Converter lining cooling method and cooling system

A cooling method and converter lining technology, applied in the manufacture of converters, etc., can solve the problems of slow cooling rate of converter lining, long working cycle of converter, unfavorable high-efficiency production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

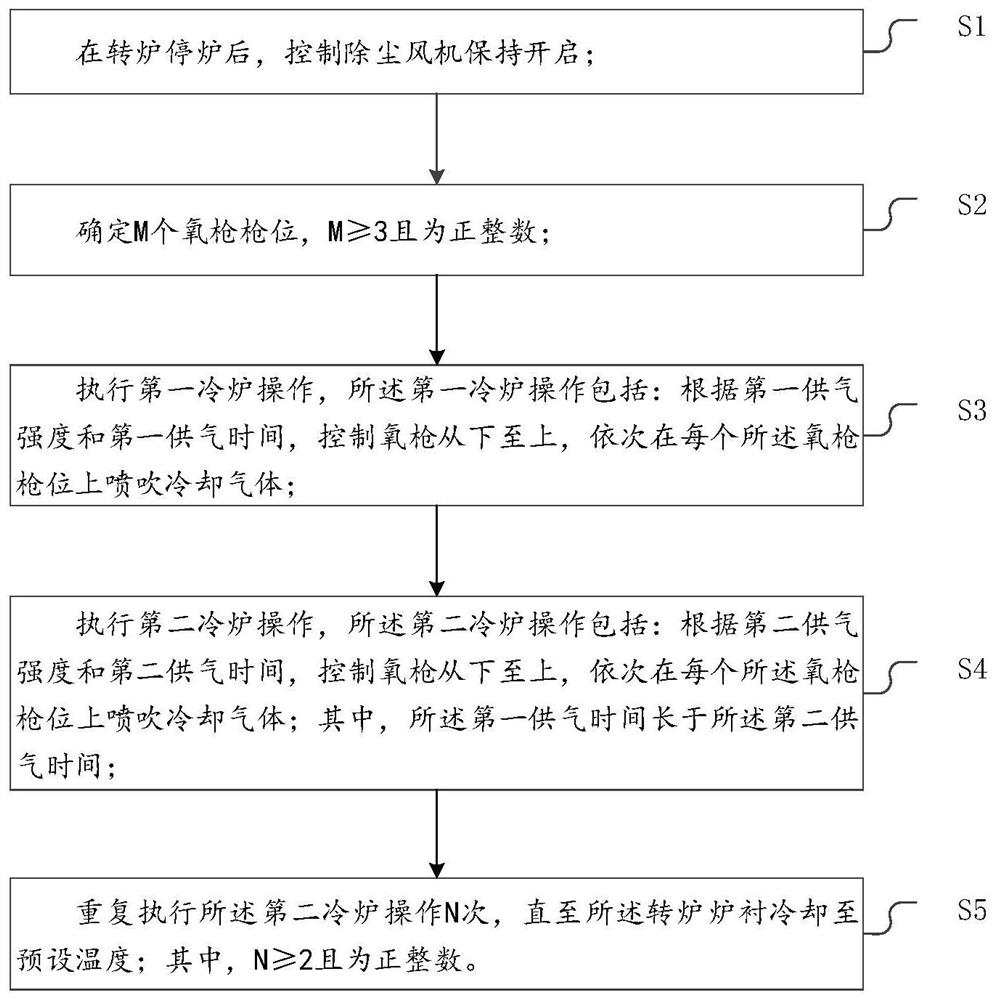

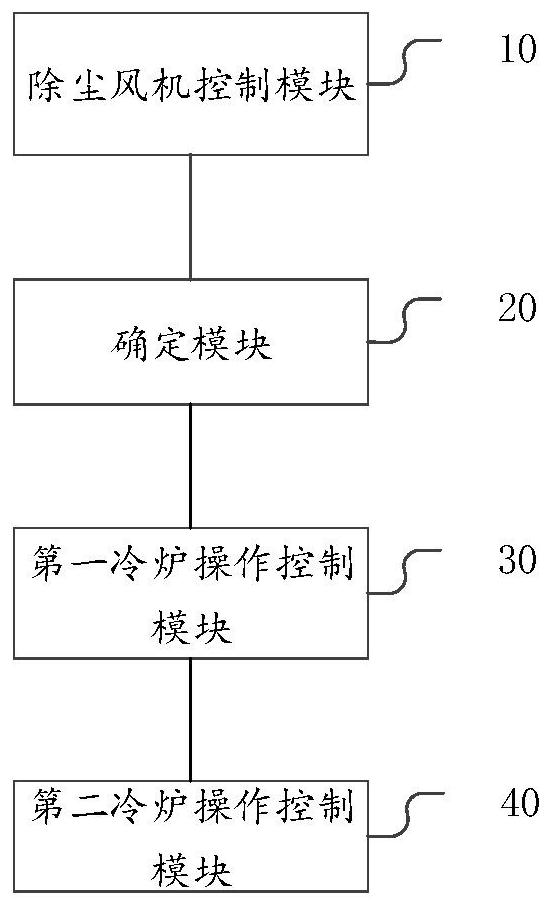

Method used

Image

Examples

Embodiment 1

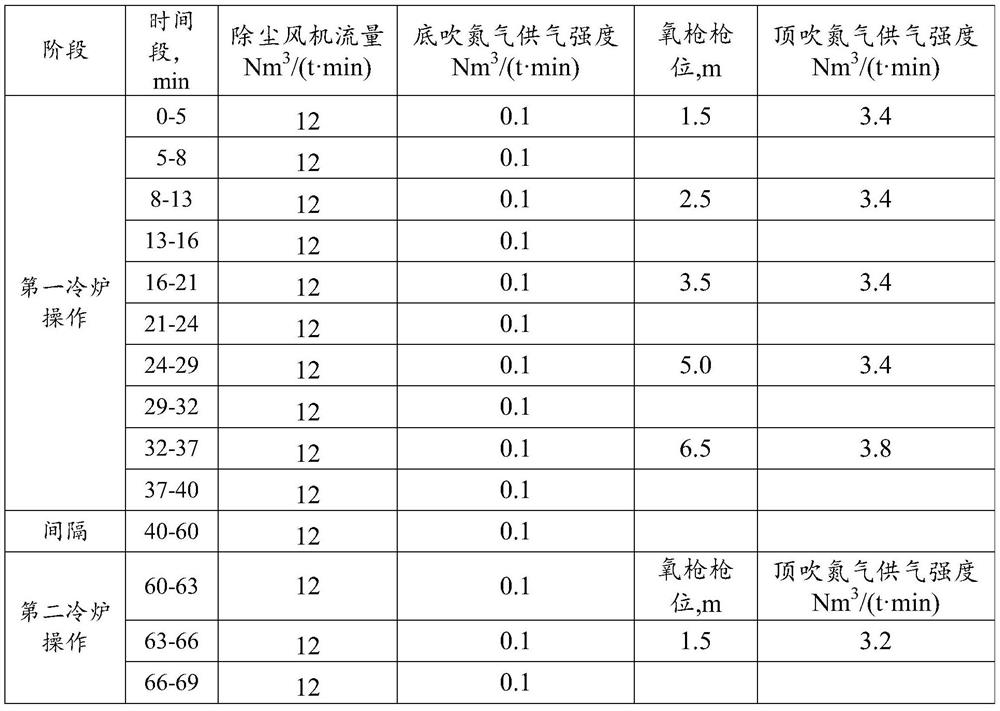

[0063] For a 210t converter, during the cooling process of the converter, the angle of the converter is controlled to be 0°; the operating control parameters of the cold furnace are shown in Table 1, where the row of the cell whose oxygen lance position is empty represents two adjacent oxygen lances interval between bits.

[0064] Table 1: Converter cooling control parameters of Example 1

[0065]

[0066]

Embodiment 2

[0068] For a 100t converter, during the cooling process of the converter, the angle of the converter is controlled to be 0°; the operating control parameters of the cold furnace are shown in Table 1:

[0069] Table 2: Converter Cooling Control Parameters of Embodiment 2

[0070]

[0071]

Embodiment 3

[0073] For the 300t converter, during the cooling process of the converter, the angle of the converter is controlled to be 0°; the operating control parameters of the cold furnace are shown in Table 1:

[0074] Table 3: Converter Cooling Control Parameters of Embodiment 3

[0075]

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com