Water purification station for underground mine

A water purification and mining technology, applied in the field of underground mining water purification stations, can solve problems such as incomplete backwashing, insufficient sewage discharge, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

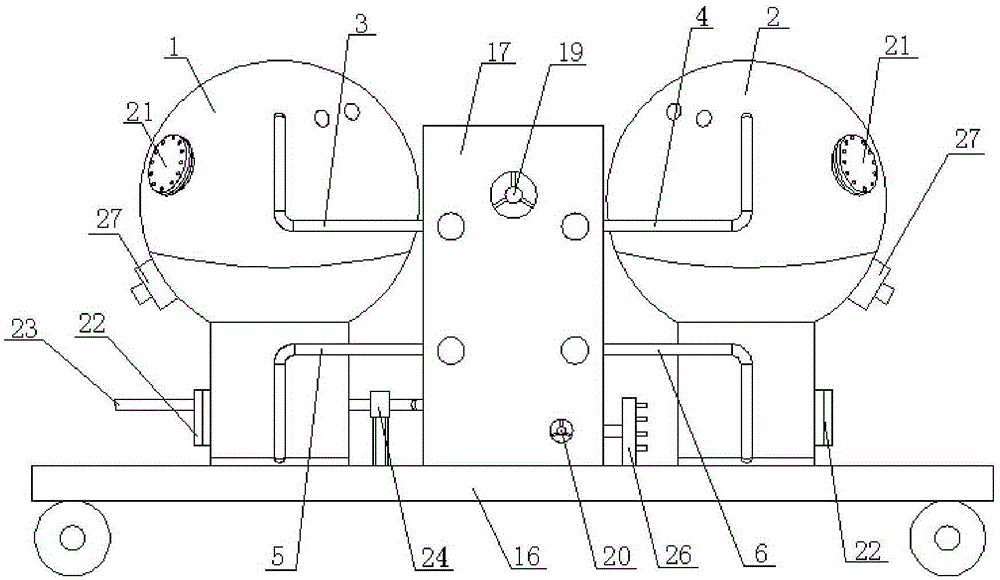

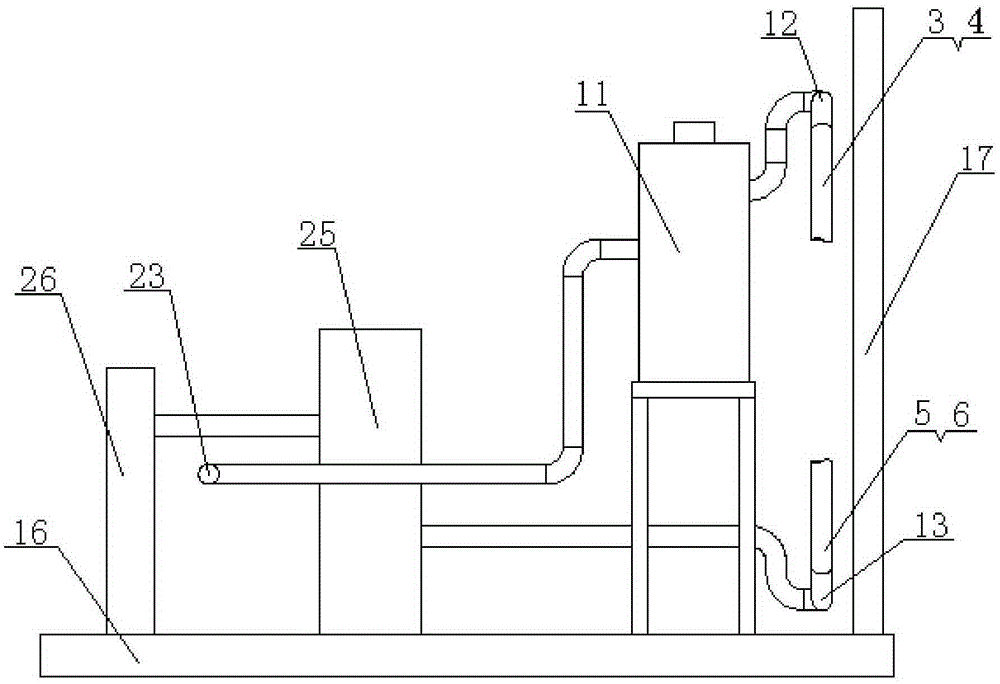

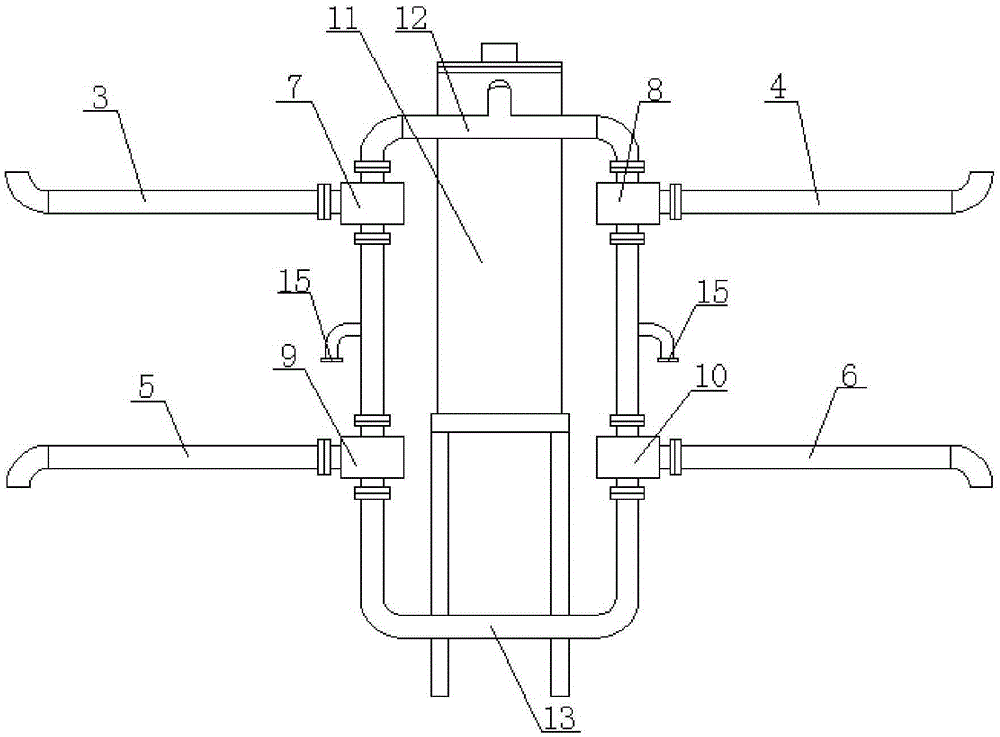

[0019] Such as figure 1 , 2 , Shown in 3, the underground mine water purification station of the present invention comprises two identical A, B tank bodies 1,2, and A, B tank bodies 1,2 are fixedly installed on the base plate 16 by pillars respectively, and the bottom of the base plate 16 Symmetrical installation of four rollers is convenient for moving A and B tanks 1 and 2. The upper half of A and B tanks 1 and 2 are spheres, the lower half are cylinders, and the diameter of the spheres in the upper half is Greater than the diameter of the lower half of the cylinder, the sphere parts of A and B tanks 1 and 2 are all provided with observation windows 21, and the cylinder parts are all provided with feeding ports 22, and the observation windows 21 are convenient to observe the water level in the tank at any time. The setting of feed opening 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com