Patents

Literature

31results about How to "Ensure efficient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

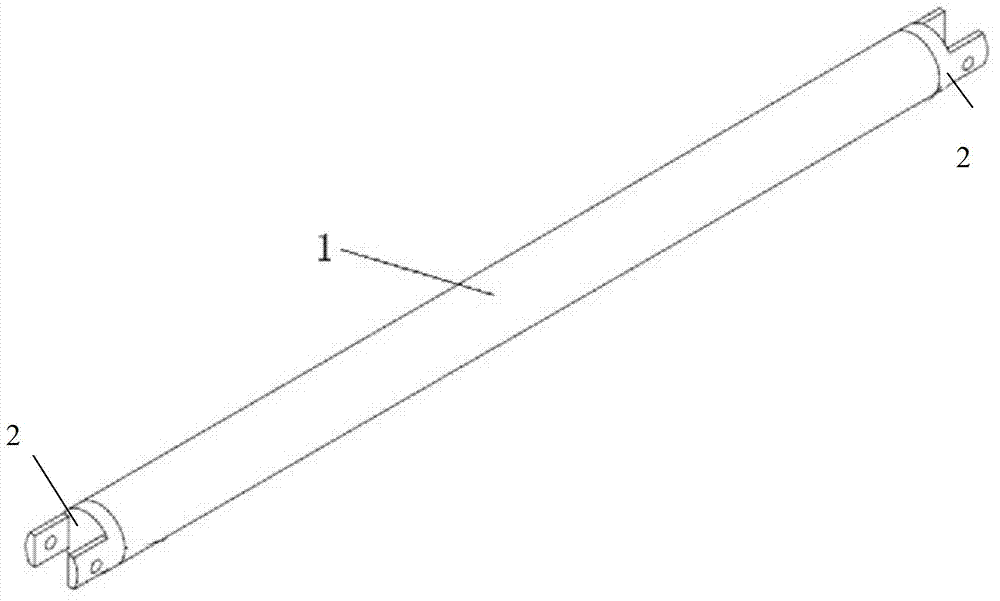

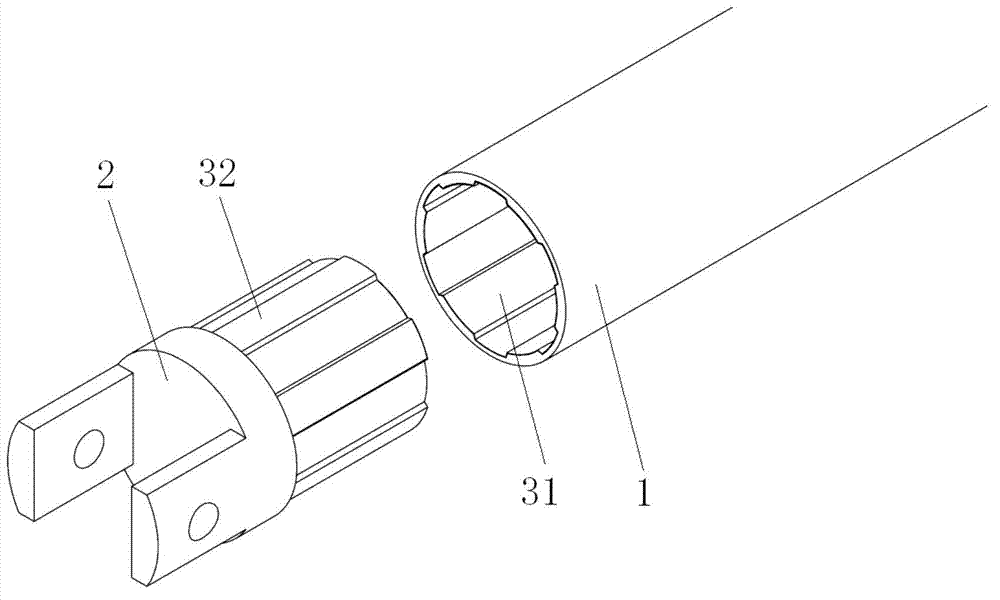

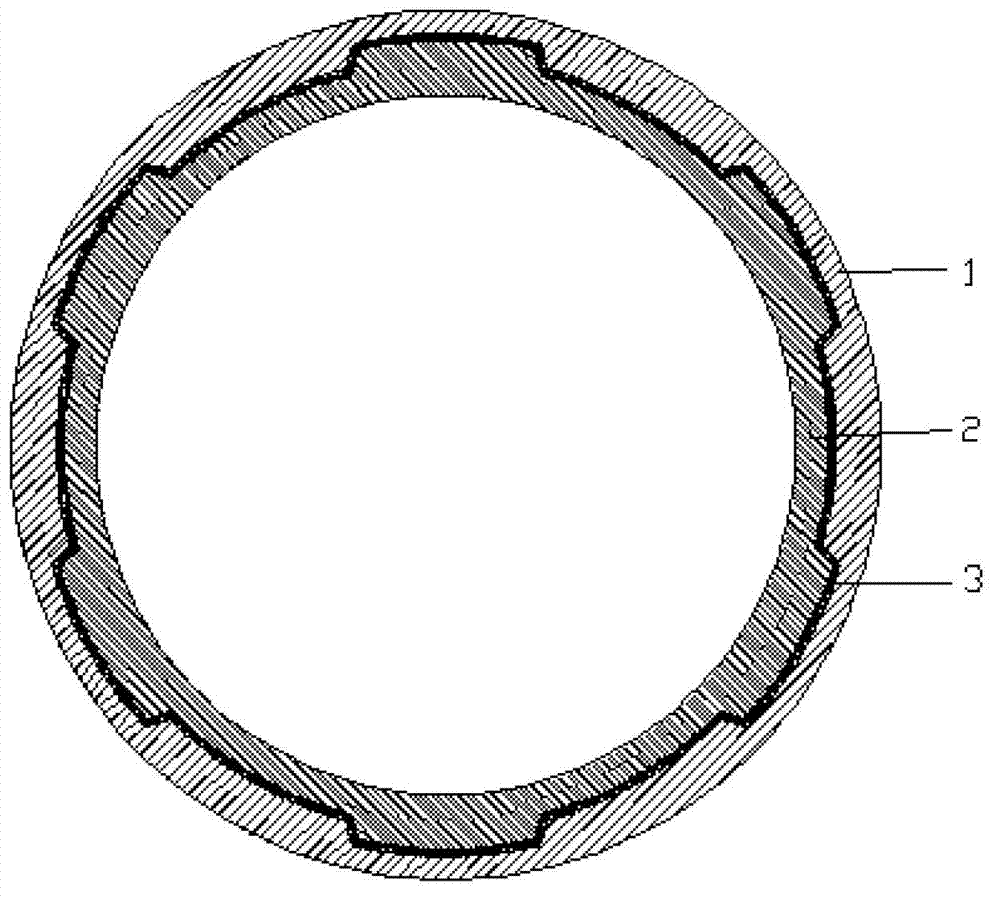

Composite-material automobile transmission shaft formed by pulling, squeezing and winding and preparation method thereof

ActiveCN102815210AEnsure efficient productionEnsure the consistency of finished product qualityControl devicesEngineeringMetal

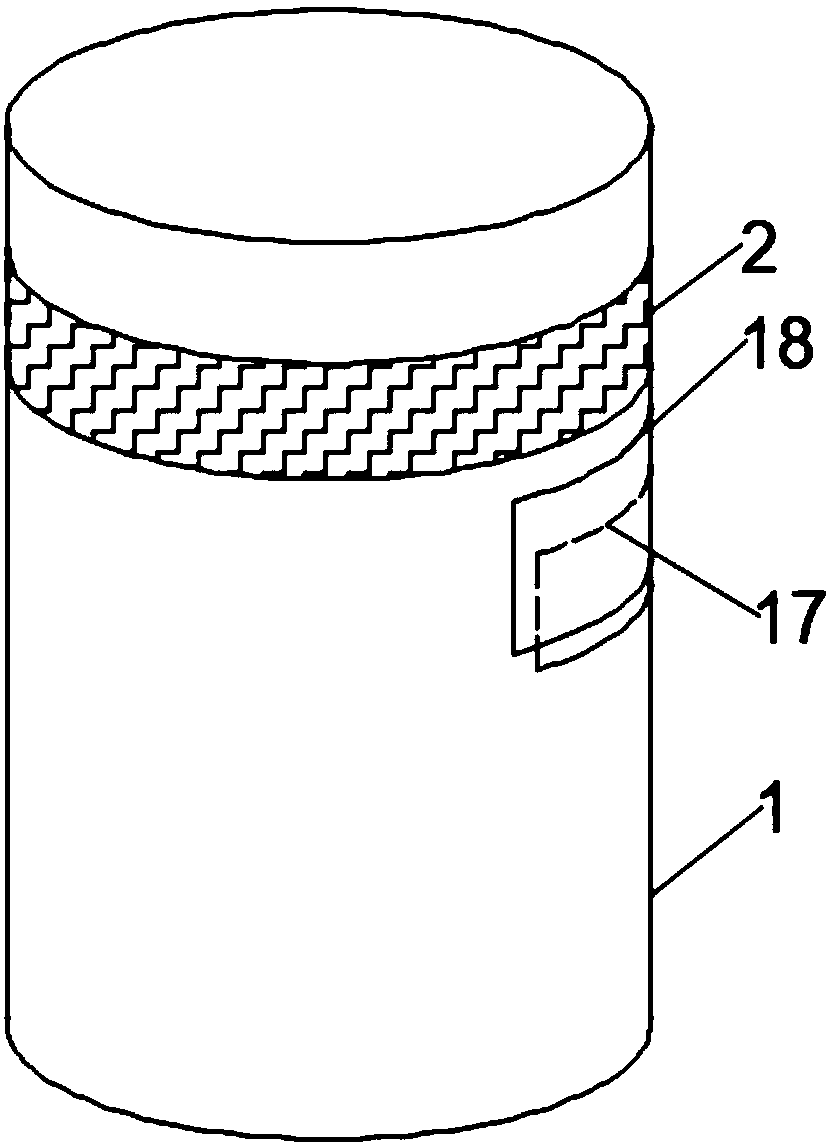

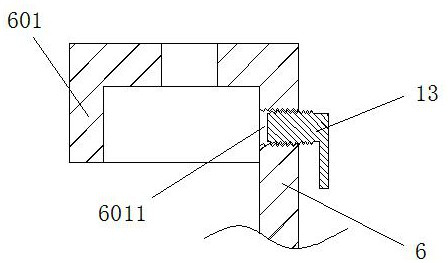

The invention belongs to the field of a composite material, and relates to a composite-material automobile transmission shaft formed by pulling, squeezing and winding and a preparation method thereof. The composite-material automobile transmission shaft comprises a shaft pipe (1), metal connection pieces (2) and a glue layer (3), wherein the shaft pipe (1) sequentially comprises a pipe body (4), a lug boss (5) and a fabric reinforcing layer (6) from outside to inside; and the both ends of the shaft pipe (1) are connected with the metal connection pieces (2) through the glue layer (3) and the lug boss (5) in a spline connection and glued connection combined manner. The reasonable composite-material automobile transmission shaft is implemented according to a pulling, squeezing and winding process, the lug boss made of a composite material formed by pulling and squeezing is arranged on the inner side of the automobile transmission shaft along the axial direction of the entire shaft pipe, and at the connection part, the shaft pipe and each metal connection piece are connected with each other in the spline connection and glued connection combined manner, so that the connection strength is enhanced, and the automobile transmission shaft can be reliable for a long time.

Owner:上海鹏霄复合材料科技有限公司

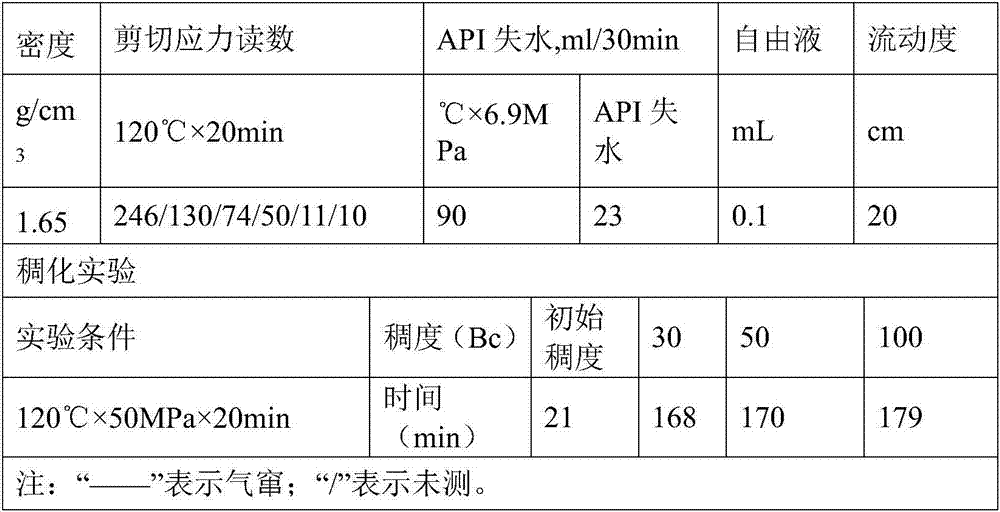

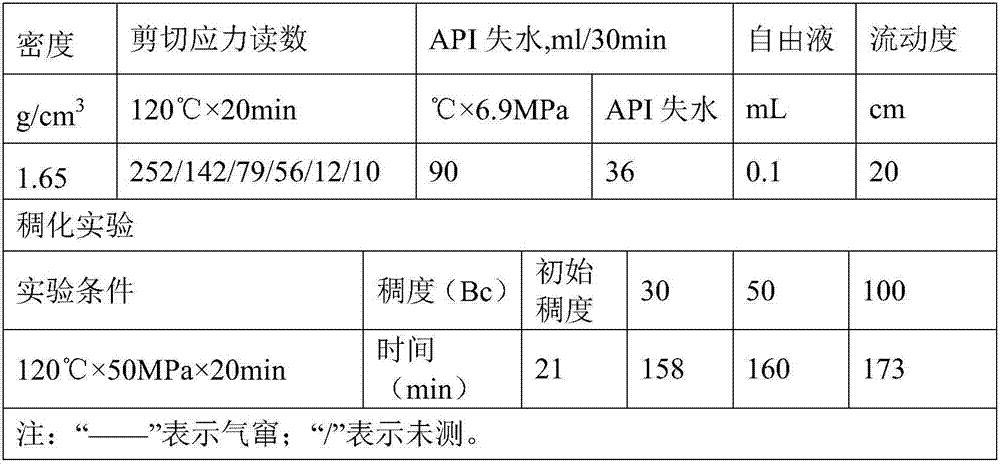

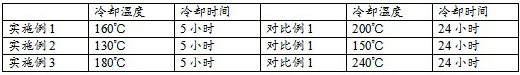

High-temperature magnesium oxychloride thermosetting resin gel system as well as solidified body and preparation method of system

InactiveCN107954680AImprove heat resistanceImprove impact resistanceDrilling compositionCarboxylic acidOrganic polymer

The invention relates to the field of oil and gas well cementing, and relates to a high-temperature magnesium oxychloride thermosetting resin gel system as well as a solidified body and preparation method of the system. The high-temperature magnesium oxychloride thermosetting resin gel system comprises an epoxy resin emulsion, an epoxy resin curing agent, a magnesium oxychloride skeleton materialand a high-temperature adjustable solidification agent, wherein the epoxy resin emulsion is at least one selected from the group consisting of glycidyl ether type epoxy resin, glycidyl ester type epoxy resin, cycloaliphatic type epoxy resin, glycidyl amine type epoxy resin, and linear aliphatic type epoxy resin; and the epoxy resin curing agent is at least one selected from the group consisting ofan anhydride, a carboxylic acid, an amine compound, a phenol compound, and a polyhydric alcohol. The high-temperature magnesium oxychloride thermosetting resin gel system provided by the invention can be cross-linked and cured to form an organic polymer material with a three-dimensional net-shaped structure under the conditions of heating, pressing and the like, and realizes annulus long-term sealing performance of cementing cement in the high-temperature environment of 90-120 DEG C relying on the advantages of excellent heat resistance, good compressive strength and toughness, excellent adhesion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

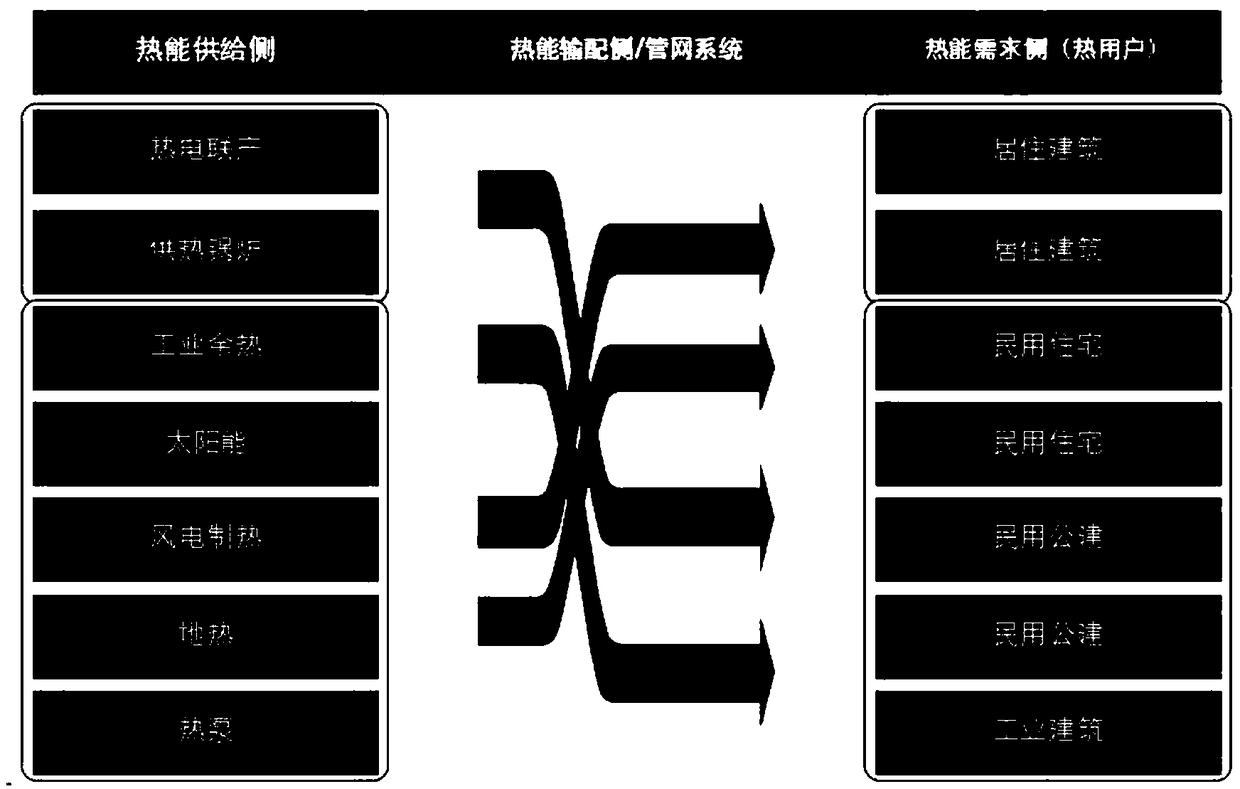

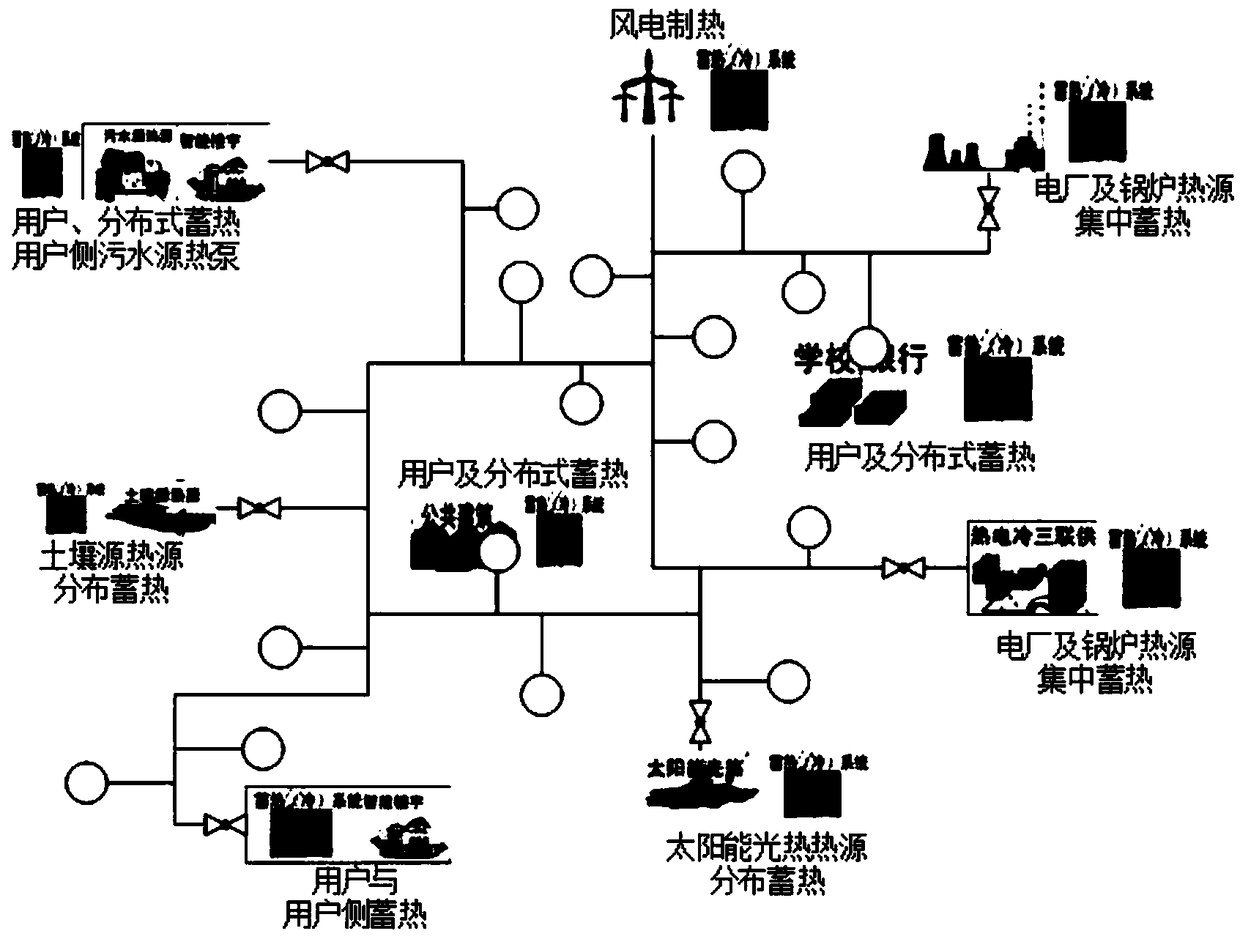

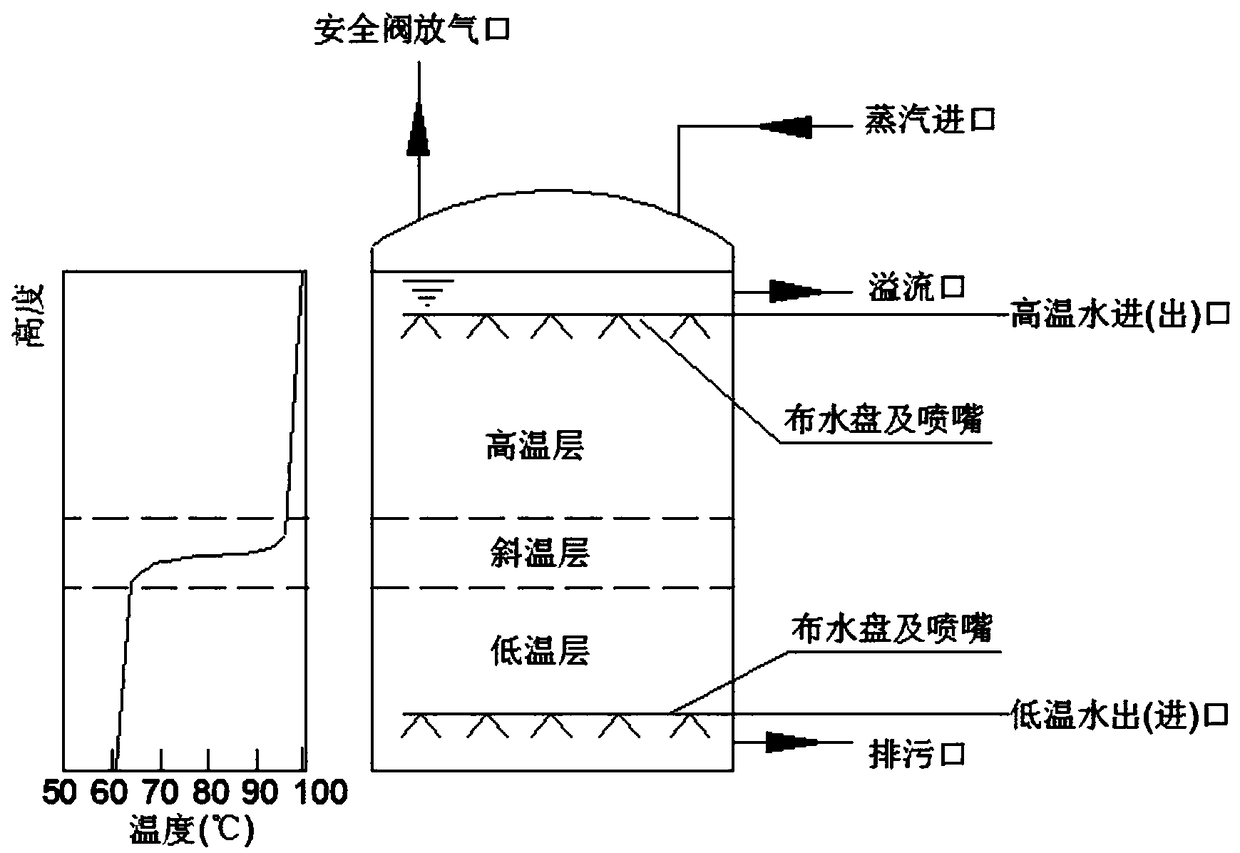

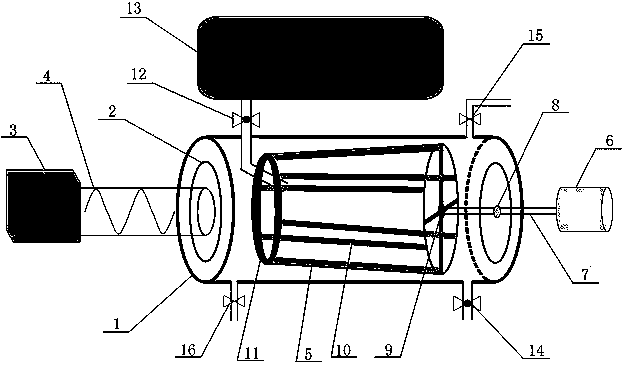

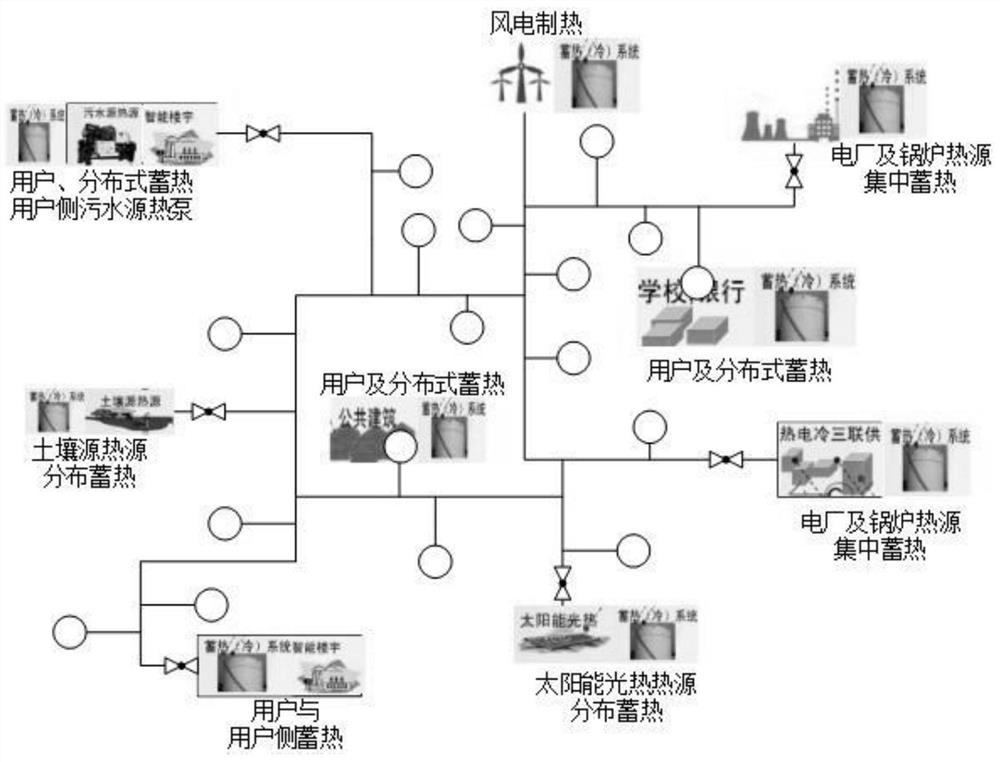

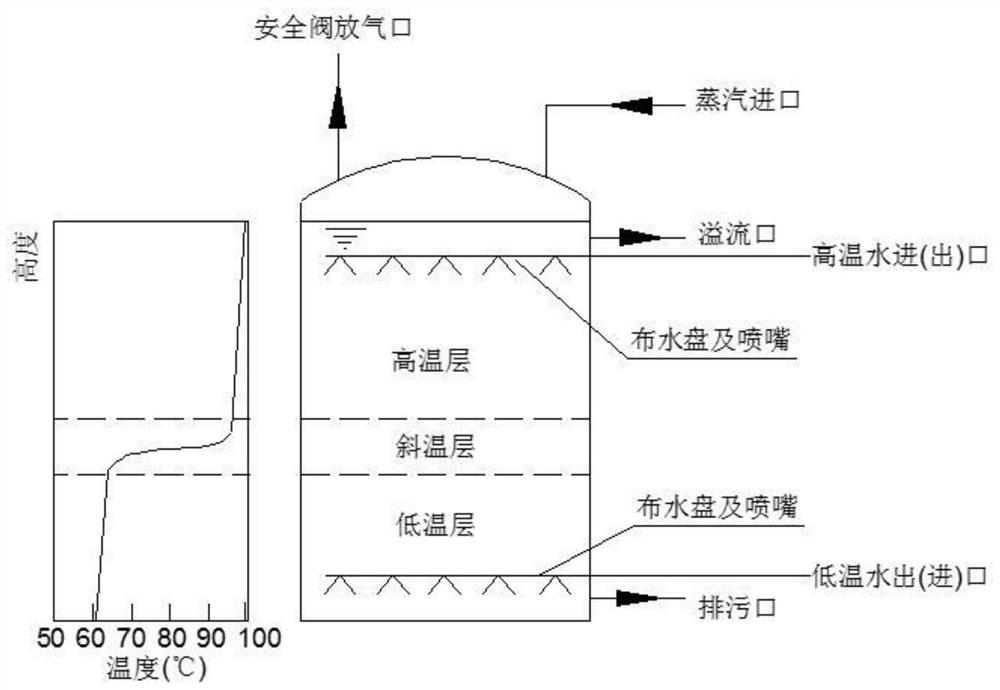

Whole network distributed heat storage and supply system and method

ActiveCN108895514AMeet peak shaving needsSolve balance problemsCentral heating with accumulated heatLighting and heating apparatusControl systemEngineering

The invention relates to a whole network distributed heat storage and supply system and method and belongs to the field of heat storage and supply systems. The whole network distributed heat storage and supply system is characterized by comprising a heat supply system, a heat storage system, a control system and a management and control platform, wherein the heat supply system is connected to theheat storage system, and the control system is separately connected to the heat supply system, the heat storage system and the management and control platform; the heat storage system includes a heatstorage tank, an electric shut-off valve, an electric regulating valve and a circulating water pump, wherein a cold water end and hot water end of the heat storage tank are separately connected to theheat supply system through the electric shut-off valve, the electric regulating valve and a circulating water pump. The whole network distributed heat storage and supply system and method have the advantages that novel heating systems of heat storage devices are installed on positions such as users' houses, heat exchange stations, pipe networks, renewable energy source areas, thermal power plantsand regional boiler rooms, and through the mode of combining user sides, pipe network sides and heat source sides for heat storage, not only are the needs of heat sources for peak shaving met, but also the advantages of being narrow in adjustment range, closer to the users, higher in flexibility and the like are achieved.

Owner:大连海心信息工程有限公司

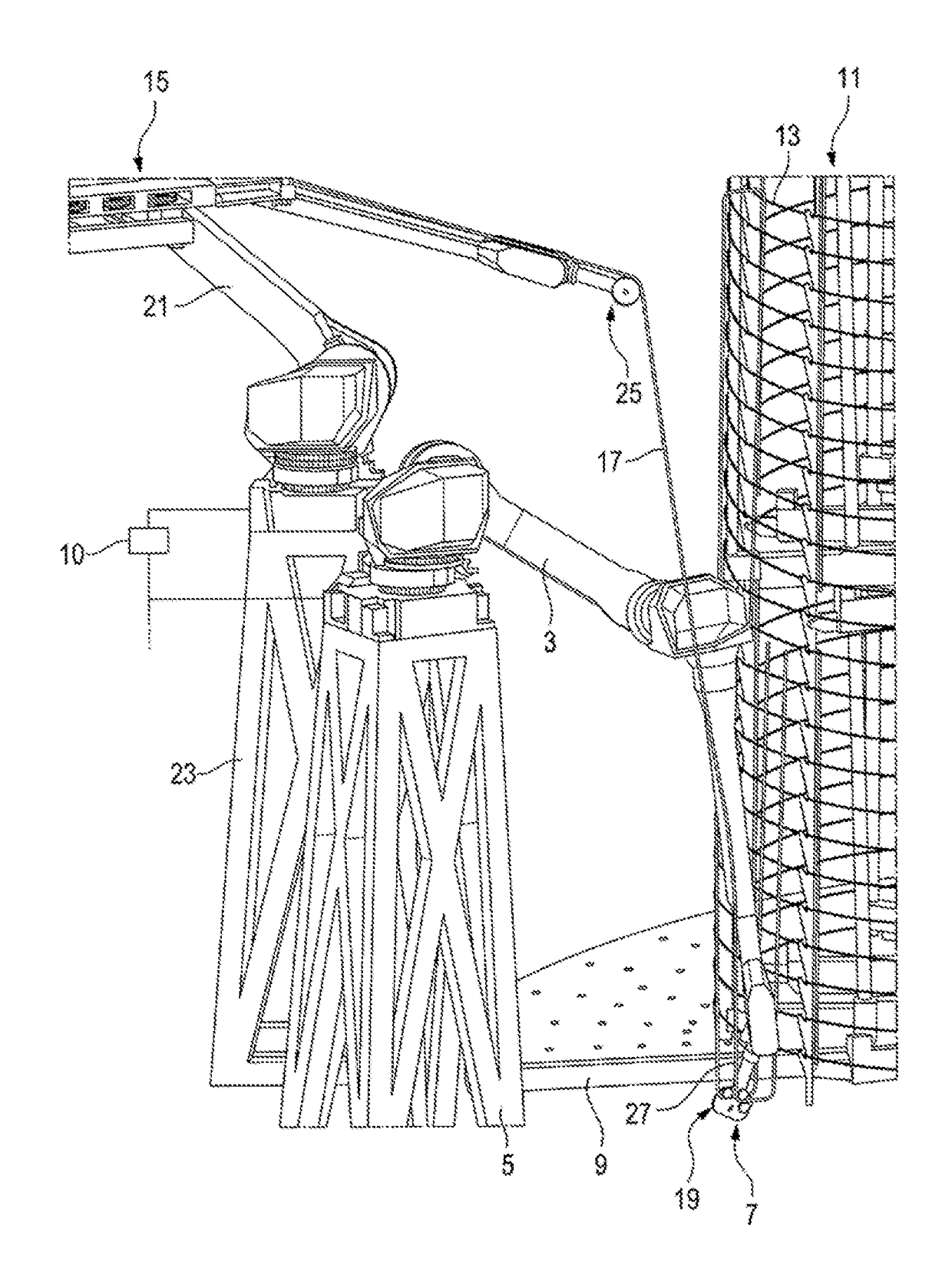

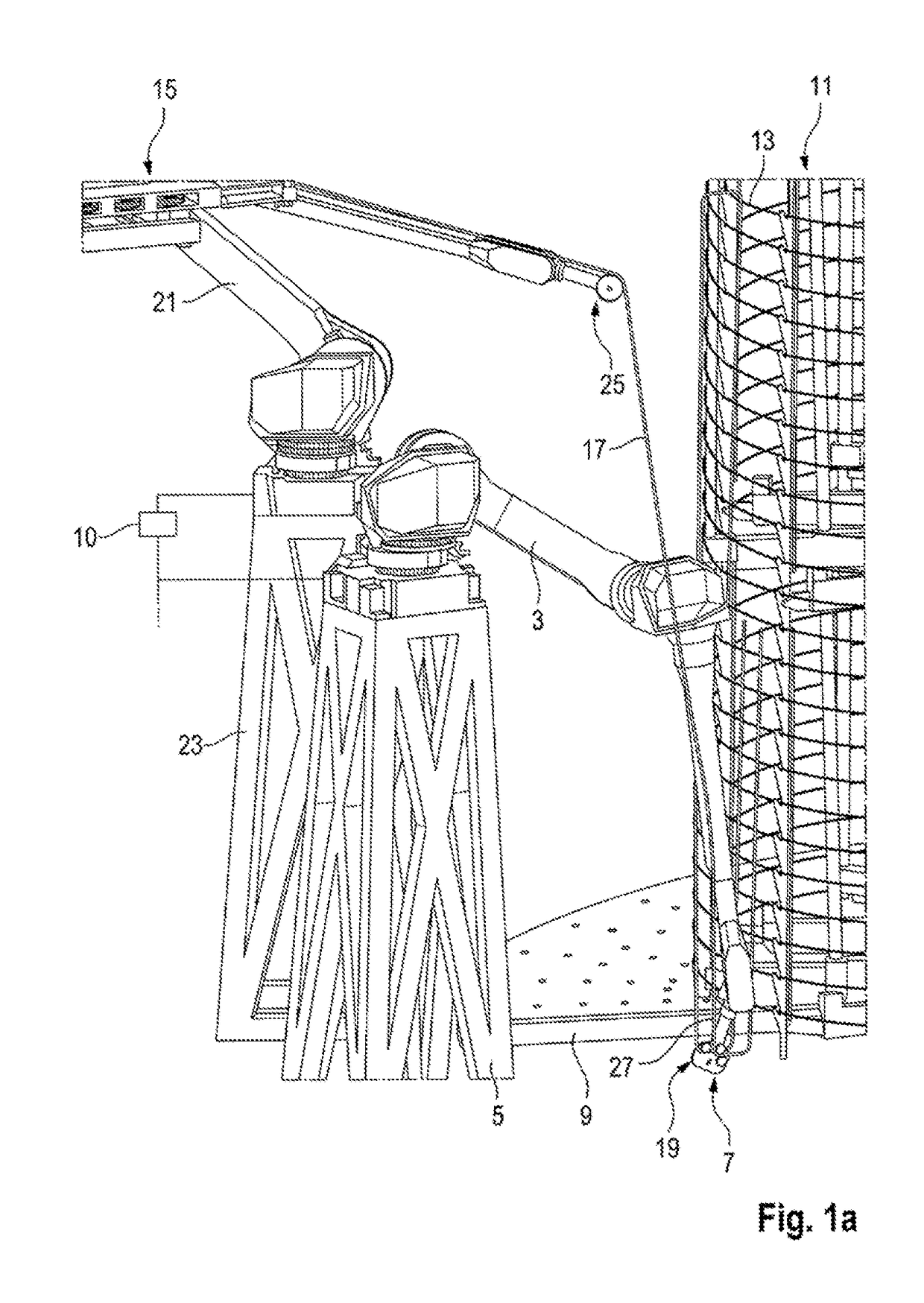

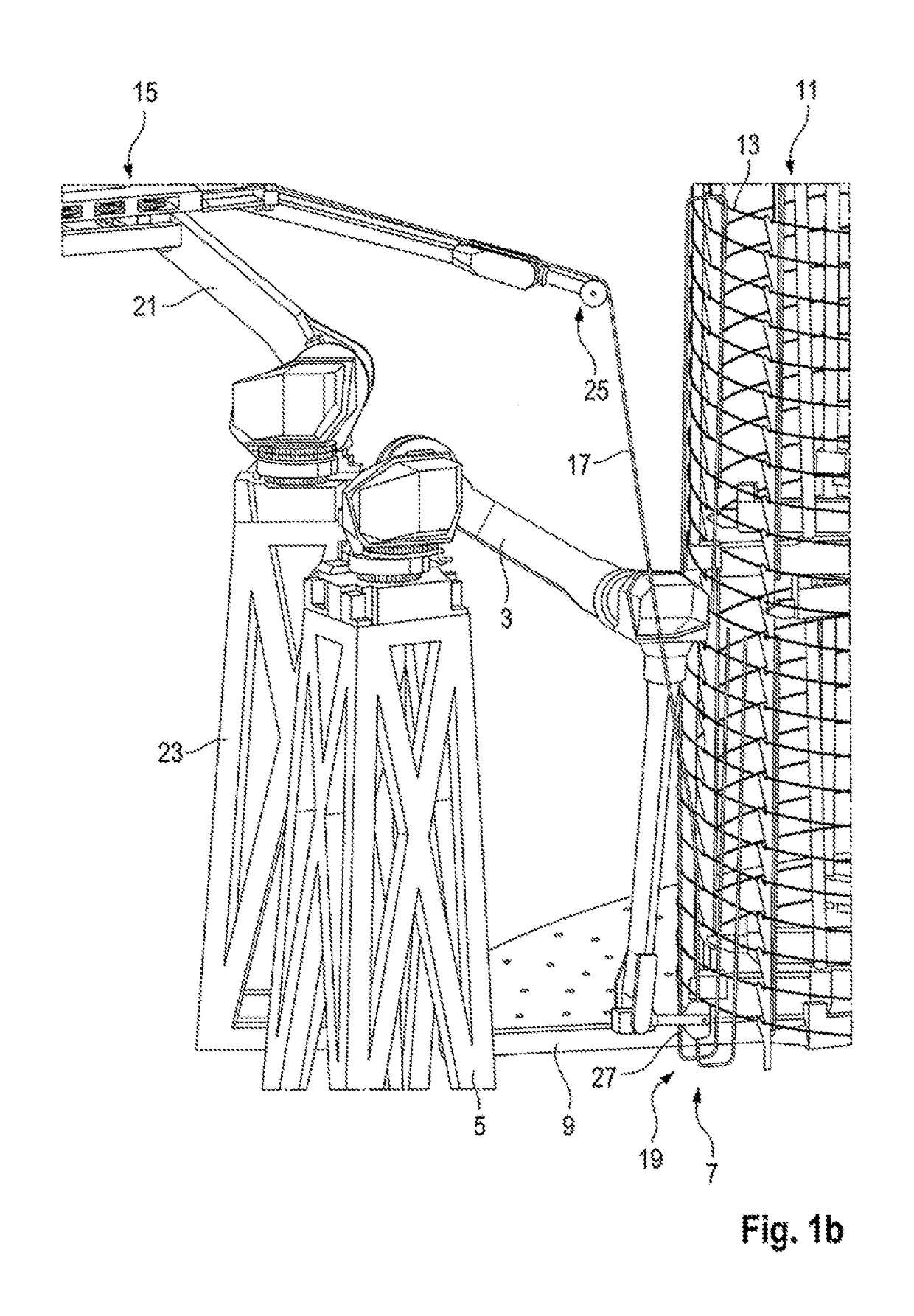

Installation for producing reinforcement cages for tower segments of wind turbines

InactiveUS10094114B2Increase productivityEnsure efficient productionProgramme-controlled manipulatorEngine manufactureEngineeringTower

A system for producing reinforcing cages for wind turbine tower segments, wherein a reinforcing cage has in each case substantially horizontally oriented ring segments and substantially vertically oriented stiffening elements. It is proposed that the system has a receiving area which is adapted so as to receive the preferably inner, substantially horizontally oriented ring segments of the reinforcing cage, a first handling robot for supplying and positioning the stiffening elements, and a second handling robot for connecting the ring elements to the stiffening elements.

Owner:WOBBEN PROPERTIES GMBH

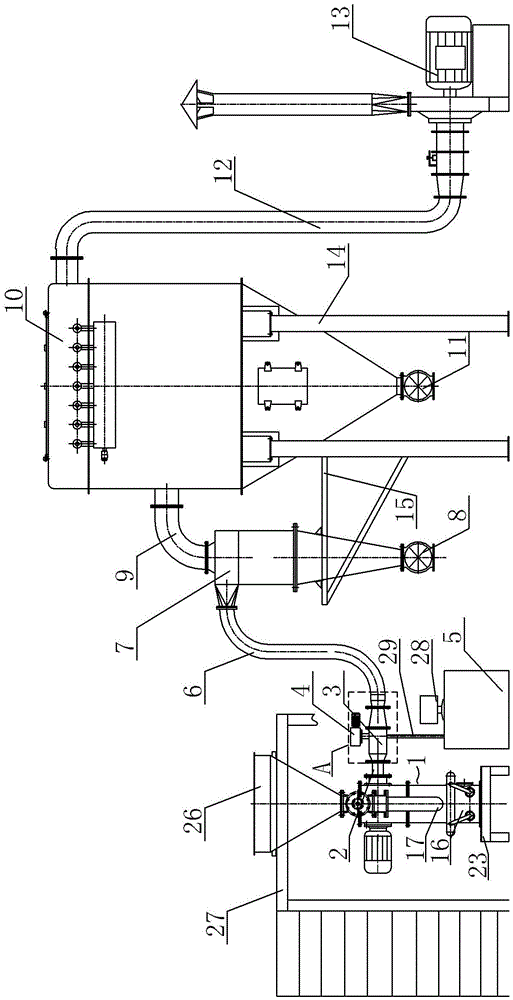

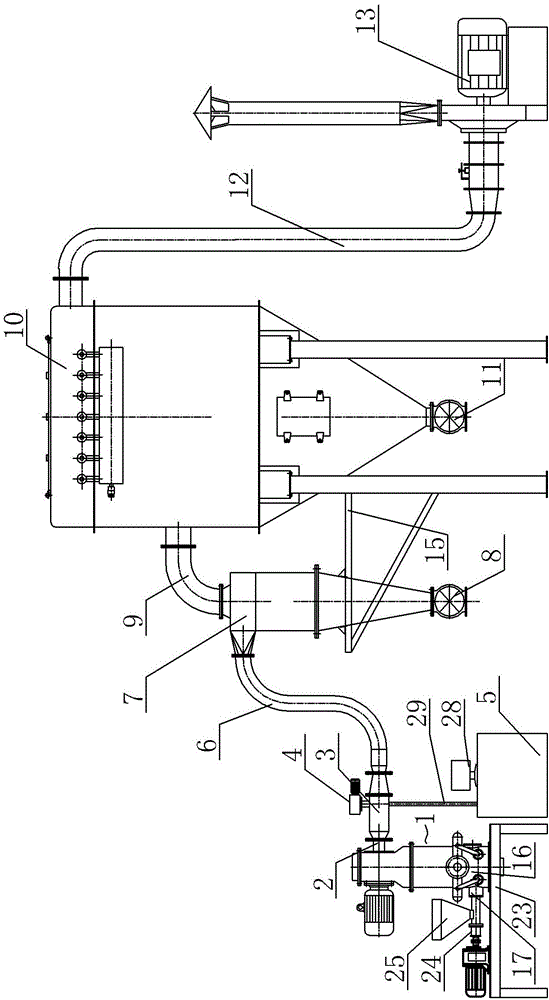

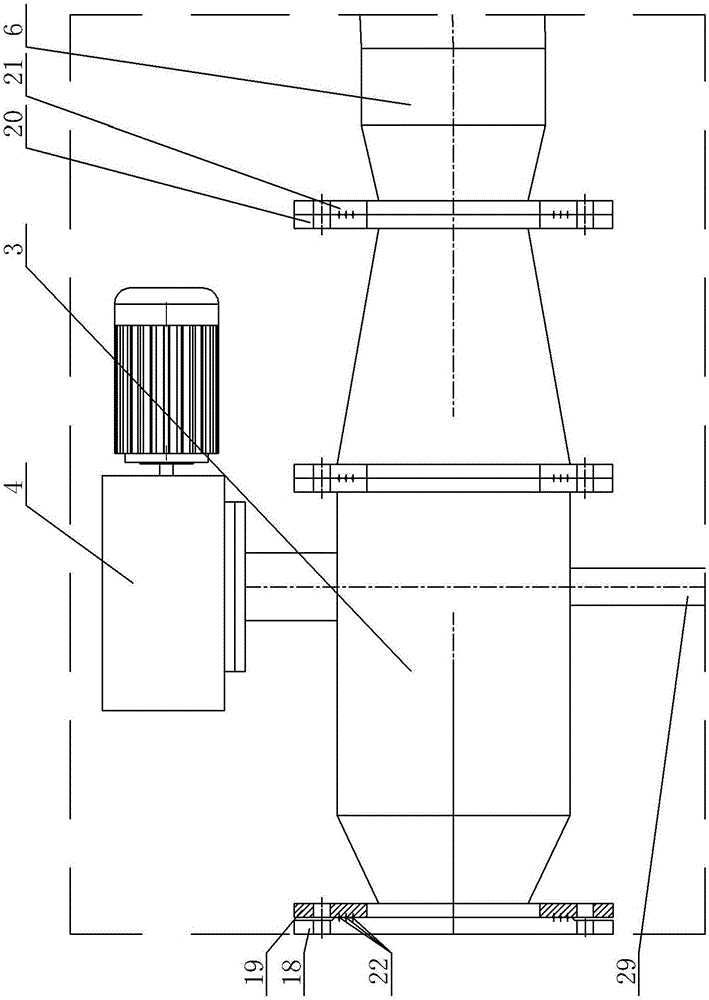

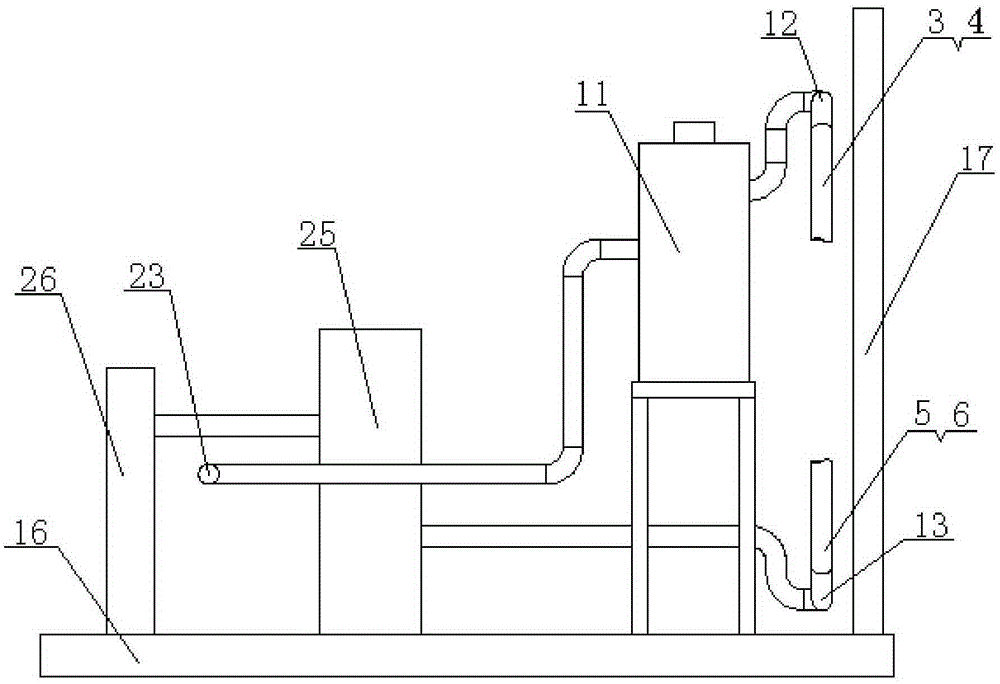

Online detection ultrafine pulverizing production line

InactiveCN106179669AEnsure efficient productionEasy to adjustInvestigating moving fluids/granular solidsGrain treatmentsProduction lineEngineering

The invention provides an online detection ultrafine pulverizing production line. The production line can obtain the situation of particles generated by an airflow pulverizer in real time, rapid adjustment is conducted, and high-efficiency production of the production line is ensured. The online detection ultrafine pulverizing production line comprises the airflow pulverizer. A discharging port of the airflow pulverizer is connected with an inlet of a detection cavity. An online sampler is arranged on the outer ring face of the detection cavity. The detection cavity is provided with a passage communicating with an inlet of the online sampler. An outlet of the online sampler is connected with a laser detector. An imaging display part is arranged on the output part of the laser detector. An outlet of the detection cavity is directly and externally connected with an inlet of a material output pipeline. An outlet of the material output pipeline is connected with an inlet of a cyclone separator. A first discharging valve is arranged at a material outlet of the cyclone separator. An airflow outlet of the cyclone separator is connected with an inlet of a dust remover through a connecting pipeline. A second discharging valve is arranged at a material outlet of the dust remover. An airflow outlet of the dust remover is connected into an induced air inlet of a high-pressure induced draft fan through a guide pipeline.

Owner:KUNSHAN MIYOU EQUIP MFG

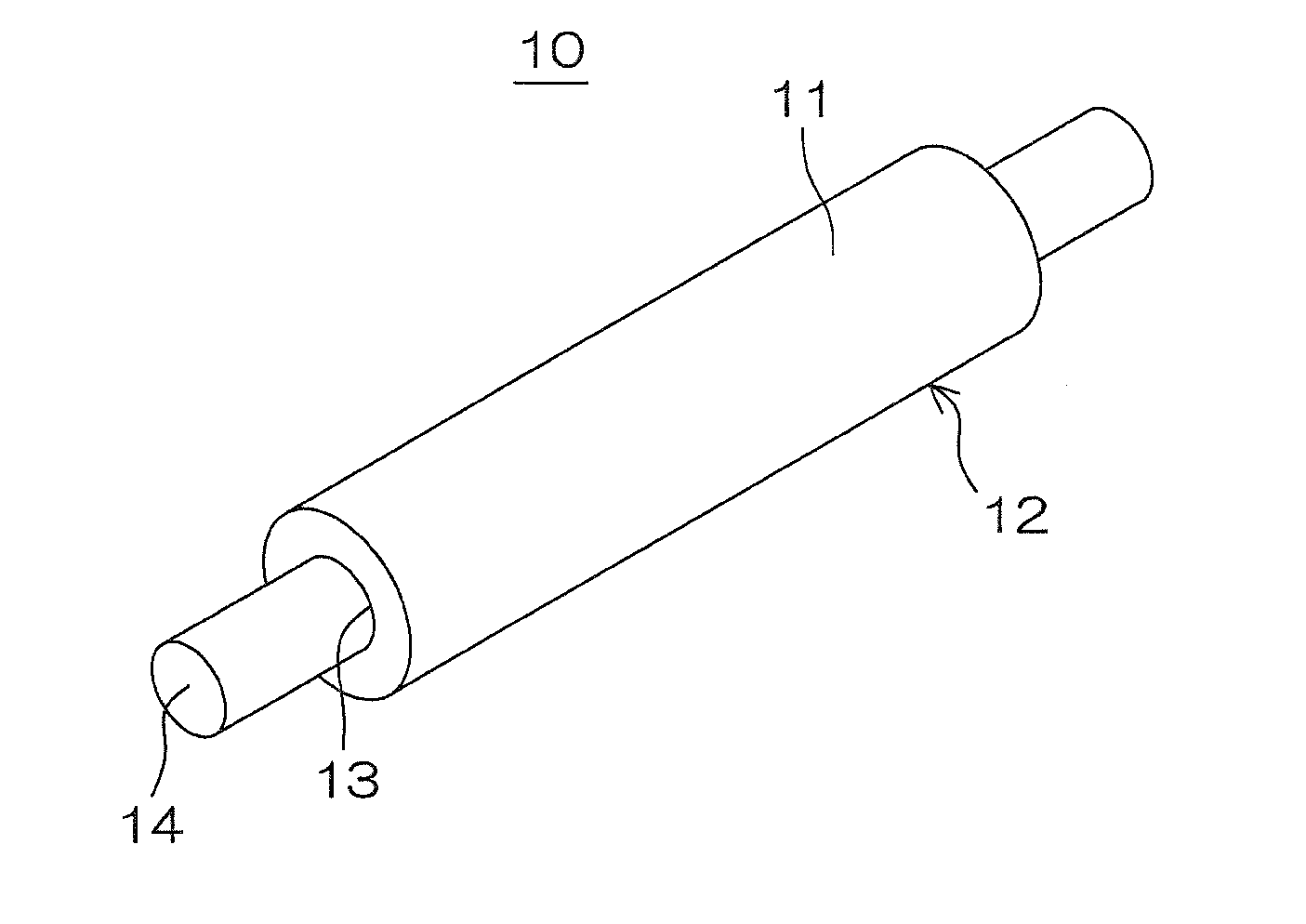

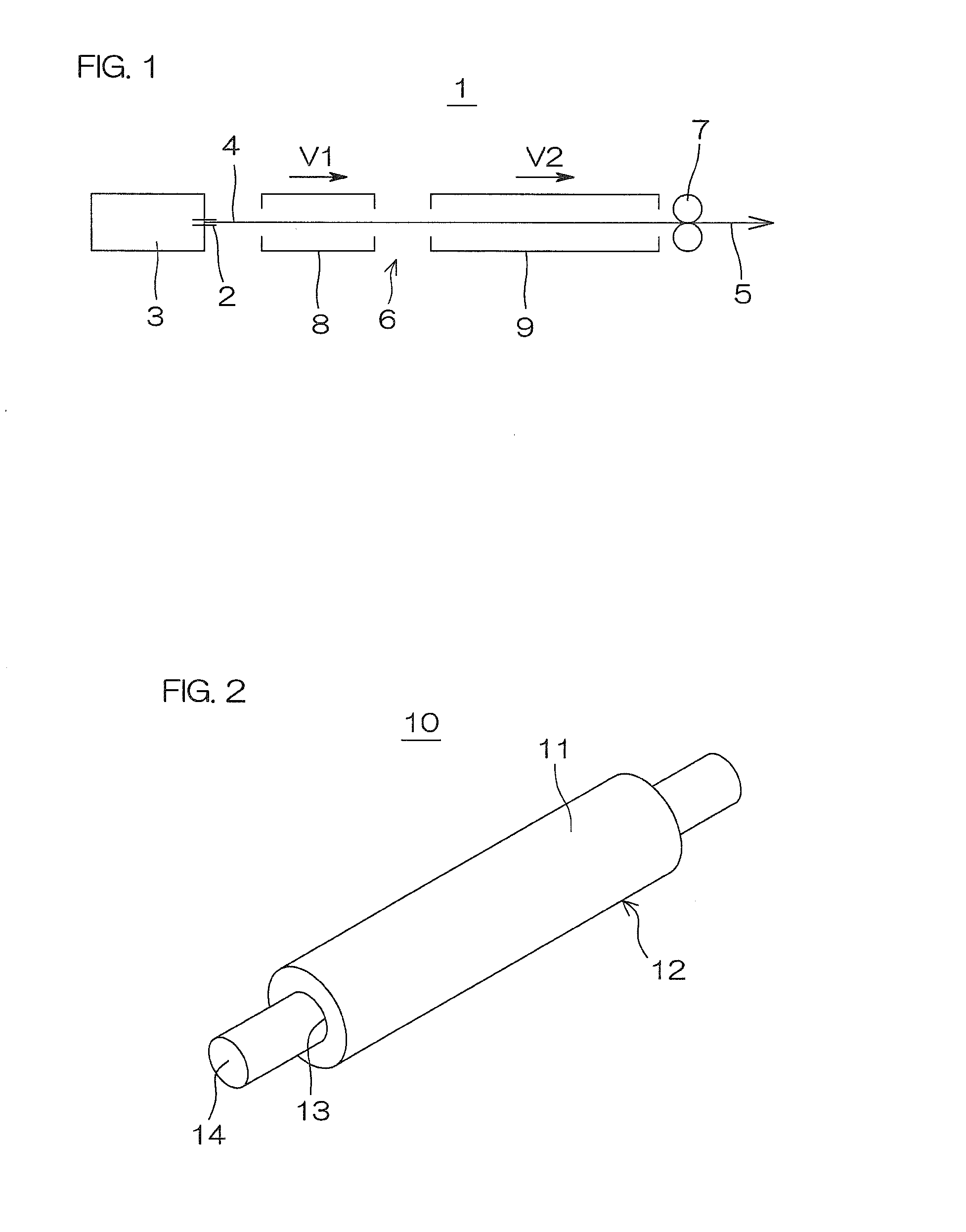

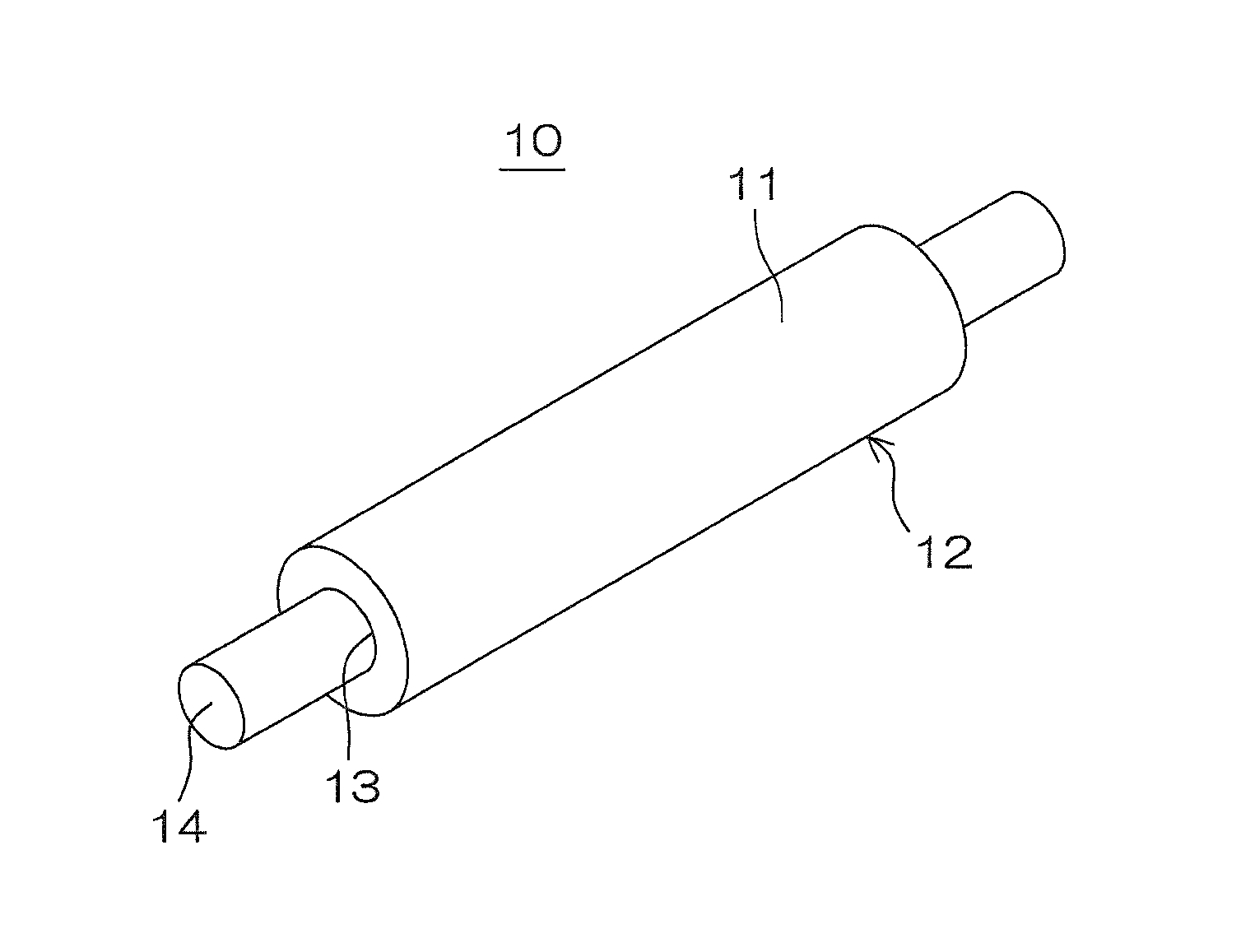

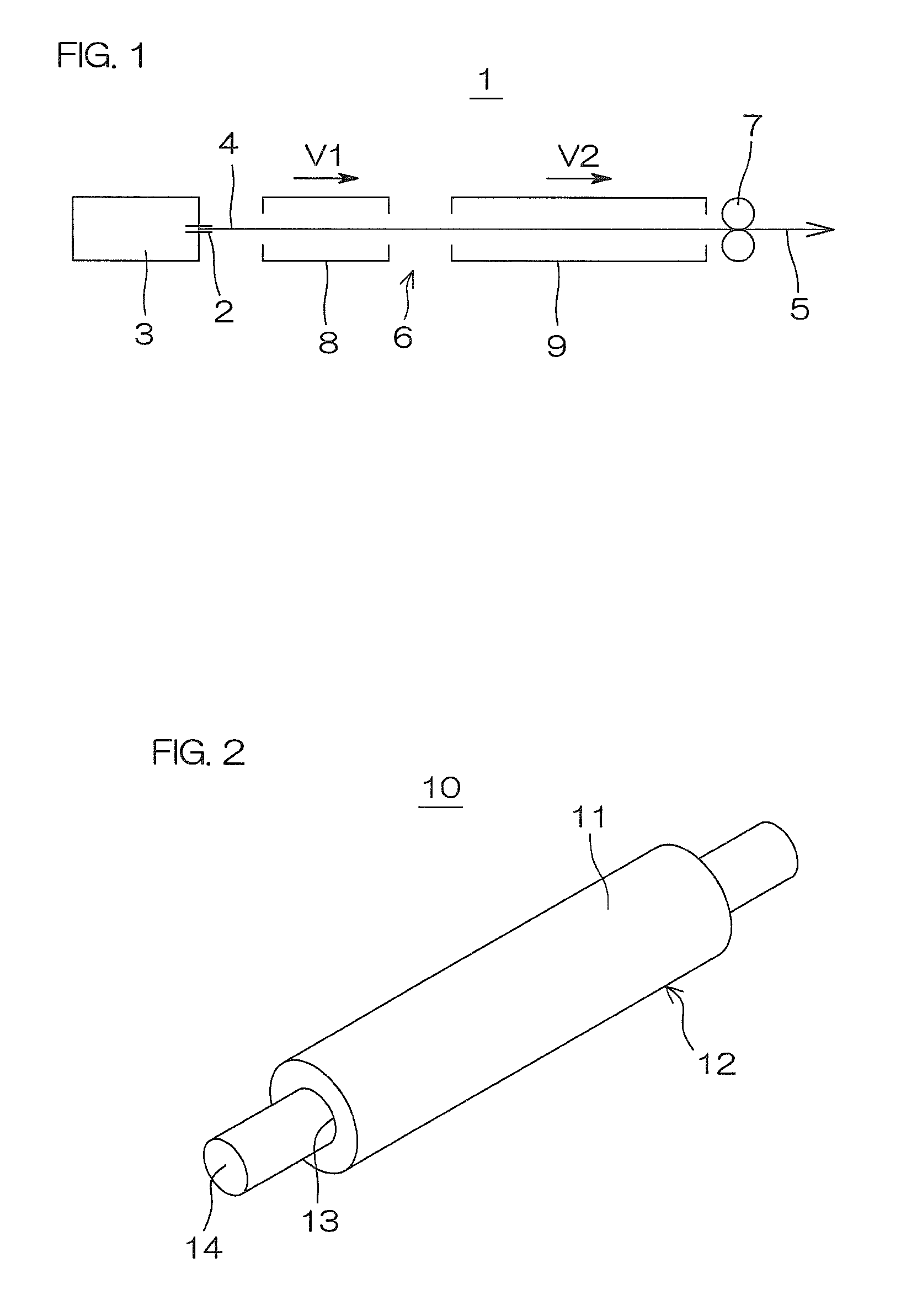

Rubber foam tube production method, electrically conductive roller, and image forming apparatus

InactiveUS20140162861A1Improve production yieldEnsure efficient productionLiquid surface applicatorsElectrographic process apparatusMicrowaveEngineering

A rubber foam tube (5) is produced by extruding a rubber composition into a tubular body (4) and feeding the tubular body (4) in an elongated state without cutting to pass the tubular body (4) through a microwave crosslinking device (8) and then through a hot air crosslinking device (9) for continuously foaming and crosslinking the rubber composition. At this time, a ratio V2 / V1 between a speed V2 at which the tubular body (4) passes through the hot air crosslinking device (9) and a speed V1 at which the tubular body (4) passes through the microwave crosslinking device (8) is not less than 1.0 and not greater than 1.6.

Owner:SUMITOMO RUBBER IND LTD

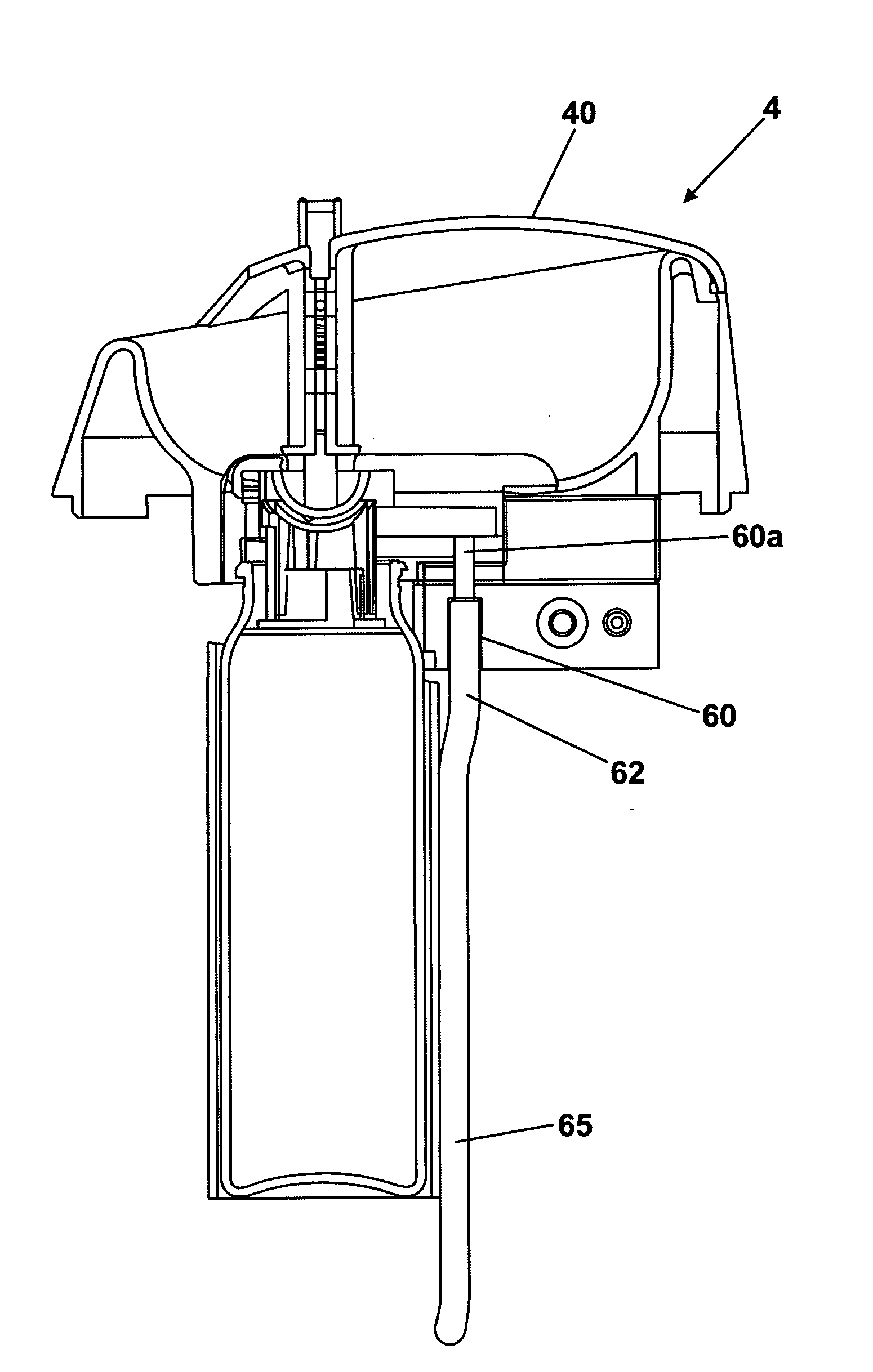

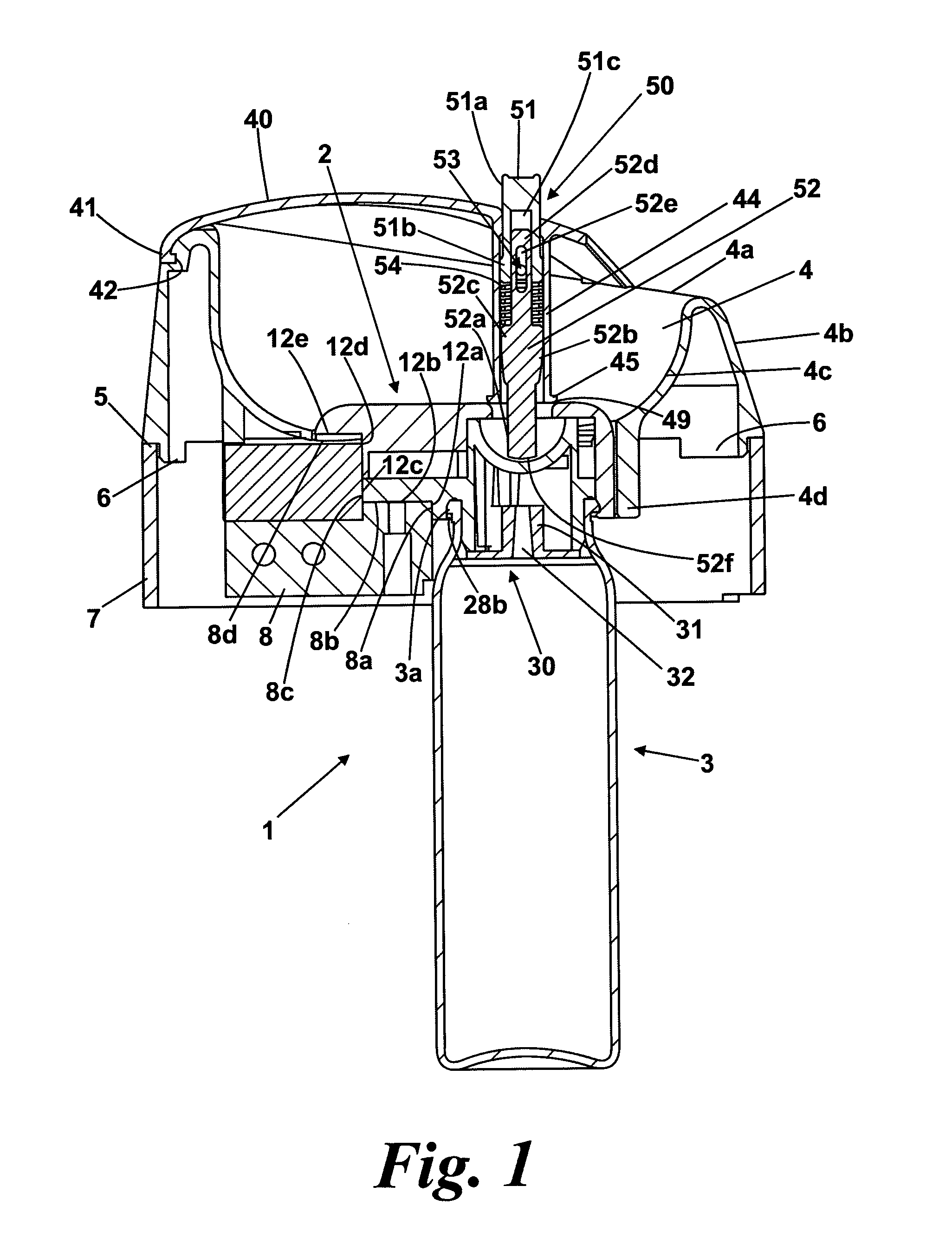

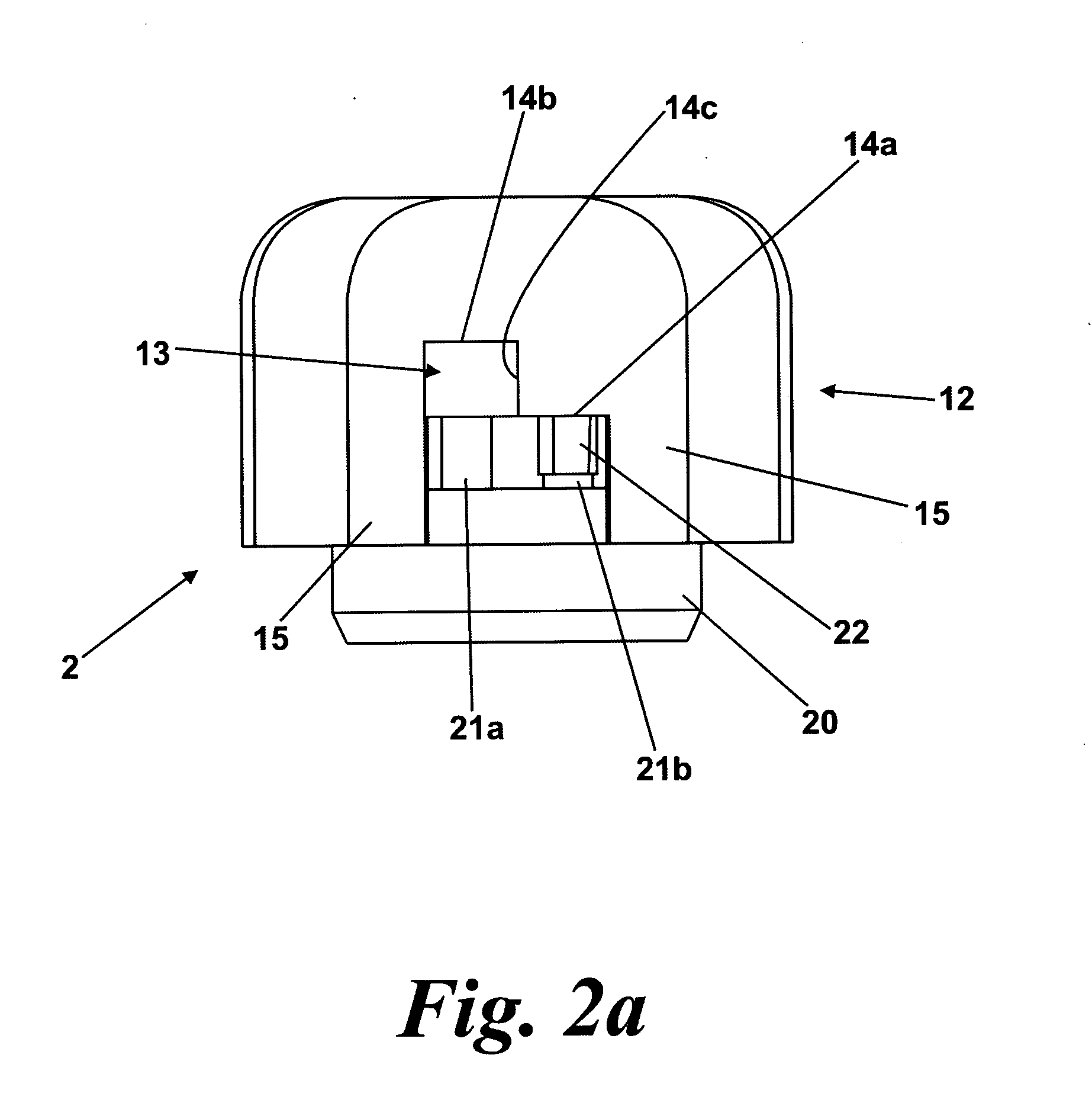

Apparatus for Producing and Delivering Open Air Factor

InactiveUS20100296974A1Inhibition releasePromote exchangeFire rescueGaseous substancesEngineeringOpen air

An apparatus for producing and delivering open air factor comprises an air supply, a supply of olefin and an ozone supply, means for introducing olefin into the air supply and means for mixing ozone with the olefin / air mixture, wherein the mixing means is arranged such that ozone is mixed with the olefin / air mixture at a period of time after introduction of olefin into the air supply.

Owner:MOVING SUN

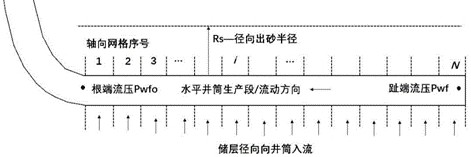

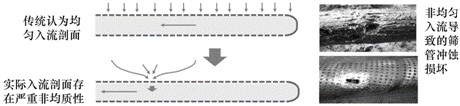

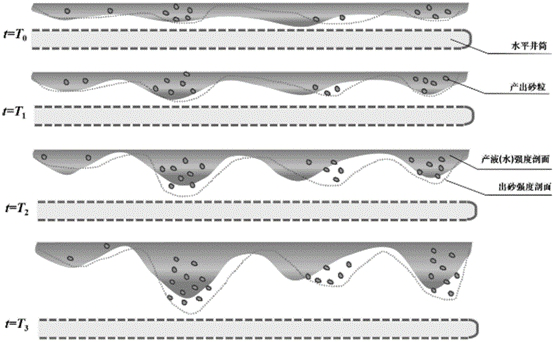

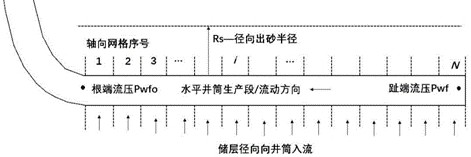

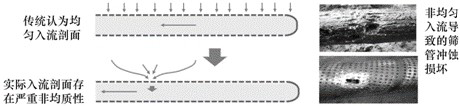

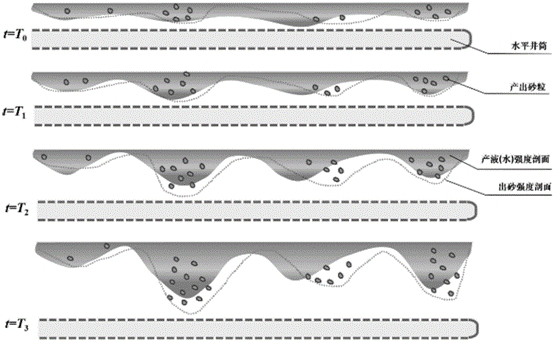

Heterogeneous reservoir horizontal well sand fluid output profile dynamic evolution simulation and prediction method

ActiveCN113591421AEnsure efficient productionImprove erosion resistanceGeometric CADDesign optimisation/simulationSoil scienceHorizontal wells

The invention discloses a heterogeneous reservoir horizontal well sand fluid output profile dynamic evolution simulation and prediction method, relates to the technical field of oil and gas exploitation engineering, and by means of the method, the sand fluid output profile evolution process can be simply and rapidly simulated, formation fluid and formation sand output profiles under the given production condition and production time can be predicted. Key output parts, namely key control well sections and positions, are provided for sand control and water control tubular column design of the horizontal well, and the purposiveness and the comprehensive effect of sand control and water control are provided. By means of the method, the high-speed inflow position of the heterogeneous reservoir horizontal well can be rapidly recognized, the high-erosion occurrence position of the sand control and water control well completion screen pipe can be judged, the screen pipe structure can be guided and optimized, the high-erosion-resistance screen pipe can be used at the high-erosion-risk position, and the comprehensive erosion resistance of the well completion screen pipe can be improved. In addition, the maximum flow velocity of the actual local high-speed inflow position can be quickly calculated by using the local inflow coefficient provided by the invention, and the method is used for predicting and preventing the erosion damage rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

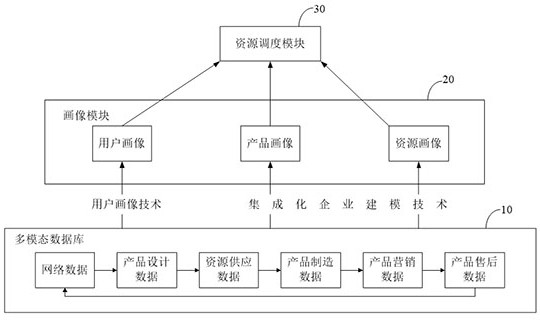

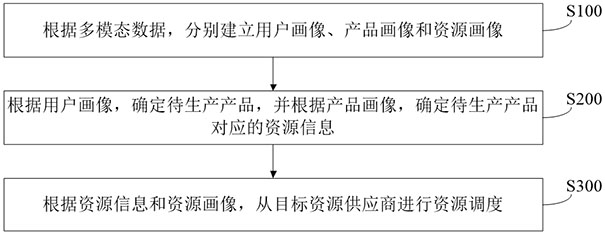

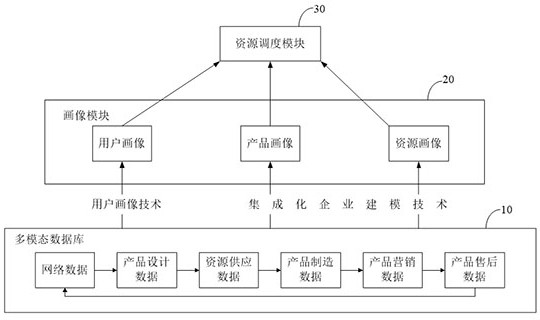

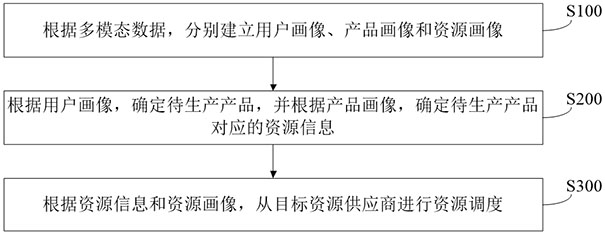

Resource scheduling method and system

ActiveCN113988727AGuaranteed personalized purchasesEnsure efficient productionResourcesMarket data gatheringPersonalizationBusiness enterprise

The invention relates to the technical field of network information, and provides a resource scheduling method and system for solving the problem that product design and manufacturing are carried out only according to user portraits in the prior art so as to achieve the purposes that users are satisfied with products, enterprises efficiently produce products and resource suppliers provide resources in time. According to the application, through three-party coordination of a user portrait, a product portrait and a resource portrait, efficient production of personalized products of users and personalized purchase of resources can be ensured, and meanwhile, resource demands are formed according to personalized design of the products, the resource portrait is established and transmitted to a resource supplier to provide resource allocation reference for the resource supplier, and rapid supply is realized. According to the method, the user, the enterprise and the resource supplier are closely combined, a multi-subject portraying technology is carried out under the driving of multi-modal data, and accurate allocation of the user, the product and the resource is realized.

Owner:QINGDAO HAIER INST OF IND INTELLIGENCE CO LTD +2

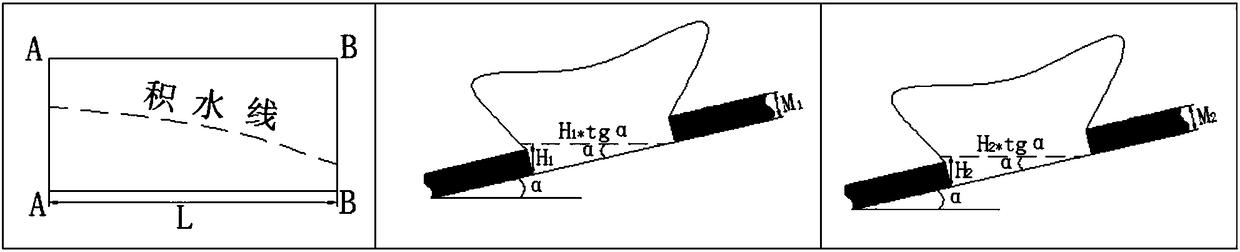

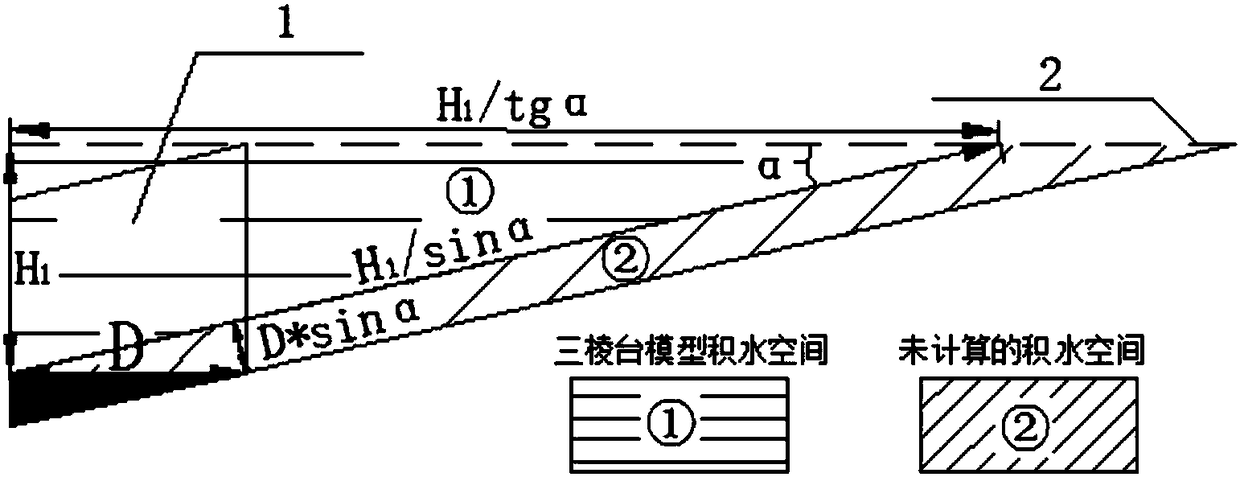

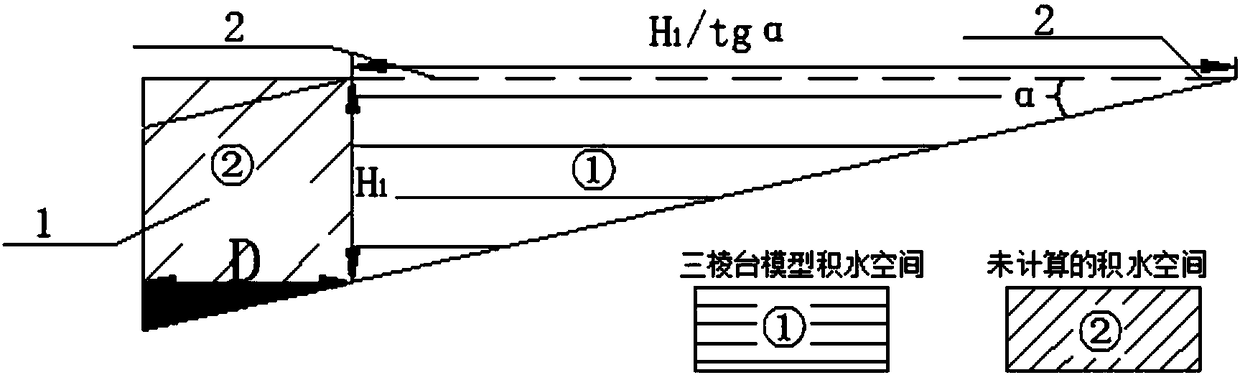

A method for measuring and controlling water accumulation in goafs of coal mines

ActiveCN106224002BImprove securityImprove guidanceMining devicesMonitoring and controlGreek letter alpha

The invention discloses a method for measuring and controlling a water accumulating volume of a coal mine goaf. The water accumulating trend length L of the goaf and a coal bed pitch alpha are measured; water accumulating water head heights H1 and H2 and a lower crossheading roadway width D are measured; a water accumulating space of the goaf is seen as a triangular pyramid model, and then a water accumulating total Q of the goaf is obtained according to the equation that Q= + water accumulating amount of a tunneling roadway. The water accumulating amount of the tunneling roadway is fully considered; through the comparison between the measurement water release amount and the actual water release amount, the measurement and controlling method conforms to lithology combination characteristics of a Xieqiao mine 13-1 coal bed roof, has good guiding effects on water accumulating amount prediction of the mine 13-1 coal bed goaf, and can greatly improve mine safety and guarantee efficient production.

Owner:HUAINAN MINING IND GRP

Conveying and reversing device for catalyst slurry

InactiveCN108117033AImprove yieldQuality improvementLiquid transferring devicesInlet valveEngineering

Owner:程晋军

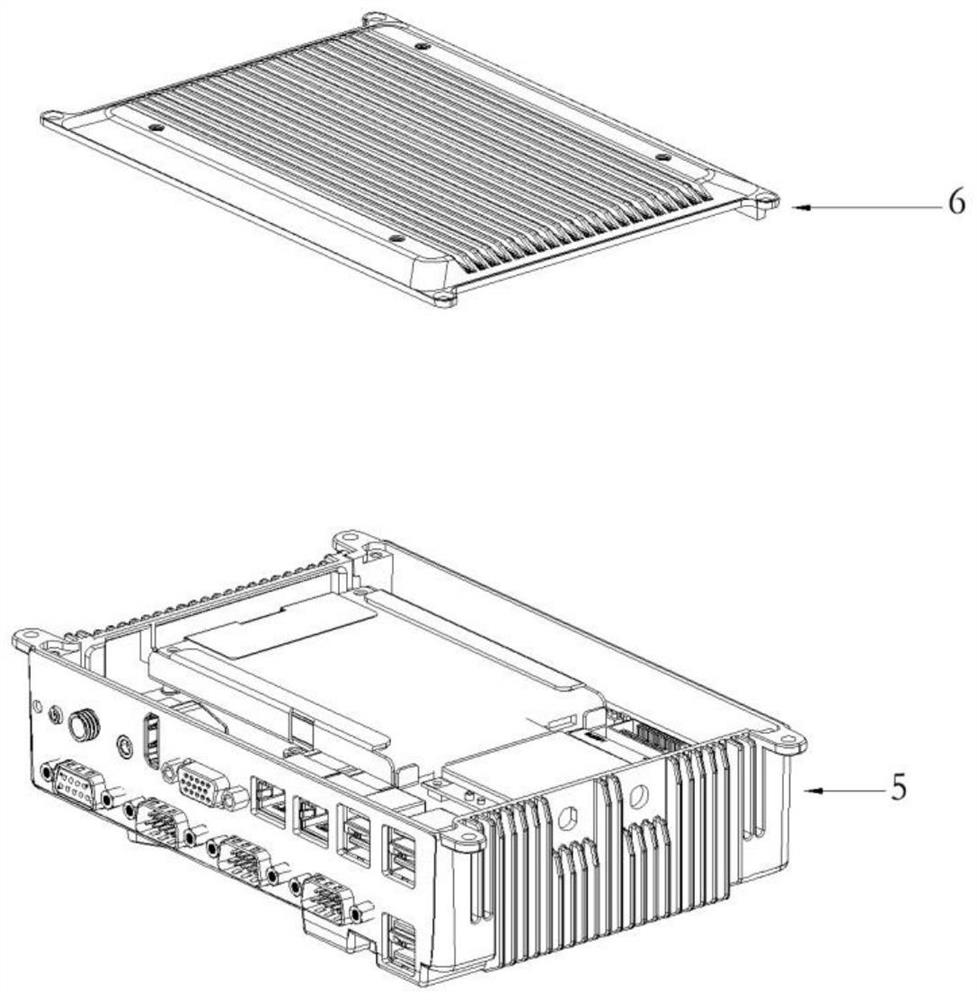

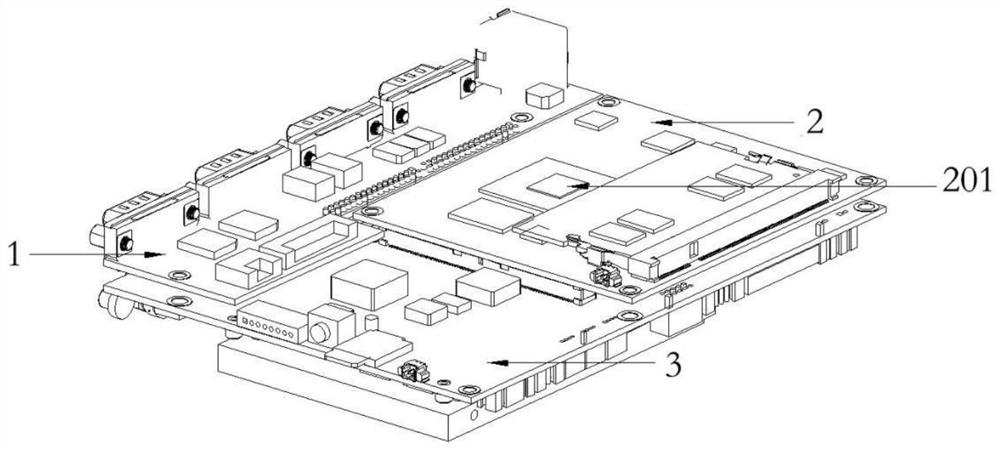

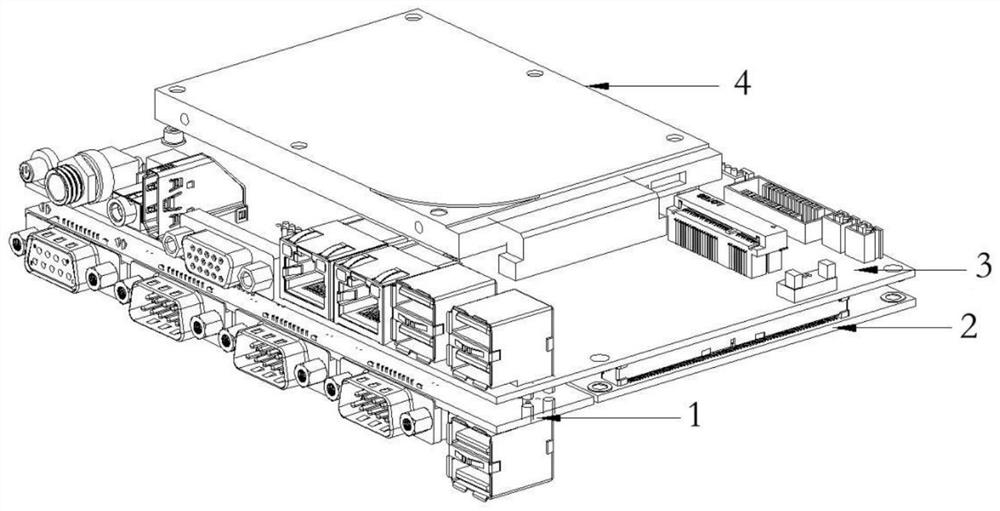

Modular edge computing industrial personal computer

PendingCN114860039AAchieve modularityMeet application needsTwo-part coupling devicesDigital processing power distributionEdge computingSoftware engineering

The invention provides a modular edge computing industrial personal computer which comprises an I / O interface module, a core mainboard 2 and a shell 5, the I / O interface module and the core mainboard 2 are both arranged in the shell 5, the core mainboard 2 comprises multiple different models of core mainboards 2, and the sizes of the multiple different models of core mainboards 2 are matched with the I / O interface module; the I / O interface module comprises an I / O expansion daughter card 1 and an I / O carrier plate 3, the I / O expansion daughter card 1 and the core mainboards 2 of various different models can be detachably connected with one side of the I / O carrier plate 3, and the other side of the I / O carrier plate 3 is provided with a hard disk and faces the top of the shell 5. Modularization of the core mainboard is achieved, various industrial personal computer configuration schemes can be achieved, application requirements of diversified products in various intelligent computing fields are effectively met, market requirements can be rapidly met, and the industrial personal computer has the advantages of being low in cost, high in working reliability and the like.

Owner:苏州稳信智能科技有限公司

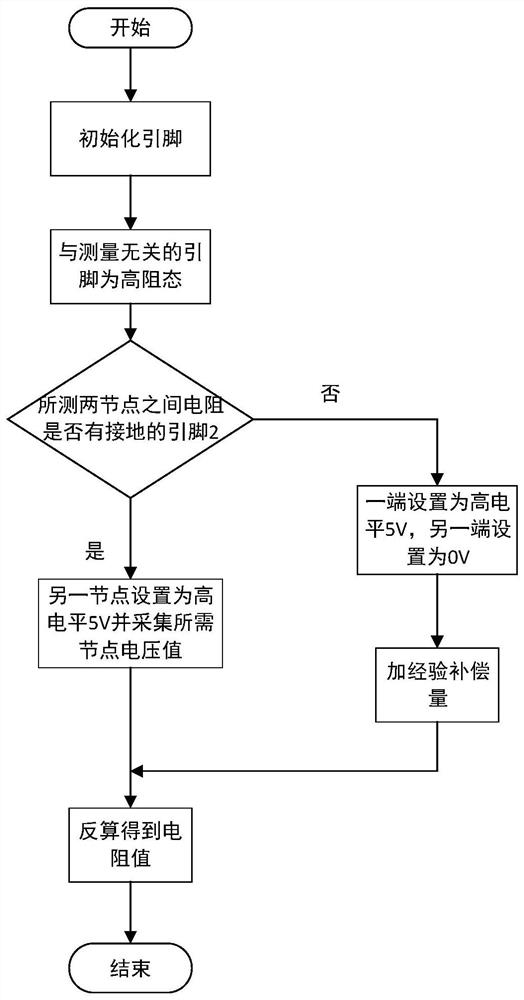

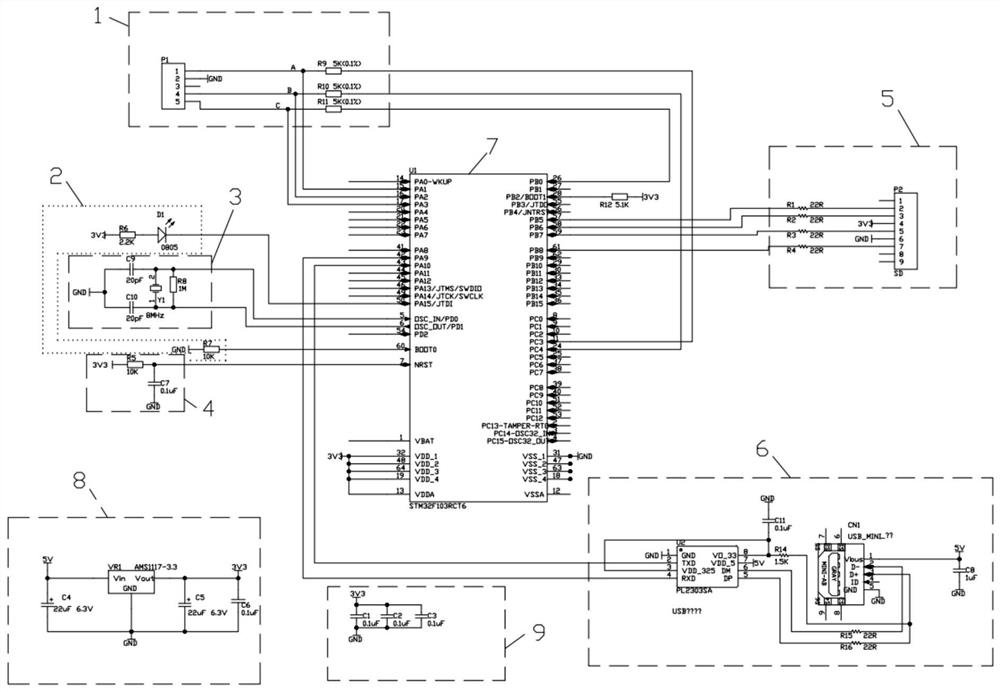

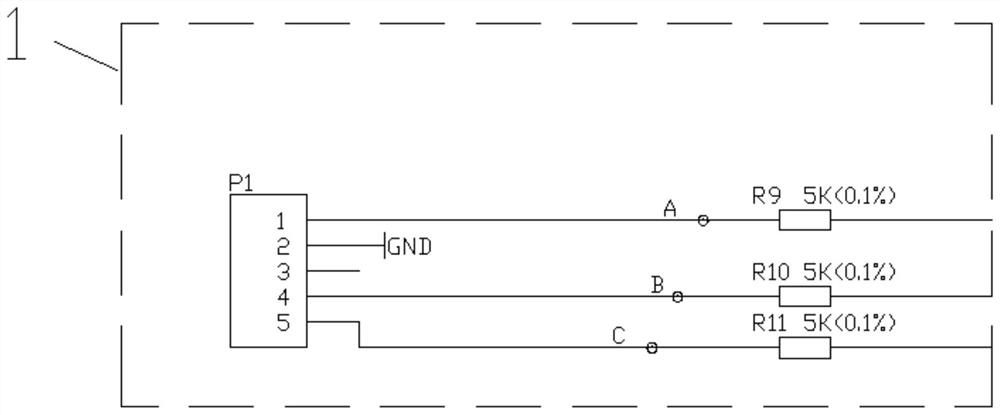

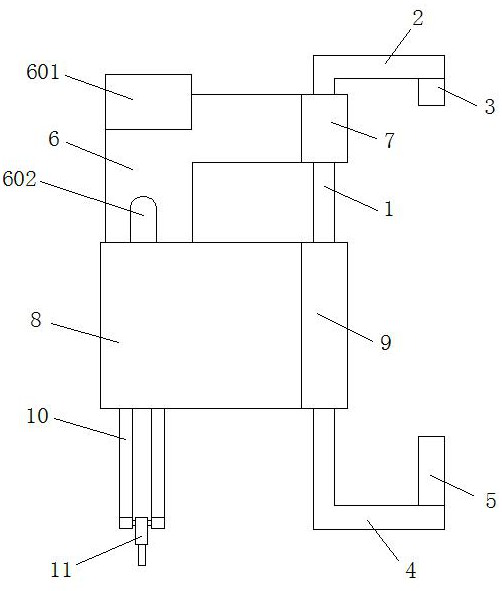

Gamepad rocker circuit board resistance voltage index detection method

PendingCN112345830AAvoid inaccuraciesImprove accuracyResistance/reactance/impedenceVoltage measurements onlyHemt circuitsSingle chip

Owner:XIAMEN SAN TE XING ELECTRONICS CO LTD

A kind of rotary knuckle device for railway vehicle coupler

ActiveCN112918506BImprove cleanlinessImprove the lubrication effectRailway coupling accessoriesStructural engineeringMechanical engineering

The invention discloses a rotary knuckle device for hanging on the hook head of a railway vehicle, which comprises a positioning piece, an upper clamping iron, and a lower clamping iron. Sliding connection; the positioning member includes a sliding rod, an upper fixing rod, and a lower fixing rod. The upper rotating shaft is coaxially arranged; the upper clamping iron includes an upper clamping plate, one end of the upper clamping plate is rotatably connected with the slide bar and the upper clamping plate can slide along the length direction of the slide bar; the front side of the top of the upper clamping plate is provided with a mounting sleeve , the mounting sleeve is provided with a locking mechanism; the lower clamping iron includes a lower clamping plate, the lower clamping plate is slidably connected to the upper clamping plate, one end of the lower clamping plate is rotatably connected to the slide bar, and the bottom end of the lower clamping plate is fixedly connected with The supporting piece is located under the mounting sleeve and is vertically arranged with the lower clamping plate.

Owner:崔雲皓

Railway vehicle hook head external hanging rotary coupler knuckle device

ActiveCN112918506AImprove cleanlinessImprove the lubrication effectRailway coupling accessoriesEngineeringStructural engineering

The invention discloses a railway vehicle hook head externally-hung rotary coupler knuckle device. The device comprises a positioning piece, an upper clamping iron and a lower clamping iron, wherein the upper clamping iron and the lower clamping iron are both rotatably connected with the positioning piece, and the upper clamping iron is slidably connected with the lower clamping iron; the positioning piece comprises a sliding rod, an upper fixing rod and a lower fixing rod, the top end of the sliding rod is fixedly connected with the upper rotating shaft through the upper fixing rod, the bottom end of the sliding rod is fixedly connected with the lower rotating shaft through the lower fixing rod, and the lower rotating shaft and the upper rotating shaft are coaxially arranged; the upper clamping iron comprises an upper clamping plate, one end of the upper clamping plate is rotatably connected with the sliding rod, and the upper clamping plate can slide in the length direction of the sliding rod; a mounting sleeve is arranged on the front side of a top end of the upper clamping plate and provided with a locking mechanism; the lower clamping iron comprises a lower clamping plate, the lower clamping plate is connected with the upper clamping plate in a sliding mode, one end of the lower clamping plate is rotatably connected with the sliding rod, the bottom end of the lower clamping plate is fixedly connected with a supporting piece, and the supporting piece is located below the installation sleeve and is perpendicular to the lower clamping plate.

Owner:崔雲皓

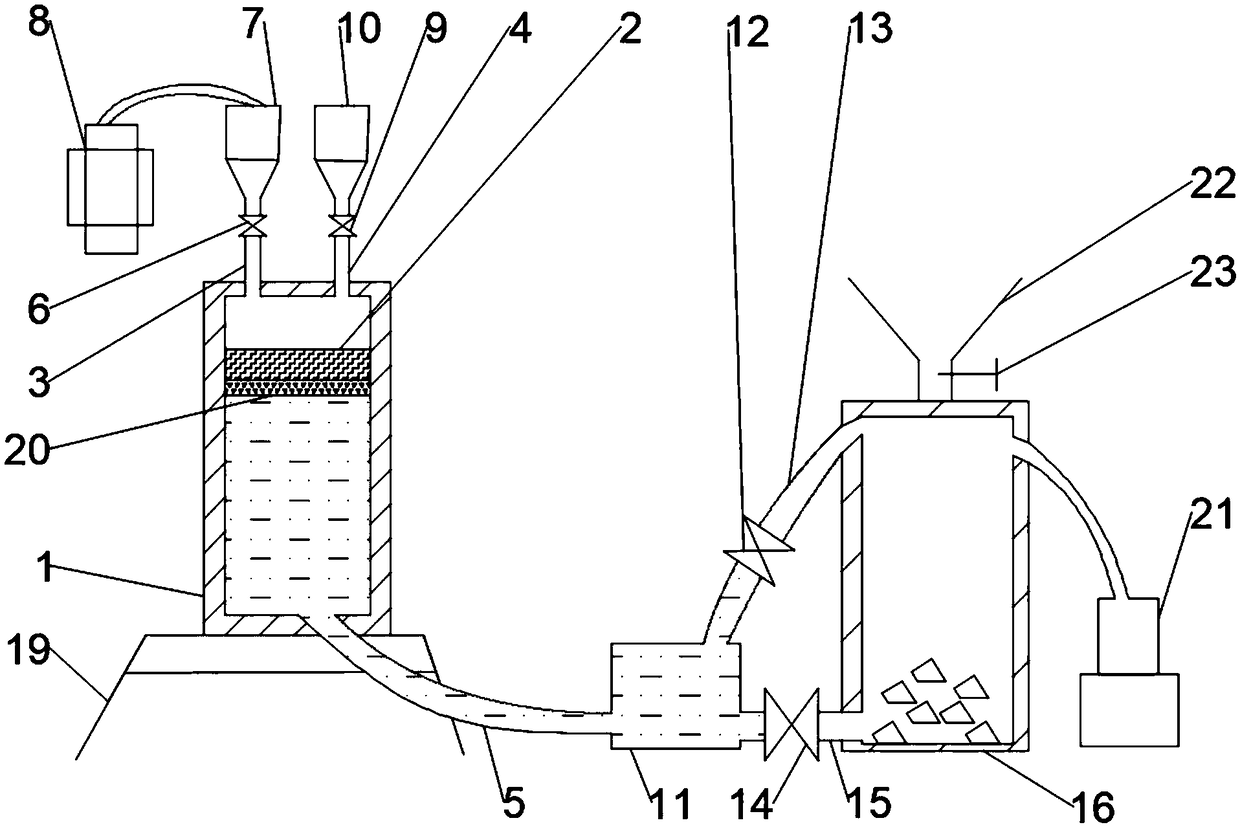

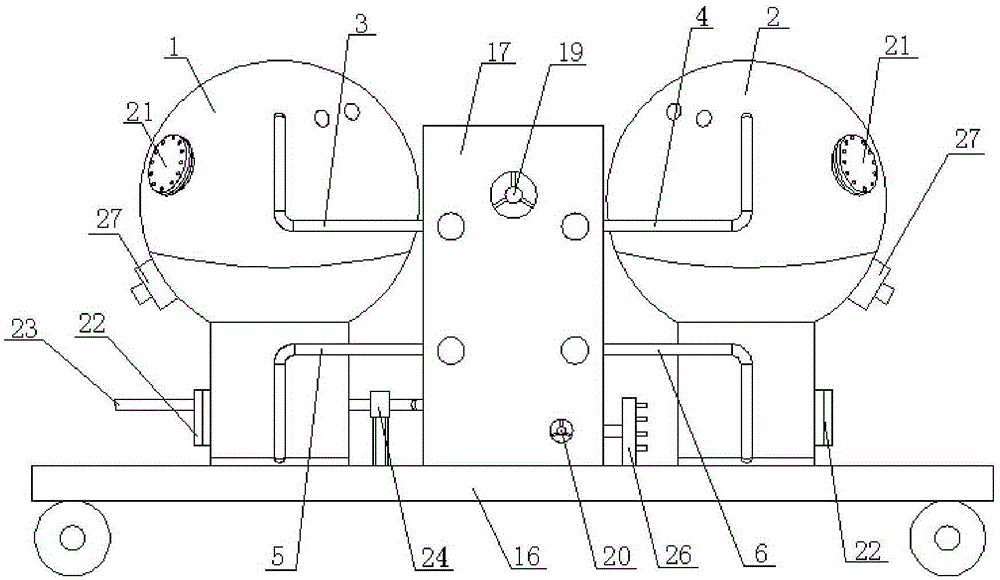

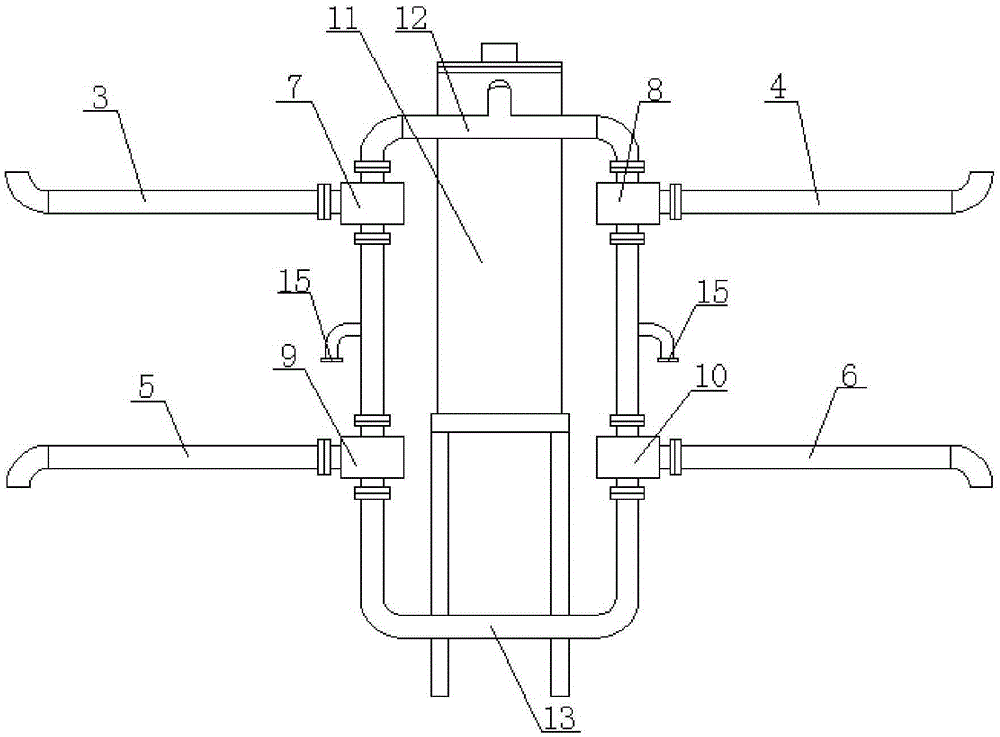

Water purification station for underground mine

InactiveCN105311877AEnsure efficient productionGuaranteed cleanlinessFiltration circuitsEmulsionSewage

The invention discloses a water purification station for an underground mine. The water purification station comprises two same tank bodies, wherein the upper half parts of the tank bodies are spheres, and the lower half parts are barrels; the diameters of the spheres are larger than the diameters of the barrels; water inlet pipes and water outlet pipes are respectively arranged at the tops and the bottoms of the tank bodies; a 3-way ball valve is arranged on each of the water inlet pipes and each of the water outlet pipes; pipelines are connected between the 3-way ball valves on the same sides; a sewage draining exit is formed in each of the two pipelines; the water inlet pipes are connected with a gap type screen drum; the water inlet of the gap type screen drum is connected with an original water inlet; the water outlet pipes are connected with a water outlet end; a fiber filter material is arranged in each of the inner cavities of the two tank bodies; an emulsion motor is arranged in each of the two tank bodies; each emulsion motor is connected with a liquid supply device through a liquid supply pipeline and a liquid returning pipeline. According to the water purification station, the structure is simple, and the backwashing of the two tank bodies is more complete through the stirring function of the emulsion motors; the emulsion motors are driven through an emulsion, so that the electric power is not consumed, the safety is guaranteed, the cost is reduced, and the efficient production of a coal mine is guaranteed.

Owner:HUAINAN RUNCHENG TECH

Process for producing electrical wire molded body

ActiveUS10559407B2Ensure efficient productionSuitable for useRubber insulatorsHot-dipping/immersion processesPolymer sciencePolyolefin

There are provided a process for producing an electrical wire molded body comprising: step I of melting and kneading a polyethylene-based resin (a), a polypropylene-based resin (b), a block copolymer (c) of an aromatic vinyl-based compound and a conjugated diene-based compound and the like, and a silane coupling agent (g), and other components, to produce a silane crosslinkable flame retardant polyolefin (A); step II of melting and kneading a polymer selected from the components (a) to (c) and a silanol condensation catalyst (i), to produce a silanol catalyst rein composition (B); and step III of mixing the components (A) and (B), melt molding the mixture on a conductor and then crosslinking the molded body in the presence of water.

Owner:RIKEN TECHNOS CORP

An integrated device for a label feeding machine

ActiveCN103848263BReduce labor intensityEasy to operateArticle deliveryEngineeringMechanical engineering

Owner:SUZHOU TRANSPARENT TECH CO LTD

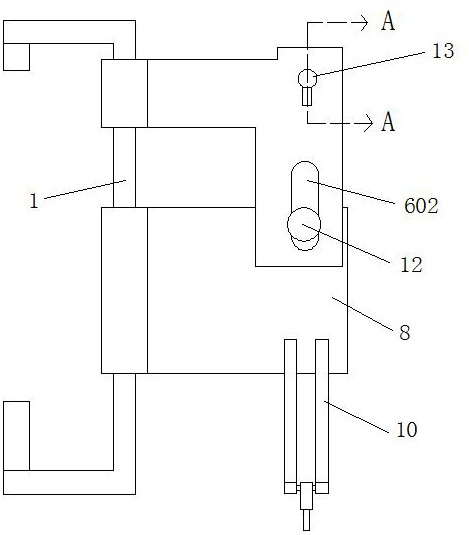

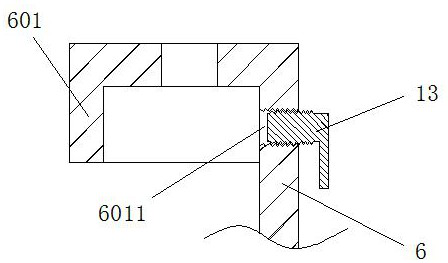

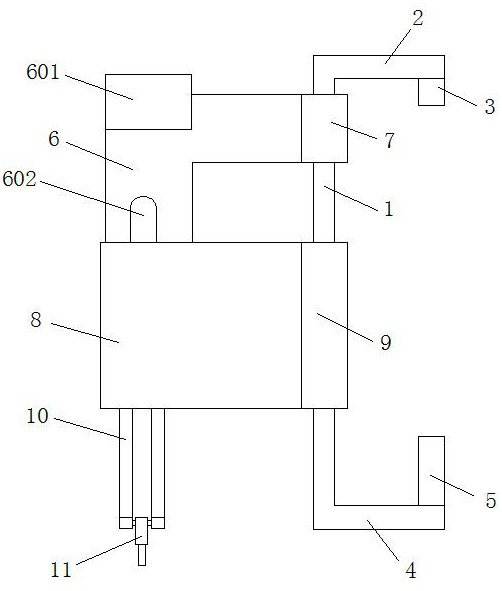

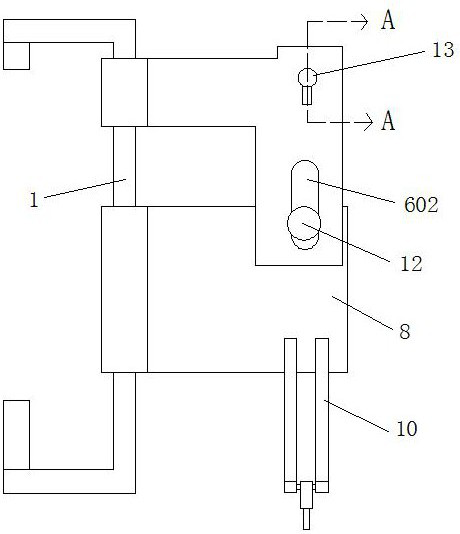

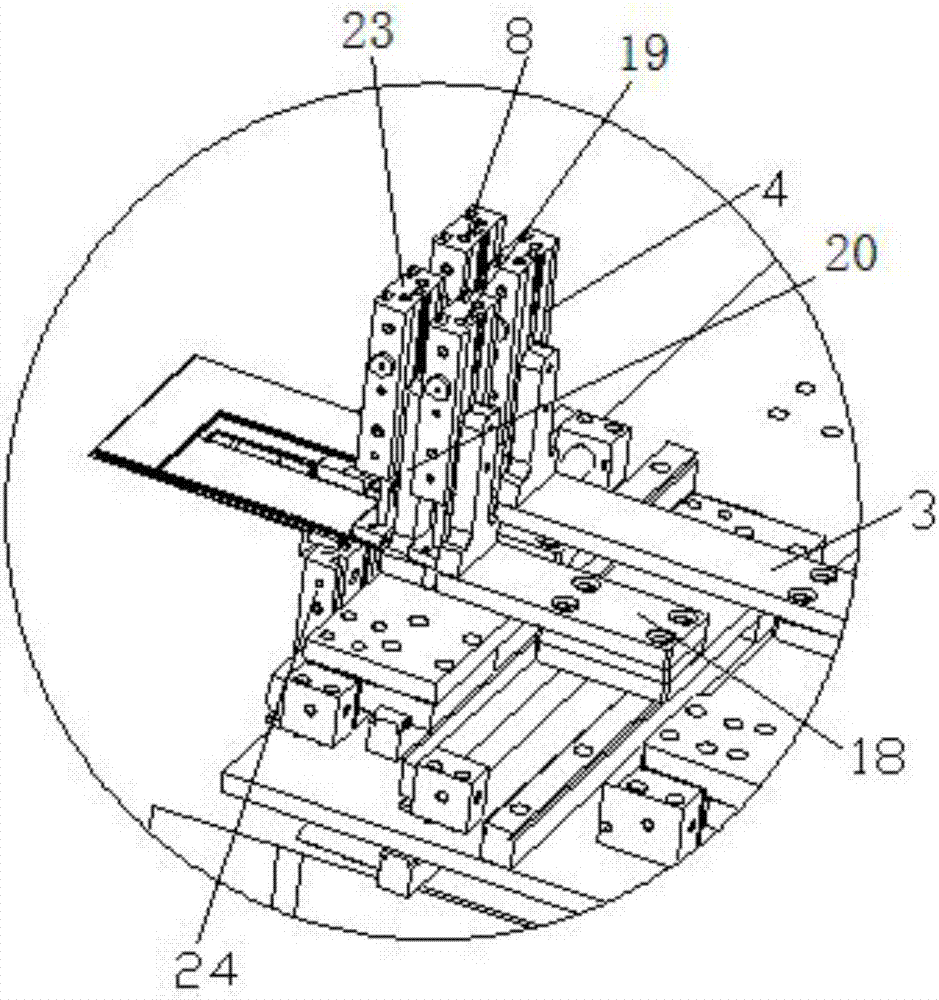

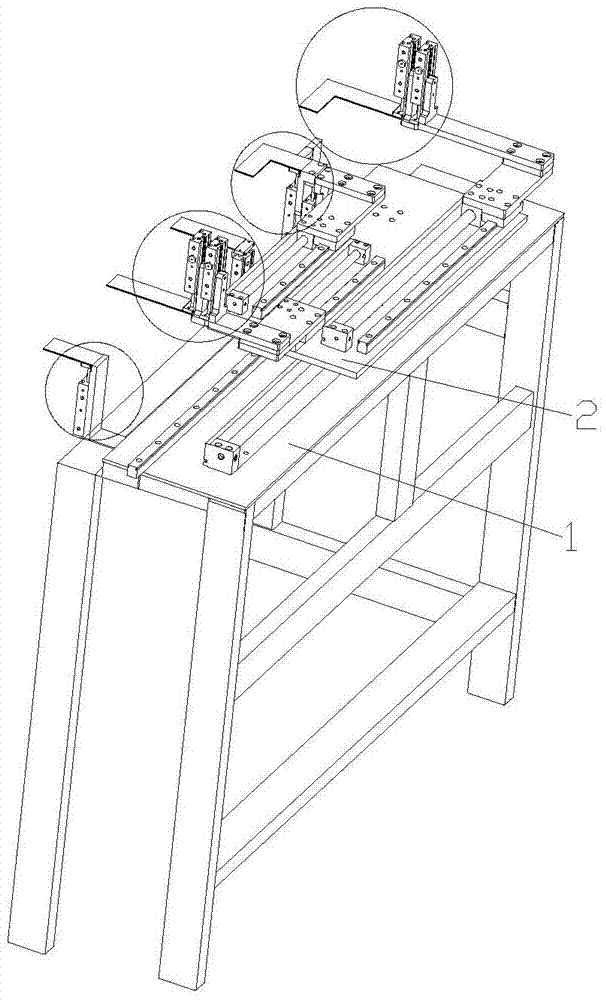

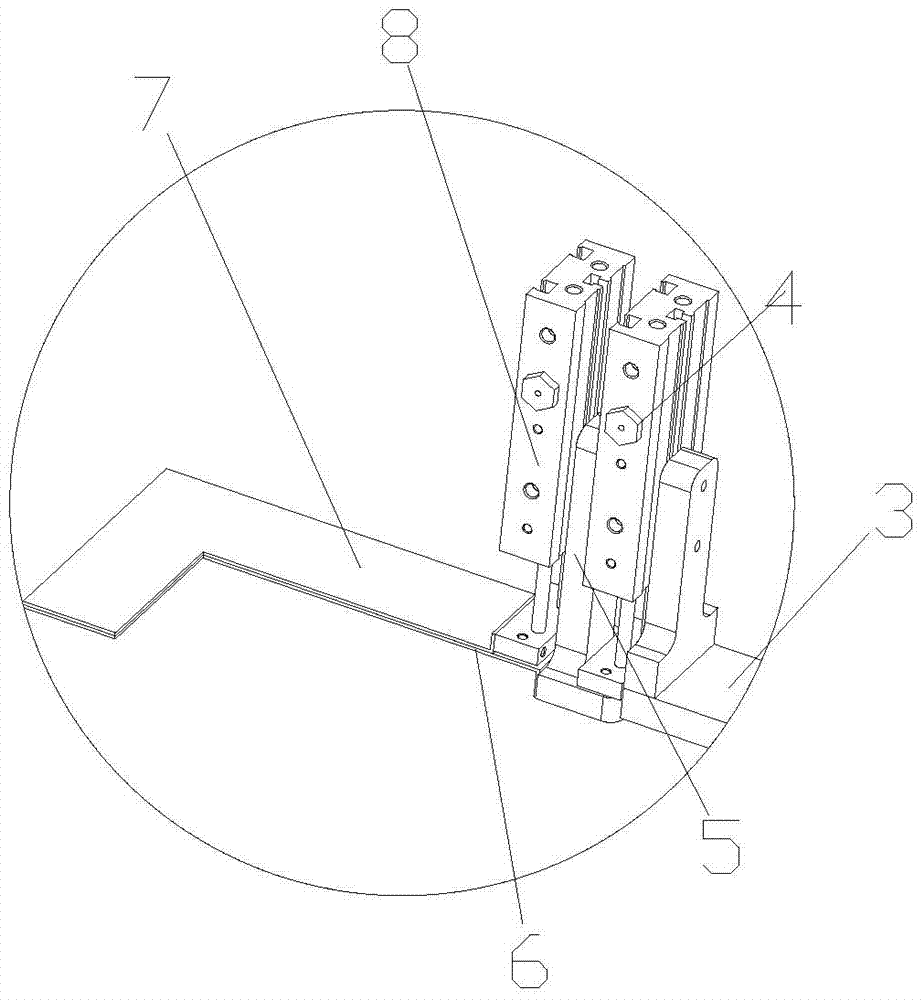

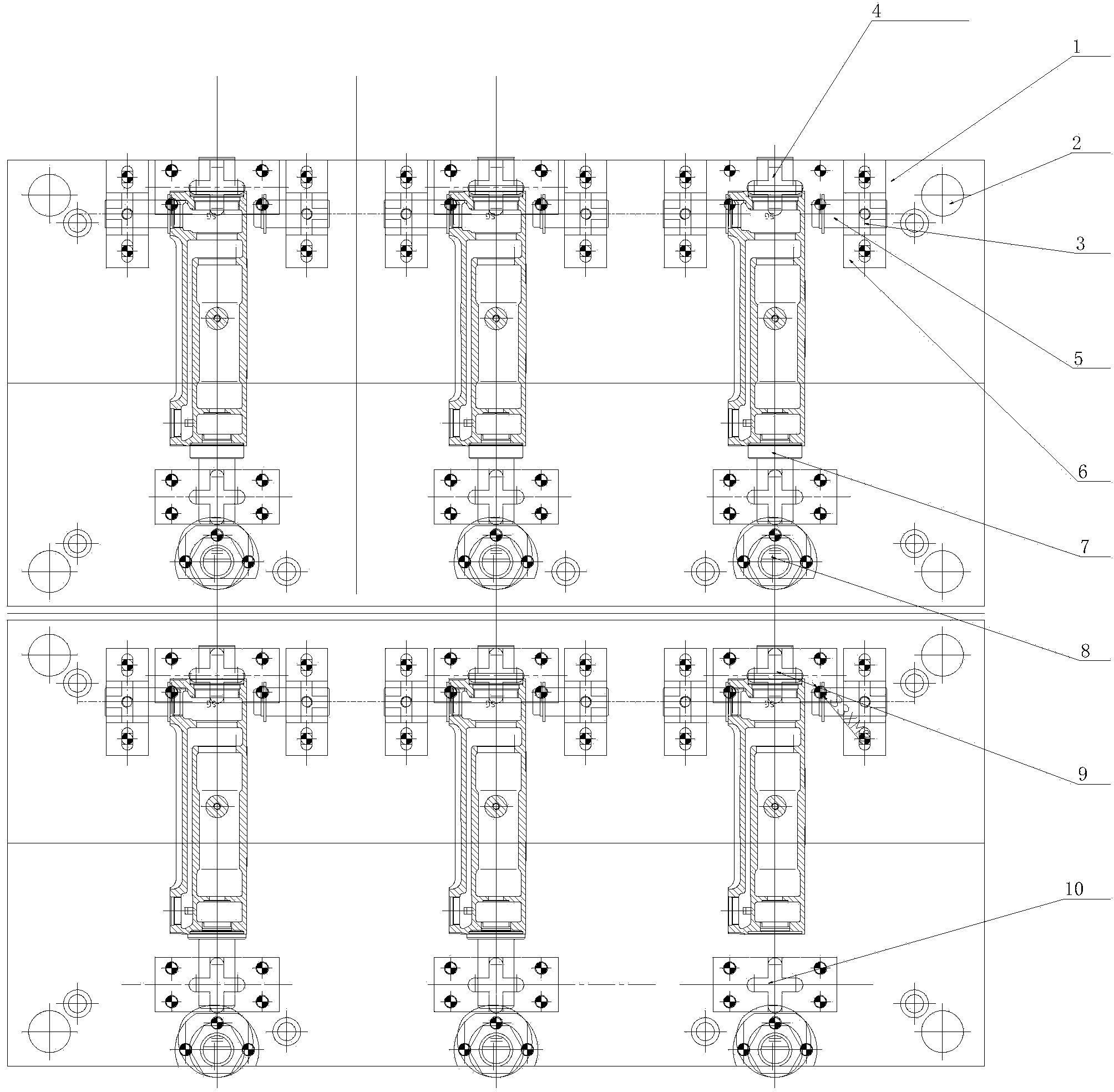

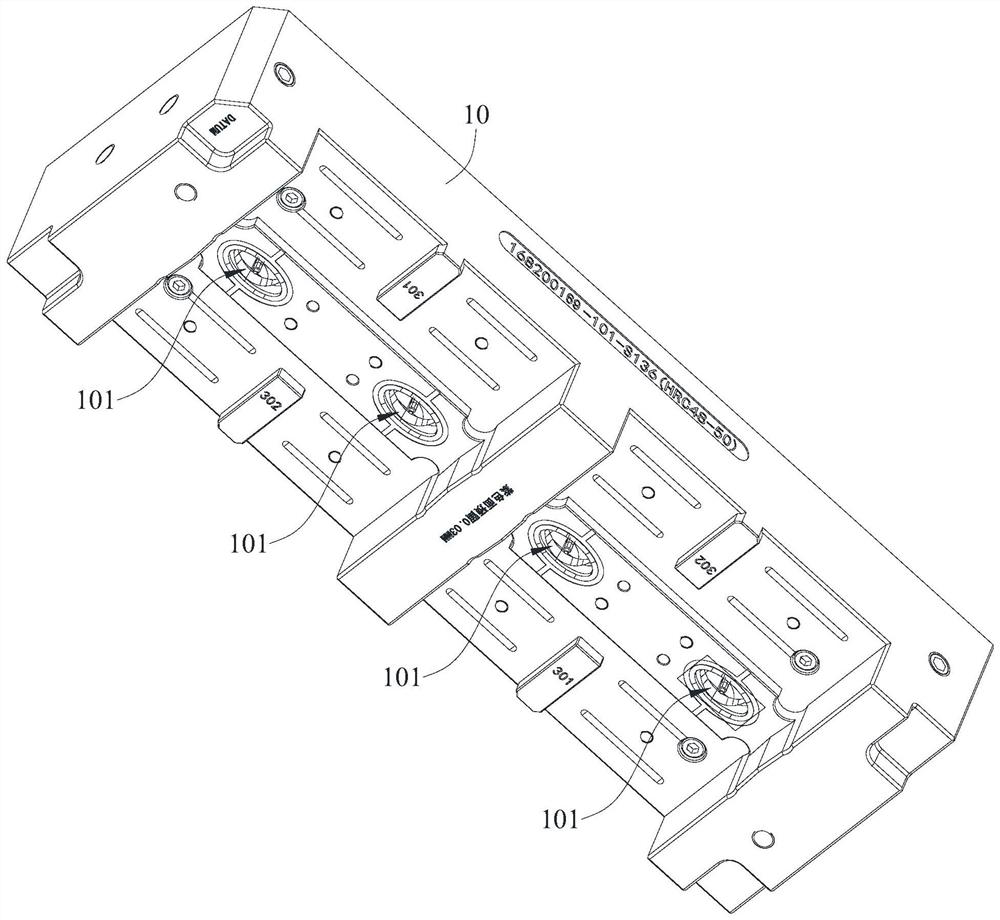

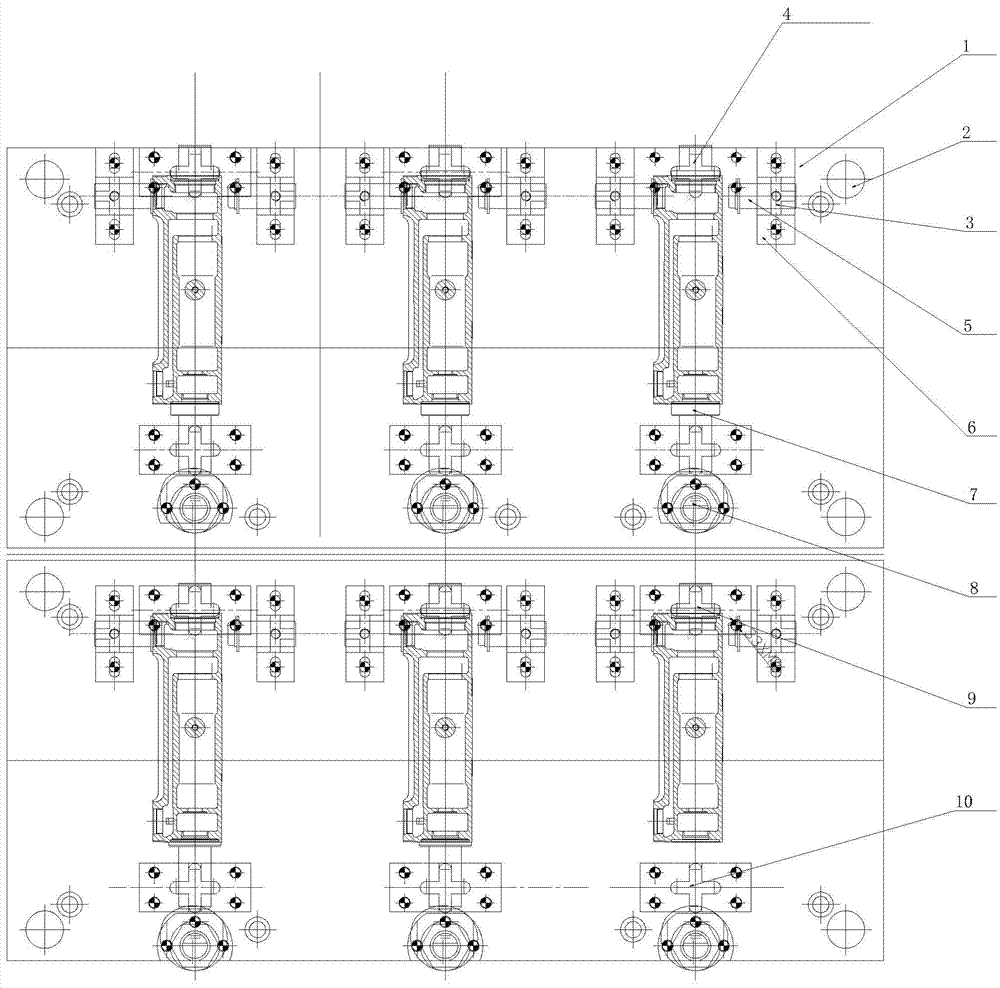

CNC (Computer Numerical Control) six-axis linked sanitary casting machining device

ActiveCN104227562AHighly integratedReasonable process structureBelt grinding machinesGrinding work supportsNumerical controlEngineering

The invention relates to a CNC (Computer Numerical Control) six-axis linked sanitary casting machining device. The CNC six-axis linked sanitary casting machining device is characterized in that the device comprises a body big plate (1), fixtures and body positioning pins (2); the number of the fixtures is six, the six fixtures are installed on the body big plate (1), the number of the body positioning pins (2) is four, and the four body positioning pins are located at the four corners of the body big plate (1) and are used for positioning the body big plate (1); each fixture comprises a first cross-shaped positioning key (3), a left valve chamber positioning device (4), a water inlet positioning device (5), a water inlet positioning sleeve (6), a right valve chamber positioning device (7) and an eccentric cam mechanism (8).

Owner:黑龙江北鸥卫浴用品有限公司

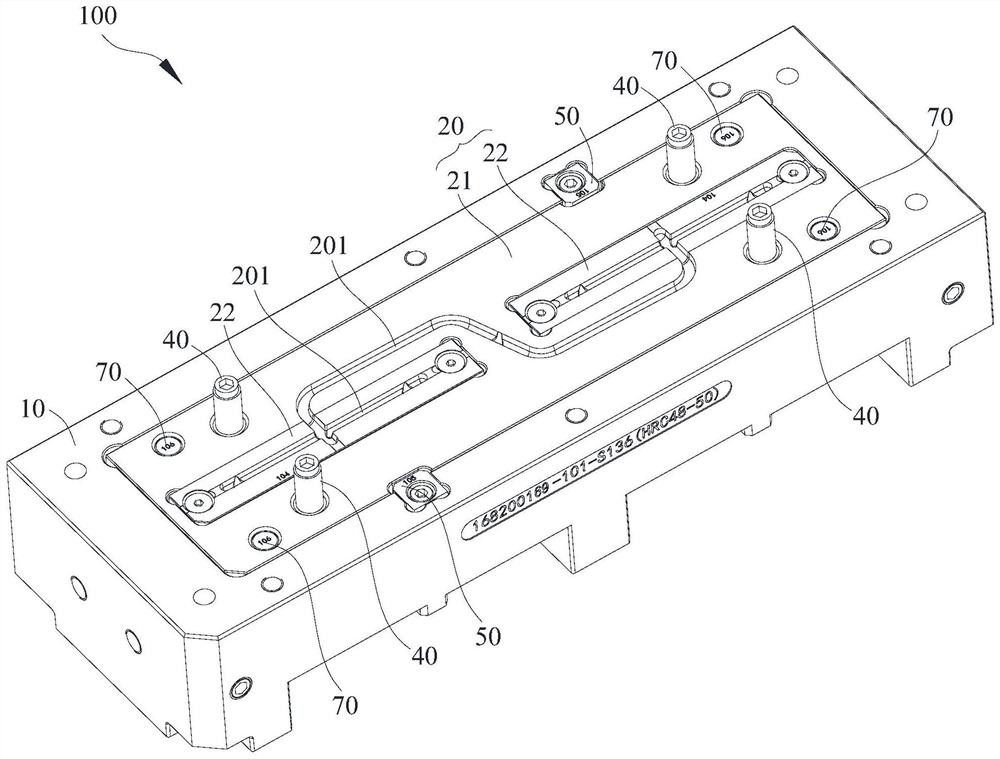

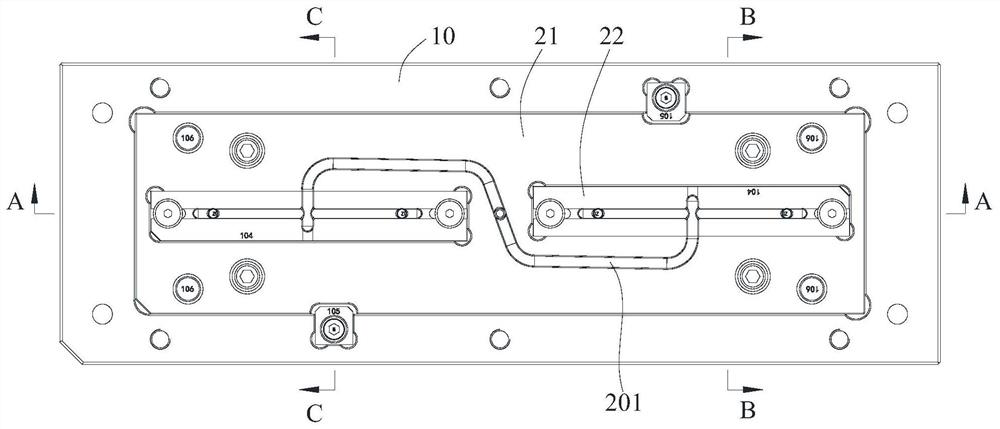

Front mold core assembly and three-plate mold

The invention relates to the technical field of molds, and provides a front mold core assembly and a three-plate mold. The front mold core assembly comprises a front mold core, a runner plate and a front mold insert; the front mold core is arranged in a mounting cavity of a plate A, and the front mold core is provided with a front mold cavity and a through hole communicated with the front mold cavity; the runner plate is movably arranged at the side, away from the front mold cavity, of the front mold core, and the runner plate is provided with a branch runner; and the front mold insert is arranged on the runner plate and penetrates through the runner plate and the through hole, a channel is formed in the front mold insert, one end of the channel is communicated with the branch runner, and the other end of the channel is communicated with the front mold cavity, wherein a first lock catch is arranged at the side, away from the front mold core, of the runner plate, and a first lock hole is formed in the side, close to the A plate, of a stripper plate. A product can be prevented from being adhered to the front mold insert and the front mold cavity, the product is prevented from being pulled to be damaged, damage of the mold due to damage of the front mold cavity can be prevented, and the normal and efficient production of the mold is ensured.

Owner:深圳铭锋达精密技术有限公司

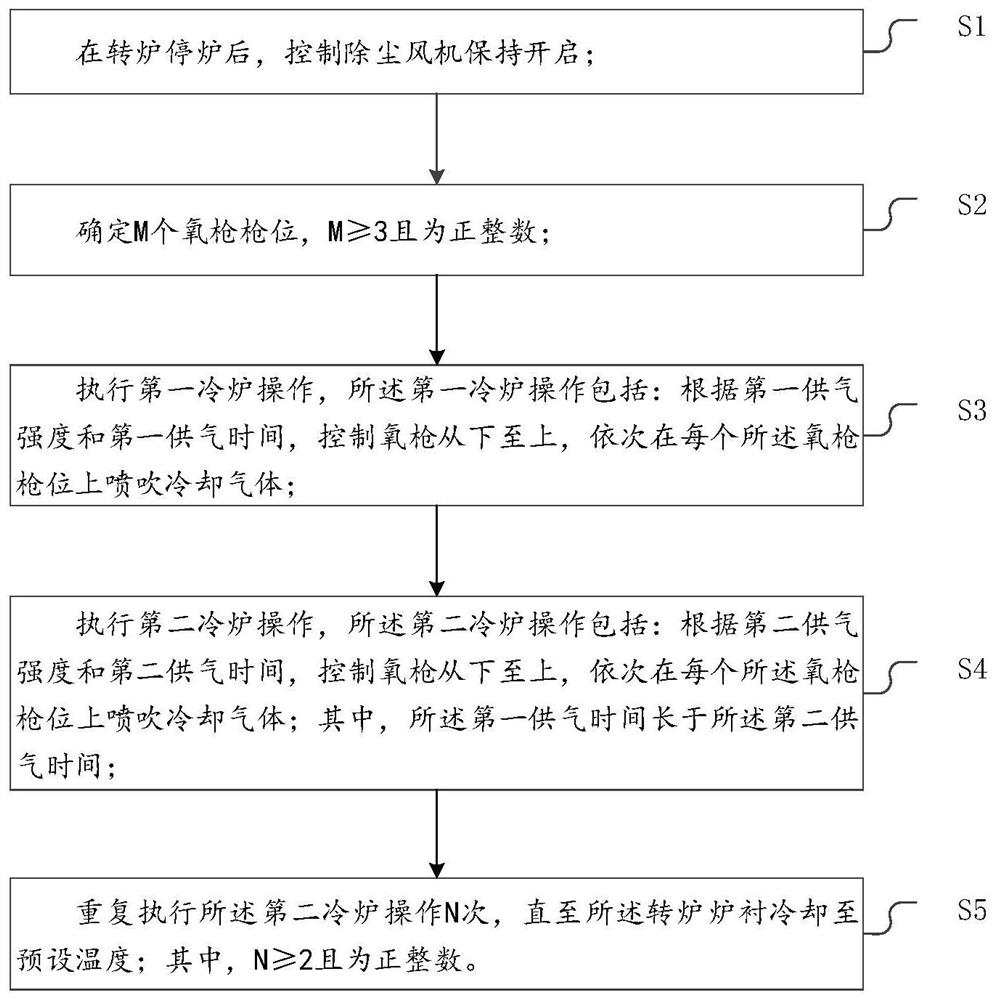

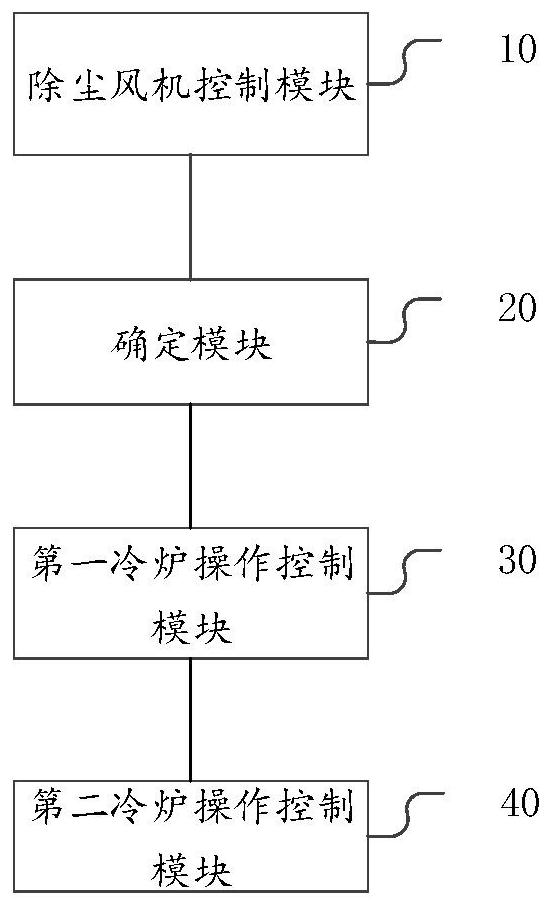

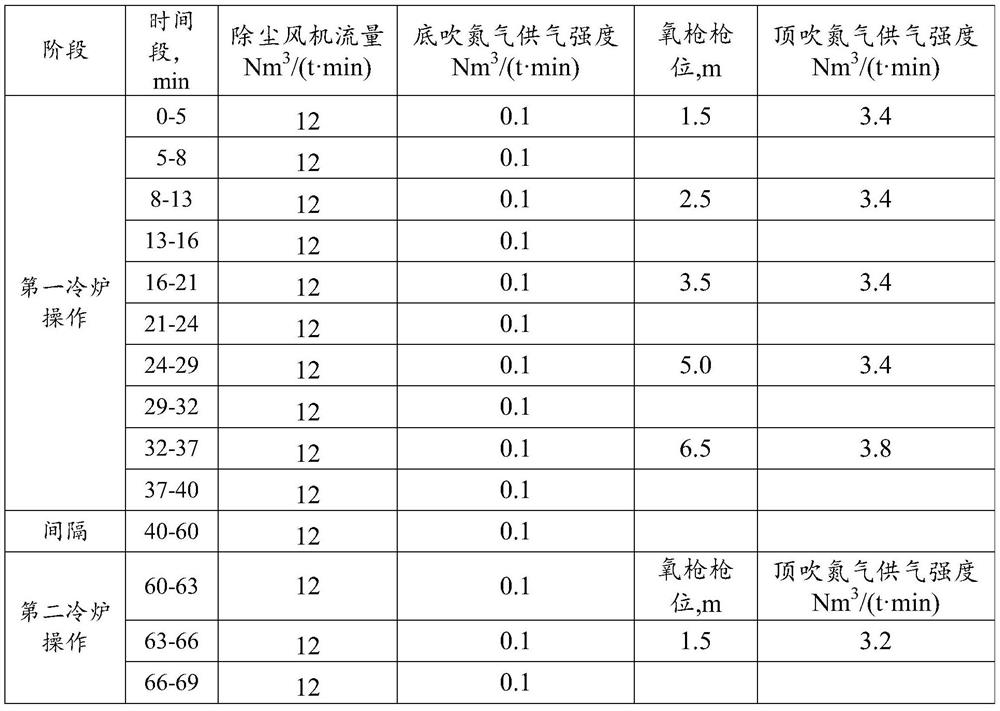

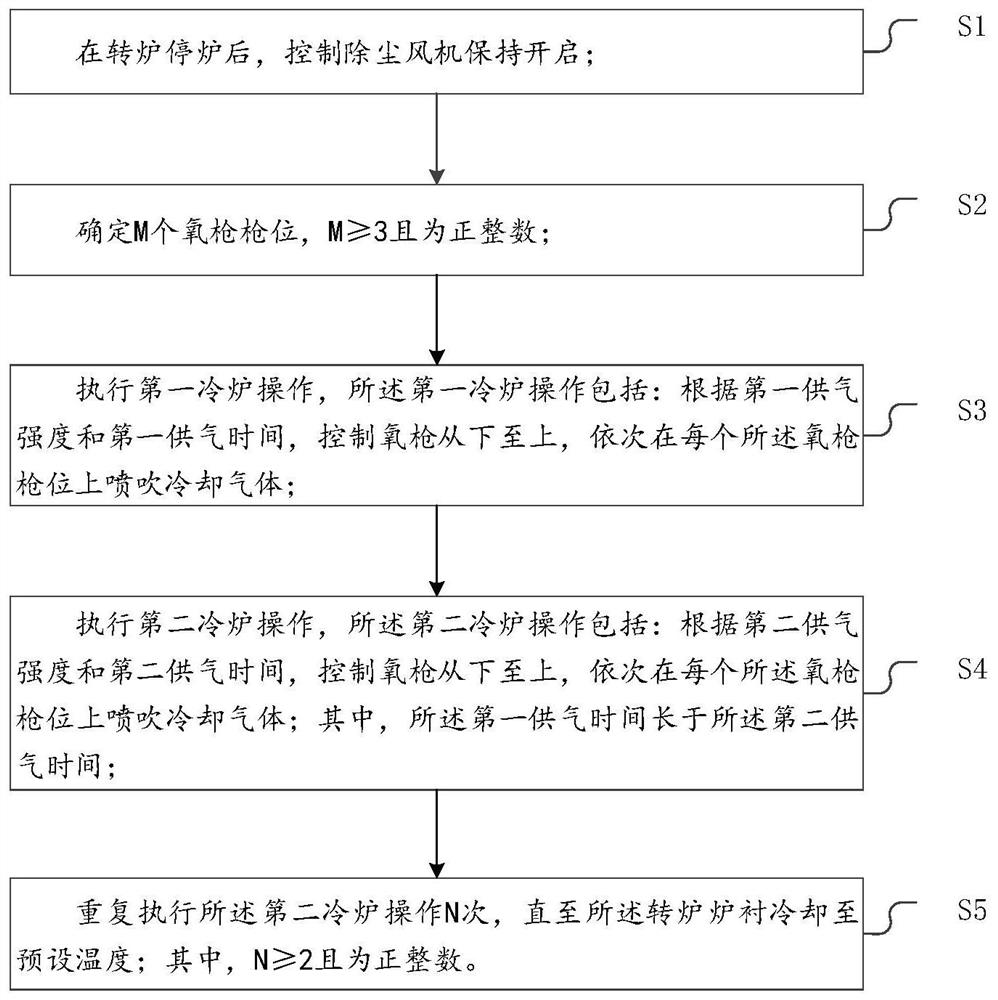

Converter lining cooling method and cooling system

ActiveCN111733309AShorten service cycleIncrease cooling rateManufacturing convertersThermodynamicsSmelting process

The invention discloses a converter lining cooling method. The method includes the steps that a dust removal fan is controlled to keep on after a converter is shut down; M oxygen lance positions are determined, wherein M is greater than or equal to three and M is a positive integer; first converter cooling operation is executed, and the first converter cooling operation includes the steps that according to first air feed intensity and first air feed time, oxygen lances are controlled to blow cooling air to the oxygen lance positions successively from bottom to top; second converter cooling operation is executed, and the second converter cooling operation includes the steps that according to second air feed intensity and second air feed time, the oxygen lances are controlled to blow coolingair to the oxygen lance positions successively from bottom to top; the first air feed time is longer than the second air feed time; and the second converter cooling operation is executed N times until converter lining is cooled to a preset temperature. The method can accelerate the cooling efficiency of the converter lining, the period of converter service is shortened, and efficient production of a converter and subsequent smelting processes can be guaranteed.

Owner:SHOUGANG CORPORATION

A cooling method and cooling system for converter lining

ActiveCN111733309BShorten service cycleIncrease cooling rateManufacturing convertersThermodynamicsSmelting process

The invention discloses a cooling method for the lining of a converter, which includes: after the converter is shut down, controlling the dust removal fan to keep on; determining M oxygen lance positions, where M≥3 and is a positive integer; performing the first cooling operation, and the second A cold furnace operation includes: according to the first gas supply intensity and the first gas supply time, control the oxygen lance from bottom to top, and spray cooling gas on each oxygen lance position in turn; perform the second cold furnace operation, the second cooling Furnace operation includes: according to the second gas supply intensity and the second gas supply time, control the oxygen lance from bottom to top, and spray cooling gas on each oxygen lance position in turn; wherein, the first gas supply time is longer than the second gas supply time Time; repeat the second cooling furnace operation N times until the converter lining is cooled to the preset temperature. The above method can speed up the cooling rate of the converter lining, shorten the working cycle of the converter, and ensure the high-efficiency production of the converter and subsequent smelting processes.

Owner:SHOUGANG CORPORATION

Composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fiber

InactiveCN102627413BHigh mechanical strengthChemically stableChemical vapor deposition coatingFiberDiamond-like carbon

The invention relates to a composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fibers. The method comprises the following steps of: 1) starting a microwave plastic chemical vapor deposition system and vacuumizing; 2) feeding natural gas into a cylindrical stainless steel vacuum chamber to enable the natural gas to be fully filled in the entire cylindrical stainless steel vacuum chamber; 3) starting a microwave source to enable the microwave source to generate microwaves to excite plasmas in a conical metal roller, so as to fully decompose the natural gas into hydrocarbon groups with activity; 4) adding raw material glass fibers into the conical metal roller; 5) starting a motor to enable the raw materials to be evenly dispersed and centrifugally move, wherein, at the moment, the hydrocarbon groups produced by the decomposed natural gas are deposited on the surfaces of the glass fibers and grow to a diamond-like carbon film, and composite fibers, i.e. the diamond-like carbon film covered glass fibers are formed and are regularly discharged; 6) repeating step 1 to step 5; and 7) after the production is finished, closing all valves and shutting down the microwave and the engine. The composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fibers provided by the invention has the advantages of low cost, simplicity in implementation and convenience in operation.

Owner:LANZHOU UNIVERSITY

Simulation and prediction method for dynamic evolution of sand fluid production profile in horizontal wells in heterogeneous reservoirs

ActiveCN113591421BEnsure efficient productionImprove erosion resistanceGeometric CADDesign optimisation/simulationThermodynamicsHorizontal wells

The invention discloses a method for simulating and predicting the dynamic evolution of the sand fluid production profile of a horizontal well in a heterogeneous reservoir, and relates to the technical field of oil and gas exploitation engineering. Using the method provided by the invention, the evolution process of the sand fluid production profile can be simply and quickly simulated and predicted. The production profile of formation fluid and formation sand under given production conditions and production time provides key production locations for the design of horizontal well sand control and water control strings, that is, key control well sections and positions, and provides the purpose of sand control and water control and combined effects. The method provided by the present invention can quickly identify the high-speed inflow position of the horizontal well in the heterogeneous reservoir, judge the high erosion occurrence position of the sand control and water control completion screen, guide the optimization of the screen structure, and use it in the high erosion risk position High anti-erosion screen improves the comprehensive anti-erosion ability of the well completion screen. In addition, the local inflow coefficient provided by the present invention can be used to quickly calculate the highest flow velocity at the actual local high-speed inflow position, which is used for prediction and prevention of erosion damage rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

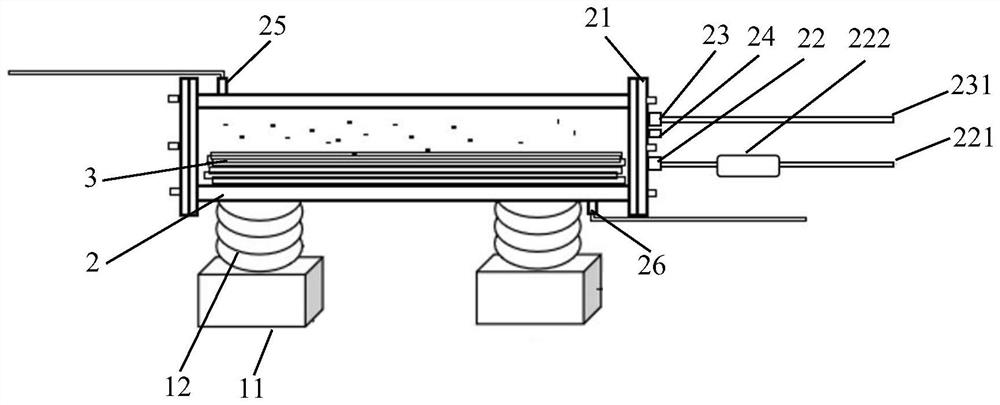

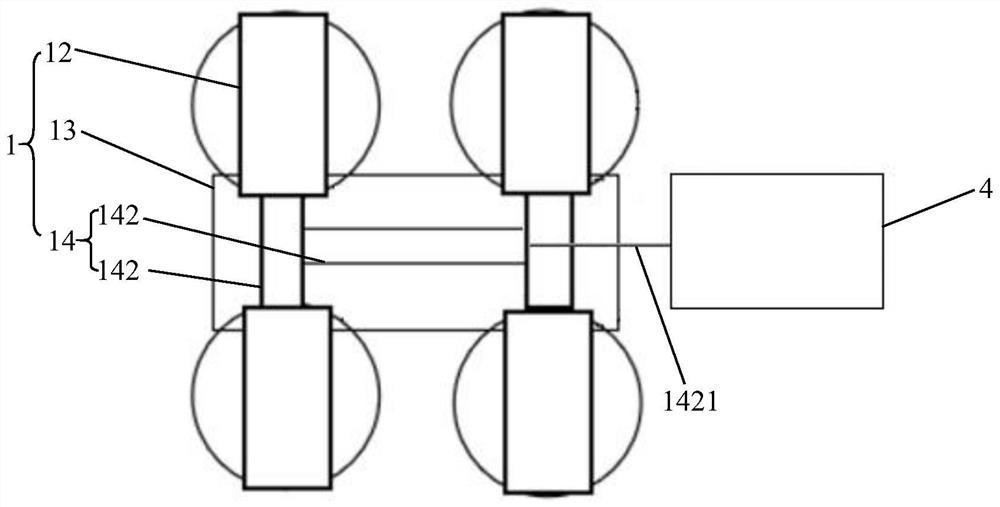

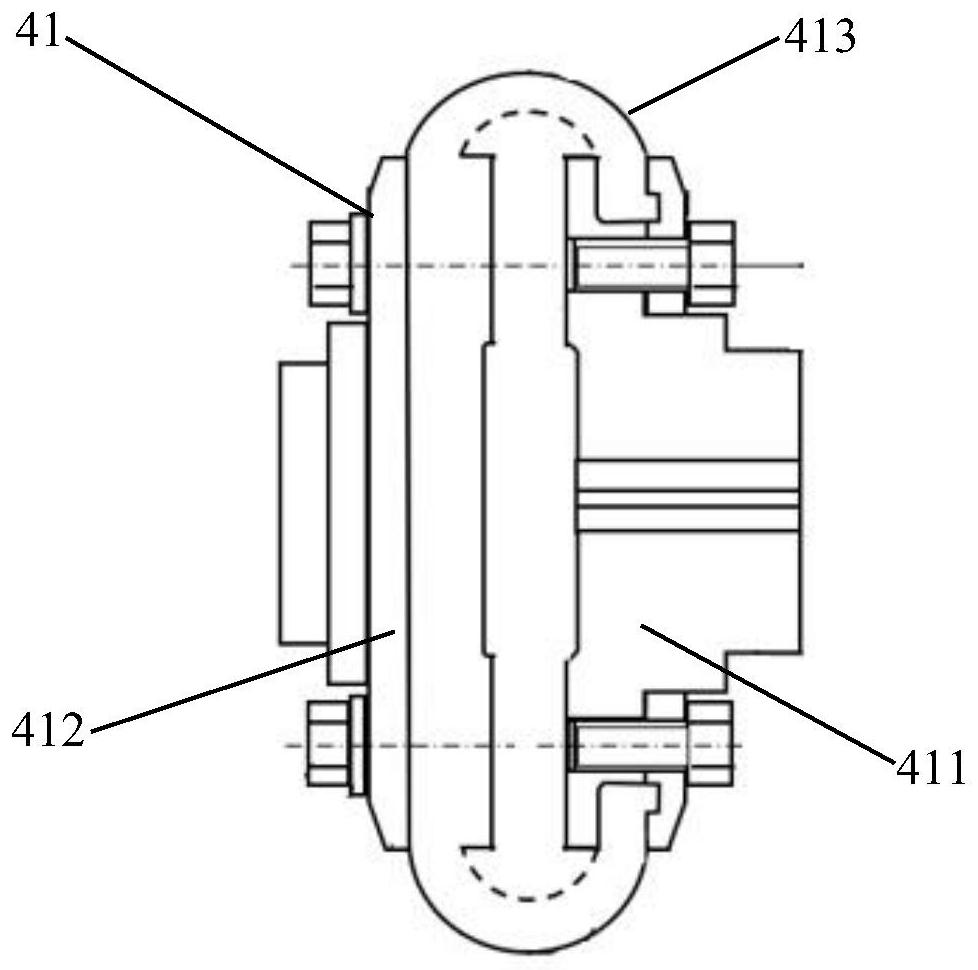

High-energy grinding machine and using method thereof

The invention discloses a high-energy grinding machine and a using method thereof. The high-energy grinding machine comprises a base, an adjustable vibration mechanism, a grinding tank, a driving mechanism and a control system. The driving mechanism provides power for the adjustable vibration mechanism, the adjustable vibration mechanism vibrates to drive the grinding tank to grind, the rotating speed of the driving mechanism can be controlled through the control system, the grinding state of the grinding tank is monitored in real time, and the grinding state is transmitted to the mobile terminal; the invention further discloses a corresponding use method, and relates to the technical field of powder metallurgy, in particular to a high-energy grinding machine for industrial production and scientific research and development and a use method of the high-energy grinding machine.

Owner:陕西智奇开物新材料有限公司

Resource Scheduling Method and System

ActiveCN113988727BGuaranteed personalized purchasesEnsure efficient productionResourcesMarket data gatheringPersonalizationBusiness enterprise

This application relates to the field of network information technology. Aiming at the problem of product design and manufacturing based on user portraits in the prior art, a resource scheduling method and system are provided to achieve user satisfaction with products, efficient production by enterprises, and timely provision by resource suppliers. purpose of the resource. By coordinating user portraits, product portraits and resource portraits, this application can ensure the efficient production of personalized products for users and the personalized procurement of resources. At the same time, according to the personalized design of products, resource requirements are formed, and resource portraits are established to be transmitted to resource supply. Provide resource allocation reference for resource suppliers to quickly supply. This application closely combines users, enterprises and resource suppliers, and under the drive of multi-modal data, it performs multi-subject portrait technology to realize the precise allocation of users, products and resources.

Owner:QINGDAO HAIER INST OF IND INTELLIGENCE CO LTD +2

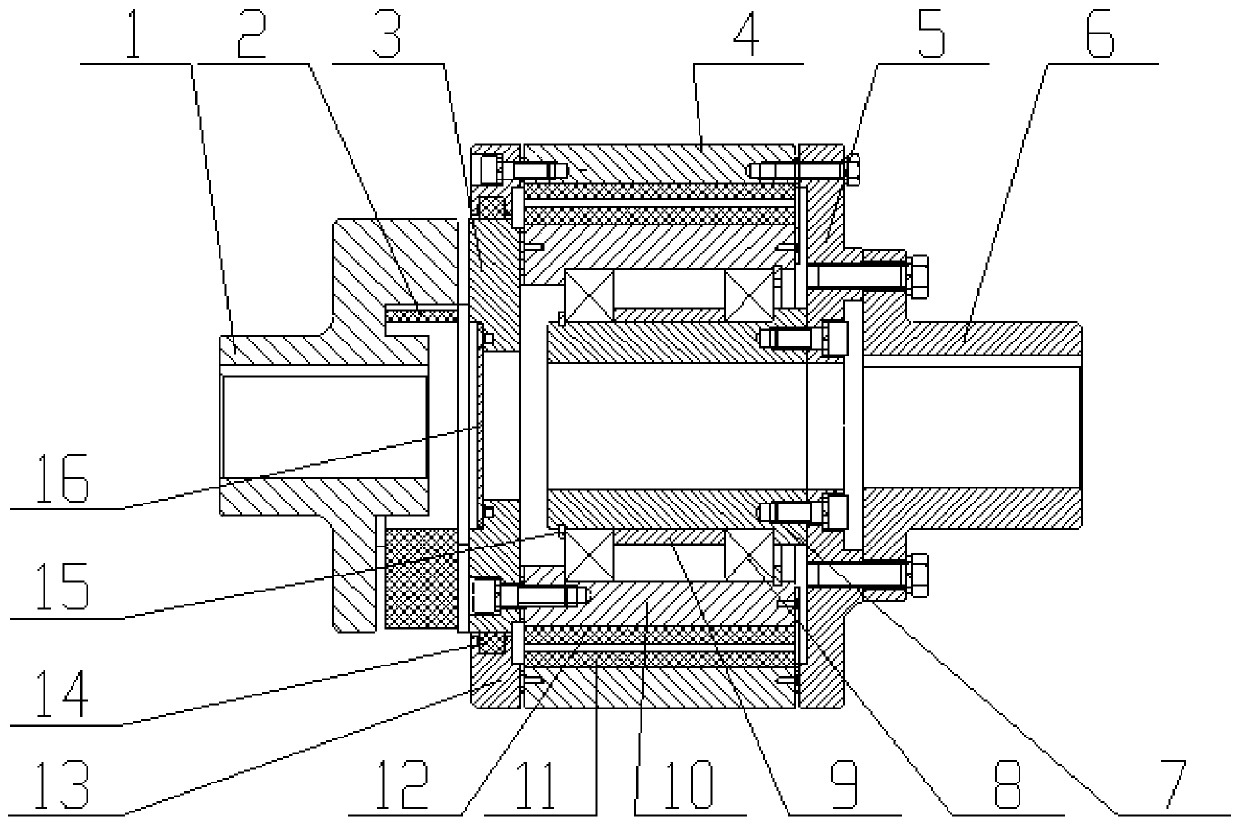

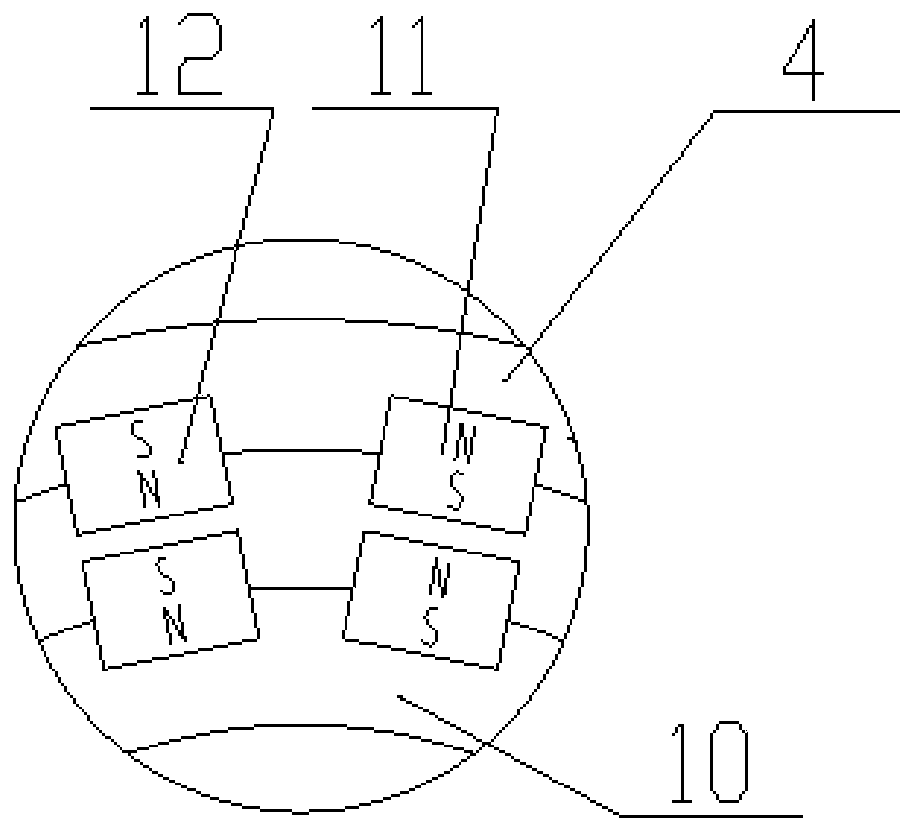

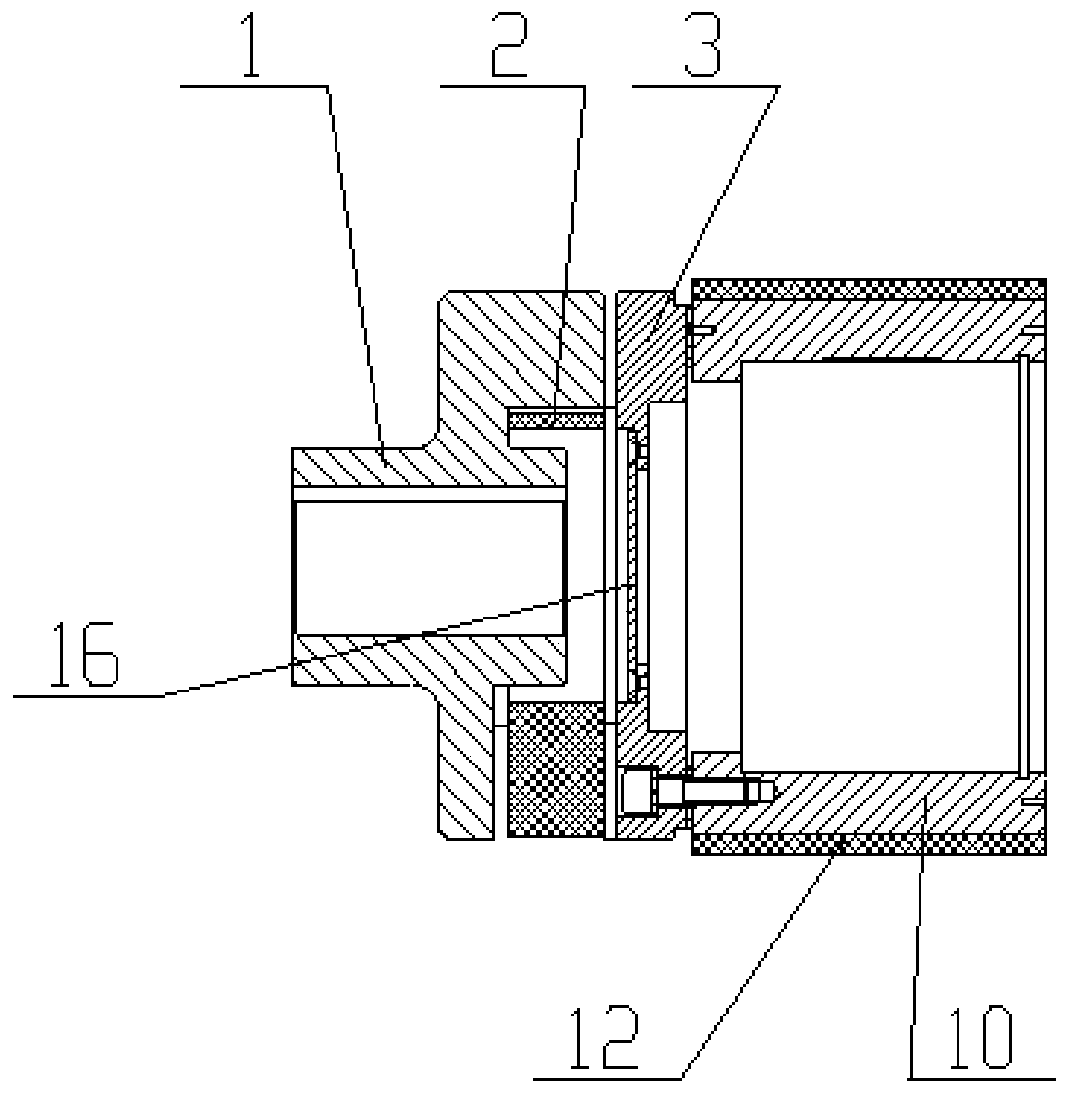

Air gap fixed type synchronous permanent magnet coupler

PendingCN111106736AVibration isolation and low noiseContactless transmissionPermanent-magnet clutches/brakesMechanical energy handlingEngineeringMagnet

The invention belongs to the technical field of permanent magnet transmission, and relates to an air gap fixed type synchronous permanent magnet coupler which comprises an inner rotor. The inner rotoris connected with the end face, close to the input end, of an input connecting disc. The coupler comprises an outer rotor which is connected with the end face, close to the input end, of an output connecting disc. The inner rotor is installed in the outer rotor. The inner rotor and the outer rotor are coaxially arranged, and an air gap is formed between the outer ring face of the inner rotor andthe inner ring face of the outer rotor. The coupler comprises an output end connecting piece which is fixedly connected with the output connecting disc. The output end connecting piece extends into the inner rotor, and the outer ring surface of the section, located in the inner rotor, of the output end connecting piece is circular and is coaxial with the inner rotor. The coupler comprises a bearing assembly which is installed between the outer ring surface of the output end connecting piece and the inner ring surface of the inner rotor, and the bearing assembly is used for rotatably positioning and supporting the output end connecting piece and the inner rotor. The permanent magnet coupler can realize relative fixation of positions, namely air gaps, between the inner rotor and the outer rotor, and avoids the problem of collision caused by displacement during operation.

Owner:CCTEG SHENYANG RES INST

Method of producing an electrically conductive roller from a rubber foam tube

InactiveUS9588454B2Improve production yieldEnsure efficient productionElectrographic process apparatusTubular articlesMicrowaveEngineering

A rubber foam tube (5) is produced by extruding a rubber composition into a tubular body (4) and feeding the tubular body (4) in an elongated state without cutting to pass the tubular body (4) through a microwave crosslinking device (8) and then through a hot air crosslinking device (9) for continuously foaming and crosslinking the rubber composition. At this time, a ratio V2 / V1 between a speed V2 at which the tubular body (4) passes through the hot air crosslinking device (9) and a speed V1 at which the tubular body (4) passes through the microwave crosslinking device (8) is not less than 1.0 and not greater than 1.6.

Owner:SUMITOMO RUBBER IND LTD

A cnc six-axis linkage machining device for bathroom castings

ActiveCN104227562BEnsure efficient productionRealization of profiling compound processingBelt grinding machinesGrinding work supportsNumerical controlBody positions

The invention relates to a CNC (Computer Numerical Control) six-axis linked sanitary casting machining device. The CNC six-axis linked sanitary casting machining device is characterized in that the device comprises a body big plate (1), fixtures and body positioning pins (2); the number of the fixtures is six, the six fixtures are installed on the body big plate (1), the number of the body positioning pins (2) is four, and the four body positioning pins are located at the four corners of the body big plate (1) and are used for positioning the body big plate (1); each fixture comprises a first cross-shaped positioning key (3), a left valve chamber positioning device (4), a water inlet positioning device (5), a water inlet positioning sleeve (6), a right valve chamber positioning device (7) and an eccentric cam mechanism (8).

Owner:黑龙江北鸥卫浴用品有限公司

Whole network distributed heat storage heating system and method

ActiveCN108895514BMeet peak shaving needsSmall adjustment rangeCentral heating with accumulated heatLighting and heating apparatusControl systemEngineering

The invention relates to a whole network distributed heat storage and supply system and method and belongs to the field of heat storage and supply systems. The whole network distributed heat storage and supply system is characterized by comprising a heat supply system, a heat storage system, a control system and a management and control platform, wherein the heat supply system is connected to theheat storage system, and the control system is separately connected to the heat supply system, the heat storage system and the management and control platform; the heat storage system includes a heatstorage tank, an electric shut-off valve, an electric regulating valve and a circulating water pump, wherein a cold water end and hot water end of the heat storage tank are separately connected to theheat supply system through the electric shut-off valve, the electric regulating valve and a circulating water pump. The whole network distributed heat storage and supply system and method have the advantages that novel heating systems of heat storage devices are installed on positions such as users' houses, heat exchange stations, pipe networks, renewable energy source areas, thermal power plantsand regional boiler rooms, and through the mode of combining user sides, pipe network sides and heat source sides for heat storage, not only are the needs of heat sources for peak shaving met, but also the advantages of being narrow in adjustment range, closer to the users, higher in flexibility and the like are achieved.

Owner:大连海心信息工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com