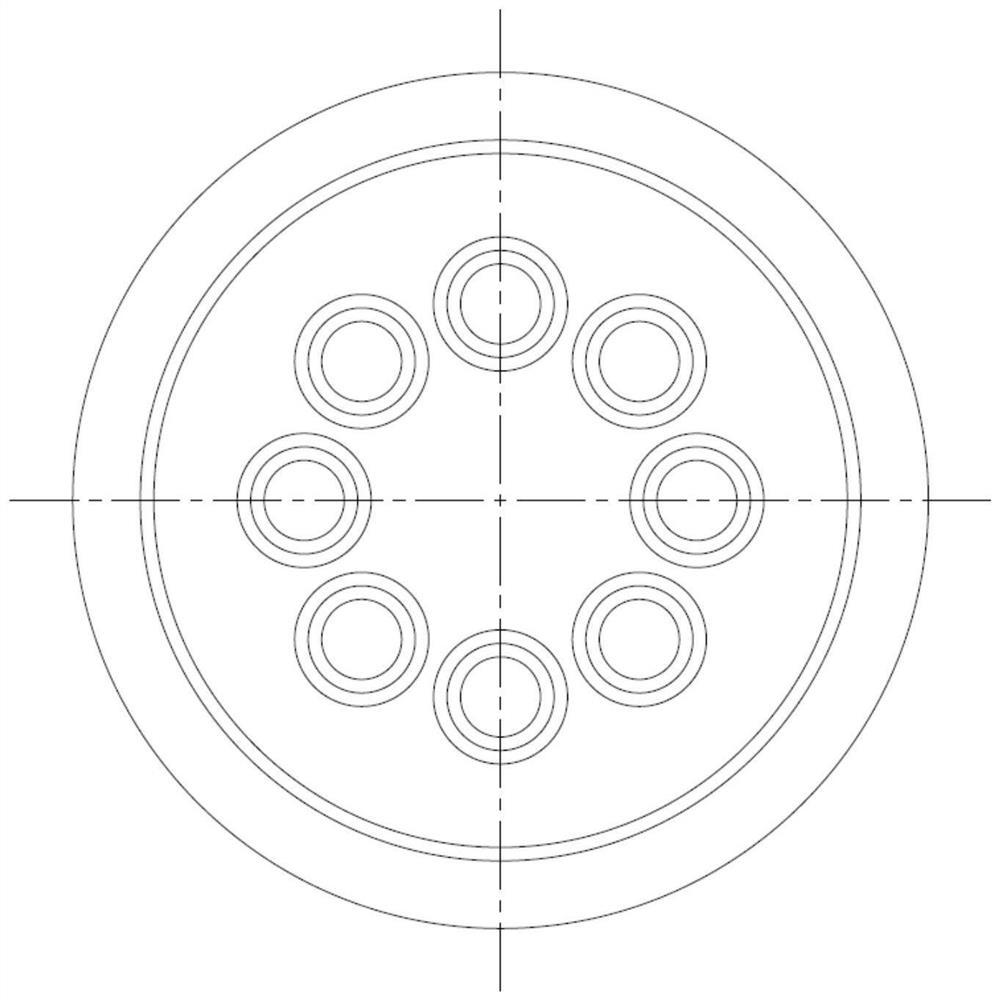

Tubular inner-hole charge structure with inner cavity partition and used for solid rocket engine, and method

ActiveCN110145411AImprove surface increaseReduce maximum pressureRocket engine plantsCombustion chamberWorking pressure

The invention discloses a tubular inner-hole charge structure with an inner cavity partition and used for a solid rocket engine. The inner cavity partition is arranged in the combustion chamber chargestructure of the solid engine, and the inner cavity partition is made from a polyurethane foam material. The tubular inner-hole charge structure with the inner cavity partition and used for the solidrocket engine has the beneficial effects of being capable of effectively improving the progressive performance of the solid rocket engine in a working process, reducing the maximum working pressure of the engine, reducing the design thickness of a shell body, reducing the passive mass of the missile engine, and increasing the missile range.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

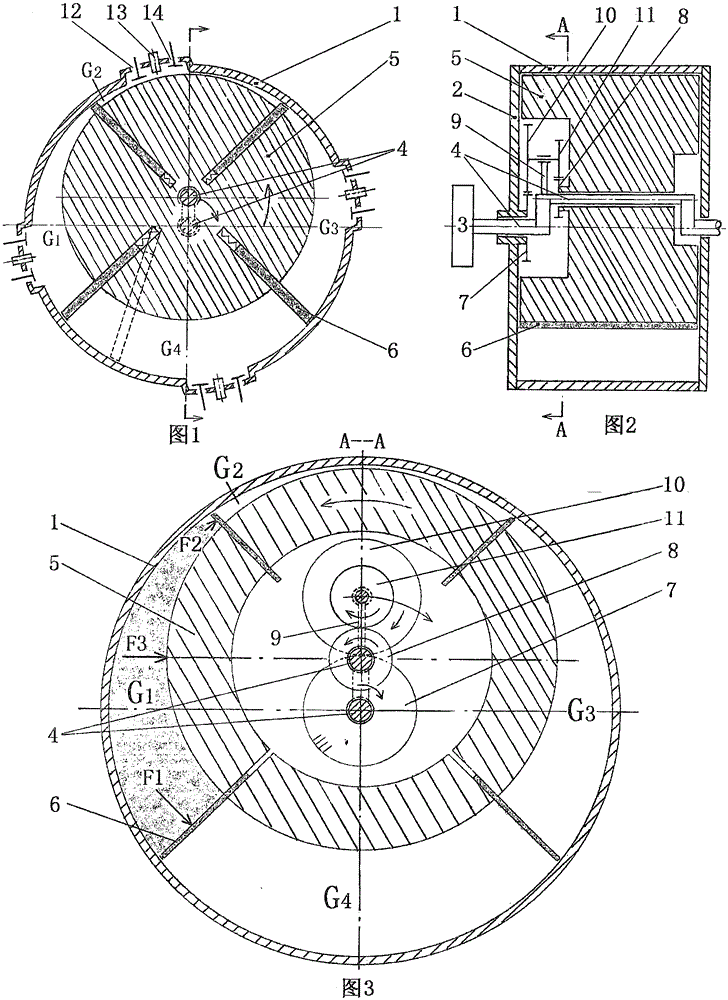

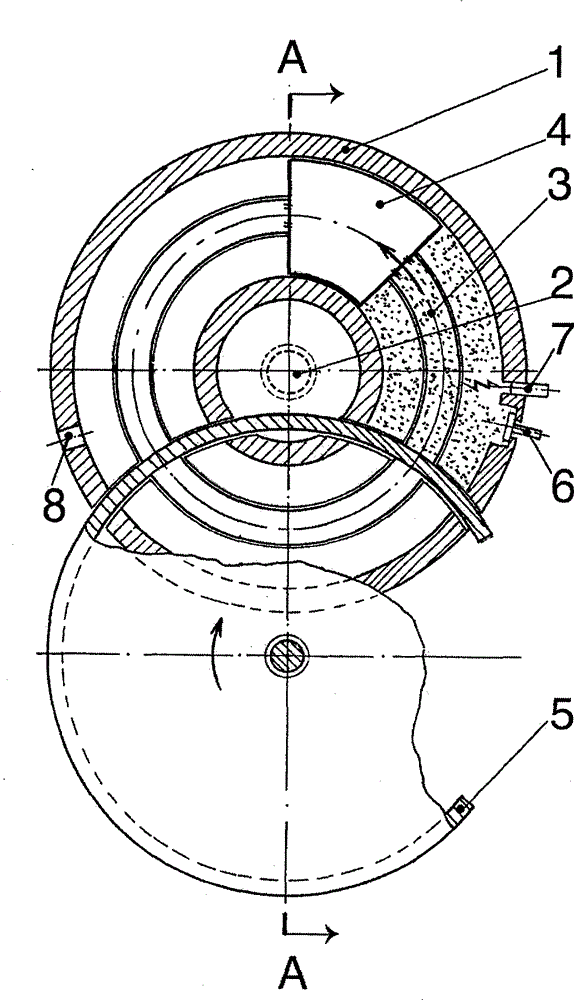

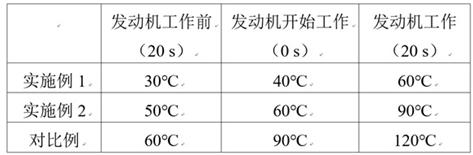

Planetary rotor engine

InactiveCN105422272ASimple structureReduce negative qualityInternal combustion piston enginesEngineeringCrankshaft

The invention discloses a planetary rotor engine. Crankshafts (4) are arranged in a cylindrical stator (1) of the planetary rotor engine, and the two ends of the cylindrical stator (1) are sealed through end covers. Main shaft necks at the two ends of the cylindrical stator (1) are supported in the centers of the crankshafts (4), and planetary columns (5) are supported on planetary shaft necks in the middle sections of the crankshafts (4). A set of telescopic blades (6) are inserted in each planetary column in the radial direction. The planetary columns and the left sides and the right sides of the blades are in sliding and sealing fit with the inner walls of the end covers, the outer sides of the blades and the inner wall of the stator. An inner cavity of the stator is divided into a set of cylinders by the blades. The planetary columns rotate in the opposite direction while revolving around the axis of the stator, so that the volumes of the cylinders are increased and decreased periodically, and the strokes including air suction, compression, acting and exhausting are completed in sequence. Fuel gas expands to push the blades and the planetary columns to act in pairs, so that the acting torque is increased; the cylinders are densely arranged, so that the power is sufficient; the rotating direction is opposite to the revolving direction, so that the speed, relative to fixed part, of moving parts is low, and the friction between the moving parts and the fixed part is small.

Owner:苗军

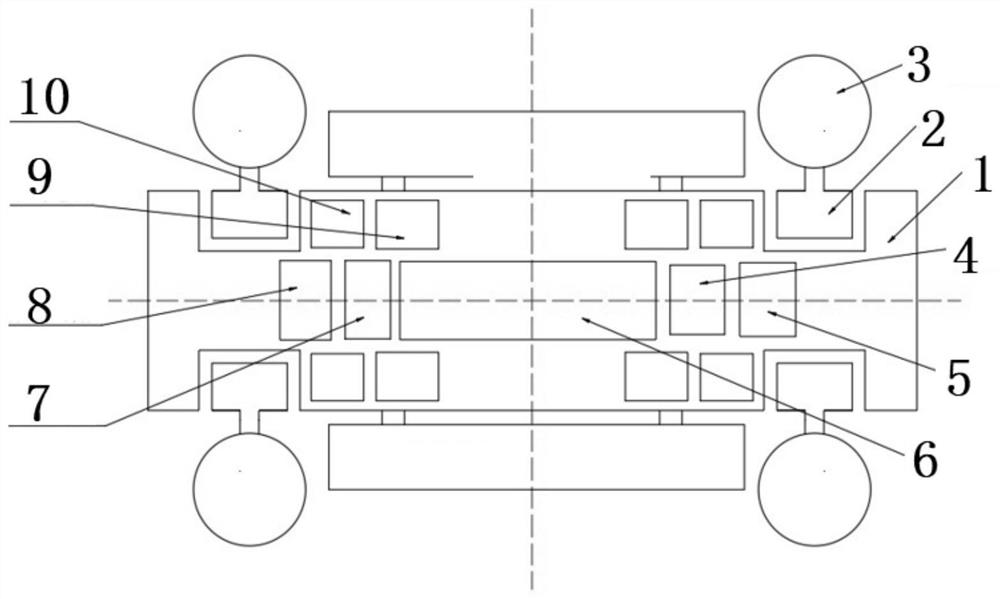

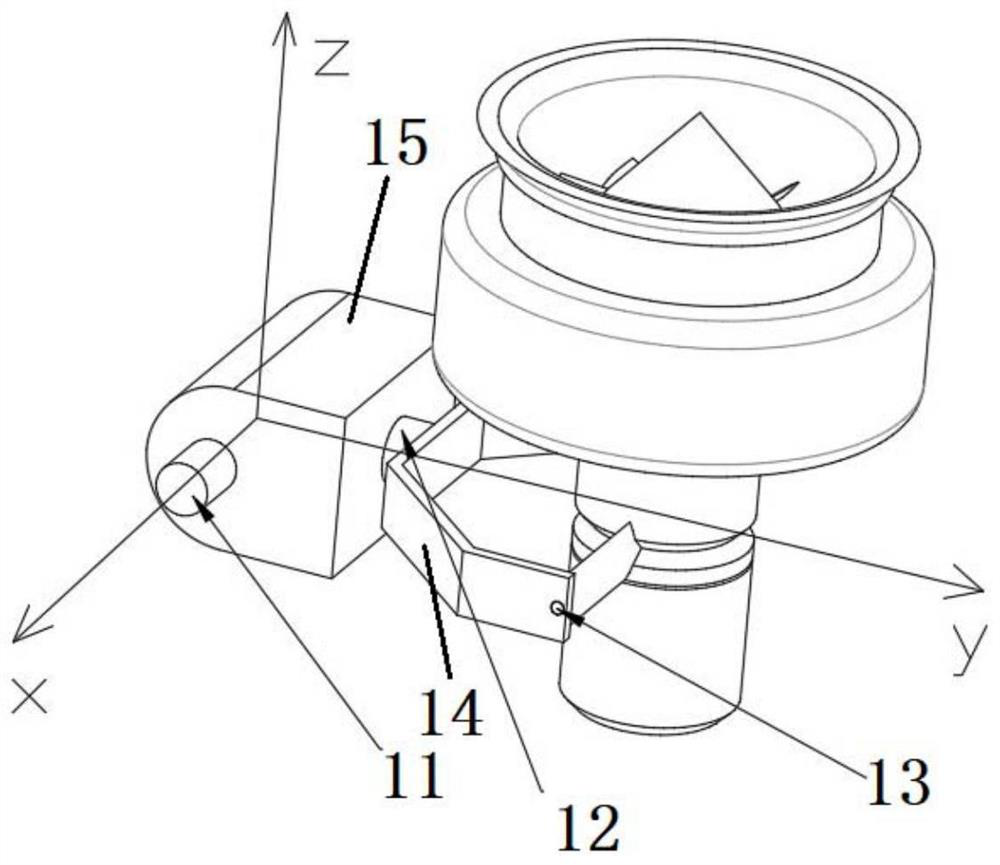

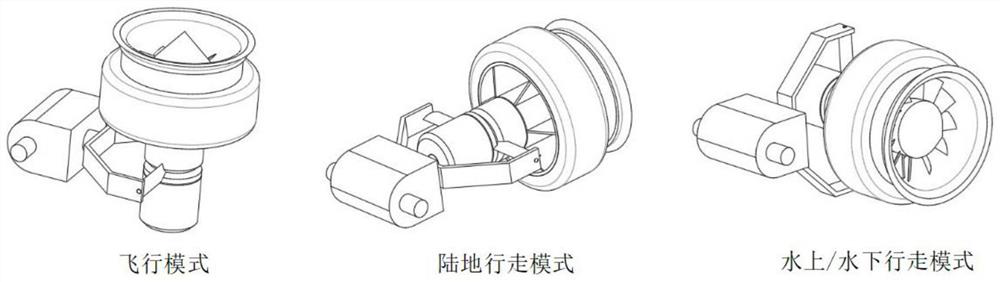

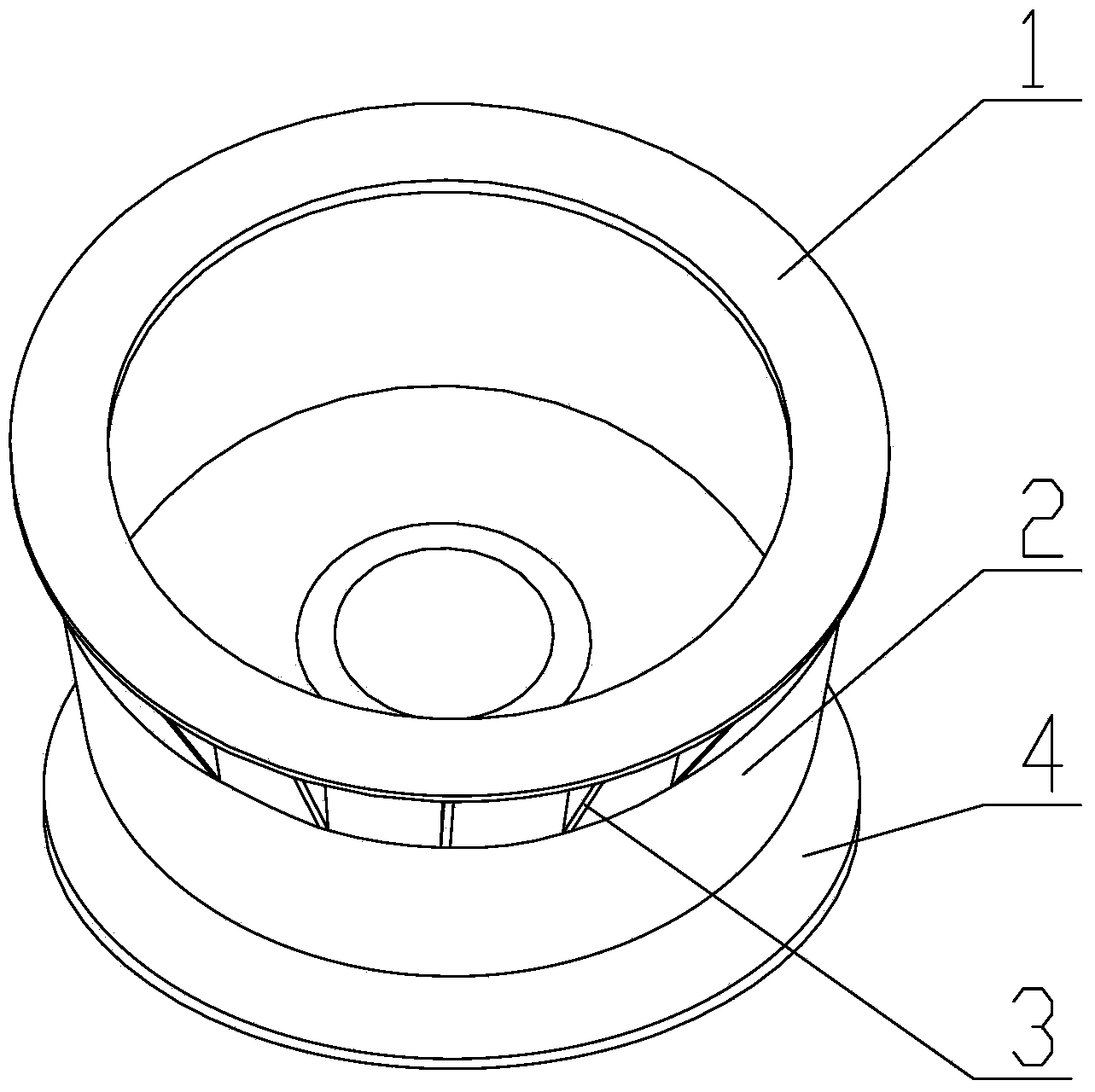

Sea-land-air-submarine multi-purpose unmanned platform shared by hub ducts

PendingCN111845232AImprove obstacle performanceHigh speedPropellersPower plant typeUnderwaterMachine

The invention discloses a sea-land-air-submarine multi-purpose unmanned platform shared by hub ducts, which can be switched among land, flight and overwater / underwater modes and provides a powerful tool for reconnaissance and rescue. The sea-land-air-submarine multi-purpose unmanned platform shared by the hub ducts comprises a machine body, a control module, four duct servo mechanisms and four duct power mechanisms. The four duct servo mechanisms are in one-to-one correspondence with the four duct power mechanisms; each duct servo mechanism is used for controlling the posture of the duct powermechanism corresponding to the duct servo mechanism; each duct power mechanism is connected with the machine body through a duct servo mechanism, the four duct power mechanisms are distributed on themachine body in a rectangular shape, the duct servo mechanisms are used for controlling the posture of the ducts to be switched among the transverse mode, the vertical mode and the longitudinal mode,so that the unmanned platform can be switched among the land mode, the flight mode and the overwater / underwater mode.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparing method for cable embedded composite material shell

ActiveCN107676814ASimple laying processReduce negative qualityContinuous combustion chamberFiberConductor Coil

The invention discloses a preparing method for a cable embedded composite material shell. The preparing method comprises the following steps that firstly, a heat insulation structure is manufactured;secondly, the shell is manufactured through fiber wet process winding; thirdly, cable pavement is conducted; and fourthly, demoulding is conducted. A cable cover is not needed for pavement of a cableon the shell, the passive mass of the shell is reduced, the cable pavement technology is simplified, and the machining efficiency is improved. The cable is embedded between carbon fiber composite material layers of the shell, the cable can well adapt to stress deformation of the shell, the two outermost sides of the cable are filled with light foam materials, and the structure coordination of a winding layer is guaranteed.

Owner:湖北三江航天江北机械工程有限公司

Base made of composite materials and manufacturing method thereof

ActiveCN103682562AImprove axial stiffnessHigh degree of modularityAntenna supports/mountingsEngineeringThermal stability

The invention discloses a base made of composite materials. The base comprises an upper end cover and a lower end cover. The upper end cover comprises an upper annular end cover body and a big-end-down first cone arranged below the upper end cover body. The lower end cover comprises a lower end cover body and a big-end-up second cone arranged above the lower end cover body. A cylinder is arranged between the upper end cover and the lower end cover. The inner wall of the upper portion of the cylinder is in close fit with the outer wall of the first cone, and the inner wall of the lower portion of the cylinder is in close fit with the outer wall of the second cone. A reinforcing rib is arranged at the position, below the upper end cover, on the outer side of the cylinder. The upper end cover, the cylinder, the reinforcing rib and the lower end cover are all made of composite materials. In addition, the invention further discloses a manufacturing method of the base made of the composite materials. All the portions of the base made of the composite materials are made of the composite materials, and the base made of the composite materials has the advantages of being high in axial rigidity, good in heat stability under the space high-low temperature environment, small in negative quality, high in modularization degree, good in reliability, excellent in overall performance and the like.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

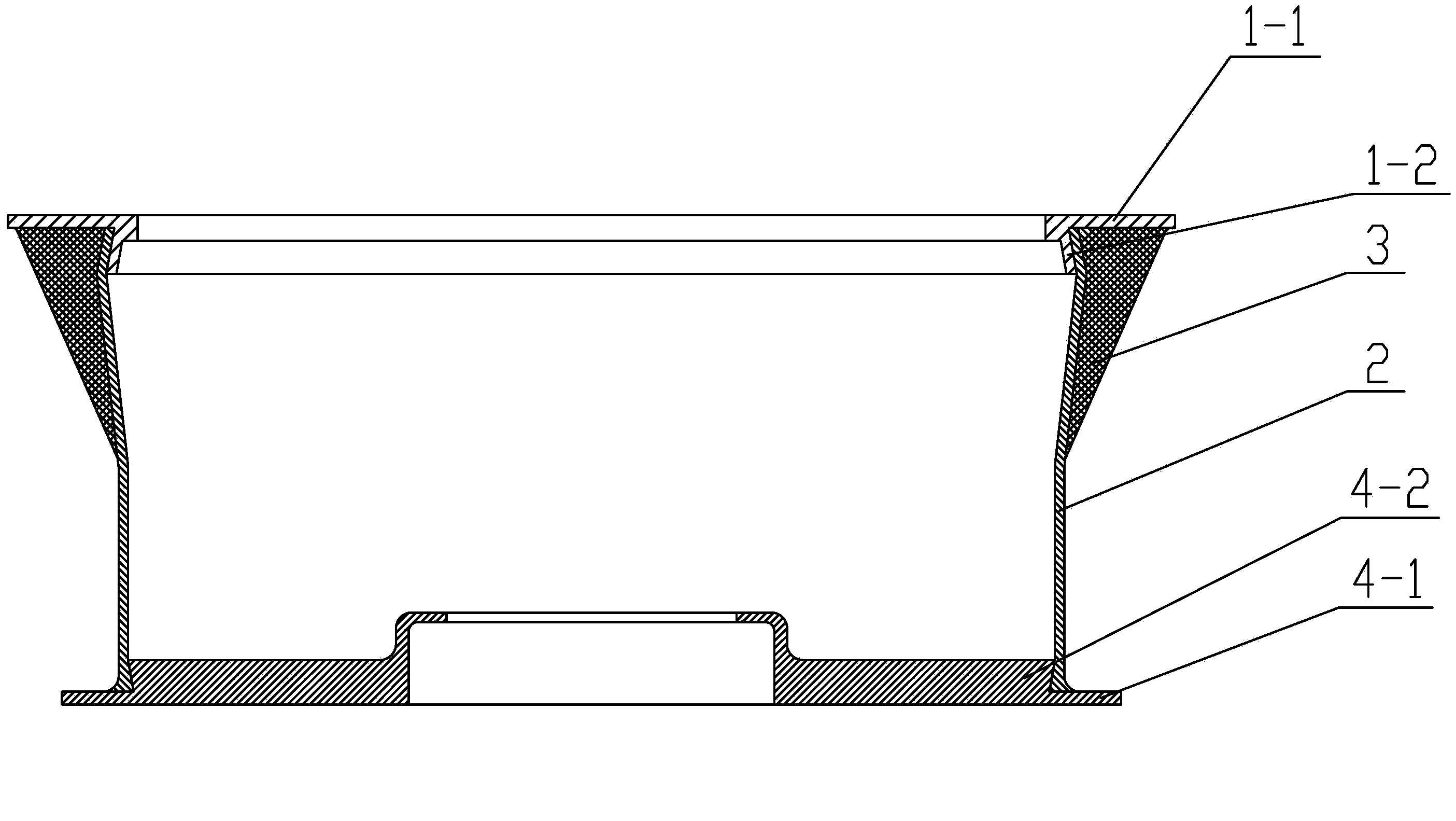

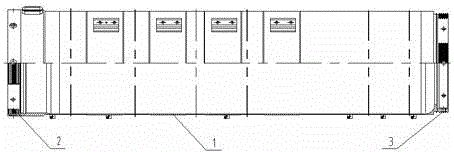

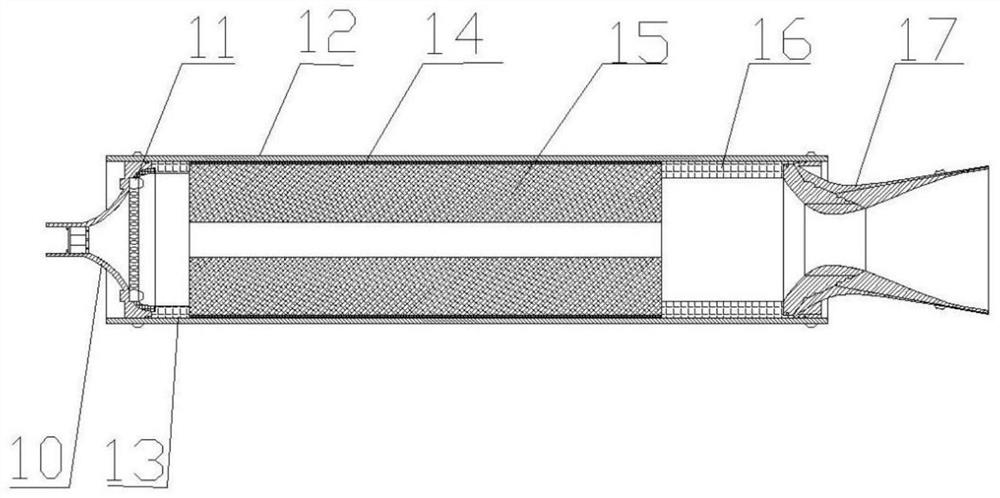

Multifunctional simulation engine for adiabatic layer ablation test

InactiveCN109163906AEasy to put inEnsure flight safetyGas-turbine engine testingJet-propulsion engine testingLow speedEngineering

The invention discloses a multifunctional simulation engine for adiabatic layer ablation test, which comprises a gas generator. One end of the gas generator is sequentially connected with a low speedsection, a medium speed section, a high-speed section, an overload section and a plume section and forms a through cavity; the low speed section, the medium speed section and the high-speed section are coaxially connected; the overload section is raised up and coaxially connected with the plume section; the end portion of the overload section is provided with a jet exhaust; the plume section is arranged on the periphery of the jet exhaust; a test piece A, a test piece B and a test piece C are respectively correspondingly installed in the inner cavity of the low speed section, the medium speedsection and the high speed section; a test piece D is mounted at the lower section of the inner cavity of the overload section; a test piece E is mounted on the upper section of the inner cavity of the overload section; and a test piece F is arranged at the corresponding jet exhaust of the plume section. According to the multifunctional simulation engine for adiabatic layer ablation test in the invention, the test pieces are mounted in the inner cavity of each section, thereby detecting and understanding the ablation phenomenon of each section.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

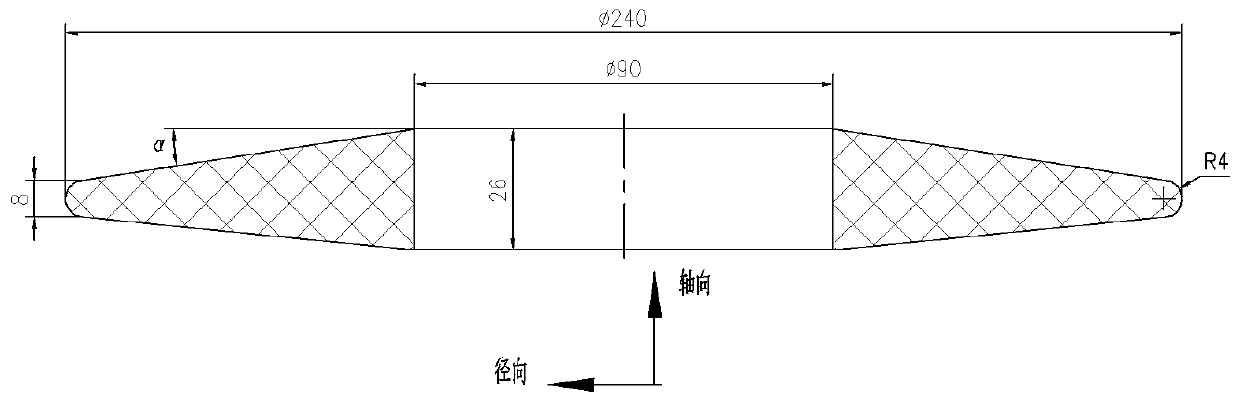

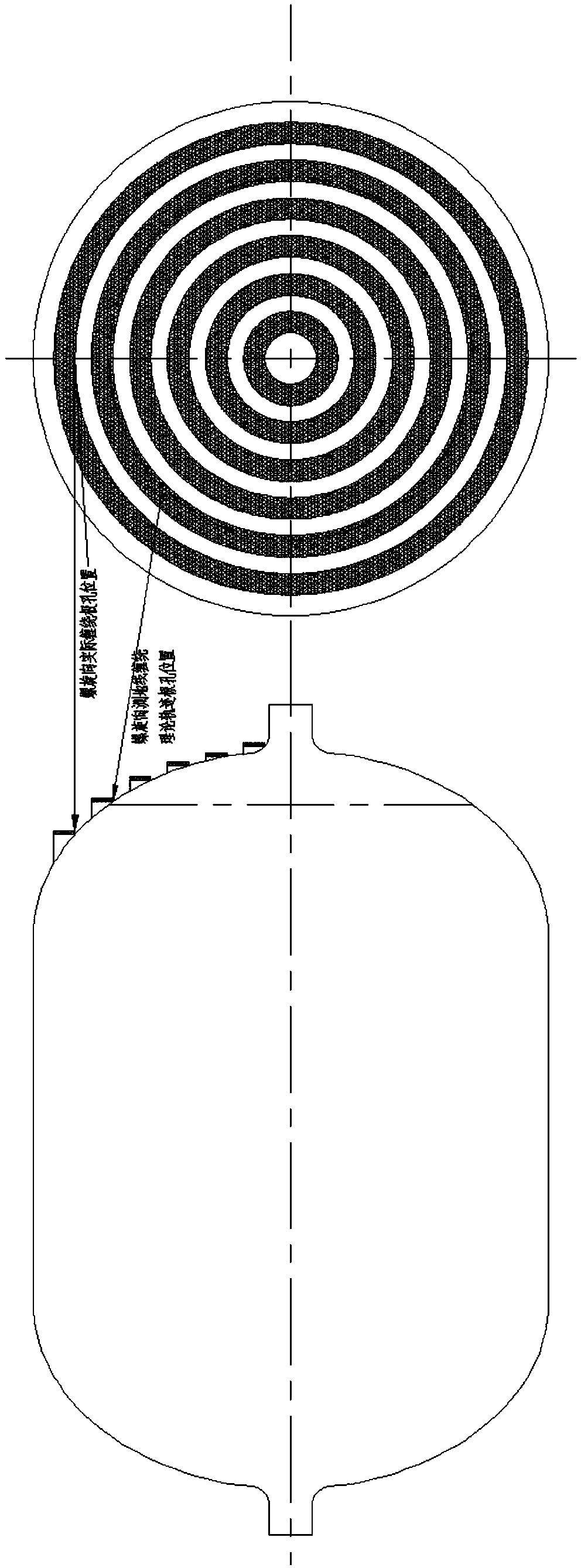

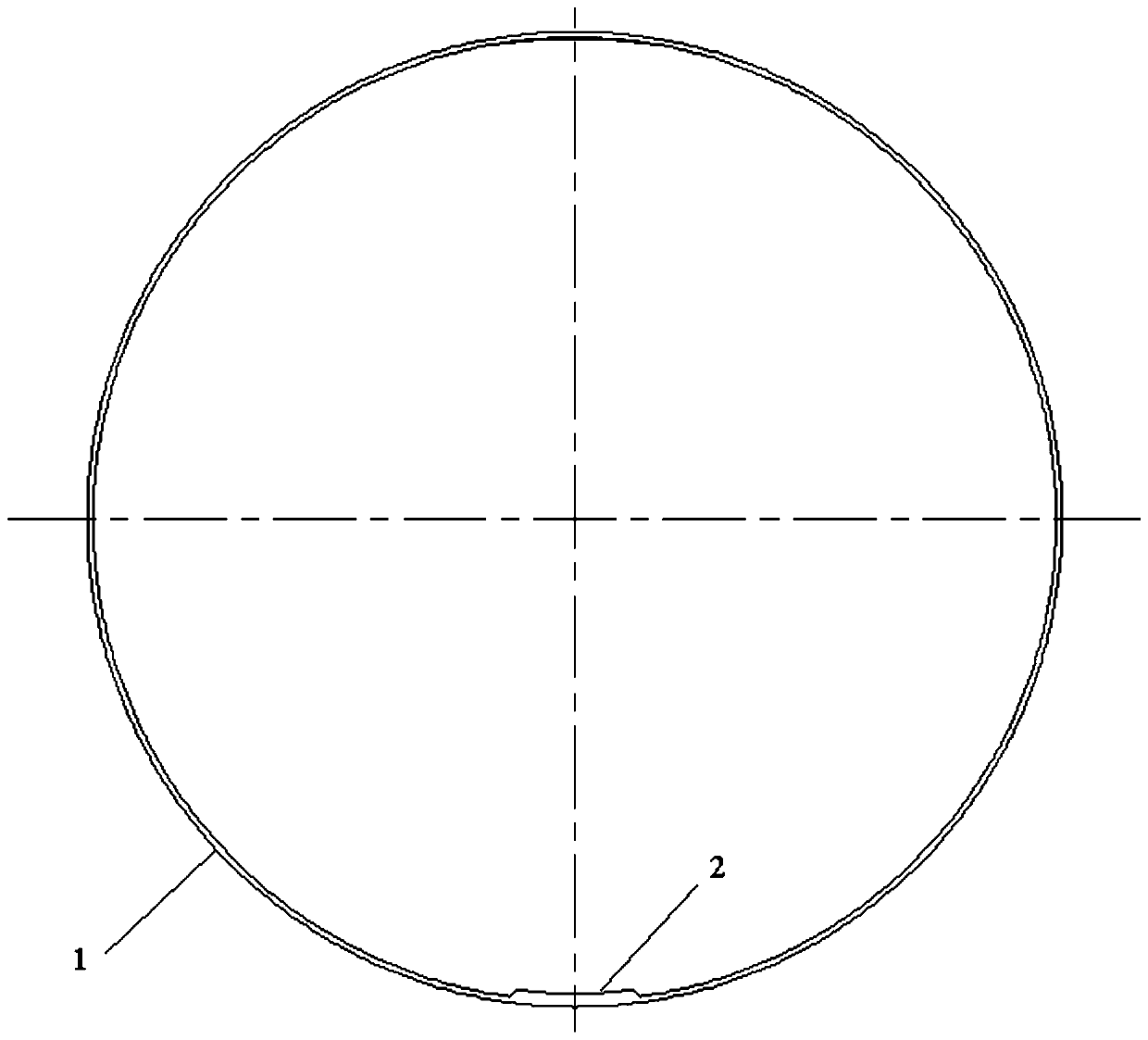

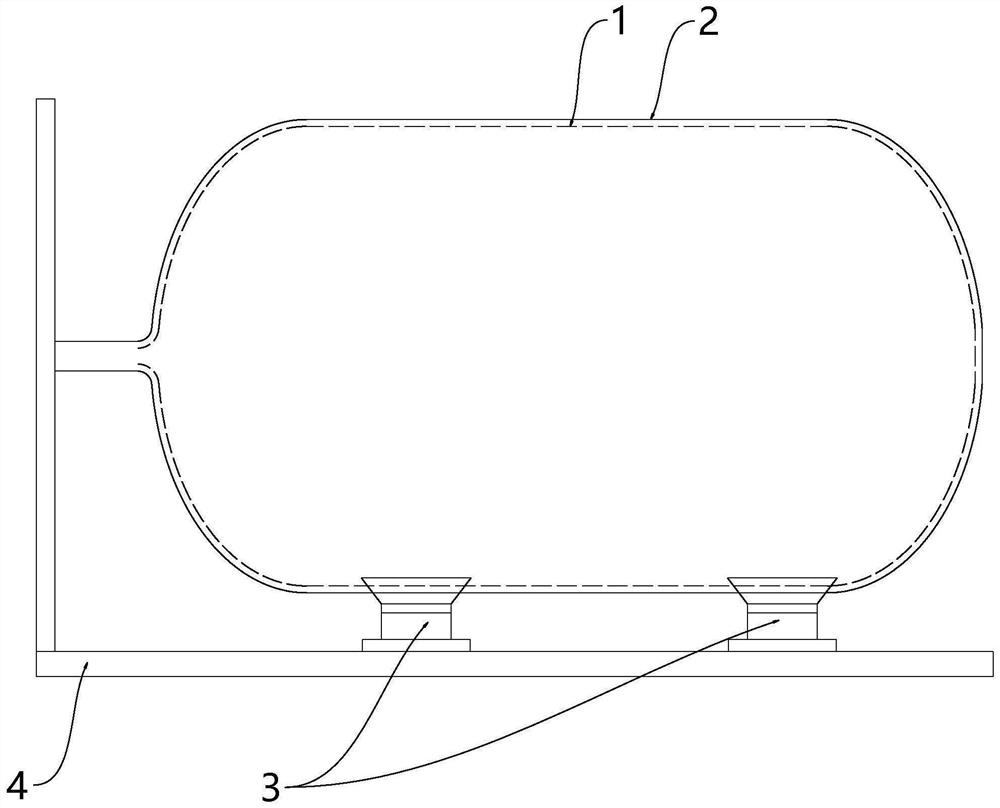

Preparation method of composite air cylinder

ActiveCN108692181AGuaranteed longitudinal strengthAvoid excessive accumulationVessel mounting detailsVessel manufacturingReal variableYarn

The invention relates to a preparation method of a composite air cylinder and relates to the technical field of manufacturing of composite pressure vessels. The preparation method of the composite aircylinder comprises the steps that a step-by-step broaching mode is adopted for winding layers in the spiral direction of the composite air cylinder, and various winding angles are determined according to the linear trajectory of a geodesic line; and in the winding process, a non-geodesic line winding mode is adopted, variable-angle variable-speed-ratio winding is carried out on an end socket section, and variable-pitch winding is carried out on an edge area of a cylinder body section. Thus, the winding angles of various points of the end socket area are relatively increased, the difference between the internal radius and the external radius of each 'fiber stacking ring' is increased to 1.5-2 times of the actual yarn sheet width, an end socket approaches the uniform thickness, the surplusmass of the end socket can be reduced effectively, the characteristic coefficient of the vessel is increased, and the lightweight purpose of the air cylinder is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

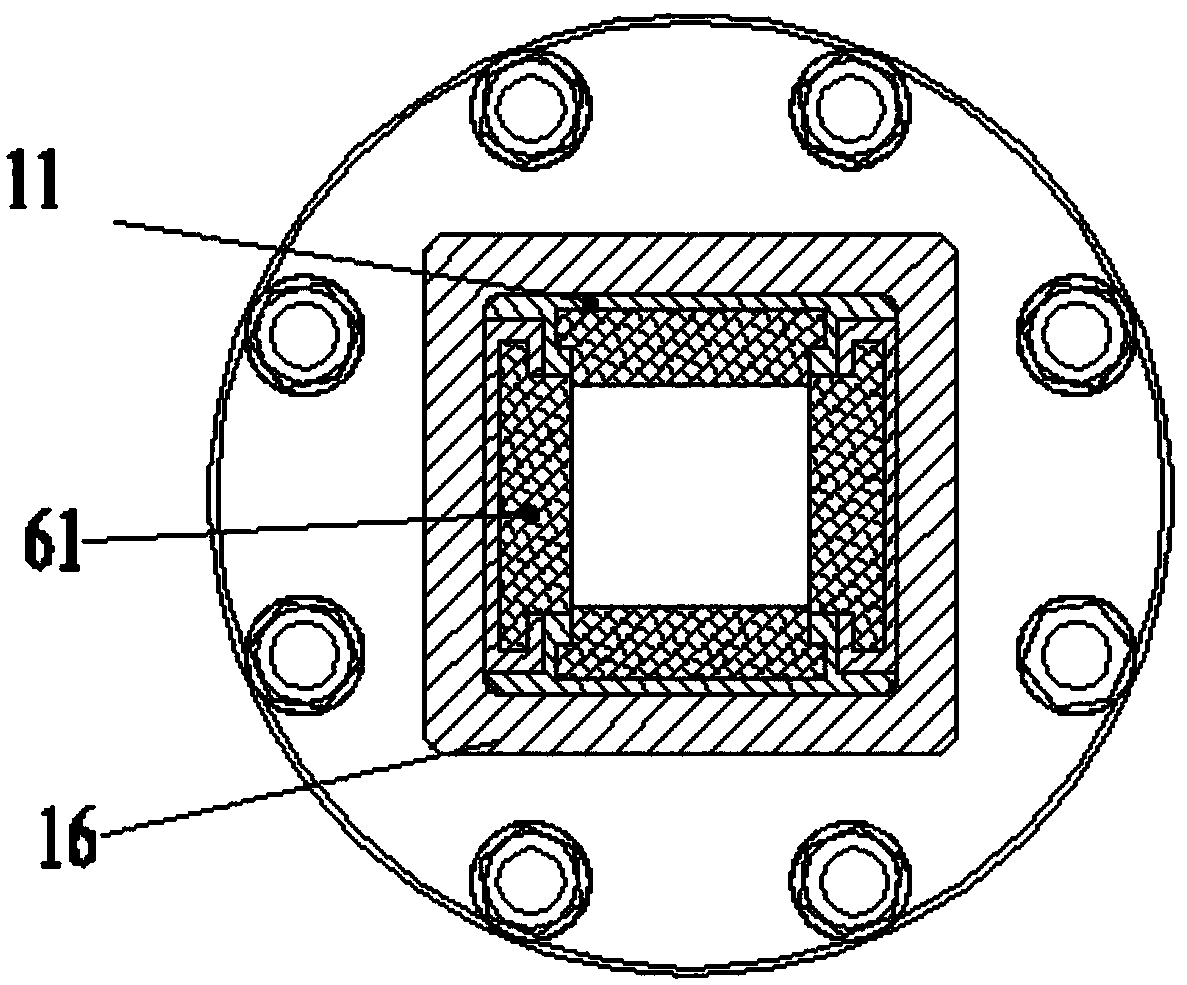

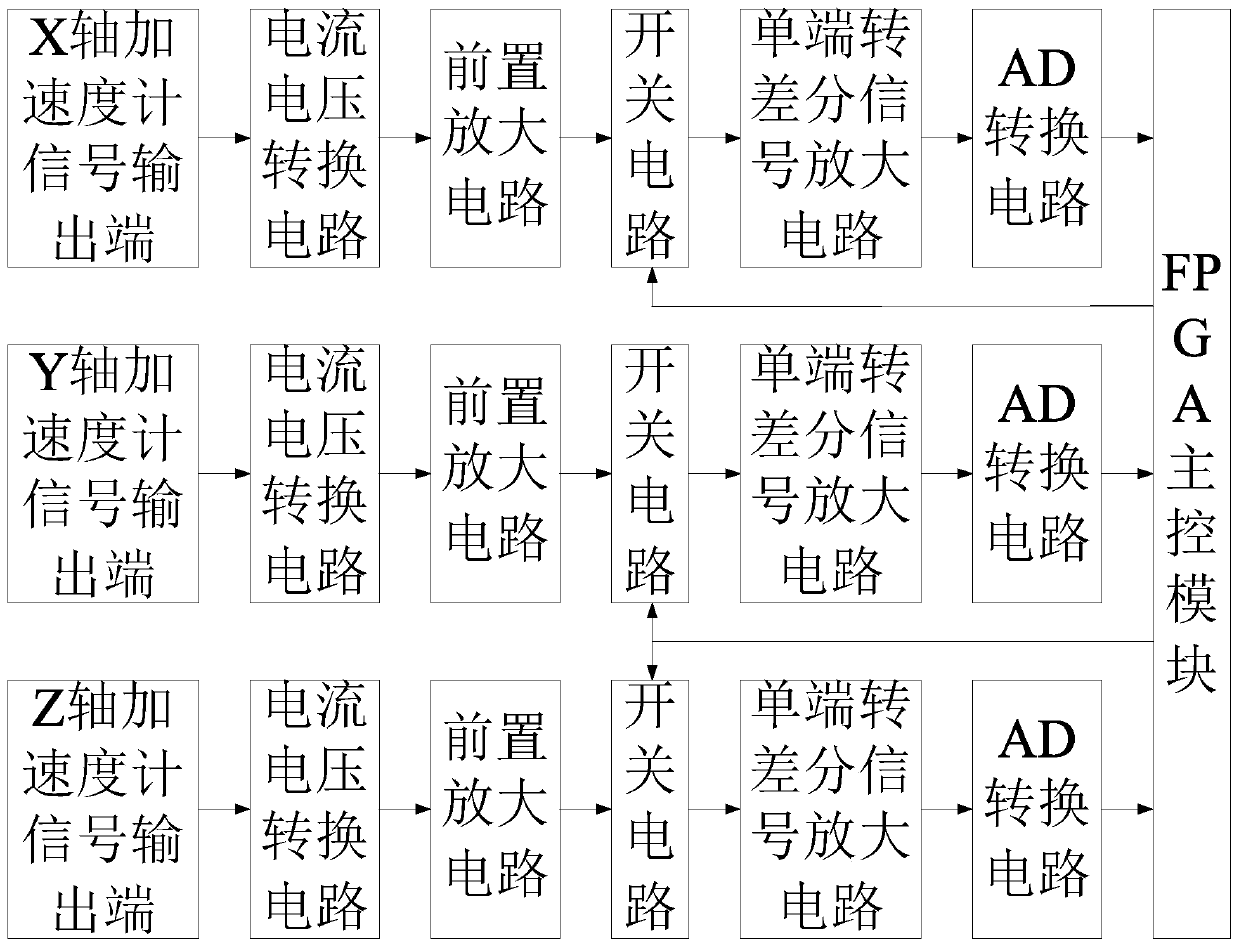

Triaxial quartz flexure accelerometer small-size signal sampling device and processing technology thereof

ActiveCN110031653AReduce negative qualityIncrease loading capacityAcceleration measurement using interia forcesAccelerometerLinearity

The invention discloses a triaxial quartz flexure accelerometer small-size signal sampling device comprising an accelerometer. The device also comprises a signal collection mechanism that comprises apre-amplification module, a switch module, a differential amplification module, an AD conversion module and a controller-integrated FPGA main control module which are sequentially connected with the accelerometer in series; and the switch module is also connected with the FPGA main control module. By using the triaxial quartz flexure accelerometer small-size signal sampling device adopting the abovementioned structure provided by the invention, a digital sub-system substrate and an analog sub-system substrate are perpendicularly interconnected via solder balls, so that the whole size is reduced, the miniaturization is achieved; meanwhile, by using the FPGA main control module, the collection and conversion from an accelerometer analog signal to a digital signal are achieved, the linear relation between the output digital signal and the acceleration signal is ensured, and the stability of zero and scale can be ensured, so that the performance of the header of the accelerometer is furthest ensured.

Owner:保定开拓精密仪器制造有限责任公司

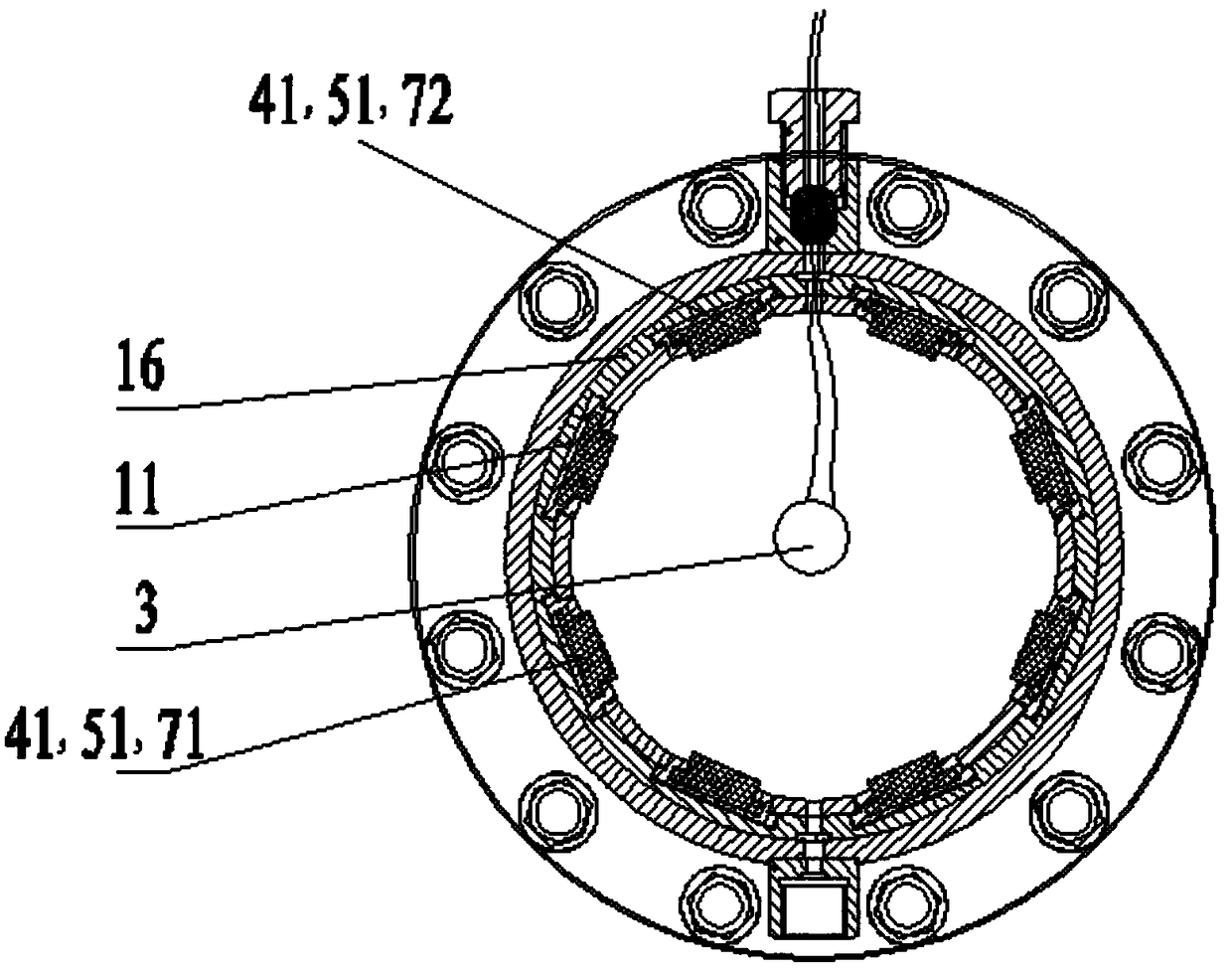

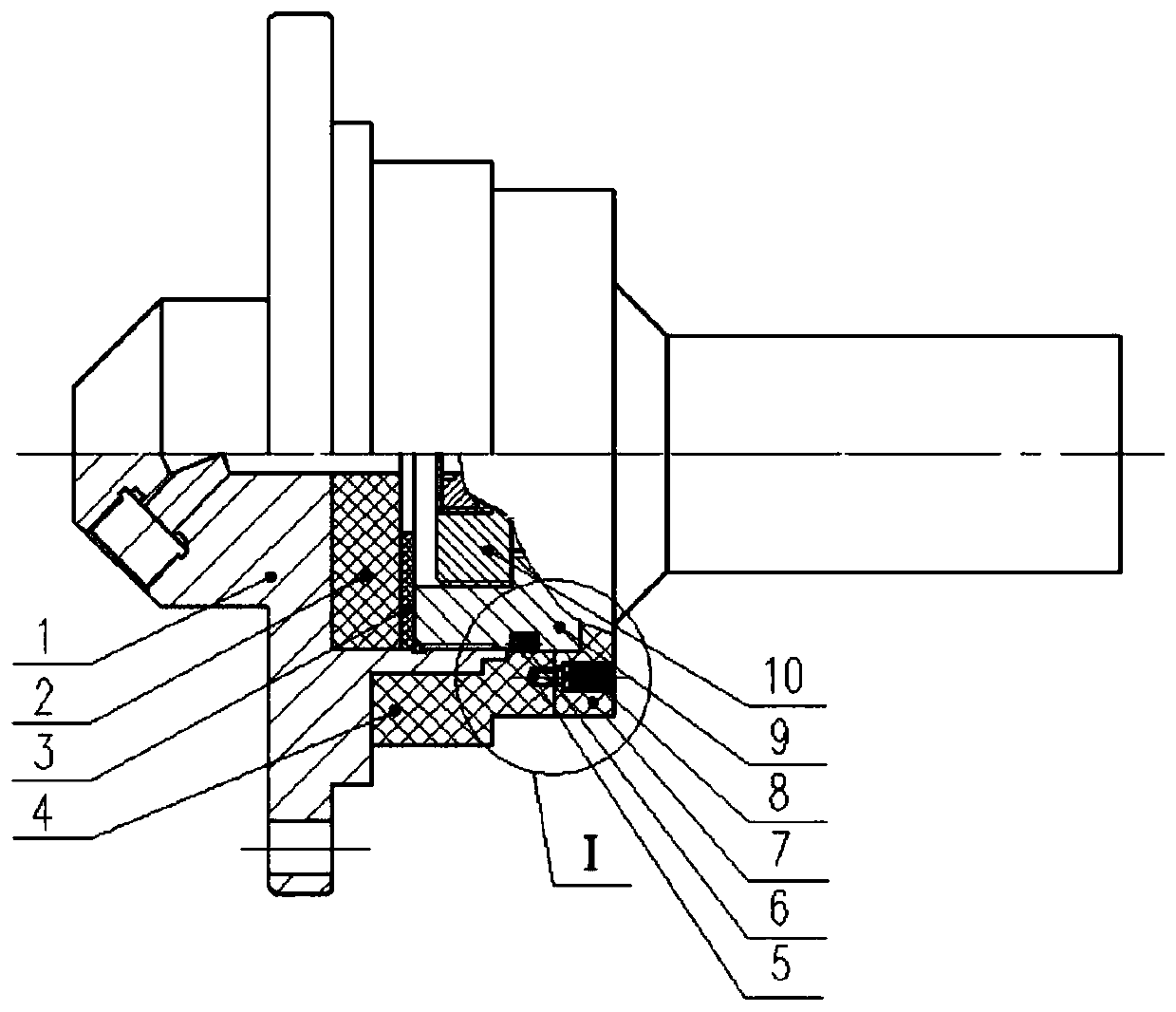

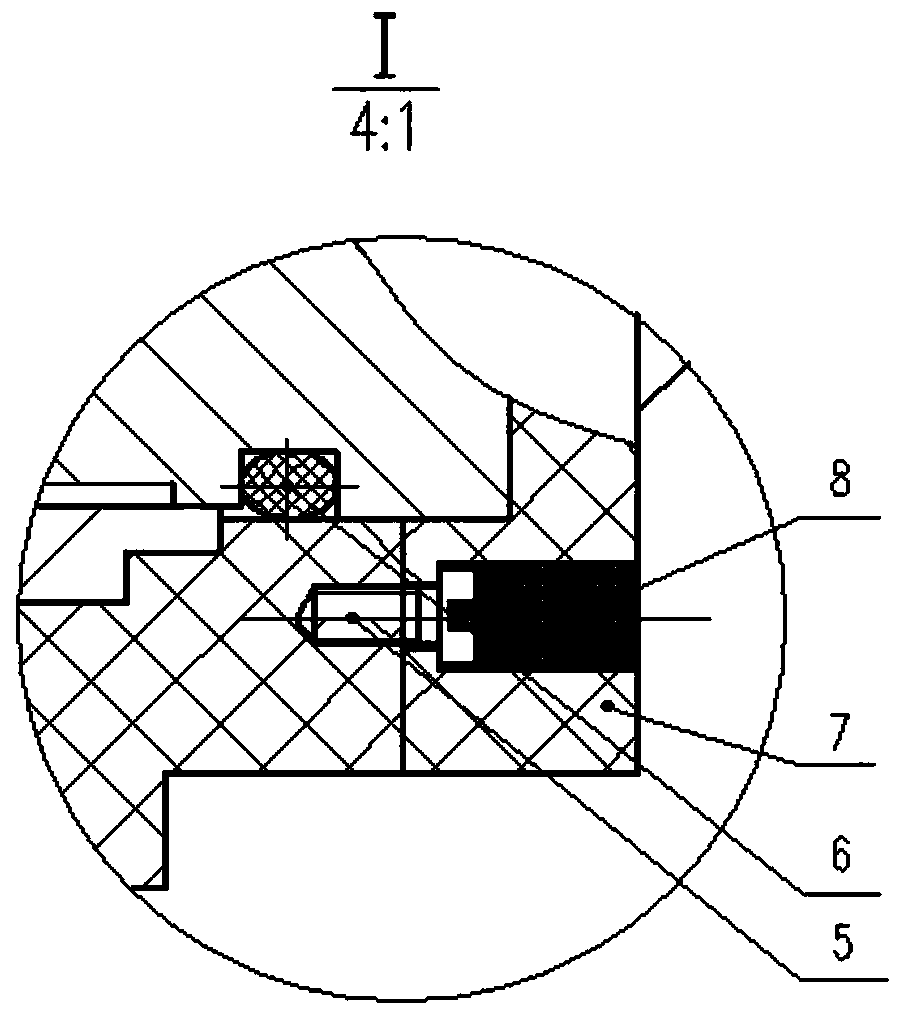

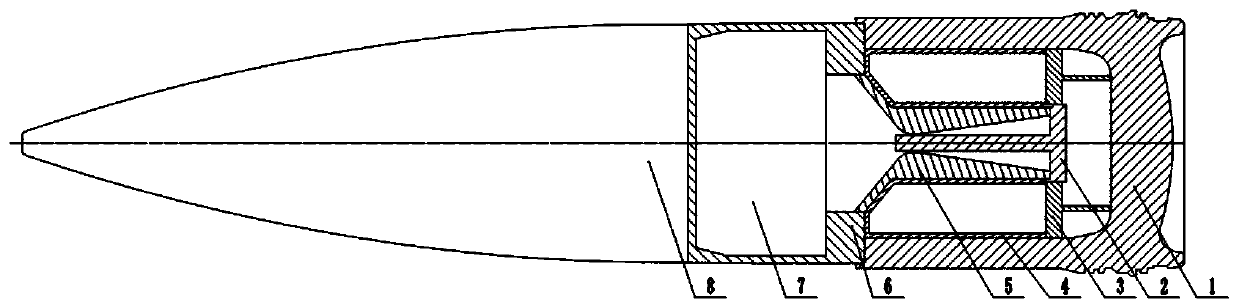

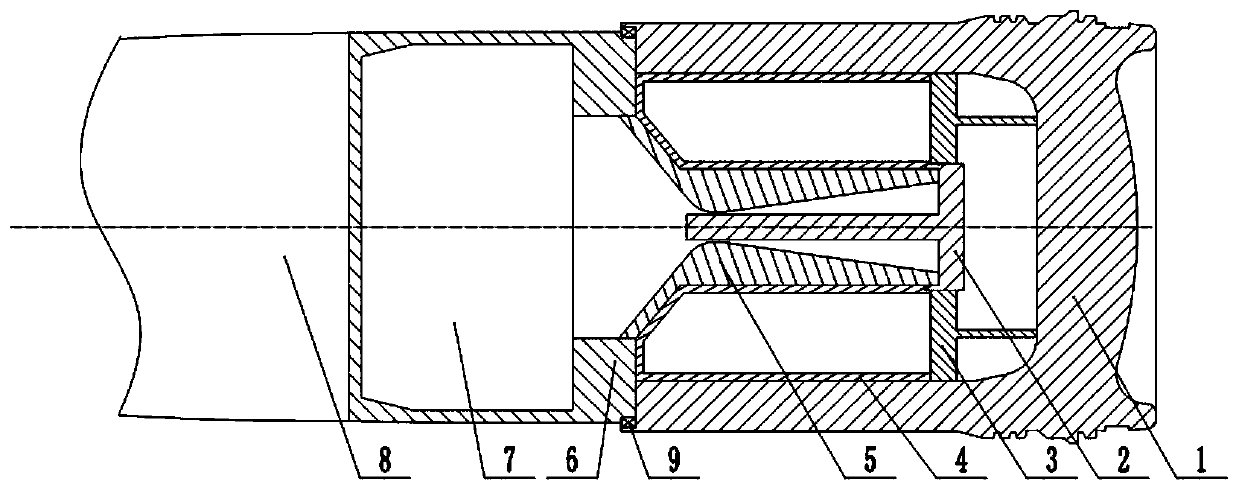

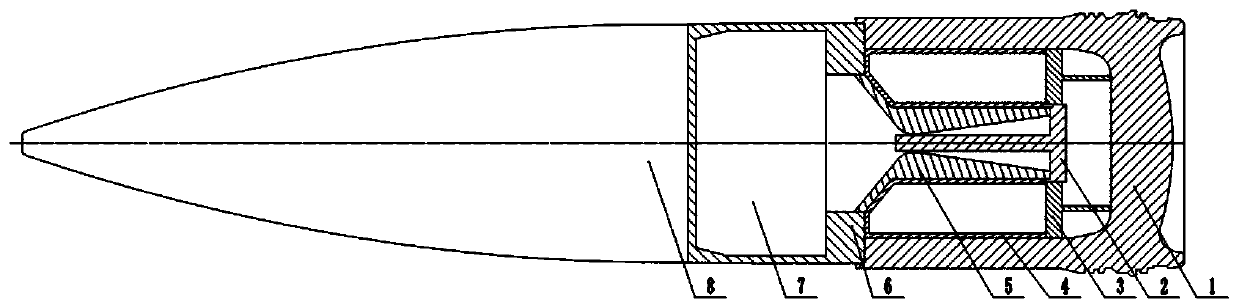

Basket type igniter of rotary solid rocket engine

PendingCN111396216ACompact ignition structureHigh structural quality and performanceRocket engine plantsInsulation layerEngineering

The invention provides a basket type igniter of a rotary solid rocket engine. The basket type igniter comprises an ignition top cover, a top cover hard heat insulation layer, a top cover soft heat insulation layer, a front heat insulation sleeve, an O-shaped sealing ring, a rear heat insulation sleeve, an igniter shell and an ignition gunpowder box. The top cover hard heat insulation layer is placed in the ignition top cover, and the top cover soft heat insulation layer adheres to the top cover hard heat insulation layer. The ignition gunpowder box is connected with inner threads of the igniter shell, the igniter shell is provided with the O-shaped sealing ring in a sleeving manner, and the igniter shell is connected with the ignition top cover through outer threads of the igniter shell and is abutted to the top cover soft heat insulation layer. The front heat insulation sleeve adheres to an end face of the ignition top cover, and the rear heat insulation sleeve adheres to the front heat insulation sleeve. The basket type igniter is high in structural quality performance, compact in ignition structure, low in negative mass, good in sealing performance, good in manufacturability, high in reliability, capable of being applied to an ignition system of the rotary solid rocket engine, low in machining precision, convenient to install, high in connection reliability, reliable in ignition performance and capable of being used for the solid rocket engine which is ignited from the head.

Owner:XIAN MODERN CHEM RES INST

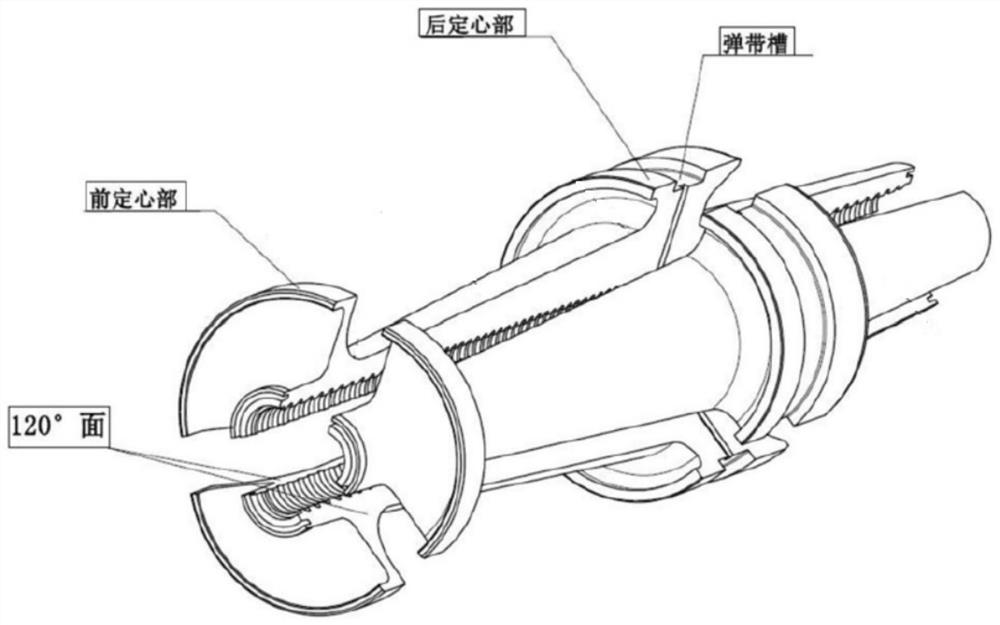

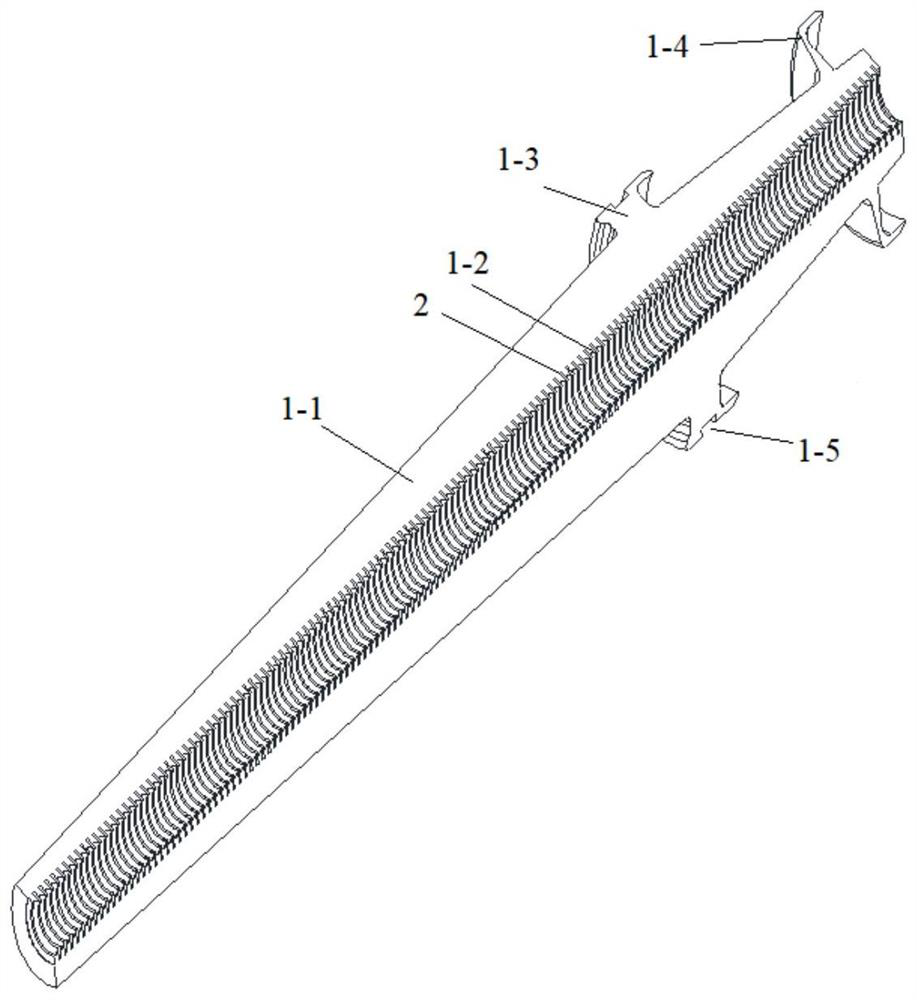

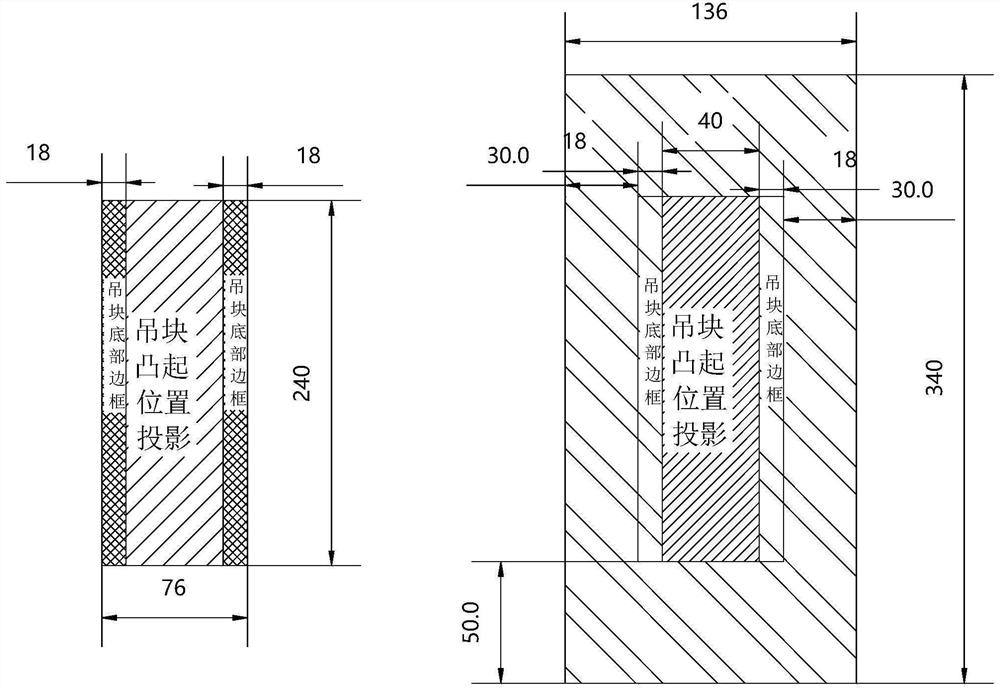

Cartridge holder clamping petal of carbon fiber composite armor-piercing bullet and forming method and forming die thereof

PendingCN114311746AHigh strengthAvoid breakingAmmunition projectilesProjectilesFiberArmor-piercing shell

The invention belongs to the technical field of armor-piercing projectile supports, and particularly relates to a carbon fiber composite armor-piercing projectile support clamping petal, a forming method of the carbon fiber composite armor-piercing projectile support clamping petal and a forming mold. The advantages of the short cut carbon fiber prepreg in complex shape forming and the high strength of continuous fibers are integrated, the structure of the bullet support clamping petal is divided into the tooth reinforcing plate and the shell, the tooth reinforcing plate is embedded in the annular groove of the shell, the tooth strength is enhanced, the tooth reinforcing plate is formed by fabric carbon fiber prepreg in a mold pressing and machining mode, and the service life of the bullet support clamping petal is prolonged. The shell is formed by mould pressing of the short carbon fiber prepreg, compared with a continuous carbon fiber mould pressing process, the laying time in the manufacturing process is greatly shortened, and the manufacturing efficiency is improved; compared with a chopped carbon fiber prepreg mold pressing process, the strength of the teeth is improved through the tooth reinforcing plate, and the teeth are prevented from being broken when the armor-piercing bullet is launched; compared with a metal sabot, the density of the product can be reduced to about 1.4 g / cm < 3 >, and the negative mass in the launching process is greatly reduced.

Owner:江苏集萃碳纤维及复合材料应用技术研究院有限公司

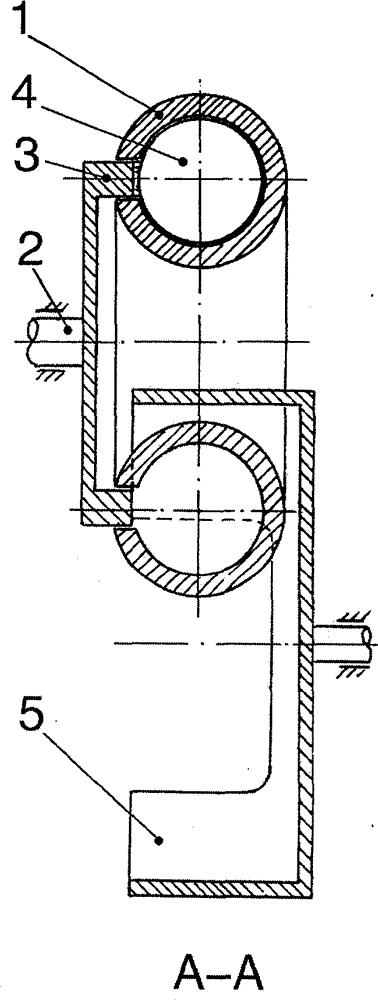

Annular cylinder engine

InactiveCN103982294ASimple structureReduce volumeInternal combustion piston enginesCombustion chamberEngineering

The invention discloses an annular cylinder engine. The annular cylinder engine is characterized in that a main shaft (2) is arranged at the center of an annular air cylinder (1) which is internally provided with a rotary piston (4), a shaft hub (3) of the main shaft is in sealing movable fit with the annular air cylinder by cutting in the side surface of the annular air cylinder, the opening end of the shaft hub is fixedly connected with the rotary piston, and a rotary drum (5) which is parallel to the main shaft and is provided with a notch is in sealing movable fit with the opening end of the shaft hub by cutting in the annular air cylinder from an opposite side of the shaft hub until the opening end of the rotary drum is attached to the opening end of the shaft hub and is in sealing movable fit with the opening end of the shaft hub; the rotary drum and the rotary piston are reversely rotated at the same speed, the notch of the rotary drum is rotated into an inner cavity of the annular air cylinder at the right moment, the notch of the rotary drum is rotated out of the inner cavity of the annular air cylinder after the rotary piston penetrates through the notch in a barrier-free way, the inner cavity is sealed by the wall of the rotary drum, a sealed combustion chamber is formed by enclosing the tail end of the rotary piston, the inner cavity of the annular air cylinder, the outer wall of the rotary drum and the opening end of the shaft hub at the moment, flammable gas is sprayed in a gas inlet (6), combustion is carried out by igniting an ignition plug (7), the rotary piston and the main shaft are pushed to do work in a circulation rotating way, and waste gas is exhausted by a gas exhaust outlet (8). The annular cylinder engine disclosed by the invention can be connected with various machines in parallel and in series, the size is small, the weight is light, and high efficiency and energy saving are realized.

Owner:苗军

Composite material base for satellite antenna bearing cylinder and preparation method

ActiveCN103647133AImprove axial stiffnessHigh degree of modularityAntenna supports/mountingsSpace environmentHeat stability

The invention discloses a composite material base for a satellite antenna bearing cylinder. The composite material base comprises a lower base and an upper base arranged above the lower base, the lower base comprises an upper end cover and a lower end cover, the upper end cover comprises an upper end cover body and a big-end-down first cone arranged below the upper end cover body, the lower end cover comprises a lower end cover body and a big-end-up second cone arranged above the lower end cover body, a first cylinder body is arranged between the upper end cover and the lower end cover, the upper base comprises a basic part, the basic part comprises a bottom plate, a top plate and a second cylinder body, the second cylinder body is arranged between the bottom plate and the top plate, and the longitudinal section of the second cylinder body is 'convex'. The invention further discloses a preparation method of the base. Various portions of the base of the satellite antenna bearing cylinder are made of composite materials, and the base has the advantages of high axial rigidity and modularity, fine heat stability in high-low temperature space environment, low negative quality, fine reliability, excellent comprehensive performance and the like.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

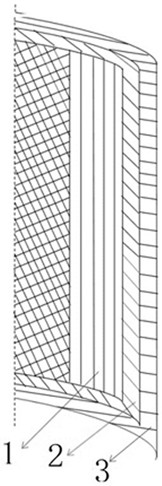

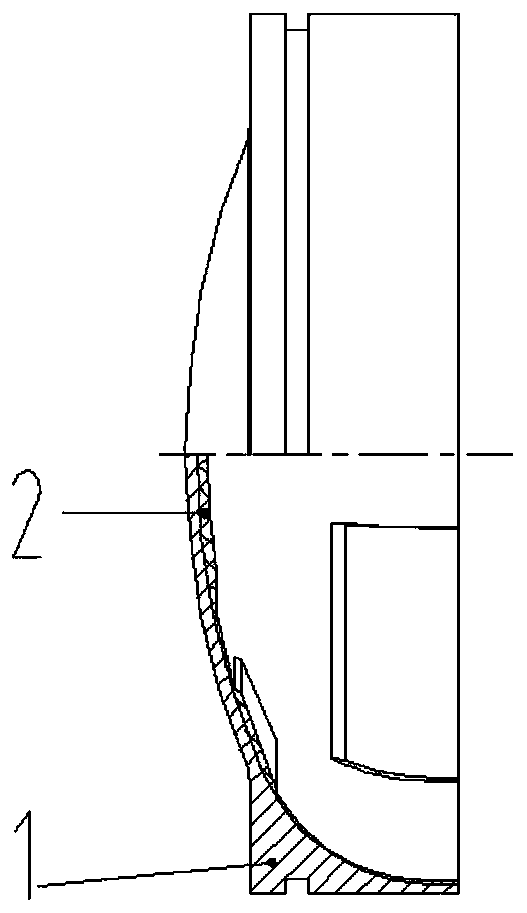

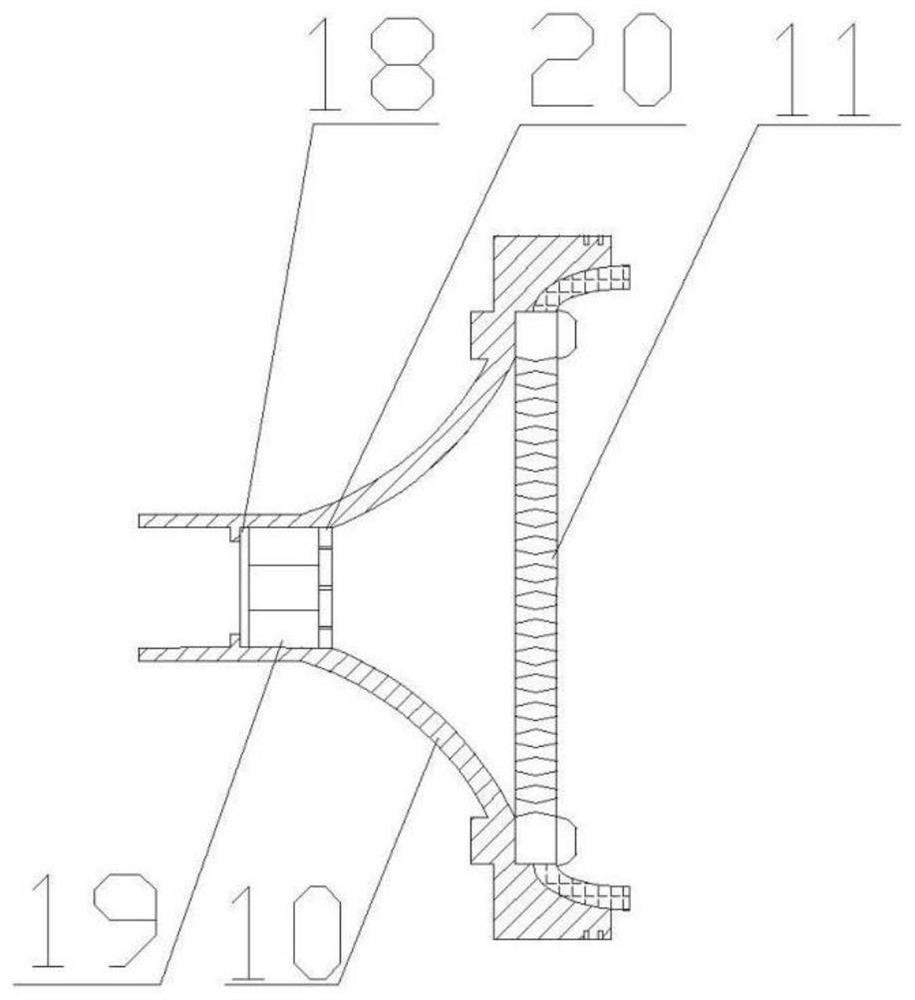

Heat insulation layer structure of solid rocket engine long-tail nozzle, and preparation method thereof

ActiveCN112223856AGood ablation resistanceImprove insulation performanceLaminationLamination apparatusThermal transmittanceEngineering

The invention provides a heat insulation layer structure of a solid rocket engine long-tail nozzle, and a preparation method thereof. The heat insulation layer structure comprises an ablation layer, afirst heat insulation layer and a low-density heat insulation layer which are arranged in an attached mode, wherein the ablation layer takes a phenolic resin as a matrix material and takes carbon fiber as a reinforcing material, the first heat insulation layer takes a phenolic resin as a matrix material and takes high silica glass as a reinforcing material, and the low-density heat insulation layer takes a phenolic resin added with a light filler as a matrix material and takes glass fiber as a reinforcing material. According to the heat insulation layer structure, the low-density heat insulation layer is arranged on the basis of the ablation layer and the heat insulation layer, and by utilizing the characteristic of low heat conductivity of the low-density material, under the condition that the ablation resistance is not influenced, the heat insulation performance of the heat insulation layer of the long-tail nozzle is improved, ablation and heat insulation are balanced, and the heatprevention efficiency of the heat insulation layer of the long-tail nozzle is improved; and the mass ratio of the long-tail nozzle product can be increased, and the problems of low mass ratio and highthermal conductivity of a traditional structure of the long-tail nozzle are solved.

Owner:北京玻钢院复合材料有限公司

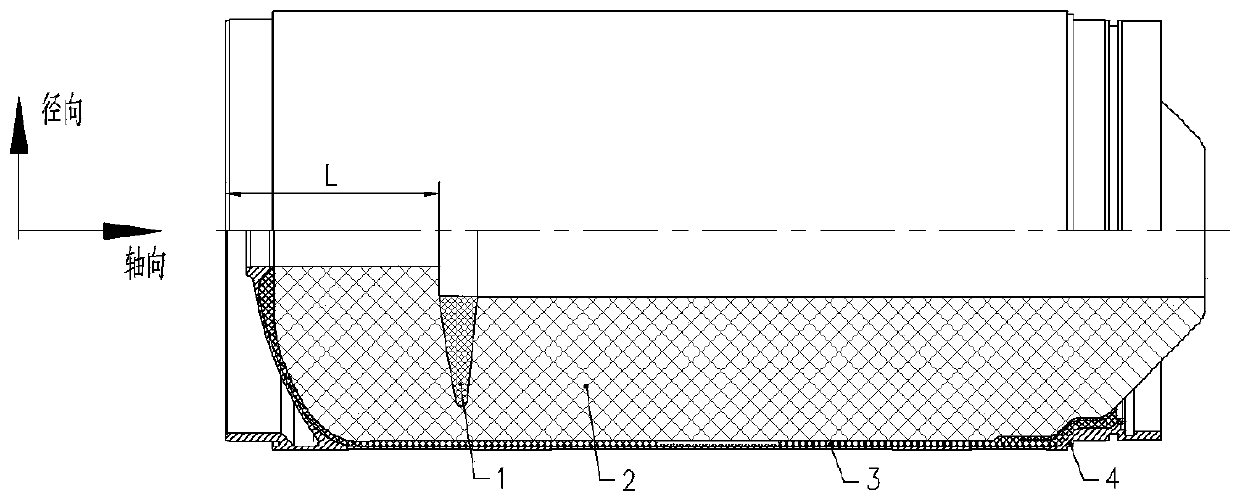

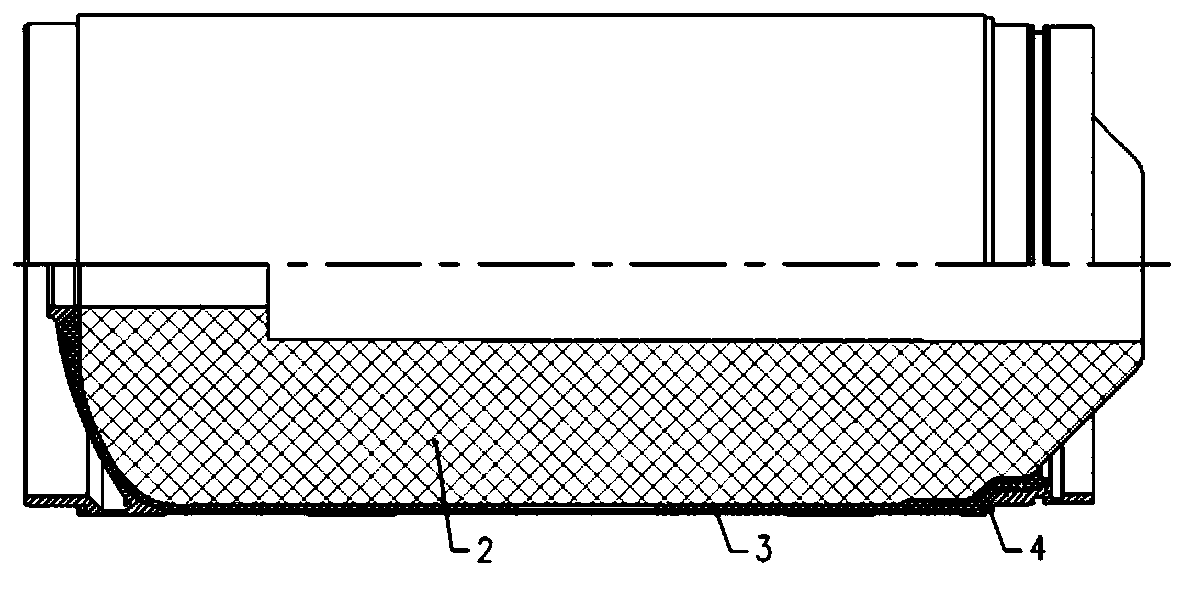

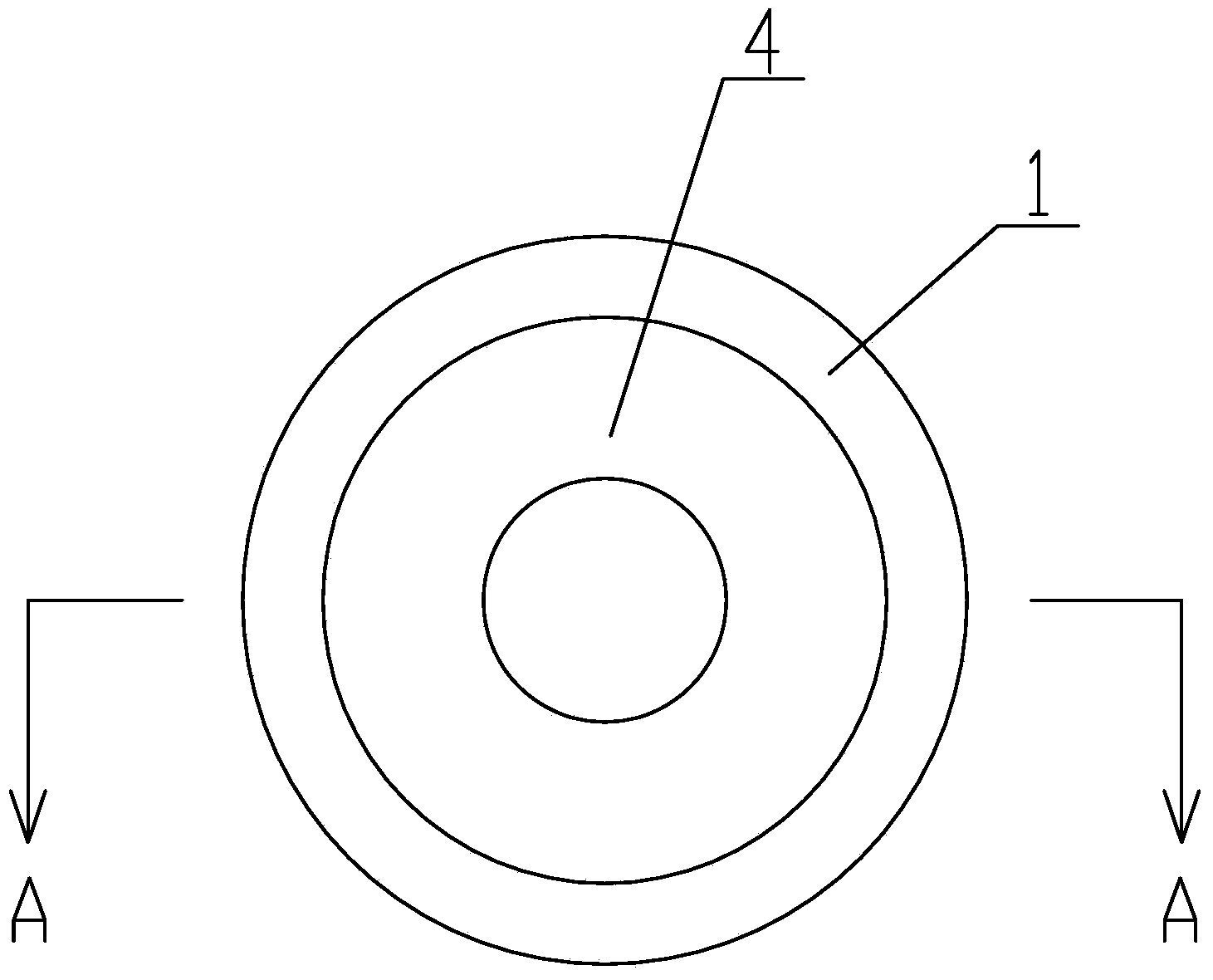

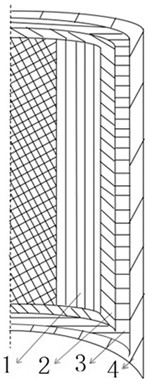

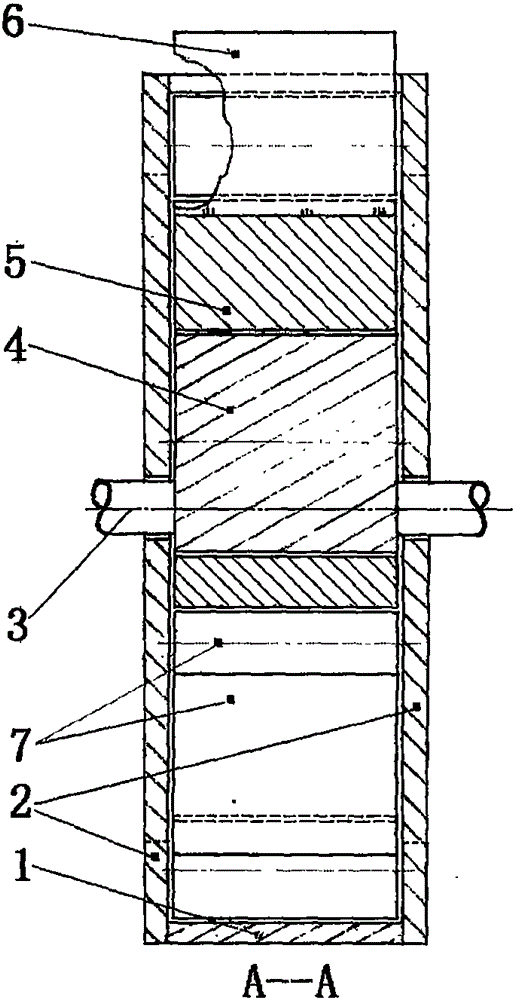

Inner heat insulation layer of front seal head of solid rocket engine and forming method of inner heat insulation layer

ActiveCN110792529AReduce design thicknessReduce negative qualityCoatingsRocket engine plantsInsulation layerSand blasting

The invention discloses an inner heat insulation layer structure of a front seal head of a solid rocket engine and a forming method of the inner heat insulation layer structure. A multi-step structureof an inner profile surface of the inner heat insulation layer is realized. The forming method of the inner heat insulation layer comprises the step 1 of manufacturing a mold according to an inner heat insulation layer structure, the step 2 of sandblasting the inner wall surface of the front seal head, the step 3 of preparing a liquid heat insulation layer, the step 4 of pouring the liquid heat insulation layer with the set mass into the front seal head, the step 5 of assembling the mold and the front seal head to a set position to ensure the designed thickness of the heat insulation layer, the step 6 of putting the product into an oven for curing, and the step 7 of taking out the product after the curing time is met, cooling the product to normal temperature, taking out the mold, and shaping and cutting the heat insulation layer to obtain the designed heat insulation layer. The heat insulation layer is high in size control precision, good in quality consistency and simple in process,and the forming method can meet the forming requirements of inner heat insulation layers in various irregular shapes.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

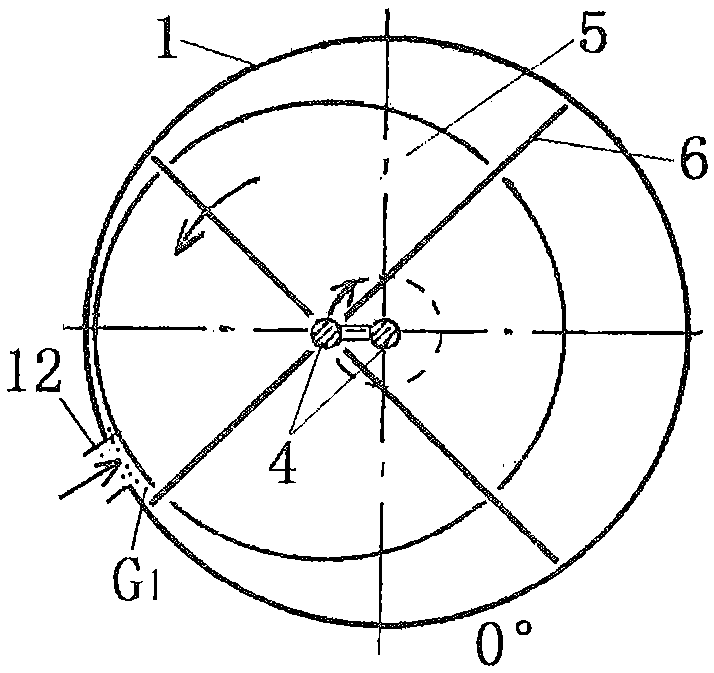

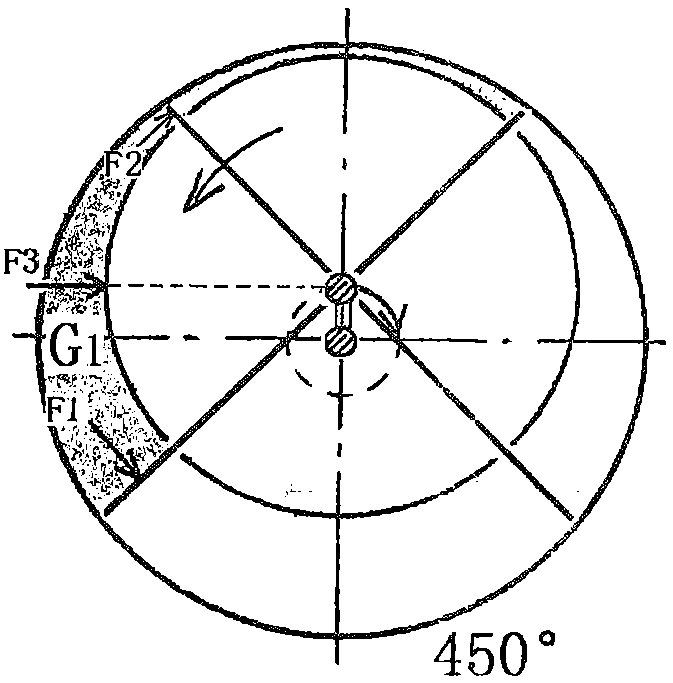

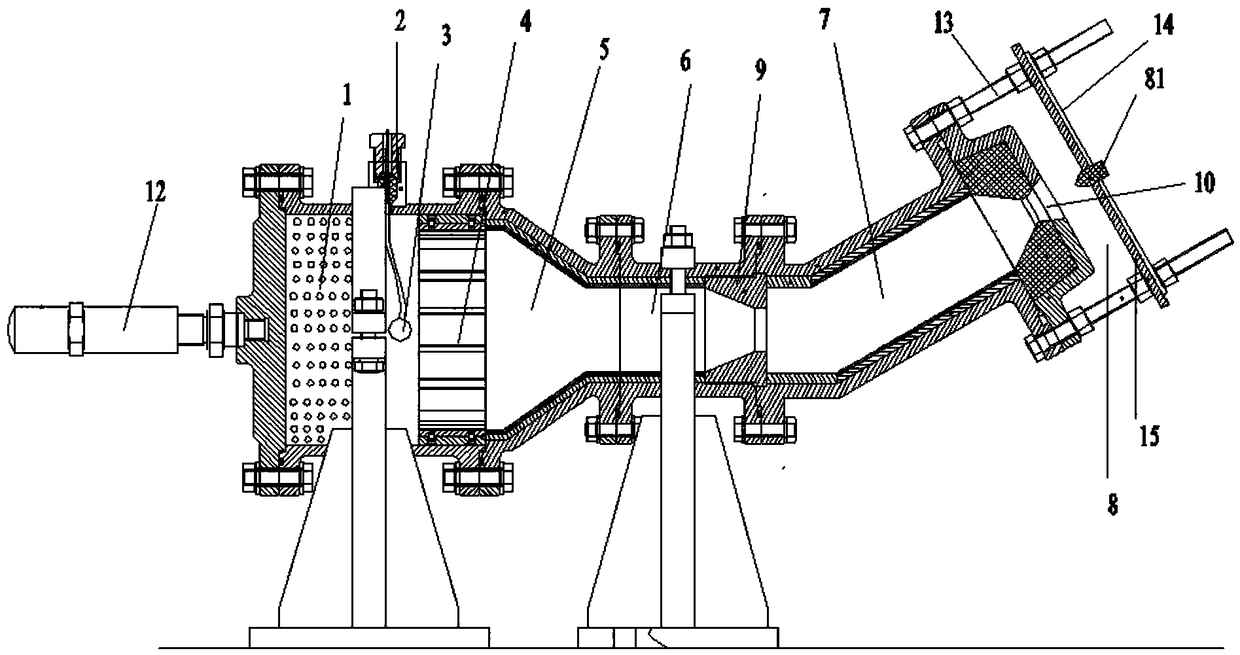

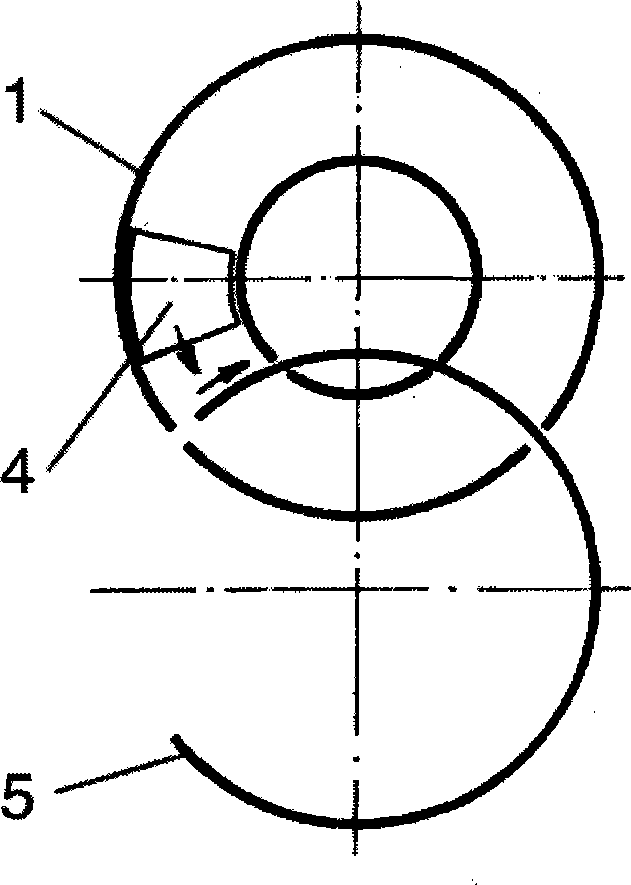

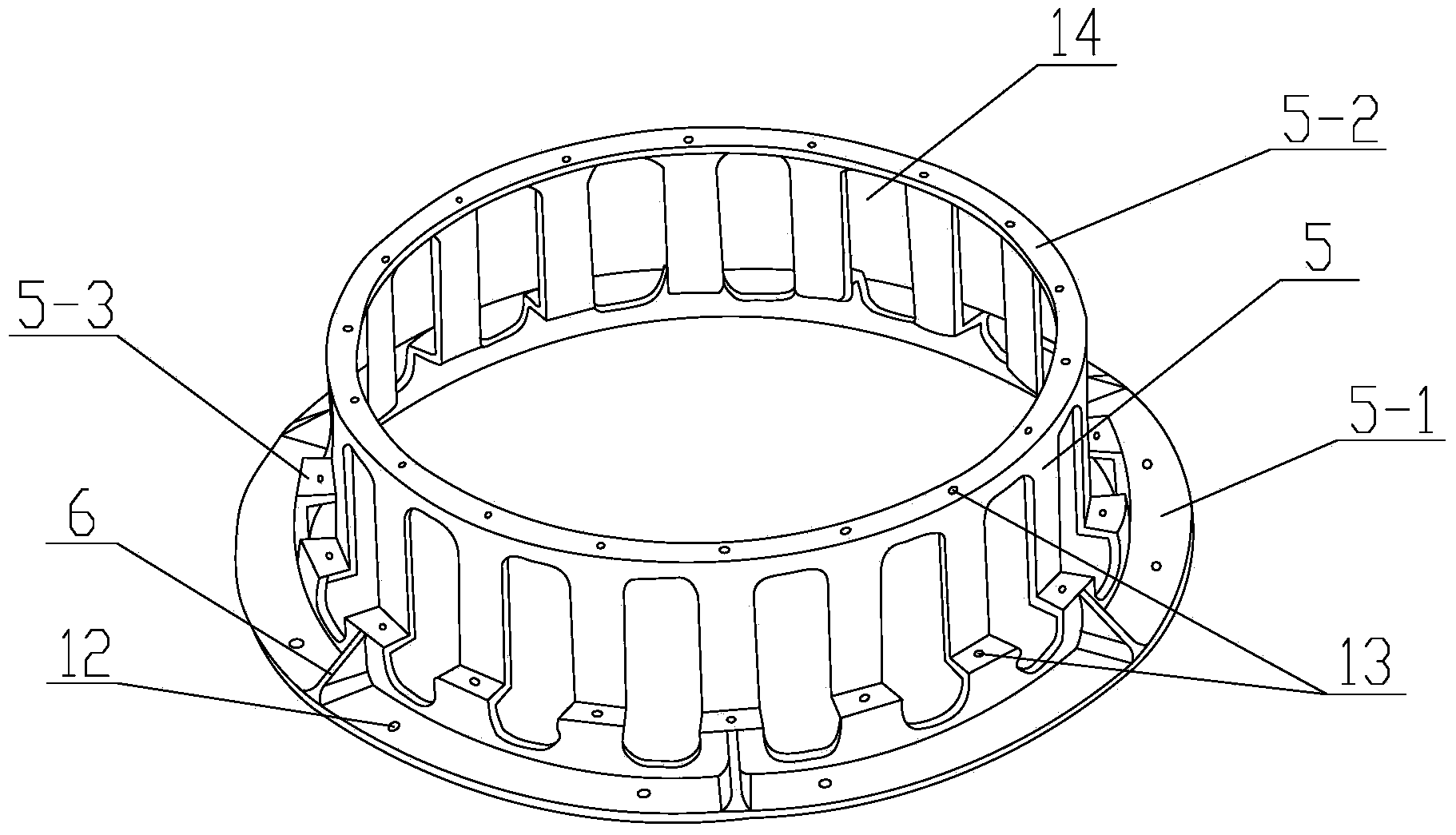

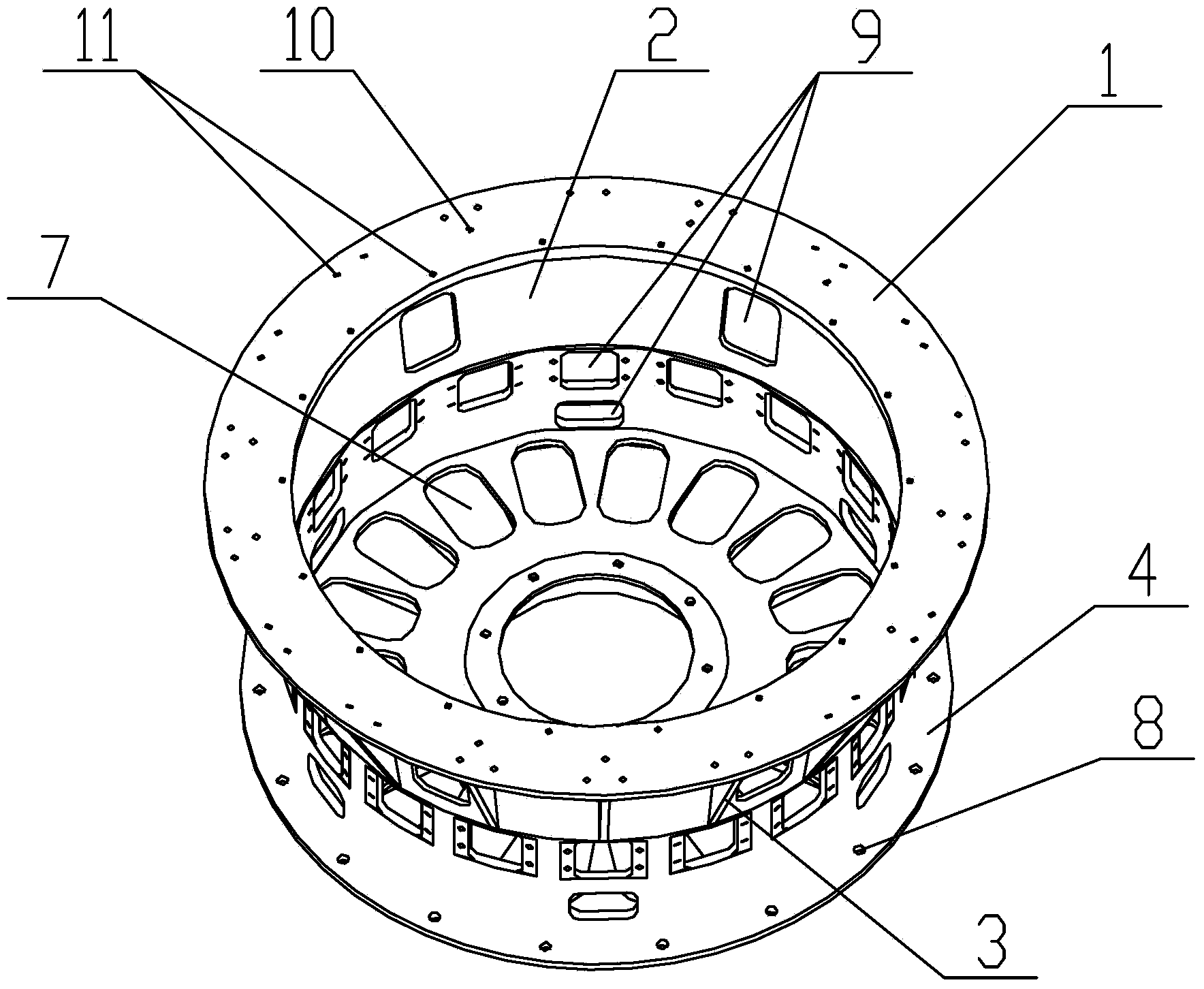

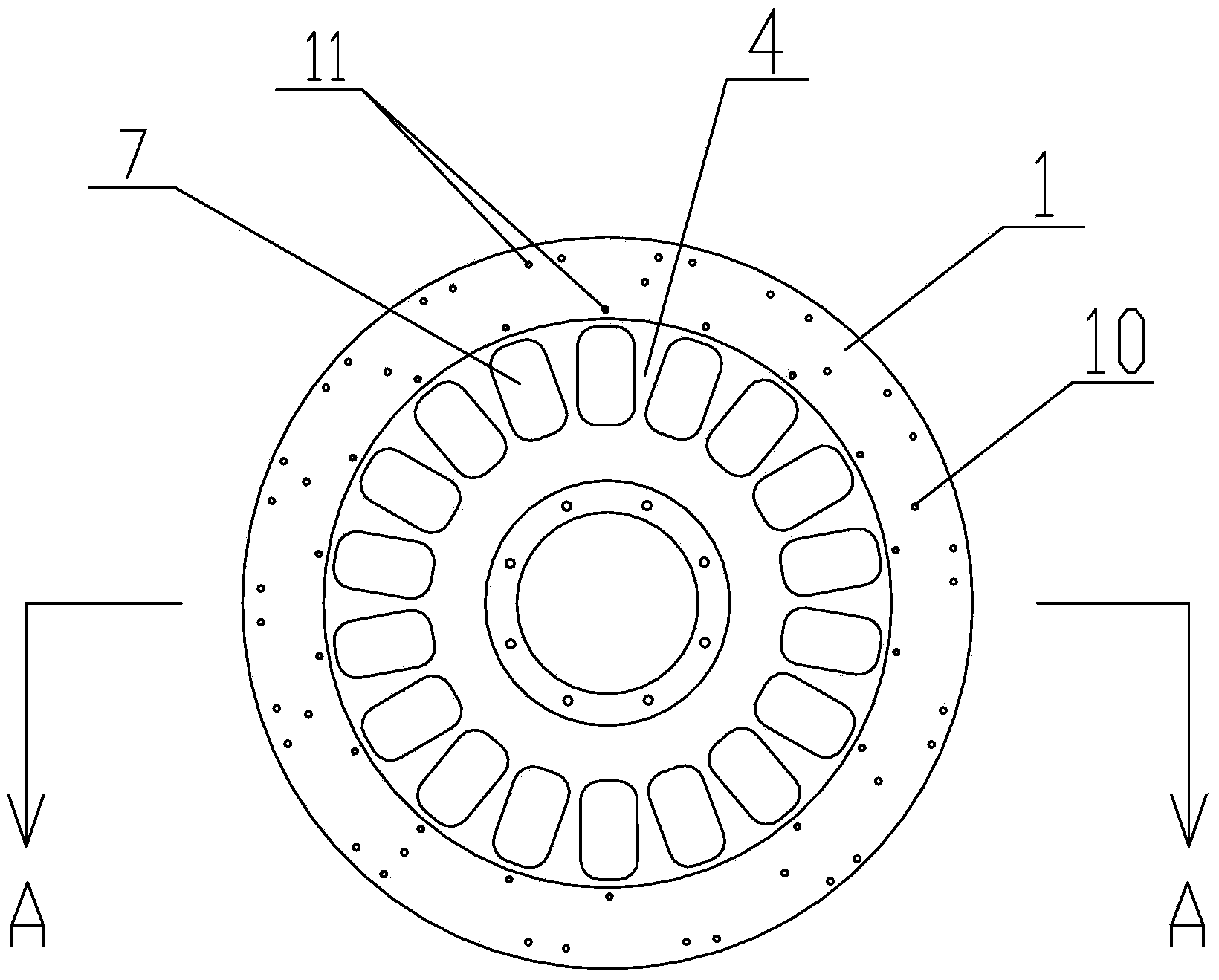

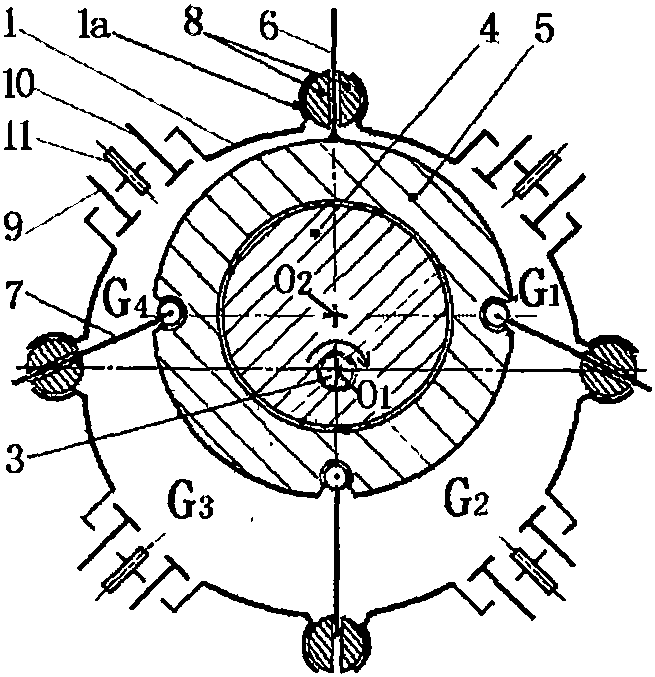

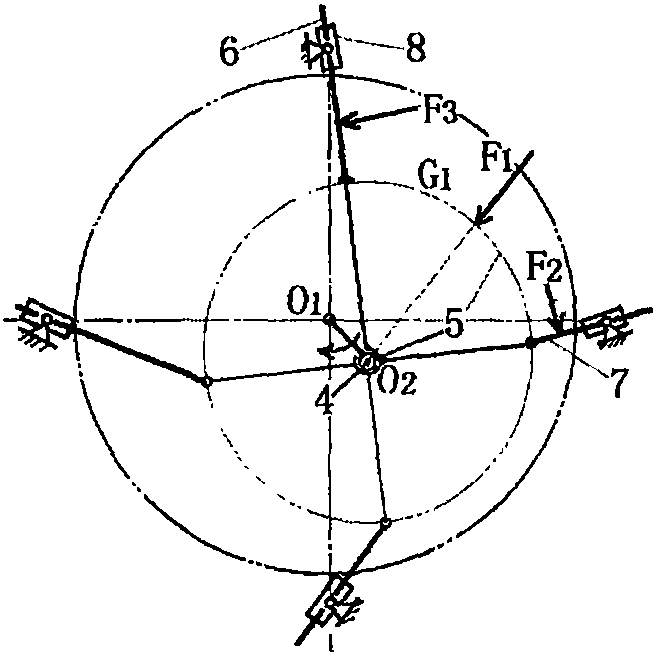

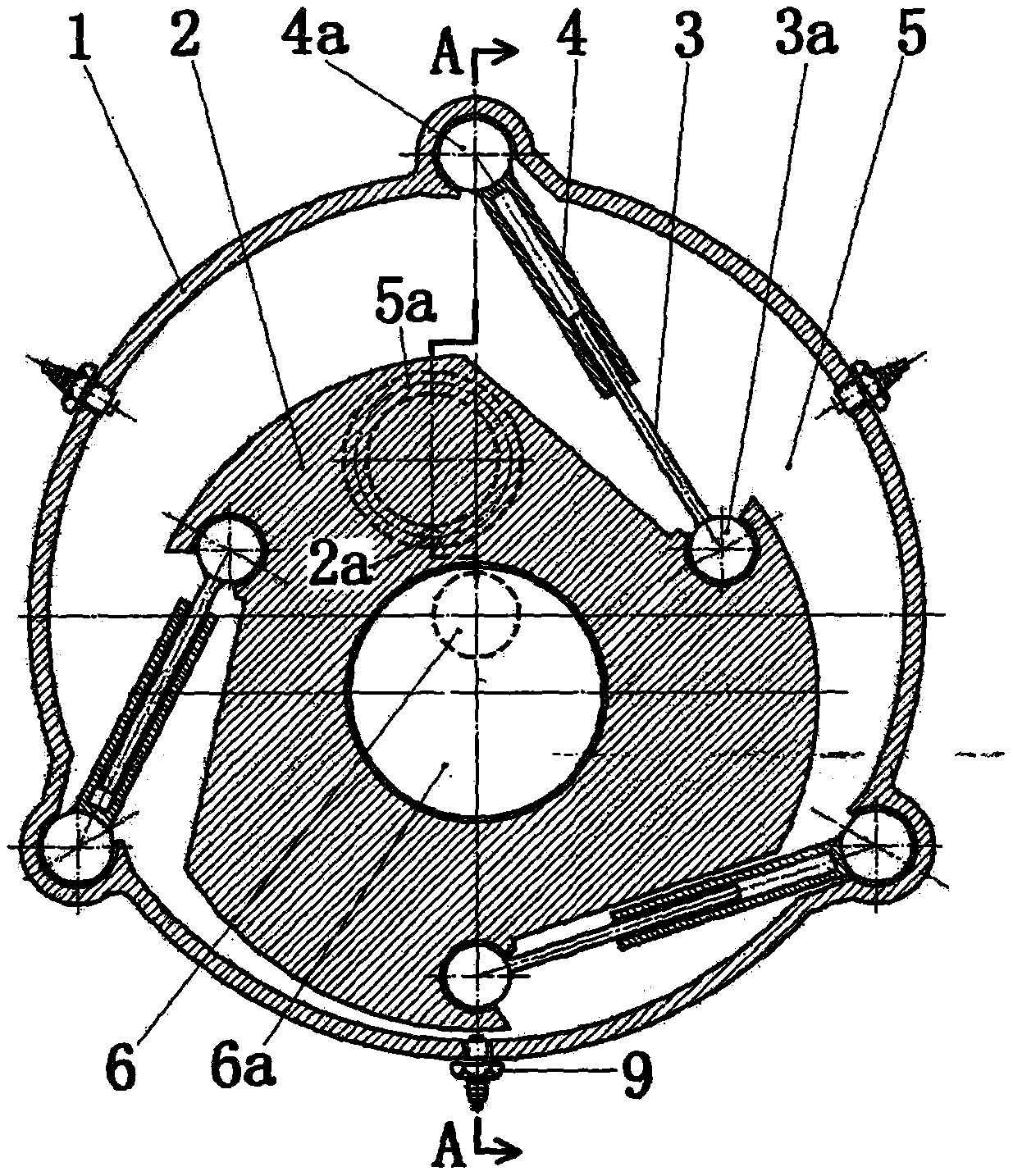

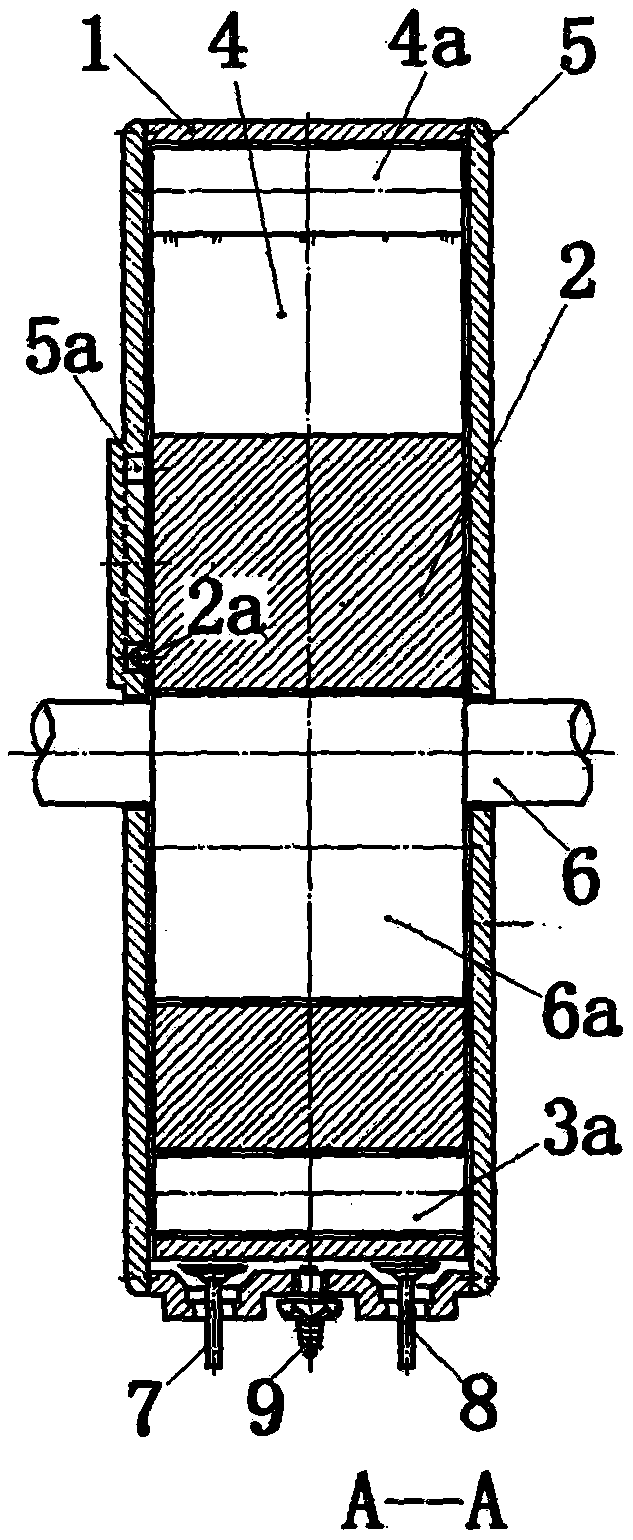

Sliding plate rotor engine

InactiveCN105781738ASimple structureReduce negative qualityMachines/enginesEngine componentsHinge angleStator

The invention discloses a sliding plate rotor engine. The sliding plate rotor engine is characterized in that two ends of a barrel-shaped stator (1) are closed through end covers (2); an internally arranged engine spindle (3) is supported on the centers of the end covers; an eccentric wheel (4) which is connected onto the engine spindle (3) is sleeved with a sliding plate ring (5); the sliding plate ring is fixedly connected with a radial fixedly-connected sliding plate (6) and is hinged to a group of outward hinge-connection sliding plates (7); the end surfaces of two ends of each of the eccentric wheel, the sliding plate ring and the sliding plates are in sliding and sealing match with the inner walls of the end covers; the parts, which face the sliding plates, of the outer wall of the stator are each provided with a longitudinal shaft seat (1a); a round shaft body (8) is arranged in each shaft seat (1a); the sliding plates radially penetrate through the corresponding round shaft bodies and are in sliding and sealing match with the corresponding round shaft bodies; and the part, between every two adjacent shaft seats, of the stator wall is provided with an air inlet valve (9), an air exhaust valve (10) and a sparking plug (11). The inner cavity of the stator is divided into a plurality of sealed air chambers through the sliding plates; and the volume of each chamber is increased and decreased regularly along with the rotation of the spindle, so that circulation of air suction, compression, working and air exhaust is realized. Rotation power is directly output; the structure is simplified; the heat efficiency is high; the power consumption is low; the size is small; and the mass is light.

Owner:苗军

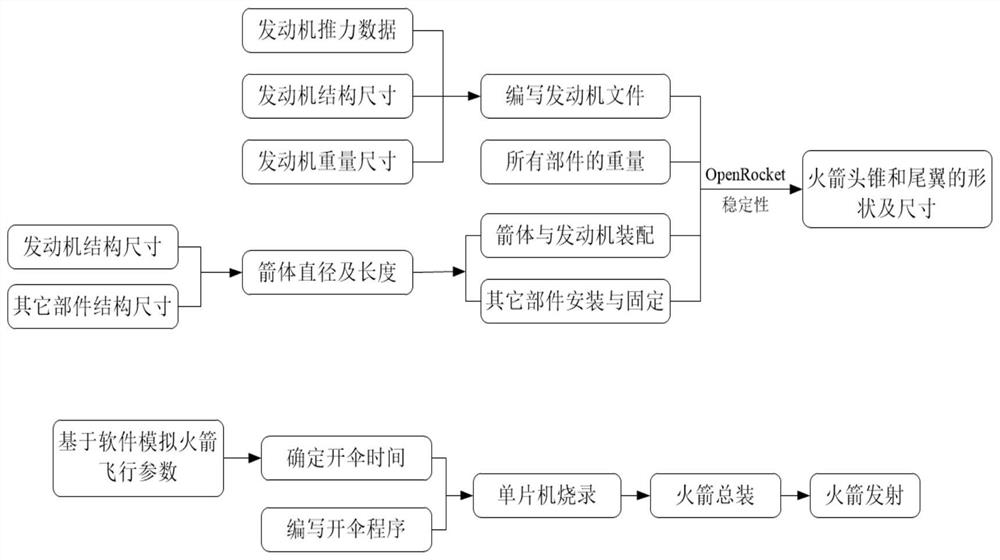

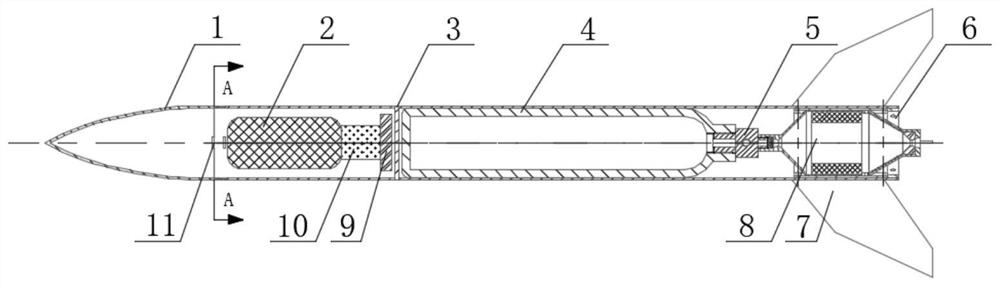

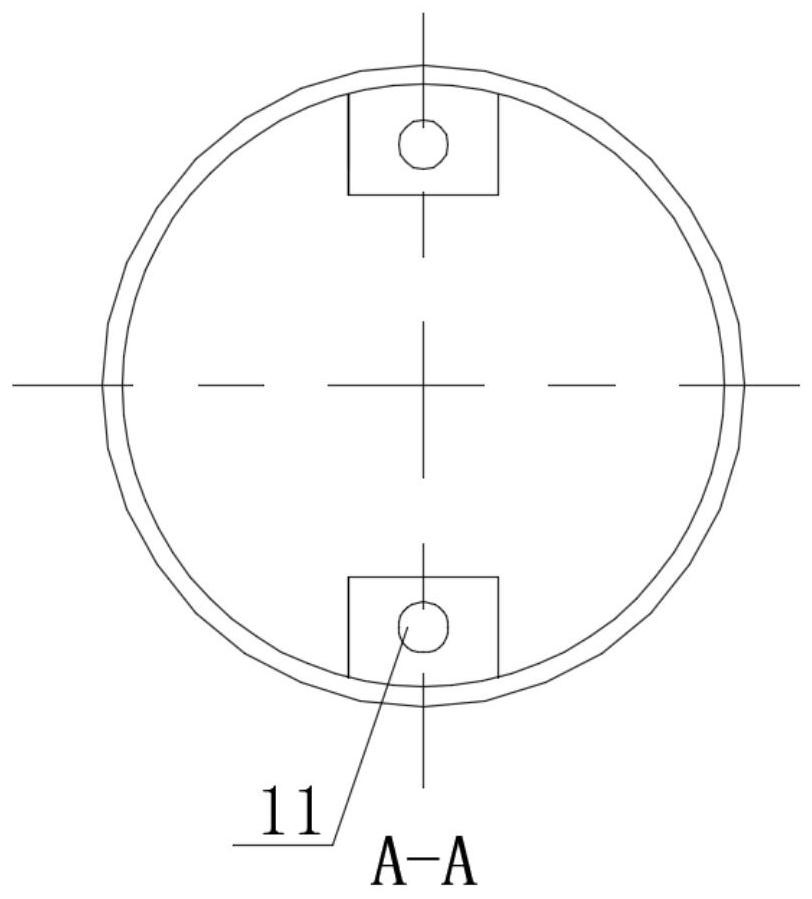

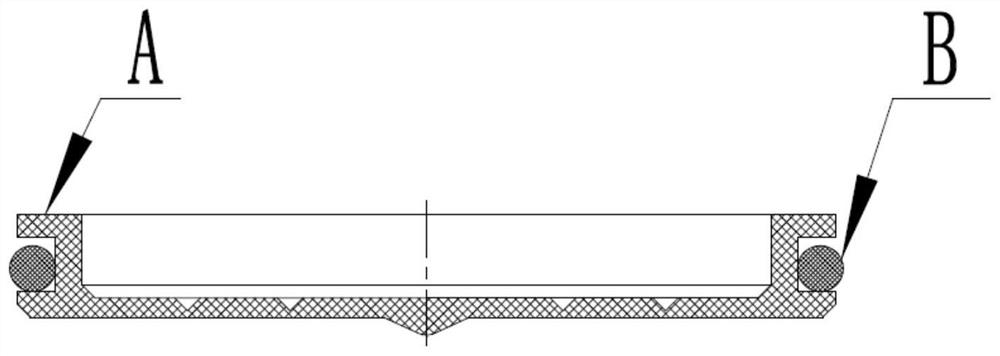

Small solid-liquid sounding rocket for teaching and popularizing science

InactiveCN111256543BSimple structureEasy to processGas handling applicationsFluid transferredGas cylinderThrust chamber

The invention discloses a small solid-liquid sounding rocket for teaching science popularization, and belongs to the field of solid-liquid hybrid engines. The small solid-liquid sounding rocket comprises a rocket shell, an empennage, a parachute recovery device, a gas cylinder, a valve and an engine thrust chamber. The rocket shell is formed by inserting a nose cone and a cylindrical skin, the parachute recovery device, the gas cylinder, the valve and the engine thrust chamber are sequentially installed in the rocket shell from the head to the tail, and the engine thrust chamber is fixed to the tail end of the skin through a thrust chamber fixing ring; the parachute recovery device is adopted for recovery; and by utilizing the characteristics that nitrous oxide takes a liquid form as a main body in a high-pressure gas cylinder and the saturated vapor pressure of nitrous oxide is high, an oxidant can be conveyed in a self-pressurization manner, so that the structure of an oxidant supplysystem is simplified, and the negative quality of the system is reduced. The rocket is suitable for science popularization and teaching demonstration, the structure of the solid-liquid hybrid engineis clearly displayed, and the principle of the solid-liquid hybrid engine can be clearly known through the structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Axial sliding type partition plate suitable for multi-pulse solid rocket engine

InactiveCN113606057AGuaranteed to workEfficient managementRocket engine plantsCombustion chamberControl theory

The invention discloses an axial sliding type partition plate suitable for a multi-pulse solid rocket engine, and belongs to the technical field of multi-pulse solid engines. The axial sliding type partition plate suitable for the multi-pulse solid rocket engine is mainly composed of a partition plate and a sealing ring. According to the axial sliding type partition plate suitable for the multi-pulse solid rocket engine, a combustion chamber of a solid rocket engine is divided into a plurality of parts through the axial sliding type partition plates, the axial sliding type partition plates slide towards the rear section of the engine, the rear section of the engine charges bear the pressure generated when the front section of the engine works, and the situation that the partition plates are broken, and consequently the rear section of the engine charges are ignited is avoided; besides, one-way breaking is achieved through prefabricating defects of the axial sliding type partition plate, normal work of the rear section of the engine is guaranteed, that is, multiple times of shutdown and starting of the multi-pulse solid rocket engine are achieved through the axial sliding type partition plate with prefabricating defects, thrust and pulse interval time are reasonably distributed, and optimal management of engine energy is achieved. The axial sliding type partition plate suitable for the multi-pulse solid rocket engine has the advantages of being suitable for complex medicine types, low in cost, light in weight, simple in structure and convenient to install.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

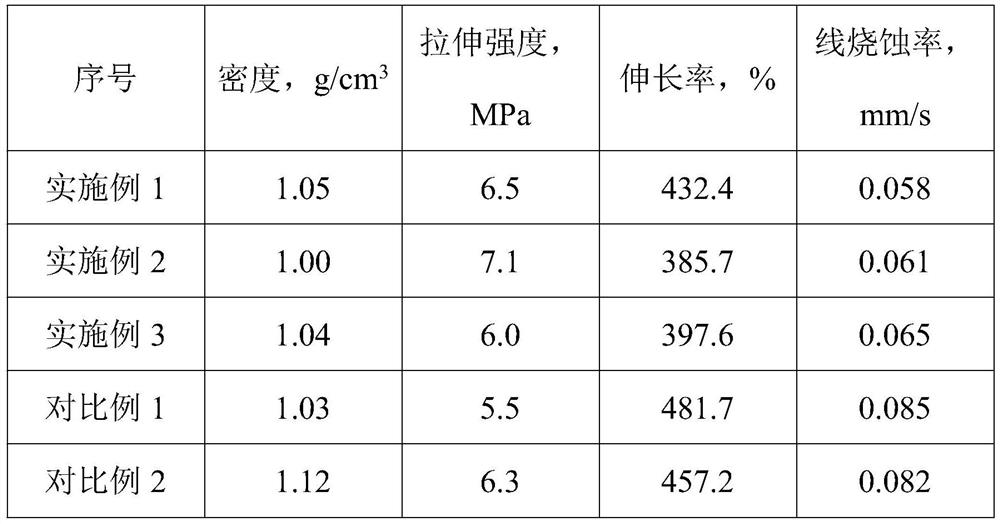

Low-density ablation-resistant ethylene propylene diene monomer material and preparation method thereof

PendingCN112812447AImprove high temperature resistanceImprove mechanical propertiesComposite materialPolymer chemistry

The invention discloses a low-density ablation-resistant ethylene propylene diene monomer material and a preparation method thereof. The low-density ablation-resistant ethylene propylene diene monomer material is prepared from 100 parts of ethylene propylene diene monomer, 15-30 parts of a reinforcing filler, 10-20 parts of organic fiber, 5-15 parts of inorganic fiber, 5-15 parts of an ammonium salt flame retardant, 3-5 parts of a light filler, 5-15 parts of a metal hydroxide filler, 10-20 parts of a tackifying resin, 5-10 parts of a petroleum softening agent and 2-4 parts of a peroxide vulcanizing agent, and is formed through mixing, open milling and hot-pressing vulcanization. According to the invention, the material not only has low density, but also can significantly improve the strength of a carbon layer and improve the ablation resistance and scouring resistance of the material by compounding the organic fiber and the inorganic fiber and matching with the ammonium salt flame retardant and the metal hydroxide filler, and is suitable for a high-temperature strong-scouring working environment of a solid rocket engine.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

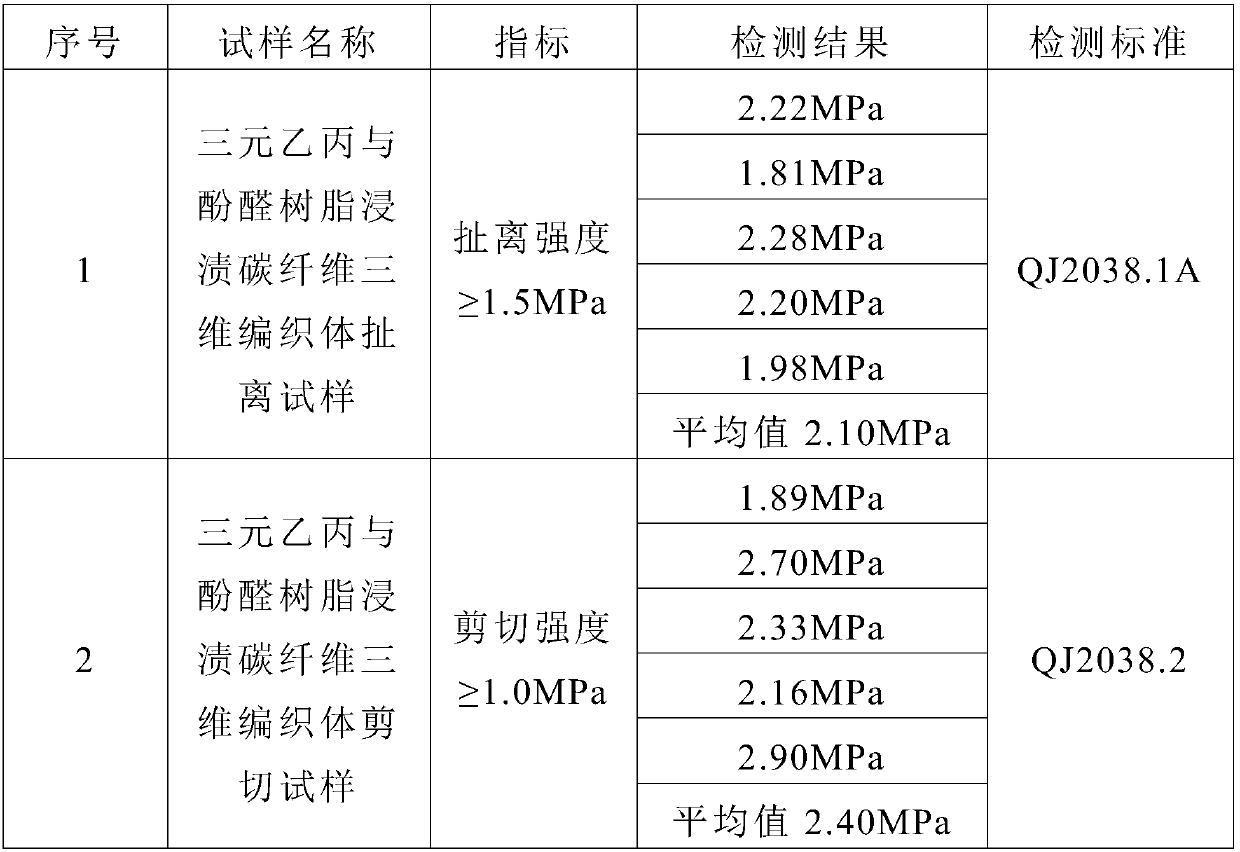

Forming method of fiber-wound solidification rocket engine multiphase heat-insulating layer

ActiveCN109605776AGood workmanshipImprove anti-ablation performanceDomestic articlesCarbon fibersNegative mass

The invention discloses a forming method of a fiber-wound solidification rocket engine multiphase heat-insulating layer. The multiphase heat-insulating layer is jointly composed of ablation-resistantEPDM and a phenolic resin impregnated carbon fiber three-dimensional weaving body; on the one hand, under the condition that the thickness of the heat-insulating layer is not increased, ablation resistance of heat-insulating materials can be improved, the negative mass of an engine shell is reduced, and the mass ratio of an engine is increased; on the other hand, a multilayer patch mode and the design of a sandwich structure are adopted, and the formed multiphase heat-insulating materials have good manufacturability; and through two times of prepressing, on the one hand, gas between the two types of heat-insulating materials and between EPDM film layers is discharged, on the other hand, good interface bonding between the phenolic resin impregnated carbon fiber three-dimensional weaving body and the heat-insulating layer on the upper and lower positions is guaranteed, and the defects such as bulges, gas entrapment and debonding between the multiphase heat-insulating materials of the EPDM and the phenolic resin impregnated carbon fiber three-dimensional weaving body are prevented.

Owner:湖北三江航天江北机械工程有限公司

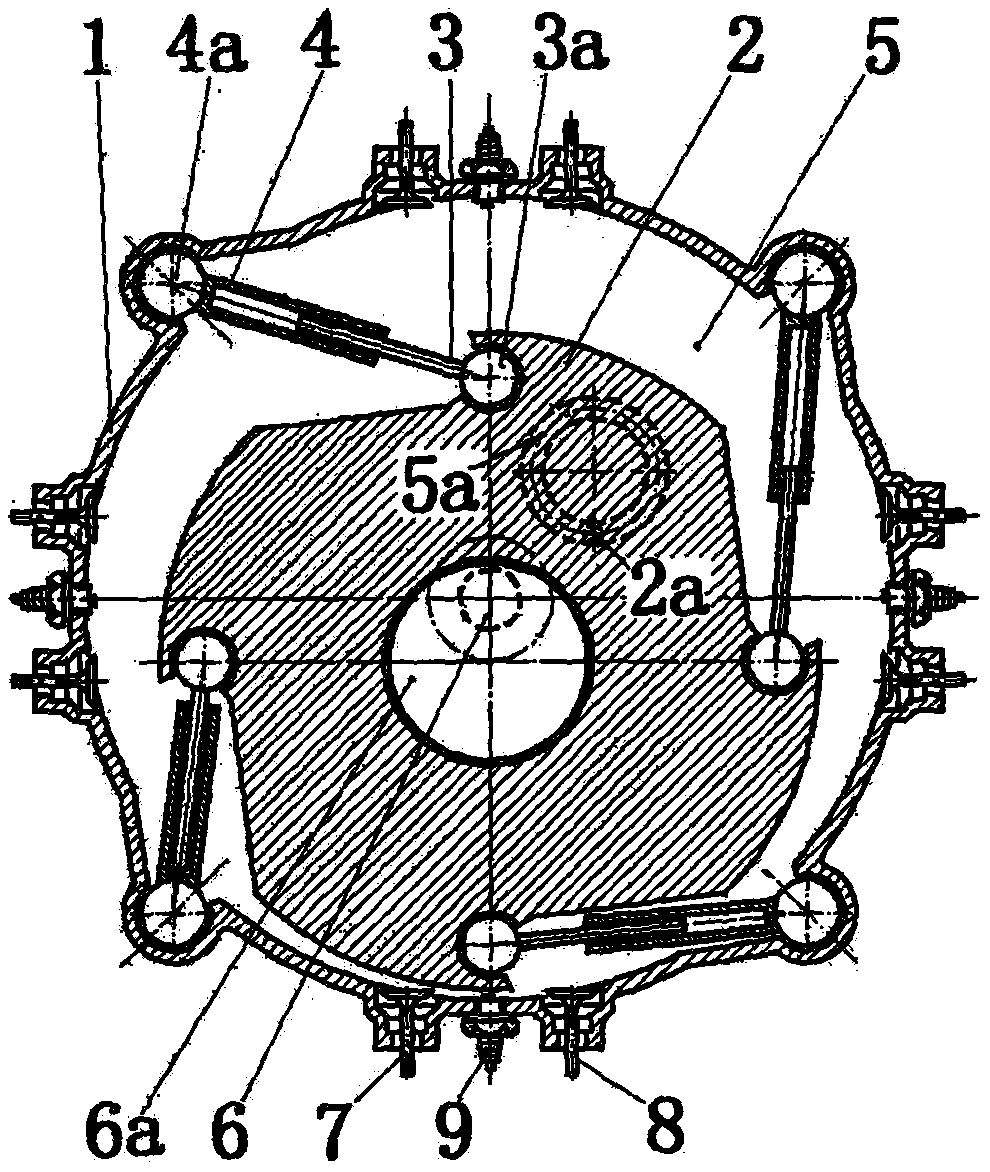

Inserting plate rotor engine

InactiveCN111102069ASimple structureCompact structureInternal combustion piston enginesExhaust valveInlet valve

The invention discloses an inserting plate rotor engine. A spindle (6) is arranged on the axis of a cylindrical case (1) with the two ends closed by end covers (5), a cylindrical rotor (2) is mountedon an eccentric shaft (6a) on the spindle in a sleeving mode, no less than three inserting grooves (4) with inward groove openings are hinged to the inner wall of the case in an even distribution mode, inserting plates (3) matched with the inserting grooves are outwards hinged to the outer wall of the rotor in an even distribution mode, the two ends of the eccentric shaft, the two ends of the rotor, the two ends of the inserting grooves and the two ends of the inserting plates are closely attached to the inner walls of the end covers correspondingly for sliding fit, all the inserting plates are inserted into the corresponding inserting grooves, an interlayer between the rotor and the case is divided into a plurality of closed cavities which are each provided with an intake valve (7), an exhaust valve (8) and a spark plug (9) to serve as engine air cylinders, and the volume of each air cylinder is periodically increased and decreased along with rotation of the spindle to complete the air suction, compression, work and exhaust stroke to drive the spindle to do work. The inserting plate rotor engine is large in power, small in size and simple in structure.

Owner:苗靖文

Projectile base separation mass reduction extended-range projectile

PendingCN111156864AReduce negative qualityLong distanceProjectilesAutomotive engineeringMass reduction

The invention discloses a projectile base separation mass reduction extended-range projectile. The projectile base separation mass reduction extended-range projectile comprises a warhead, a solid engine and a projectile base separation mechanism. The solid engine comprises a solid engine shell, a solid engine cartridge case, a spray tube used for spraying a combustion product and a fixed firing igniter. The solid engine cartridge case is arranged inside the solid engine shell. The projectile base separation mechanism comprises a projectile base, a base bleed shell and a base bleed igniter. According to the projectile base separation mass reduction extended-range projectile, the projectile base separation mechanism is separated from the projectile through fuel gas generated from base bleedpowder charge and solid engine powder charge, and the solid engine continues to propel the remaining effective load to fly; through the projectile base separation mechanism, the negative mass of the projectile in the flying process is effectively reduced, and the projectile flies much farther under the same powder charge condition. Through the projectile base separation design method, the negativemass of the projectile in the flying process is effectively reduced. Moreover, the method is simple and easy to realize. The projectile base separation mass reduction extended-range projectile has the advantages of being safe, reliable and low in using requirement.

Owner:ZHONGBEI UNIV

Locally-inward-convex spinning shell of solid-propellant rocket engine

InactiveCN109736969AReduce negative qualityImprove quality ratioRocket engine plantsMass ratioAerodynamic heating

The invention relates to a locally-inward-convex spinning shell of a solid-propellant rocket engine. The locally-inward-convex spinning shell of the solid-propellant rocket engine comprises a shell body, and an inner convex body is arranged on the inner side surface of the shell body. The shell body is of a tubular structure, the inner convex body penetrates through the shell body in the axial direction of the shell body, the thickness of the inner convex body is larger than the thickness of the shell body, and the inner convex body is connected with the shell body through inclined edges withthe same angles on the two sides. The locally-inward-convex spinning shell of the solid-propellant rocket engine can improve interchangeability and production efficiency of the spinning shell, reduceflight resistance and aerodynamic heating degree of a missile, increase flight speed of the missile, reduce negative quality of the engine and improve the mass ratio of the engine.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Variable thickness housing of solid rocket engine

InactiveCN104696105AGuaranteed structural strengthImprove reliabilityRocket engine plantsVariable thicknessMass ratio

The invention discloses a variable thickness housing of a solid rocket engine, which comprises a spinning cylinder body, a front section and a rear section, wherein the spinning cylinder body is in a variable thickness structure; the front section and the rear section are welded at the front end and the rear end of the spinning cylinder body; missile wing support lugs are welded on the spinning cylinder body; and integral reinforcement with 0.5mm wall thickness is arranged on welding surfaces of the missile wing support lugs. The variable thickness housing of the solid rocket engine ensures the structural strength of the engine during working; the reliability of the engine is improved via partial thickening sections; the integral reinforcement is performed on welding parts of the missile wing support lugs via the thickening sections; external bearing requirements of missile wings on the missile wing support lugs are ensured; the passive mass is reduced; a utilization rate of a raw material is increased; and a mass ratio of the engine is increased.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Preparation method of ablation-resistant anti-scouring ethylene-propylene-diene monomer rubber heat insulating material

The invention relates to a preparation method of an ablation-resistant anti-scouring ethylene-propylene-diene monomer rubber heat insulating material. The preparation method comprises the following steps: S1, adopting an ethylene-propylene-diene monomer rubber material as a matrix material, and adding an ablation-resistant auxiliary material, fibers, a softener, a reinforcing agent, a vulcanizingsystem and other preservatives into the matrix material; S2, carrying out plastication and mixing procedures, and formulating a basic formula meeting mechanical and ablation performance; S3, manufacturing small samples, mechanical test pieces and ablation test pieces, and detecting mechanical and ablation performance; S4, analyzing performance detection data on the basis of detection, and adjusting the proportion of the auxiliary materials; S5, adjusting the formula, and then preparing small samples; S6, preparing mechanical test pieces, ablation test pieces, heat-conducting test pieces and density test pieces, carrying out detection to obtain detection data, and finally detecting a final formula; and S7, preparing a novel material according to the final formula to obtain the heat insulating material. The heat insulating material provided by the invention has the advantages of low density, good anti-scouring and ablation-resistant performance, excellent bonding performance and excellent comprehensive performance.

Owner:陕西逸丰品科航空科技有限公司

Extrusion type oxidizing agent supply solid-liquid mixing engine

ActiveCN114320667AImprove combustion efficiencyReduce negative qualityInternal combustion piston enginesRocket engine plantsCombustion chamberGas cylinder

The invention discloses an extrusion type oxidizing agent supply solid-liquid mixing engine, and belongs to the technical field of aerospace propulsion. Comprising an extrusion gas cylinder, an oxidant storage box, an oxidant conveying pipeline and a combustion chamber, an outlet of the extrusion gas cylinder is communicated with an inlet of the oxidant storage tank through a pressure reducing valve and a flow regulating valve; an outlet of the oxidant storage tank is communicated with an inlet of the combustion chamber through an oxidant conveying pipeline; a multi-branch aluminum pipe inlet of the oxidant conveying pipeline is communicated with an outlet of the oxidant storage tank, a first outlet of the oxidant conveying pipeline is communicated with an inlet of the combustion chamber through a flow regulating valve and a pneumatic valve in sequence, and a second outlet of the oxidant conveying pipeline is communicated with the pneumatic valve through a pressure reducing valve and an electromagnetic valve in sequence; on-off of an oxidizing agent conveying system pipeline and two oxidizing agent filling modes are achieved through remote control; according to the invention, the injector and the spray pipe are fixed on the cabin wall of the combustion chamber by selecting a radial screw connection mode as a fixing mode, so that the combustion efficiency of the solid-liquid mixing engine is improved, and the negative quality caused by a flange plate is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Forming method of high-frequency-vibration-resistant high-pressure gas cylinder wound with support

The invention designs a forming method of a high-frequency vibration resistant high-pressure gas cylinder wound with a support, which is characterized by comprising the following steps: S1, cleaning the surface of a lining, and brushing an adhesive; s2, longitudinally winding, annularly winding and reinforcing the winding layer according to the thickness of the composite layer required by the design, and then pre-curing; s3, bonding of the support is completed; s4, outer reinforcement and winding of the support are completed; and S5, the wound gas cylinder is subjected to final curing. According to the gas cylinder connecting structure, the negative mass of the extrusion type rocket engine high-pressure gas cylinder is reduced, and the reliability of the gas cylinder connecting structure is improved; the winding core mold is simple in principle, easy to process, detachable and low in cost; and the prepared composite material has the advantages of high reliability, good loading capacity and the like.

Owner:湖北三江航天江北机械工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com