Base made of composite materials and manufacturing method thereof

A technology of composite materials and bases, which is applied in the direction of antenna supports/installation devices, etc., can solve the problems of satellite antennas such as low reliability, low axial stiffness, and poor thermal stability, and achieve excellent dimensional stability and axial stiffness High, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

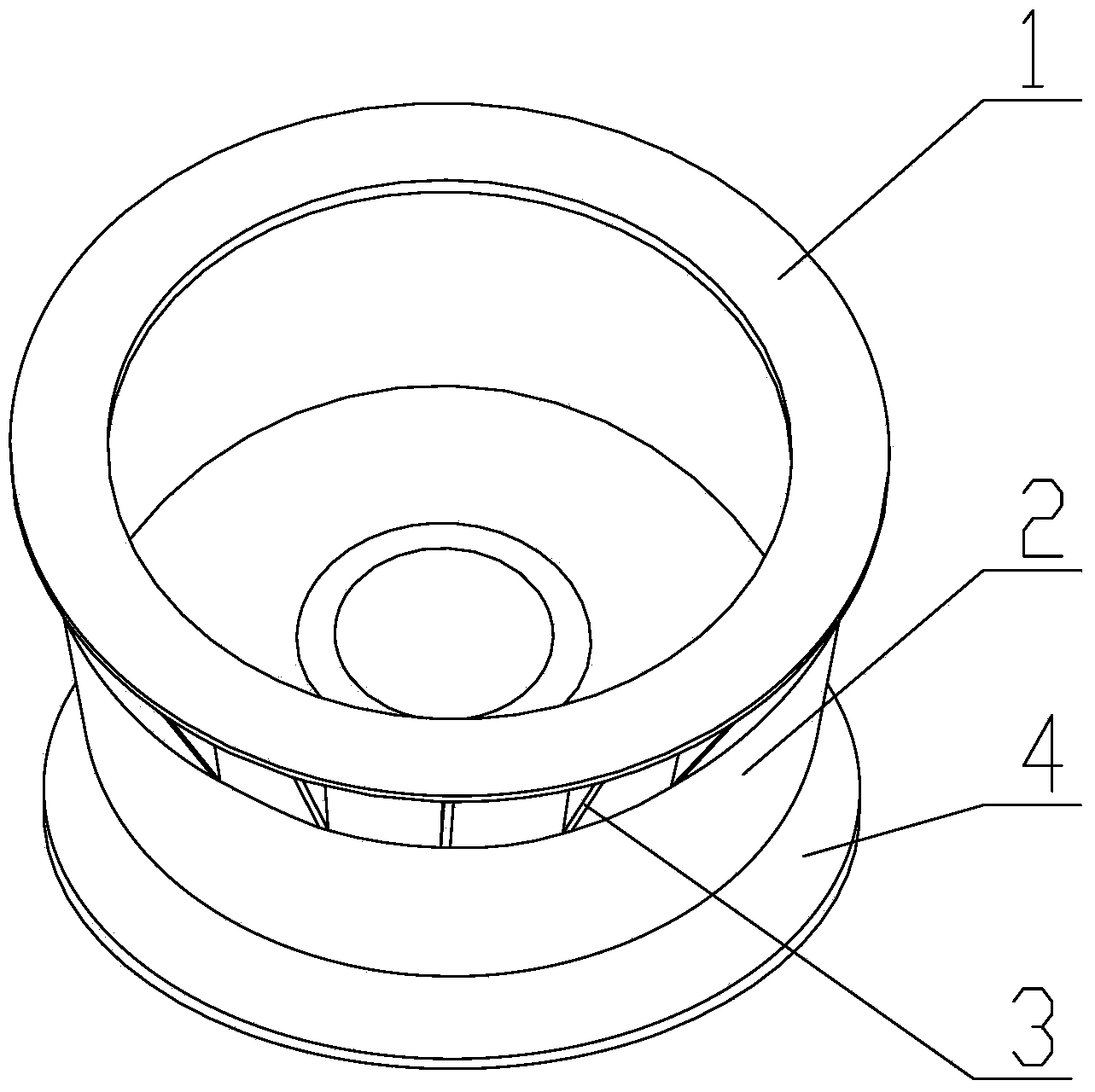

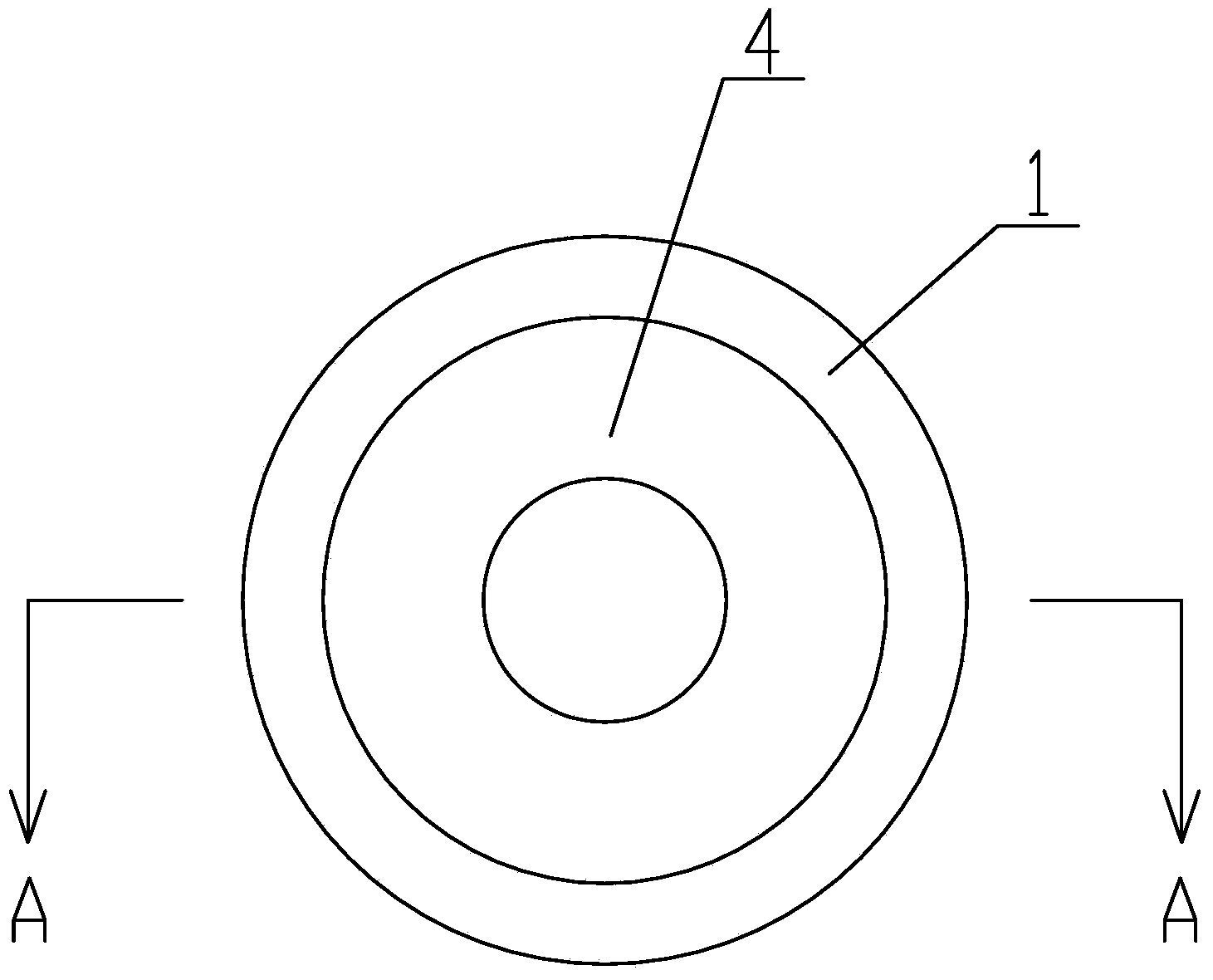

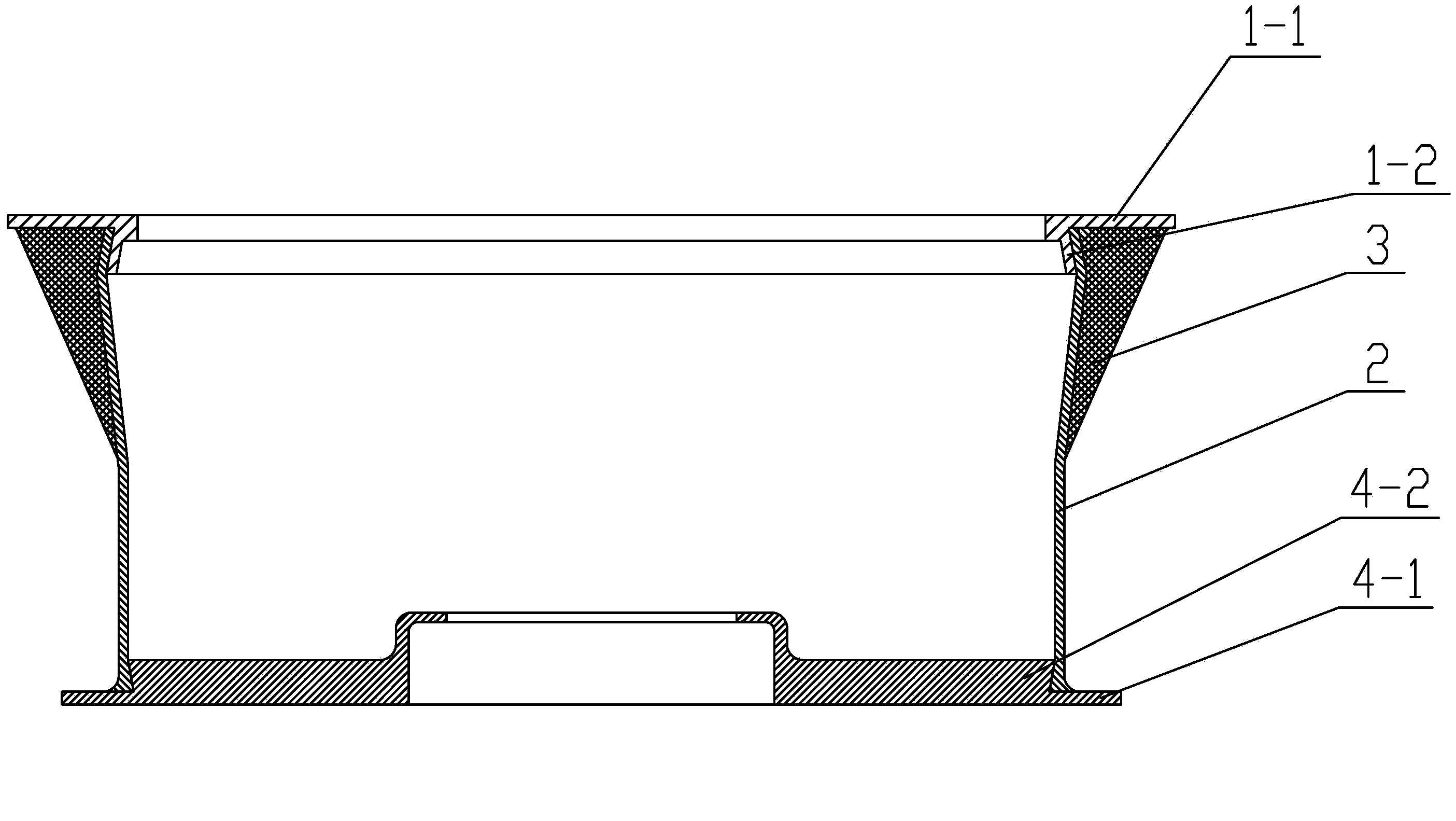

[0035] like figure 1 , figure 2 and image 3 As shown, the composite material base of this embodiment includes an upper end cover 1 and a lower end cover 4, and the upper end cover 1 includes a circular upper end cover body 1-1 and an upper and lower lower end cover body 1-1 arranged below the upper end cover body 1-1. A large first cone 1-2, the lower end cap includes a lower end cap body 4-1 and a second cone 4-2 with a large top and a small bottom arranged above the lower end cap body, the upper end cap body 1-1 Integral structure with the first cone 1-2, the lower end cover body 4-1 and the second cone 4-2 integral structure, the cylinder 2 is arranged between the upper end cover 1 and the lower end cover 4 , the upper inner wall of the cylinder 2 is closely matched with the outer wall of the first cone 1-2, the lower inner wall of the cylinder 2 is closely matched with the outer wall of the second cone 4-2, and the upper end cover 1 is below and A reinforcing rib 3 is...

Embodiment 2

[0050] like figure 1 , figure 2 and image 3 As shown, the structure of the composite base of this embodiment is the same as that of Embodiment 1, and the difference lies in: the angle between the conical surface of the first cone 1-2 and the vertical direction and the angle between the second cone 4 The included angle between the conical surface of -2 and the vertical direction is 2 degrees; the number of the reinforcing ribs 3 is 16.

[0051] This embodiment requires the preparation of a base with the following dimensions: the outer diameter of the upper end cover body 1-1 is 300mm, the inner diameter is 200mm, the outer diameter of the lower end surface of the first cone 1-2 is 250mm, and the inner diameter is 220mm, and the upper end cover 1 The height is 15mm, the outer diameter of the lower end cover body 4-1 is 280mm, the outer diameter of the upper end surface of the second cone 4-2 is 240mm, the overall height of the lower end cover 4 is 10mm, the thickness of the ...

Embodiment 3

[0061] like figure 1 , figure 2 and image 3 As shown, the structure of the composite base of this embodiment is the same as that of Embodiment 1, and the difference lies in: the angle between the conical surface of the first cone 1-2 and the vertical direction and the angle between the second cone 4 The included angle between the conical surface of -2 and the vertical direction is 10 degrees; the number of reinforcing ribs 3 is 10.

[0062] This embodiment requires the preparation of a base with the following dimensions: the outer diameter of the upper end cover body 1-1 is 400mm, the inner diameter is 300mm, the outer diameter of the lower end surface of the first cone 1-2 is 350mm, and the inner diameter is 320mm, and the upper end cover 1 The height is 20mm, the outer diameter of the lower end cover body 4-1 is 380mm, the outer diameter of the upper end surface of the second cone 4-2 is 340mm, the overall height of the lower end cover 4 is 15mm, the thickness of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com