Patents

Literature

41results about How to "Backwash thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

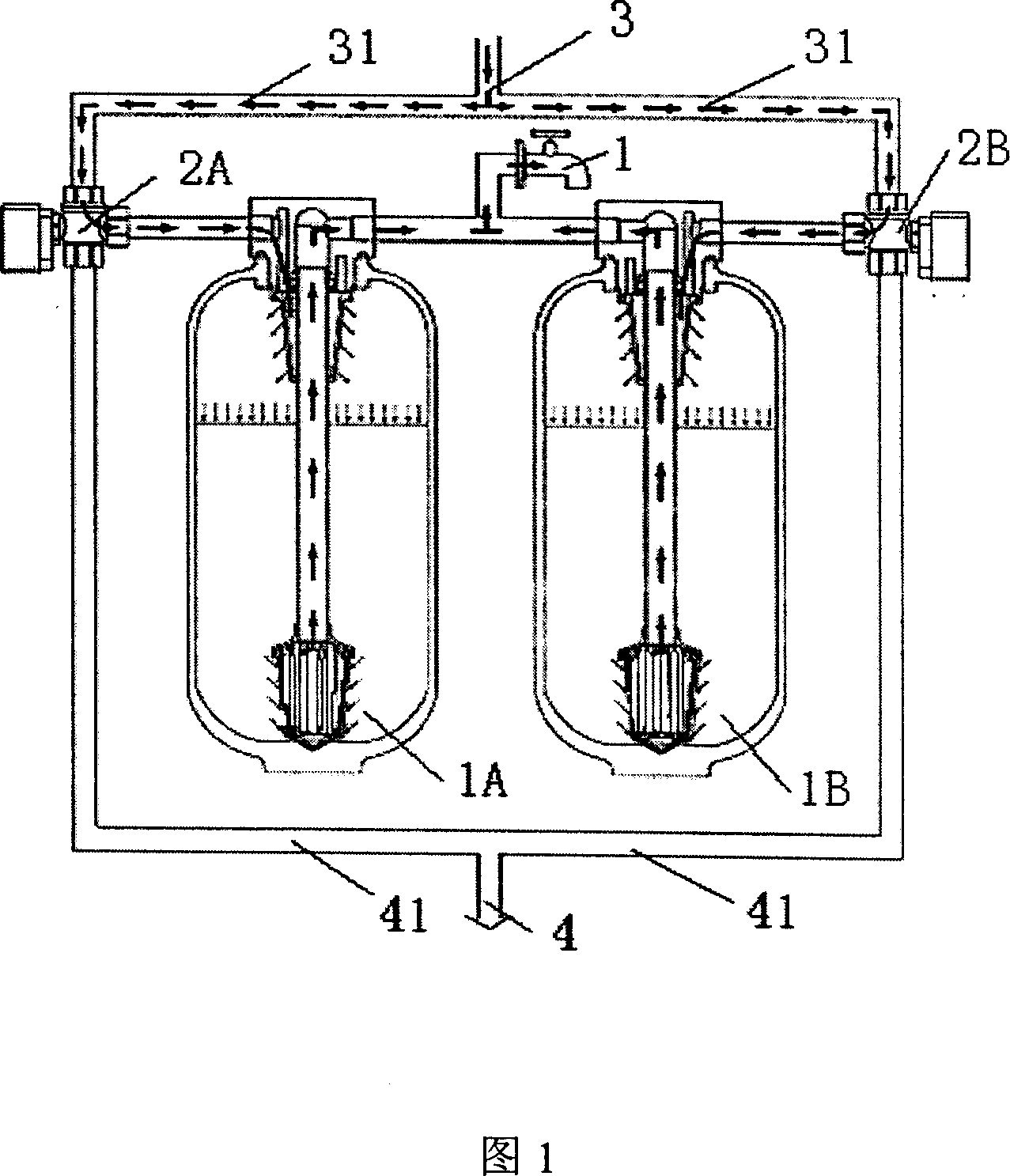

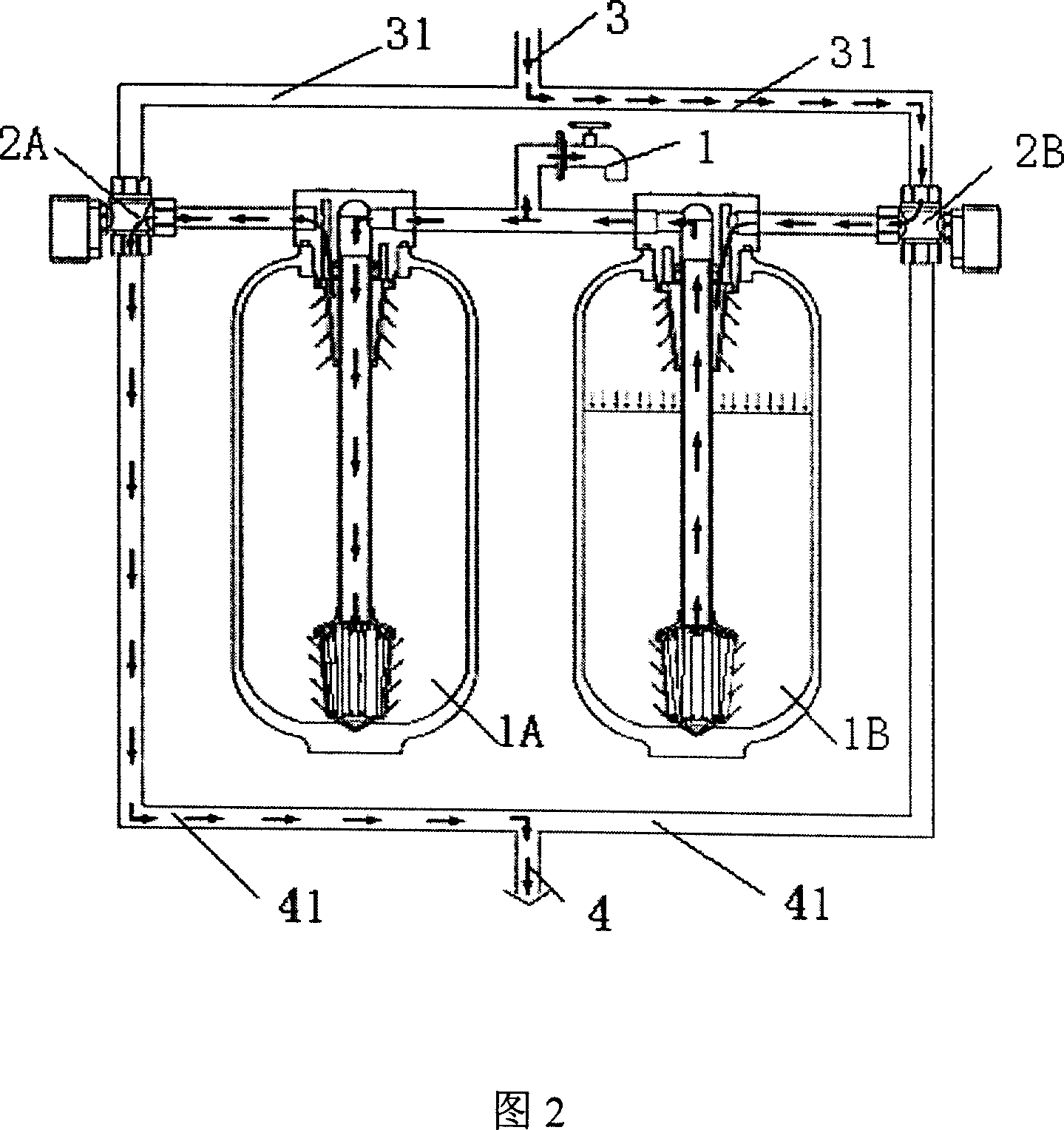

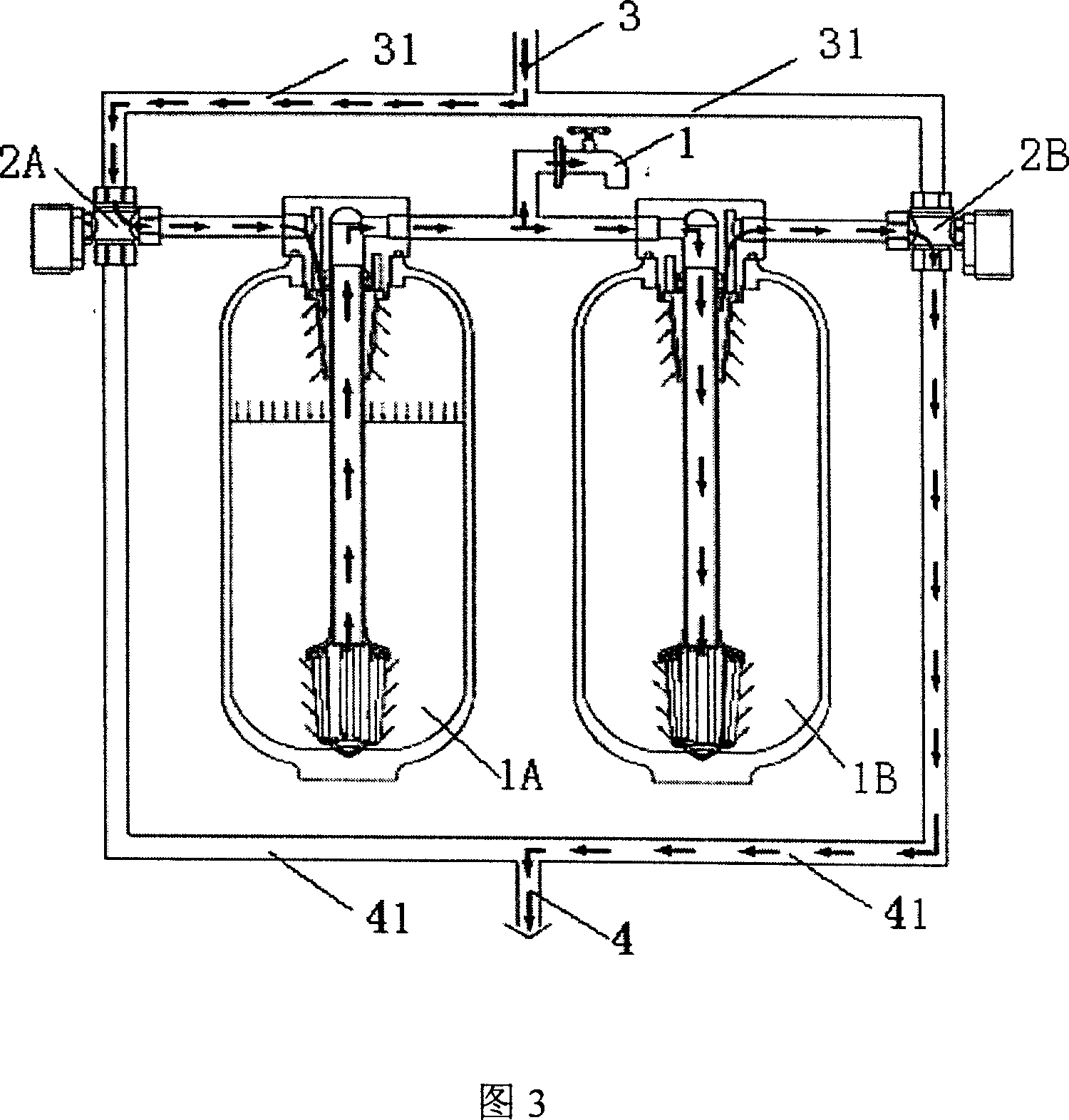

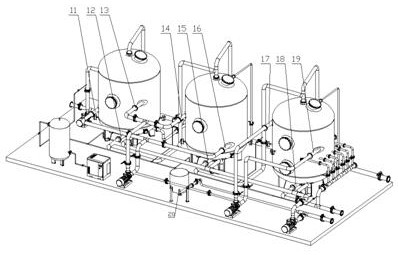

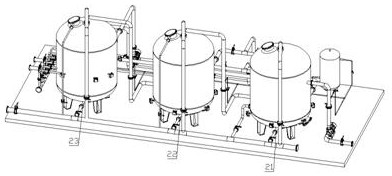

Water purifying appliance

InactiveCN101032673ARecovery responseRestore adsorption capacityWater/sewage treatmentFiltration circuitsWater qualityEnvironmental engineering

The water purifying machine includes at least two water purifying tanks connected in parallel and with parallel draining pipes connected to the water inlet pipes. It can provide purified water in 24 hr a day including the time during reverse rinsing, and has effective complete reverse rinsing to ensure high water quality, long filter material life and low use cost.

Owner:CANATURE HEALTH TECH GRP CO LTD

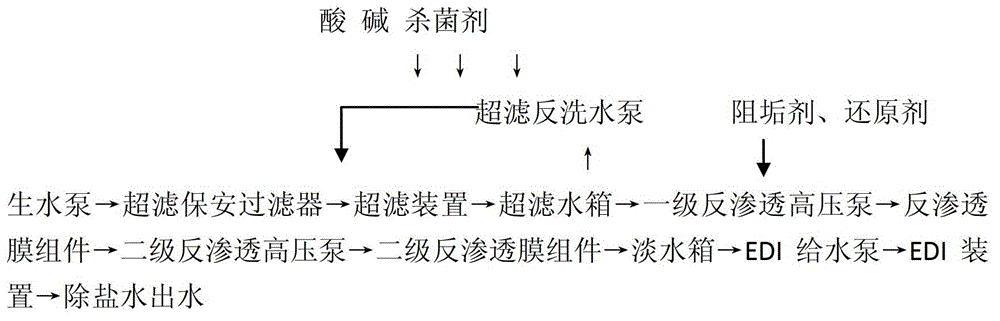

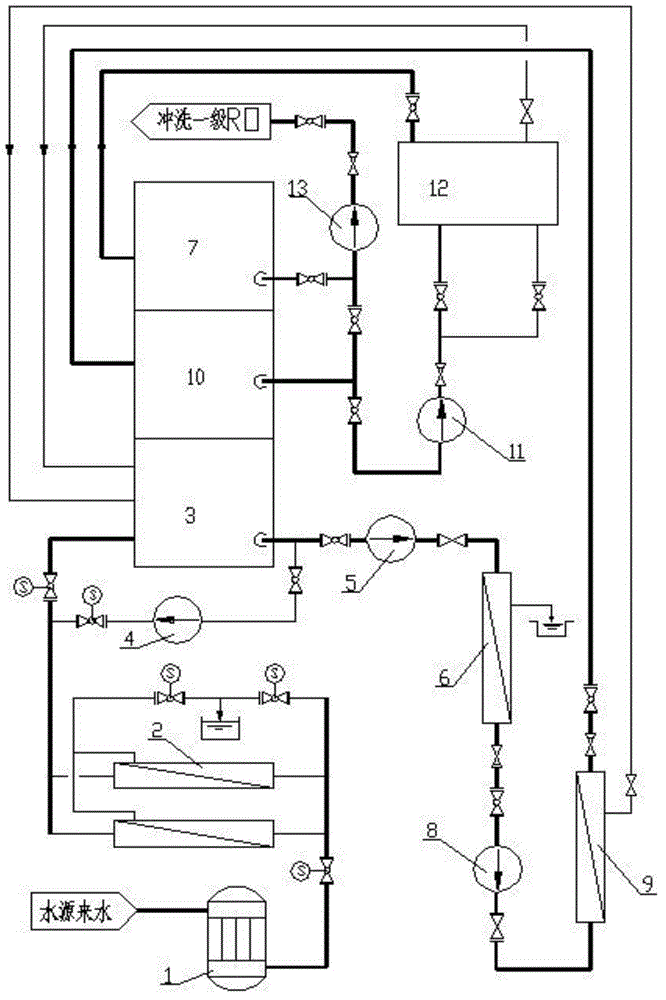

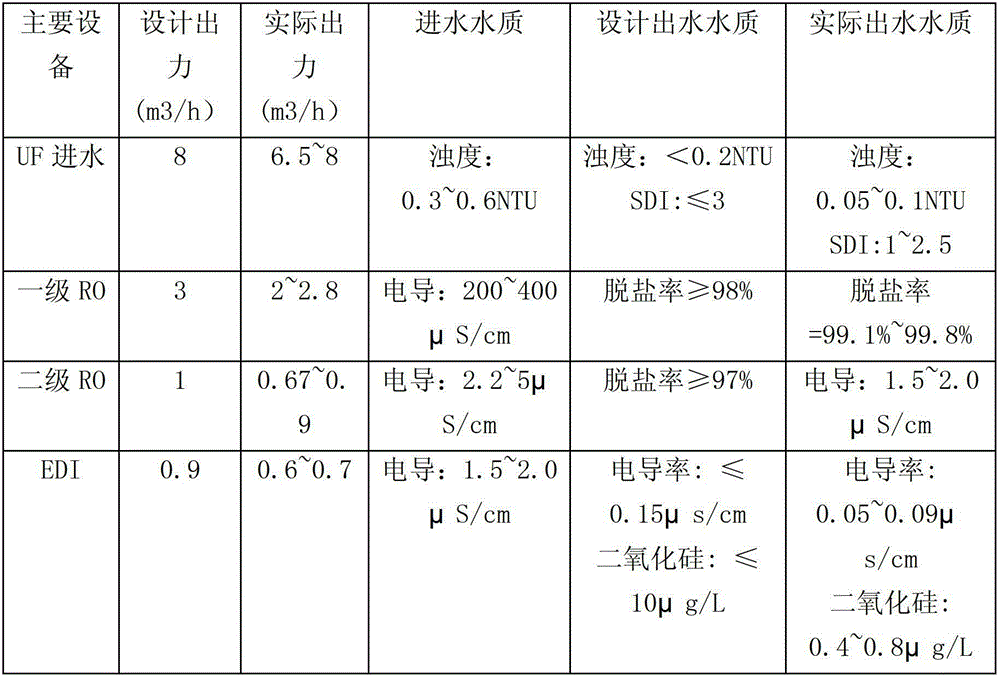

Whole-membrane-process water treatment integration device

InactiveCN102942265AMaximize utilizationAdaptive to water quality fluctuationsMultistage water/sewage treatmentSaline waterFiltration membrane

The invention discloses a whole-membrane-process water treatment integration device. The whole-membrane-process water treatment integration device is characterized in that 'whole-membrane-process' water treatment components are integrated into a small-size device, and comprise a raw water pump, an ultra-filtration safety filter, an ultra-filtration membrane component, an ultra-filtration water tank, an ultra-filtration backwashing water pump, reverse-osmosis high-pressure pumps, reverse-osmosis membrane components, a fresh-water tank, an EDI (Electrodeionization) water feeding pump, an EDI membrane block, an acid dosing device, an alkali dosing device, a bactericide device, a scale inhibitor device, a reducing-agent device, a valve, pipelines and a PLC (Programmable Logic Control) control system; the ultra-filtration device consisting of the raw water pump, the ultra-filtration safety filter and the ultra-filtration membrane component, the ultra-filtration water tank, the first-stage reverse-osmosis high-pressure pump, the reverse-osmosis membrane component, the second-stage reverse-osmosis high-pressure pump, the second-stage reverse-osmosis membrane component, the fresh-water tank, the EDI water feeding pump and the EDI device are connected by the pipelines in the following sequence till the desalting water is discharged; and the ultra-filtration backwashing waterpump is arranged to be connected with the ultra-filtration membrane component for backwashing; and the acid dosing device, the alkali dosing device and the bactericide device are respectively connected to the ultra-filtration device.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

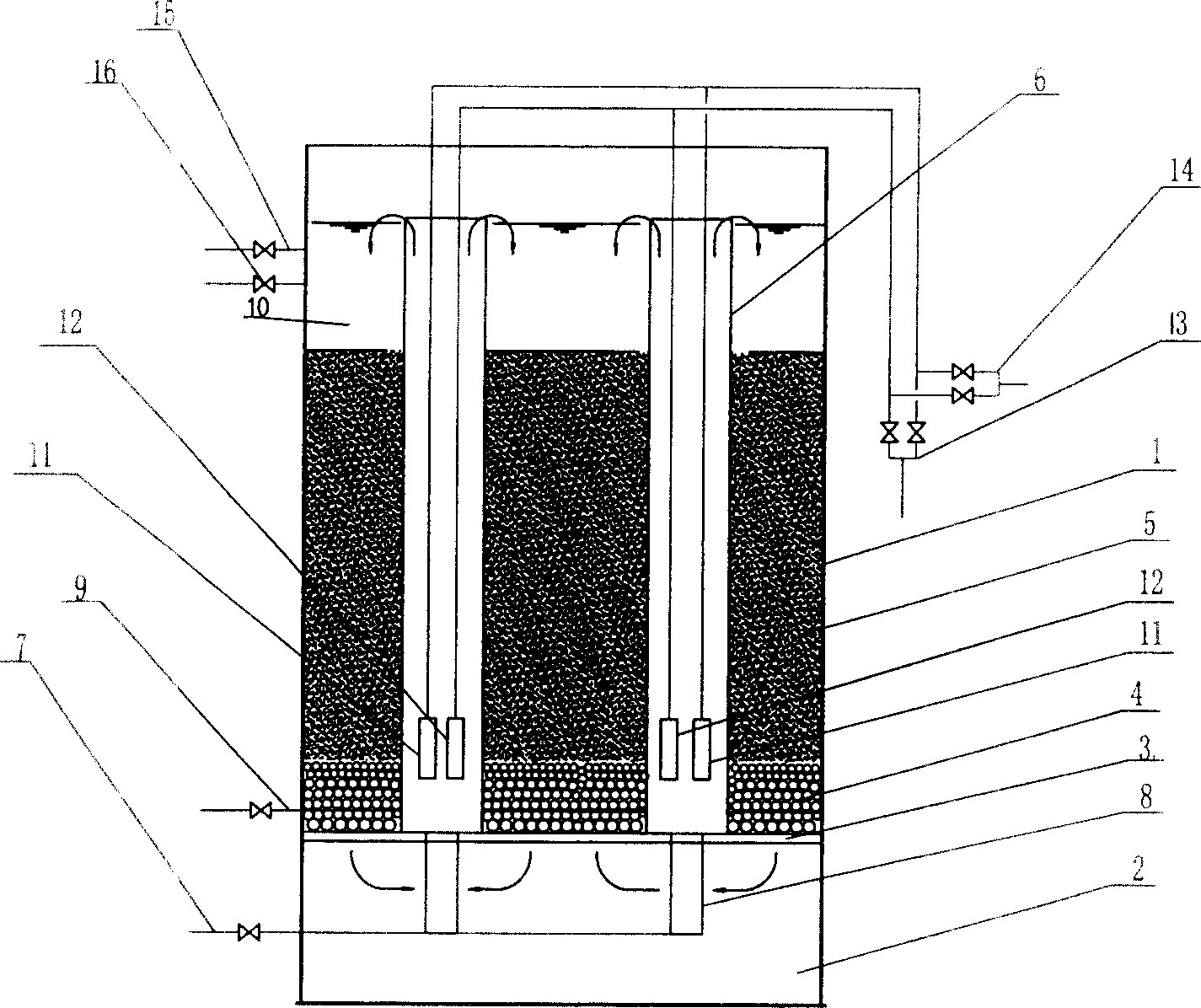

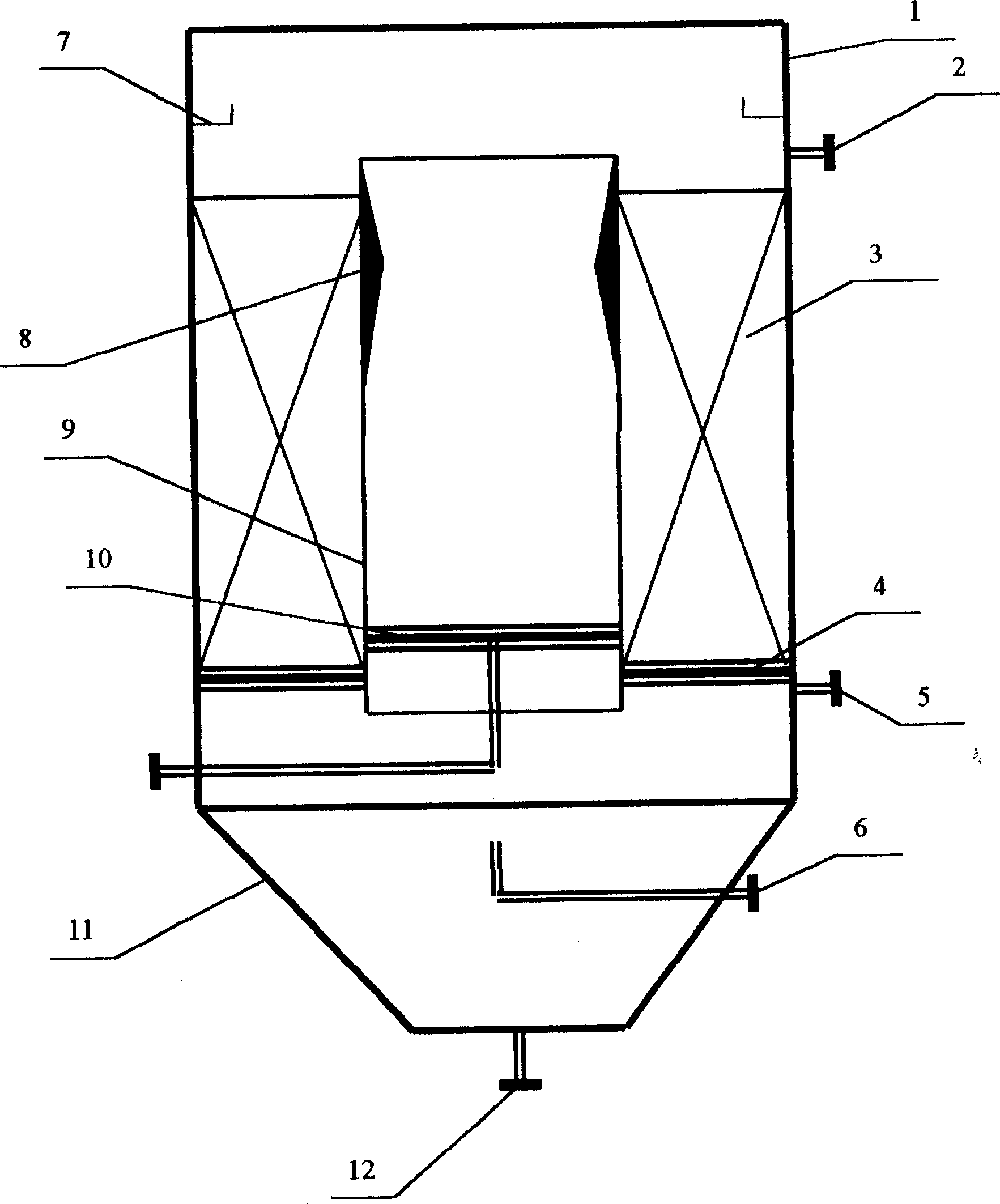

Biological reactor with internal circulating double filtering

InactiveCN1693230AImprove dirt holding capacityIncrease shock loadTreatment using aerobic processesSustainable biological treatmentActivated sludgeWater quality

A bioreactor with internal with internal circulation and dual filters for treating sewage is composed of water distributing chamber with water distributor, bearing plate, bearing layer, fitlering layer and cyclic aerating cylinder with filter-water outlet unit. The sewage is circulating through said water distributor, cycle aerating cylinder and filter layer, and is filtered by filter layer and the filter-water outlet unit.

Owner:魏刚 +2

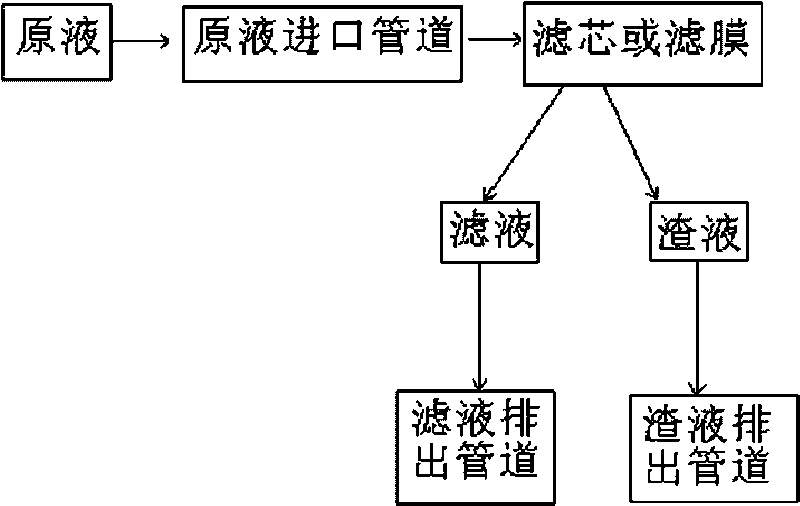

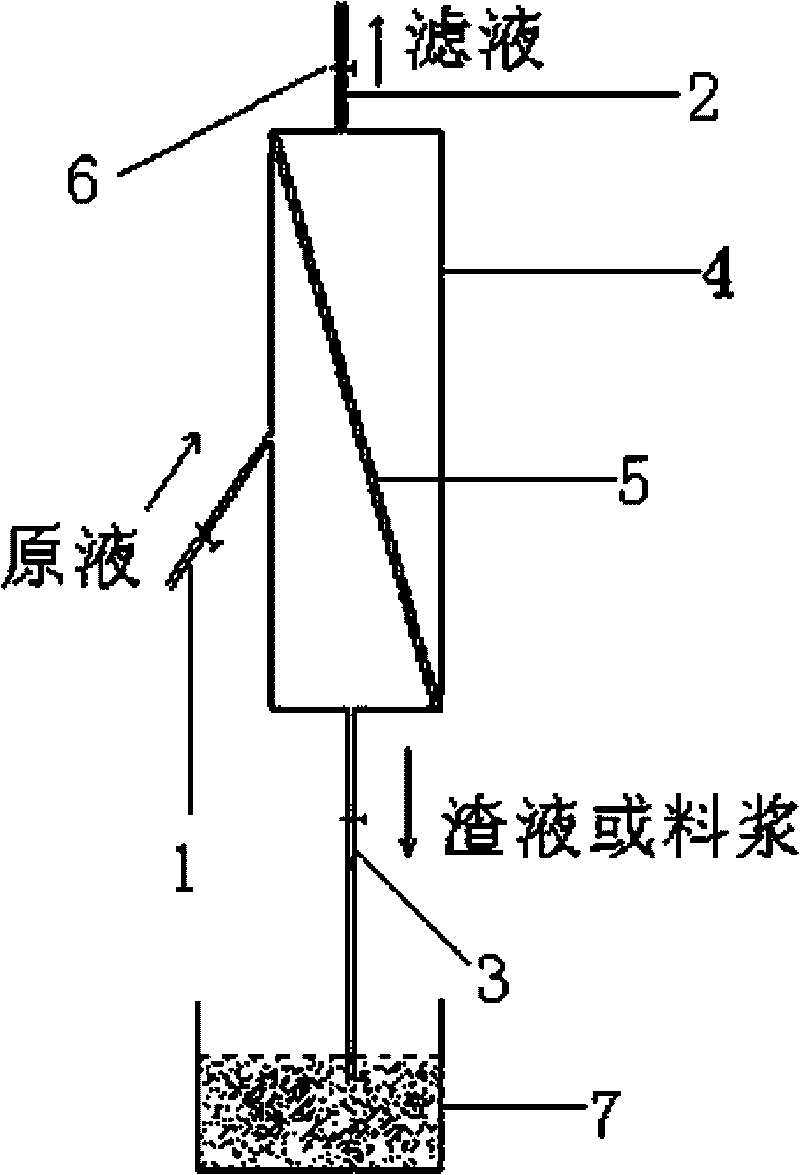

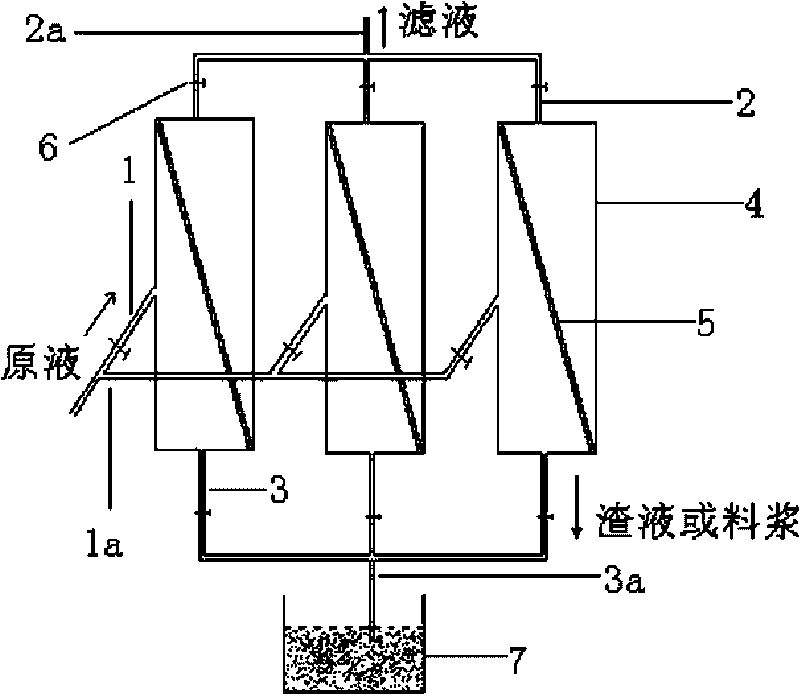

Method for liquid filtration

InactiveCN101716440AIncrease productivityReduce production energy consumptionTitanium halidesFiltration circuitsChemical reactionSlag

The invention relates to a method for liquid filtration and belongs to the field of separation. The invention aims to solve a technical problem of providing a liquid filtration method that can improve liquid filtration efficiency. The method for liquid filtration comprises the following steps: allowing raw liquid to enter a filter from a raw liquid inlet pipe of the filter to be filtered by a filter element or filter membrane and obtaining filtrate and slag liquid, wherein the filtrate is discharged from a filtrate discharge pipe, and the slag liquid is discharged from a slag liquid discharge pipe; and hermetically sealing the outlet of the slag liquid discharge pipe by using a liquid seal device and discharging the slag liquid into the liquid seal device from the slag liquid discharge pipe. The method prevents the air from entering the filter, so that the air does not undergo chemical reaction with the substances in the filter and the filtration effect is improved. The method of the invention can synchronously realize production and backwashing and avoids external power supply during backwashing. In the method of the invention, the liquid in the filter generates a concentration gradient during backwashing, so the backwashing is more complete.

Owner:CHENGDU INTERMENT TECH

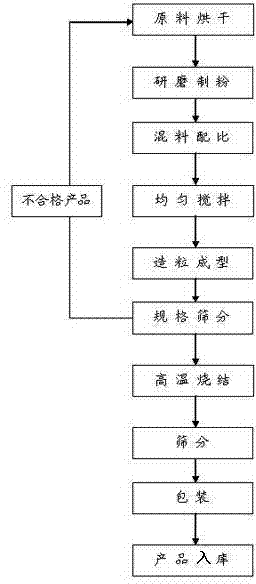

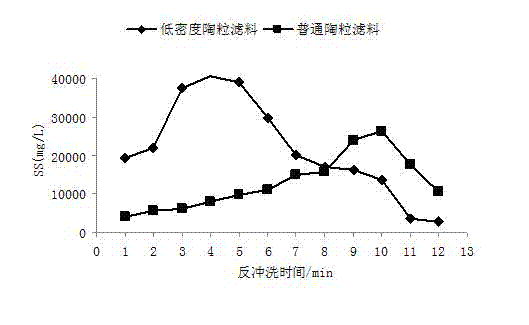

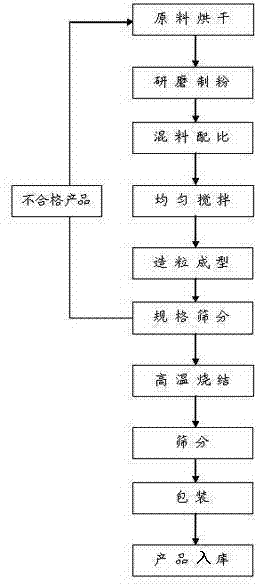

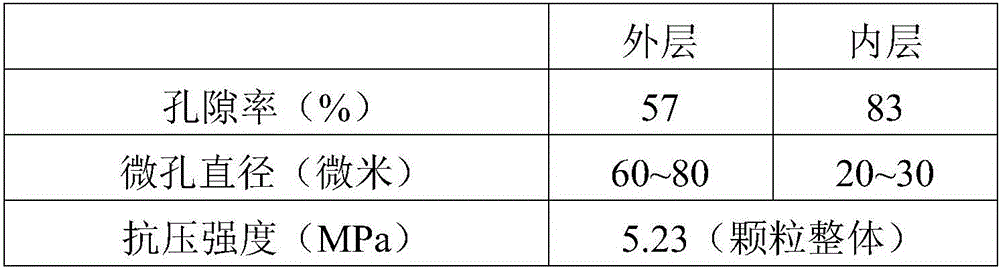

Low-density ceramsite filter material for biological aerated filter and preparation method thereof

InactiveCN102258913AReduce energy consumptionLow water consumptionSustainable biological treatmentFiltration separationFilter materialHigh surface

The invention relates to a low-density ceramsite filter material for a biological aerated filter, and a preparation method thereof. The invention provides the low-density ceramsite filter material for the biological aerated filter, and the low-density ceramsite filter material is mainly prepared from Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and a charcoal material. Theinvention also provides a preparation method for the low-density ceramsite filter material. The invention has the advantages that: the Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and charcoal powder are used as raw materials, so that the excellent physical properties such as a large specific surface area, and high surface roughness and mechanical strength and the like of the low-density conventional heavy ceramsite filter material are kept, the density of the low-density ceramsite filter material is reduced well so as to reduce energy consumption during backwashing, contribute to complete backwashing, and avoid the problem that the filter material is hardened during long-term running and the like, the production cost and the waste water treatment cost are greatly reduced, and the popularization and application of the biological aerated filter process can be facilitated.

Owner:谭海燕

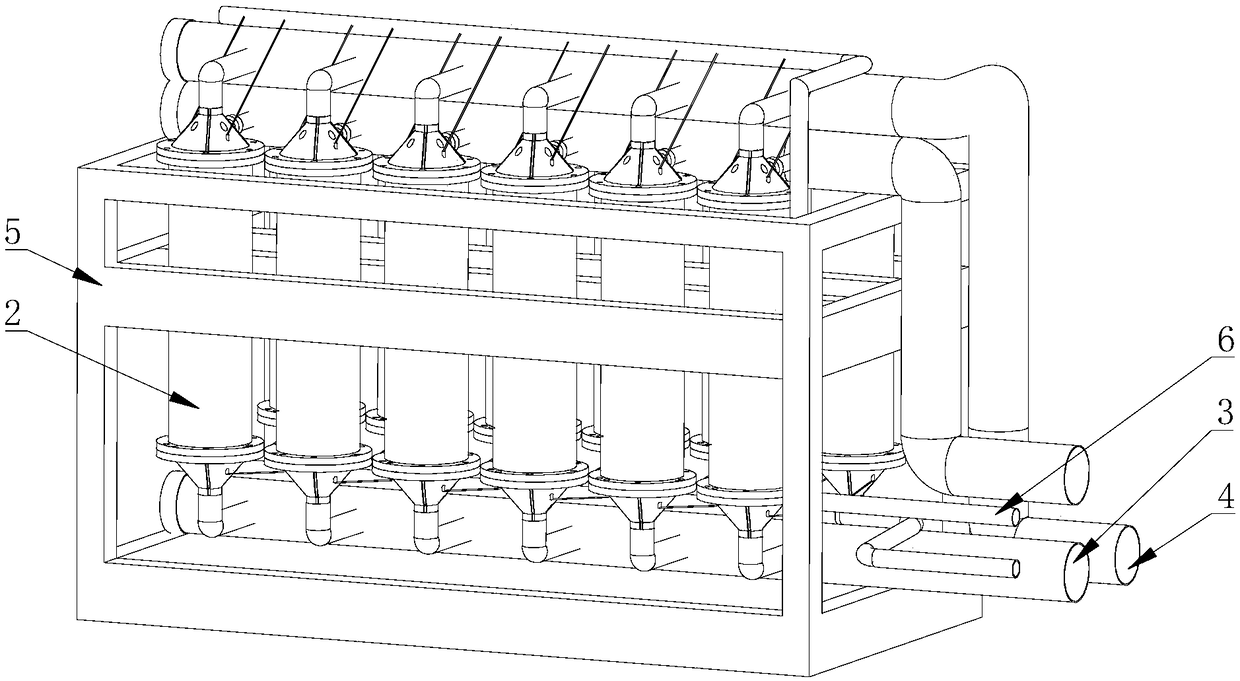

Modularized membrane capacitance deionizer

InactiveCN108217866ALarge amount of processingImprove removal efficiencyDispersed particle separationWater/sewage treatment apparatusCapacitanceEngineering

The invention relates to the technical field of water treatment and particularly relates to a modularized membrane capacitance deionizer which is provided with a water inlet pipe, a water outlet pipe,a power transmission line pipe and a plurality of arrayed CDI membrane component modules, wherein the bottom of each CDI membrane component module is provided with a water inlet, the top of each CDImembrane component module is provided with a purified water outlet, the water inlets of all the CDI membrane component modules are connected to the water inlet pipe, and the water purification outletsof all the CDI membrane component modules are connected to the water outlet pipe; each CDI membrane component module comprises a plurality of electrode pairs which are sequentially stacked from top to bottom; each electrode pair is composed of an anode plate layer, an anion exchange membrane layer, a screen layer, a cation exchange membrane layer and a cathode plate layer which are sequentially stacked from top to bottom; and the centers of the anode plate layer, the anion exchange membrane layer, the screen layer, the cation exchange membrane layer and the cathode plate layer in each electrode pair are provided with through holes serving as raw water channels. The modularized membrane capacitance deionizer has a simplified structure and increases the water treatment capacity.

Owner:JIANGSU MAYMUSE ENVIRONMENTAL TECH CO LTD

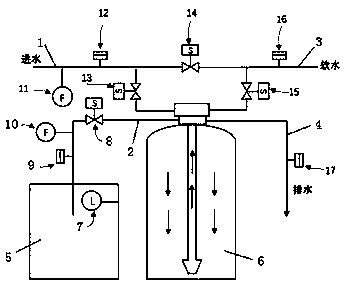

Intelligent water softener and control method thereof

InactiveCN110436569ARealize intelligent controlRealize instant responseWater treatment parameter controlSpecific water treatment objectivesSaline waterWater softening

The invention provides an intelligent water softener and a control method thereof. The water softener comprises a water inlet pipe, a water softening pipe, a brine pipe, a water discharging pipe, a salt tank and a resin tank, the water inlet pipe, the water softening pipe and the water discharging pipe are connected with the resin tank, and the brine pipe is connected between the salt tank and theresin tank; the water inlet pipe is provided with an influent water flow sensor, an influent water quality sensor and a water inlet solenoid valve in sequence in the direction of the resin tank; thewater softening pipe is provided with a soft water solenoid valve and a soft water quality sensor in sequence in the direction of the resin tank; a bypass solenoid valve is connected between the influent water quality sensor of the water inlet pipe and the soft water quality sensor of the water softening pipe; the brine pipe is provided with a salt tank solenoid valve, a reclaimed brine quality sensor and a reclaimed brine flow meter; and the water discharging pipe is provided with a discharged water quality sensor. The water softener provided by the invention realizes instant response to change of water quality through the intelligent sensors, and makes the corresponding intelligent adjustment to the softening process, the regeneration process, the backwashing and the washing process in real time according to change of water quality.

Owner:山东省建设项目环境评审服务中心

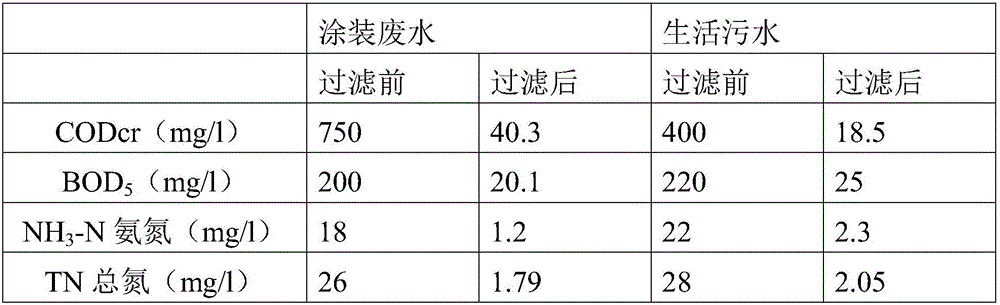

Ceramic particle for adsorbing wastewater impurities

ActiveCN106673698AImprove water purification effectReduced activityWater/sewage treatment by sorptionCeramicwareFiltrationDesorption

The invention relates to a ceramic particle for adsorbing wastewater impurities. The ceramic particle comprises an inner layer and an outer layer, wherein the outer layer contains the following raw materials in parts by weight: 35-45 parts of activated aluminum oxide, 25-35 parts of calcined kaolin, 25-30 parts of anatase type titanium dioxide, 4-6 parts of glass fibers and 1-3 parts of vermiculite, and the average particle size of the raw materials of the outer layer is 50-80 microns; and the inner layer contains the following raw materials in parts by weight: 45-55 parts of common aluminum oxide, 25-35 parts of common kaolin, 15-20 parts of rutile type titanium dioxide, 3-8 parts of the quartz and 2-4 parts of preprocessed graphene, and the average particle size of the raw materials of the outer layer is 10-30 microns. The ceramic particle prepared by virtue of the invention has a double-layer structure, is capable of easily forward adsorbing the wastewater impurities, easy to backwash and desorb and low in desorption pressure and has the good desorption effect, and the water filtration efficiency is greatly improved.

Owner:山东祥路新材料科技有限公司

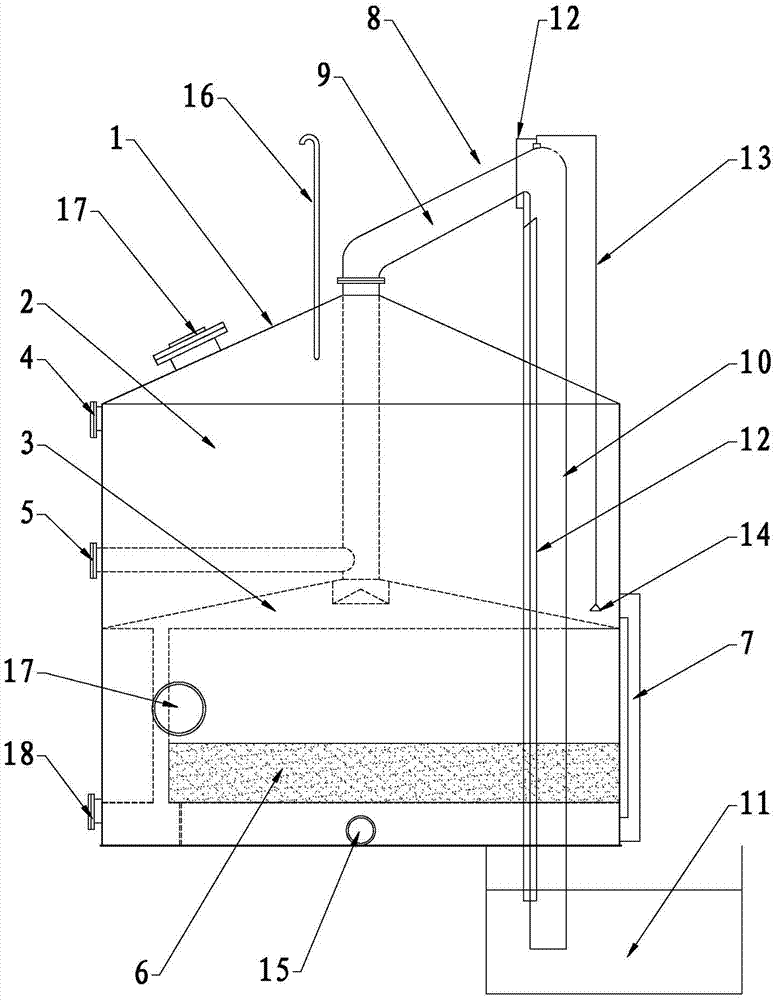

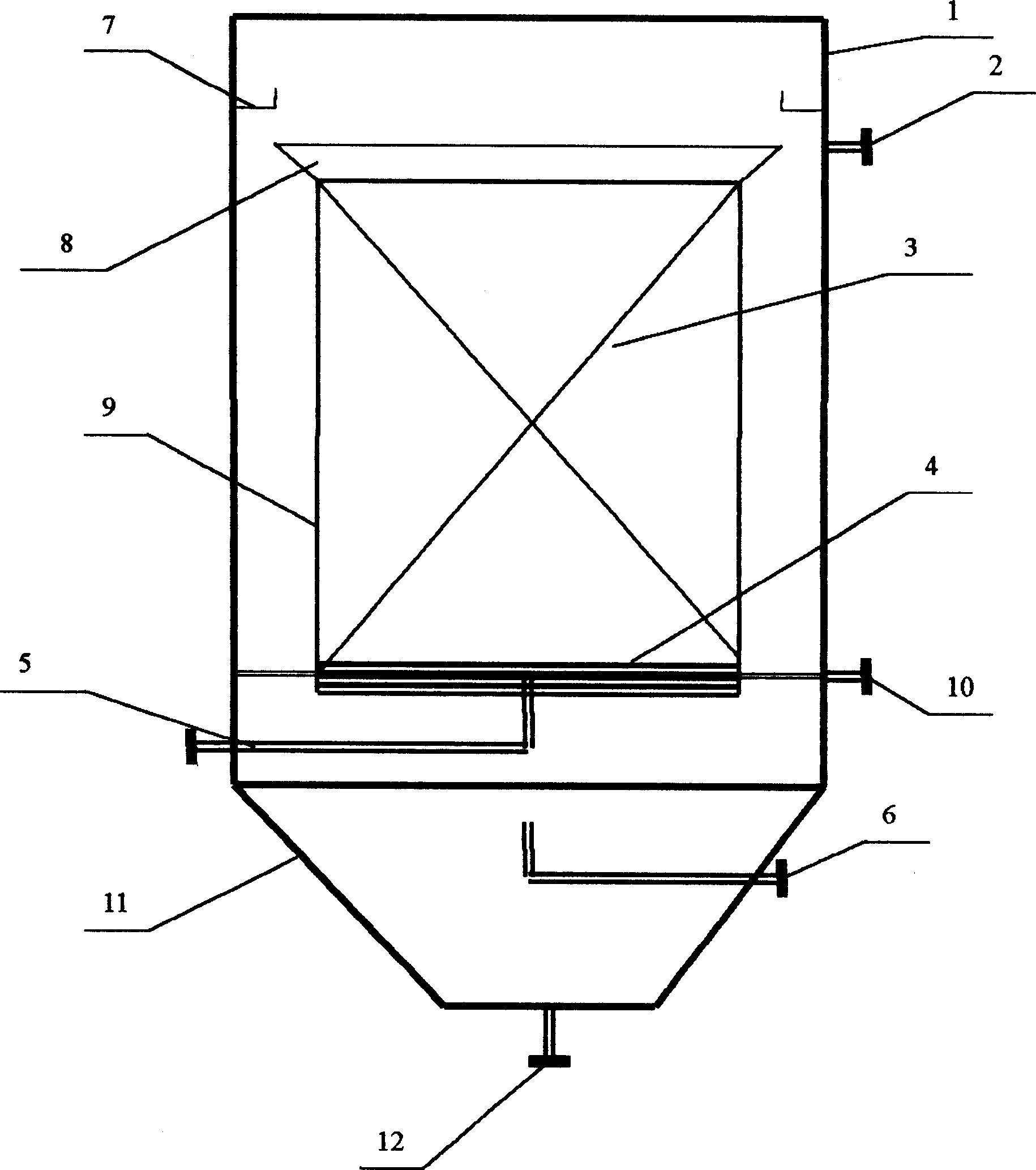

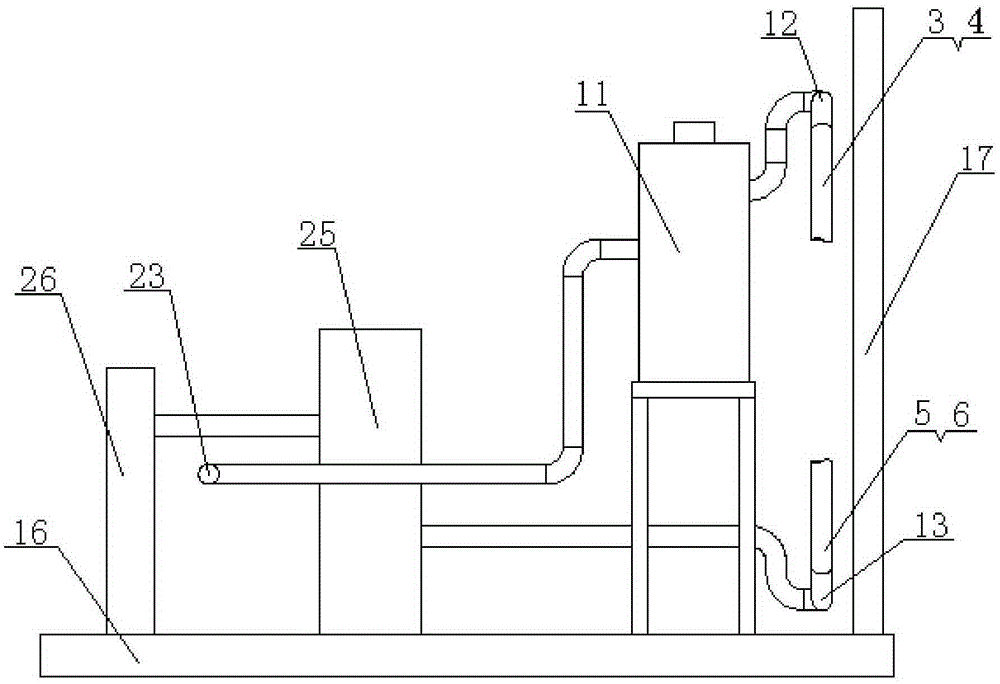

Siphon type valveless filtering pool

InactiveCN103239905ASimple structureSimple operation and maintenanceLoose filtering material filtersGravity filtersSiphonEngineering

The invention discloses a siphon type valveless filtering pool comprising a pool body (1), a clean water tank (2), a filtering water chamber (3), a water outlet (4), a water inlet pipe (5), a filtering layer (6) and a closed pipe (7), wherein the pool body (1) is provided with a siphon pipe (8) which is communicated with an outlet end of the water inlet pipe (5); the siphon pipe (8) comprises a siphon ascending pipe (9) and a siphon descending pipe (10); the lower end and the upper end of the siphon ascending pipe (9) are respectively connected with the outlet end of the water inlet pipe (5) and the upper end of the siphon descending pipe (10); the lower end of the siphon descending pipe (10) is immersed into a water seal tank (11) located at the lower side of the pool body (1); and the lower wall of the upper end of the siphon ascending pipe (9) is provided with a siphon assisting pipe (12) and the upper wall of the top end of the siphon pipe (8) is provided with a siphon damaging pipe (13) with the lower end located at the bottom of the clean water tank (2). According to the siphon type valveless filtering pool disclosed by the invention, the backwashing speed is high, the efficiency is high and the backwashing is complete, so that the siphon type valveless filtering pool is suitable for being popularized and used.

Owner:JIANGSU RUISHENG WATER TREATMENT

Improved internal electrolytic iron bed apparatus for treating water

InactiveCN1390789ALarge mass transfer areaEasy to handleWater/sewage treatmentElectrolysisDistributor

An improved internal electrolytic iron bed as water treating apparatus is composed of a water-treating cylinder, an axially arranged internal short cylinder, silt collecting hopper under said water-treating cylinder, the cubic iron filler between said internal and external cylinders or in internal one, and air distributor under the space between said internal and external cylinders. Its advantages are high activity, large mass transfer area and high treating effect.

Owner:宜兴市天立环保有限公司

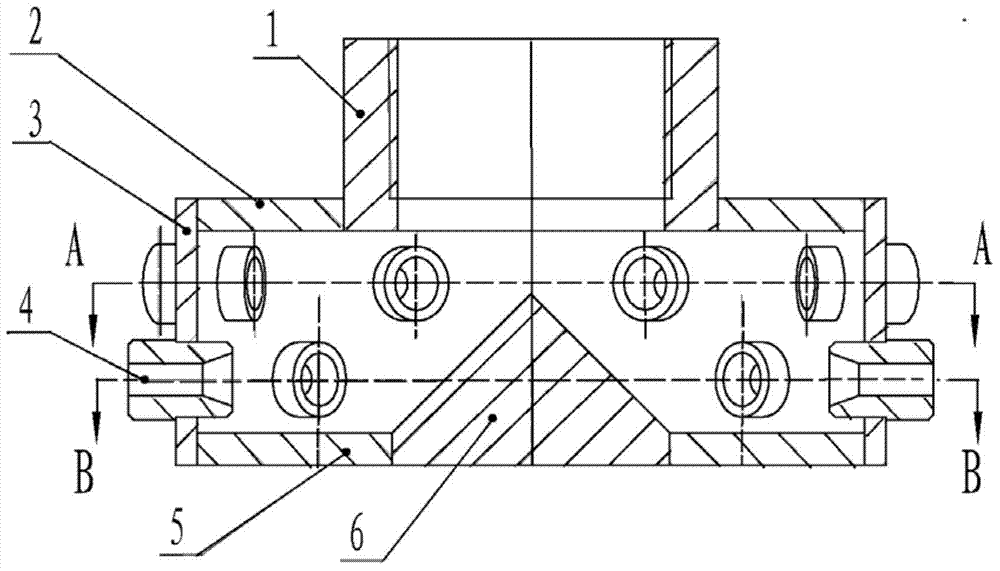

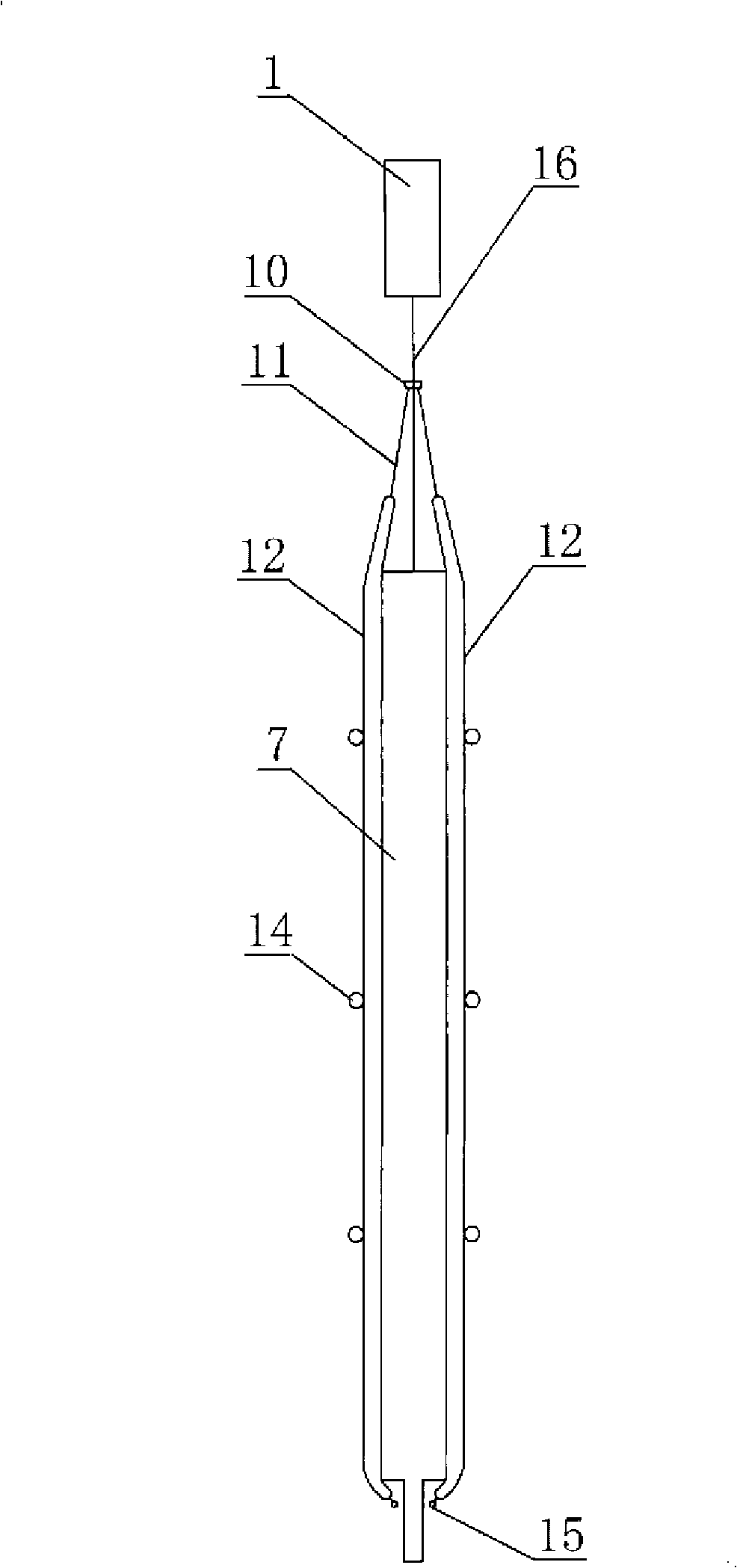

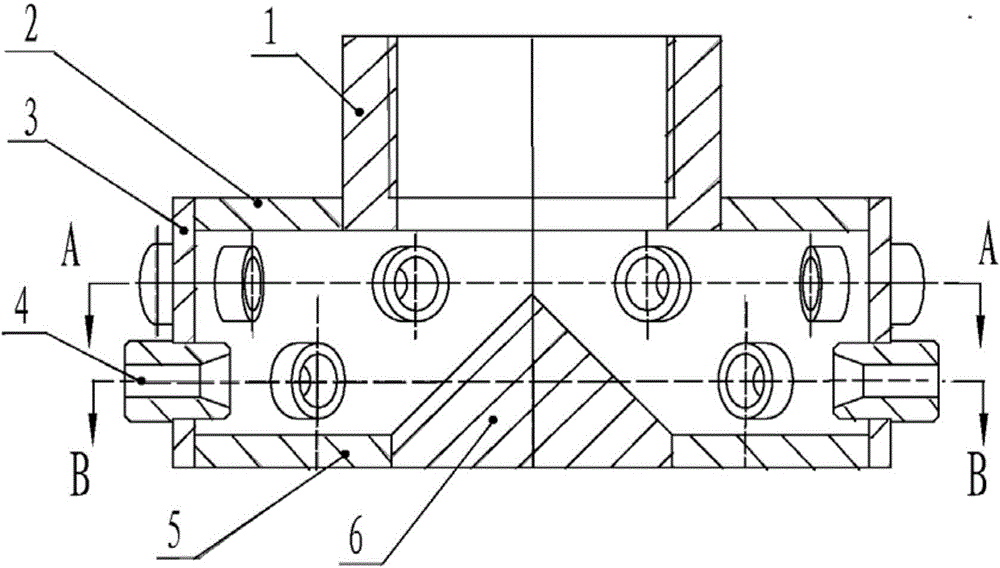

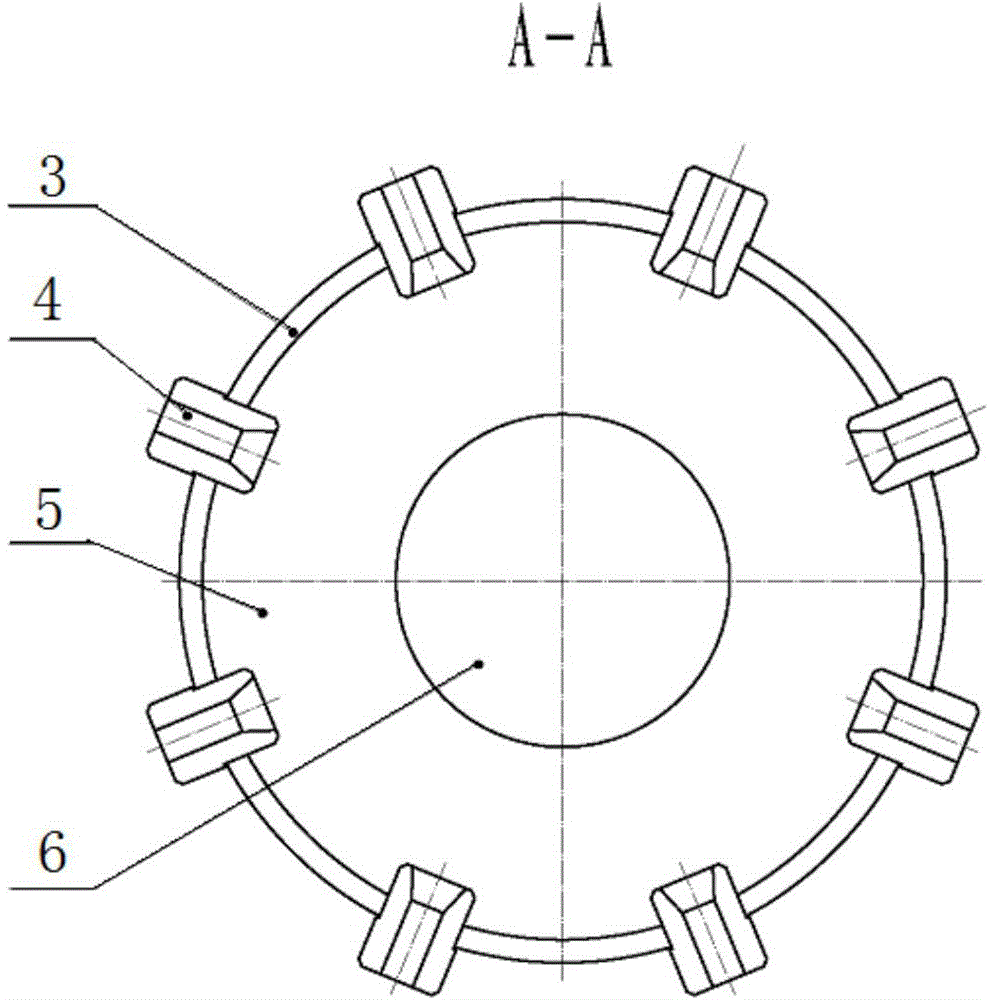

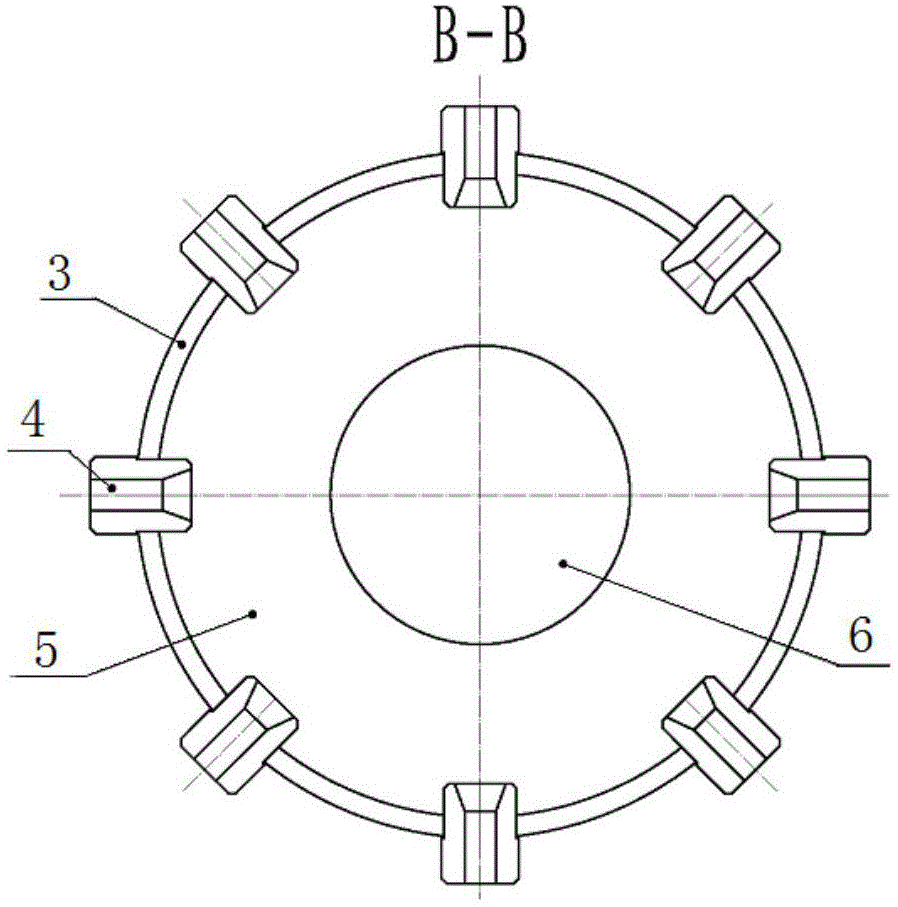

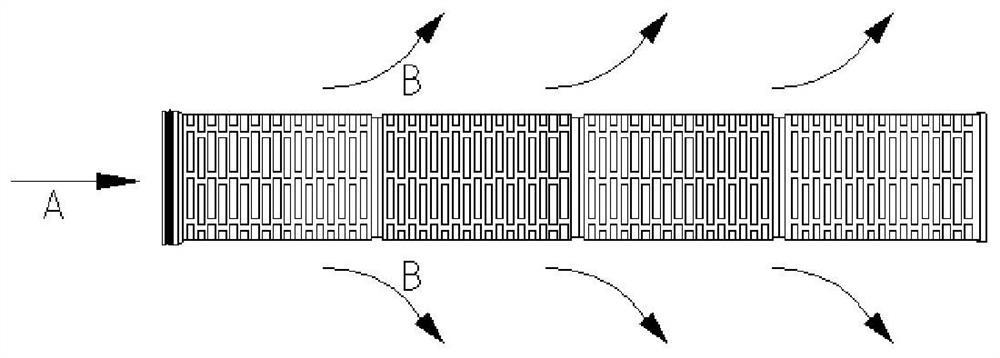

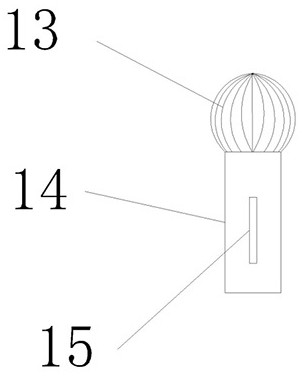

Backwash spray nozzle for granular filter material filter device

ActiveCN103611343ASimple structureDoes not cause excessive wearLoose filtering material filtersGravity filtersSpray nozzleFilter material

The invention relates to a backwash spray nozzle for a granular filter material filter device. The backwash spray nozzle comprises a connecting head, a cylinder body, nozzles and a base plate, wherein an upper ring connected with the connecting head is arranged at one end of the cylinder body, the base plate is arranged at the other end of the cylinder body, a cone head is arranged in the base plate, and 1-3 rows of nozzles are arranged on the cylinder body; 6-18 nozzles are arranged in one row, central angles alpha between every two adjacent nozzles in each row are equal, the nozzles in different rows are arrayed in a staggered manner, and staggering angles are equal to (1 / 2)alpha. In a use process, the spray nozzle is mounted at the bottom of a filter layer, a high-speed water inlet pipe and a high-speed air inlet pipe are communicated with each other, gas-water mixed liquid is ejected at high speed in a radial manner to drive peripheral filter materials to be diffused outwards at high speed to form three-phase flow of the gas, the water and the filter materials, the gas with the least specific gravity rapidly floats to penetrate through the whole filter layer due to a buoyancy effect, the three-phase flow is transversely and longitudinally covered, the filter materials are locally collided, rubbed and stirred with one another, and the three-phase flow transmits the energy to the periphery, so as to realize the effective backwash and regeneration of the whole filter layer. The backwash spray nozzle is simple in structure and good in backwash effect and is convenient to use.

Owner:武汉市汉江石油物资技术开发有限责任公司

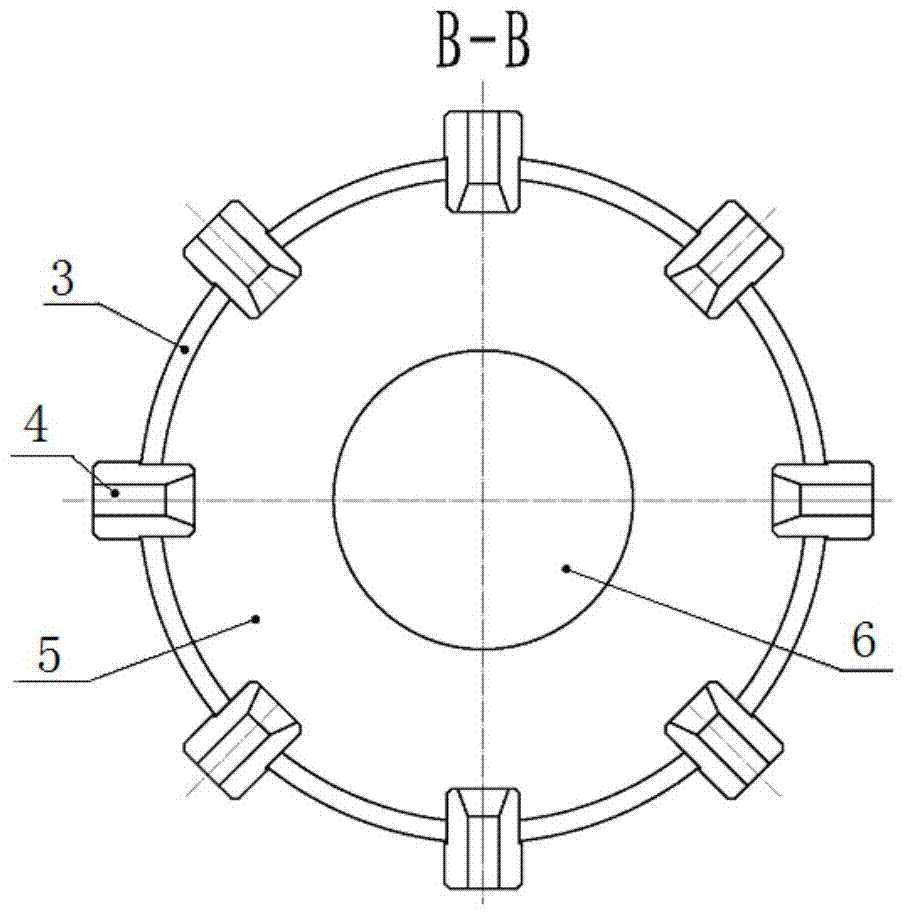

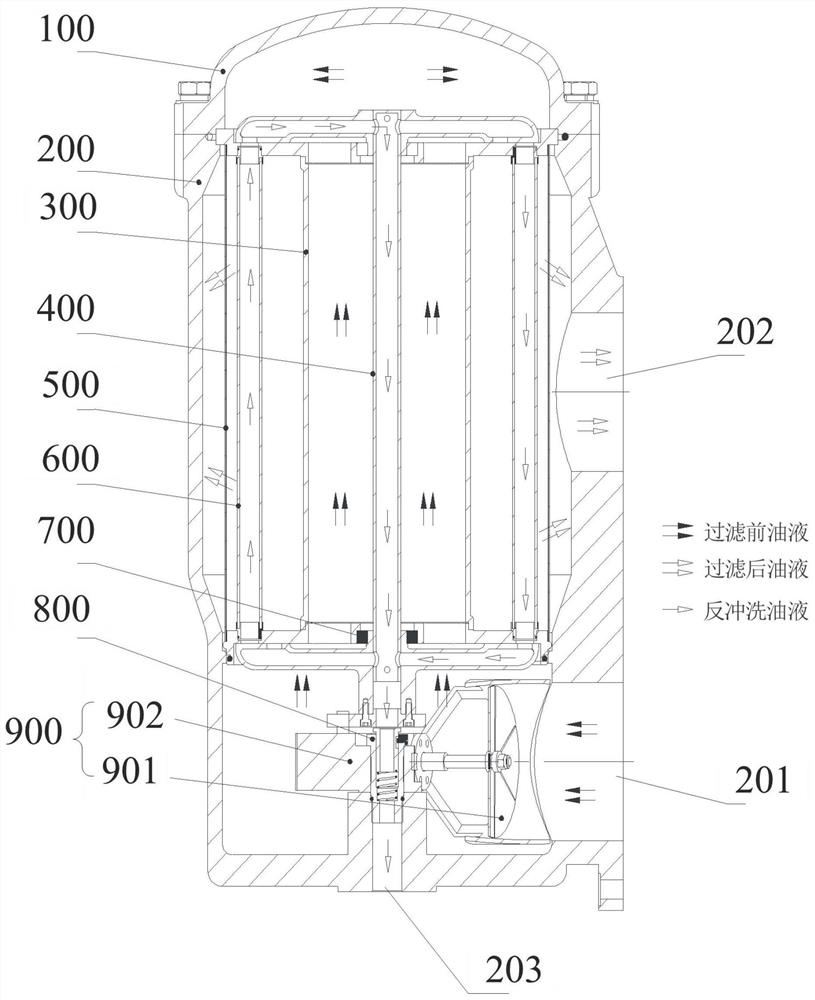

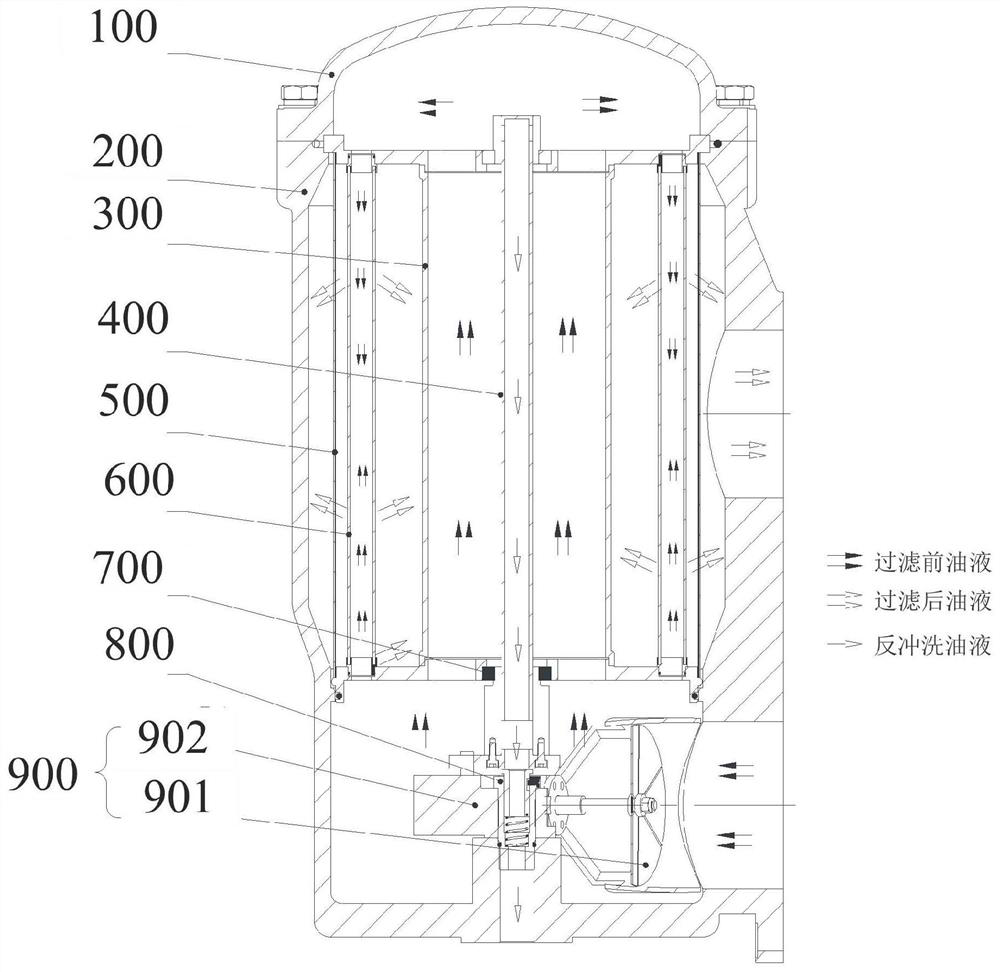

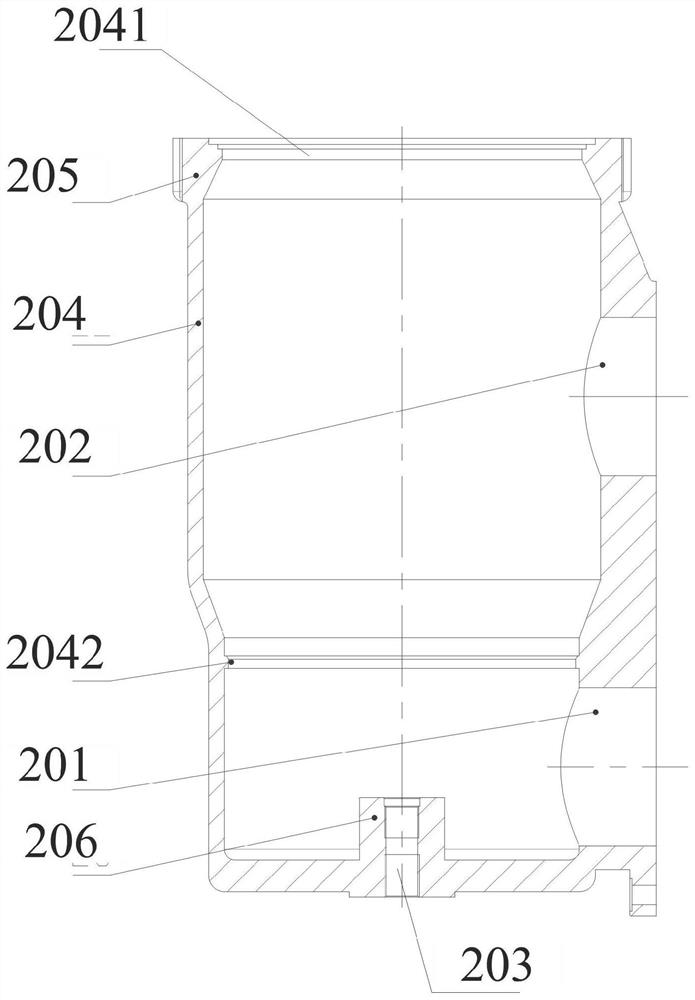

Self-operated bidirectional time-staggered backwashing self-cleaning filter and filtering backwashing method thereof

PendingCN111841109ACompact structureSolve the problem of incomplete cleaningStationary filtering element filtersSewageControl theory

The invention relates to a self-operated bidirectional time-staggered backwashing self-cleaning filter and a filtering backwashing method thereof. The filter comprises a tank body in which a circulating cavity is formed; a driving speed reducing mechanism is arranged at the bottom of the circulating cavity and corresponds to the oil inlet in position, and power for oil to enter drives the drivingspeed reducing mechanism to rotate; a fixing assembly is fixed in the circulating cavity, and two circles of filter element mounting holes which are arranged in a staggered manner and are correspondingly arranged up and down are formed in the top and the bottom of the fixing assembly; two circles of filtering elements are sequentially connected in the radial direction of the fixing assembly from inside to outside; the output end of the driving speed reducing mechanism drives the end part of a sewage suction assembly, the sewage suction assembly rotates in the fixing assembly, and two ends of the sewage suction assembly are respectively connected with suction nozzles which synchronously run with the sewage suction assembly and are communicated or blocked with the inner-ring or outer-ring filter element mounting hole; while the filtering elements are used for filtering, the two filtering elements are always communicated with the top suction nozzle and the bottom suction nozzle, and two-way time-staggered backwashing is formed under the action of external pressure difference.

Owner:中国船舶集团有限公司第七零七研究所九江分部 +1

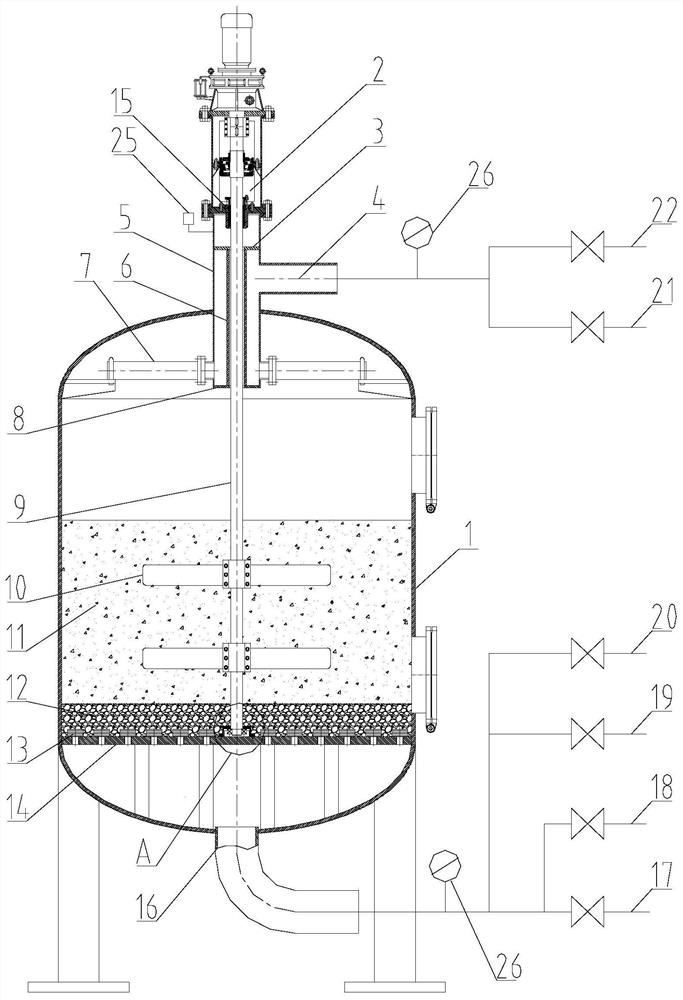

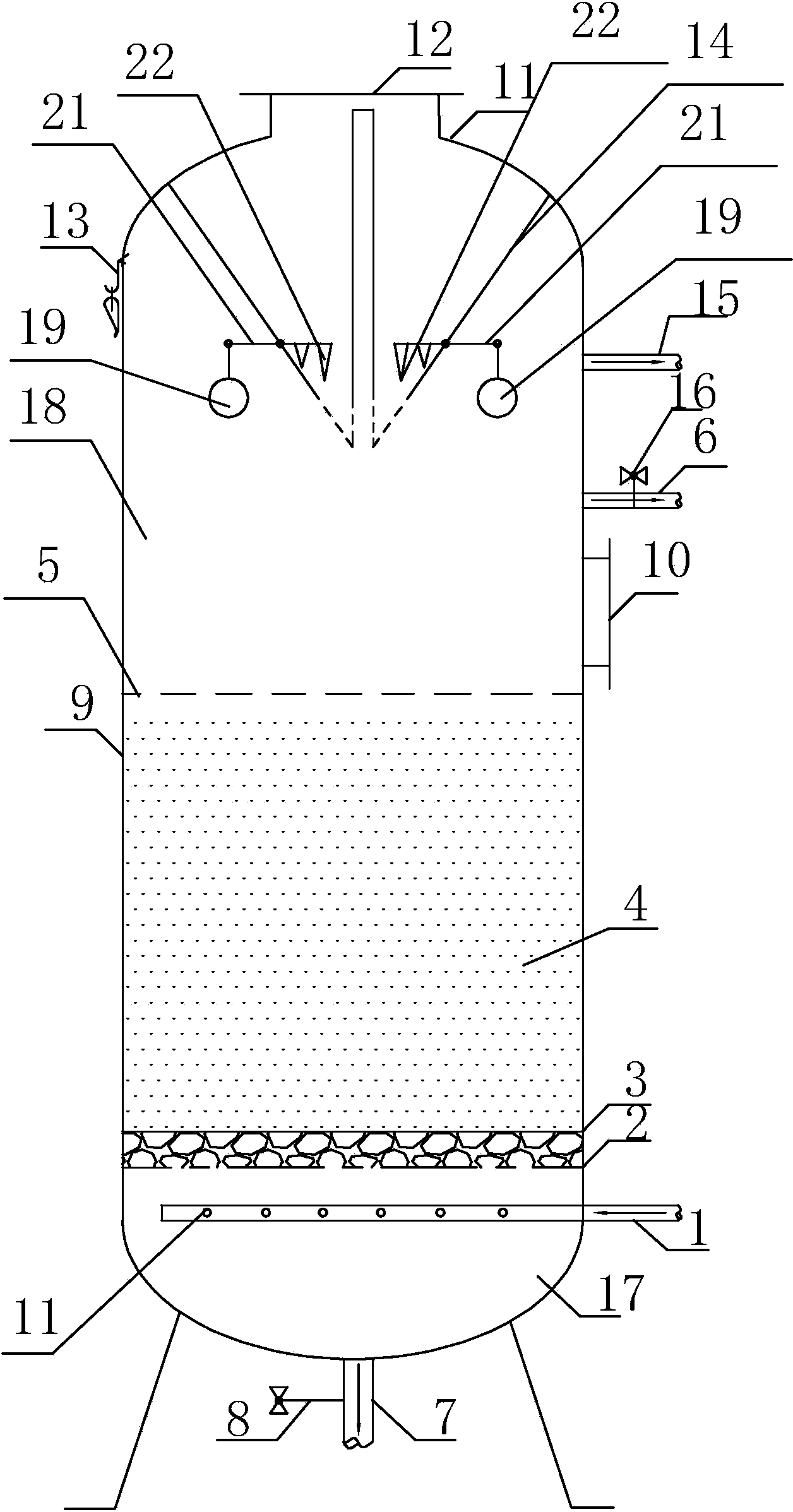

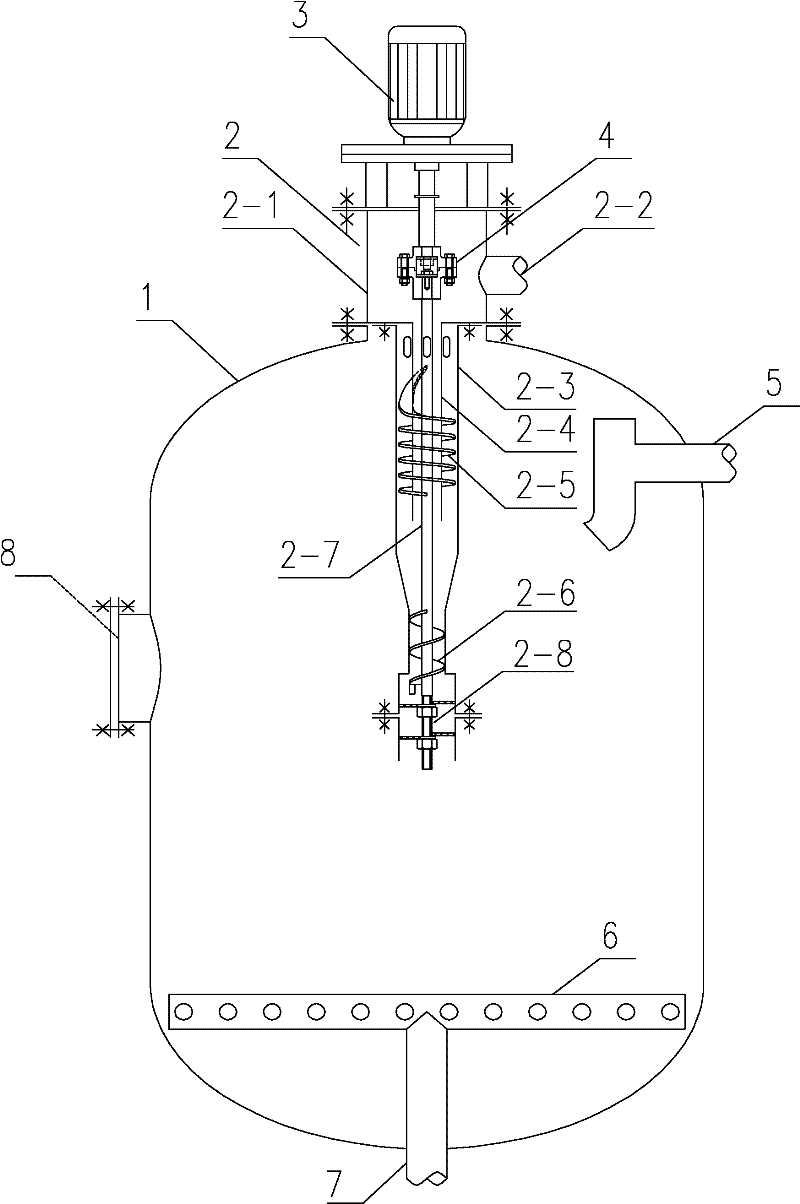

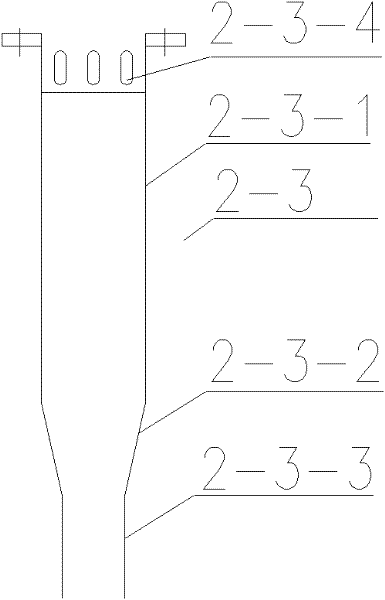

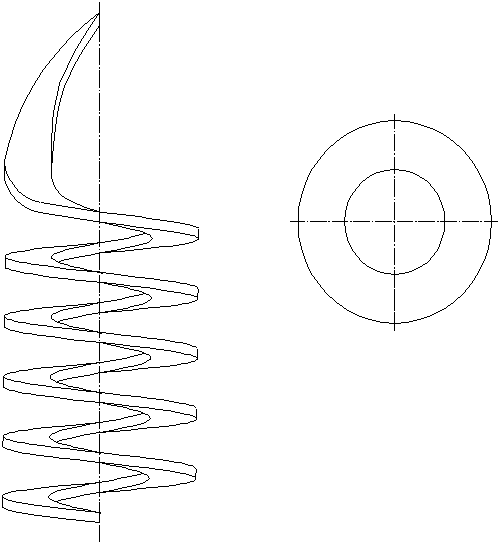

Deep backwashing filter and backwashing method

InactiveCN111729359AIncrease backwash regeneration strengthExtended service lifeMembrane filtersLoose filtering material filtersAluminium chlorideColloidal particle

The invention provides a deep backwashing filter and a backwashing method. The invention relates to the field of oilfield sewage treatment equipment. The deep backwashing filter comprises a tank bodyand a stirrer, a lower connecting pipe is arranged at the bottom of the end socket of the tank body and connected with a water outlet pipeline, a backwashing water inlet pipeline, a compressed air pipeline and a dosing pipeline in parallel through valves, and an upper connecting pipe is connected with a water inlet pipeline and a backwashing water outlet pipeline in parallel through valves. Polyaluminium chloride and colloidal particles in the sewage are used for purification, the stirrer is used for stirring, dispersing and mixing a quartz sand filter material layer, colloidal particles attached to the surface of the quartz sand filter material and a water body break the stability and form tiny floccules, under the impact and carrying effects of bubbles formed after the compressed air isdivided by a filter cap, the floccules and the quartz sand filter material layer are separated and ascend to flow out of the tank body, chemical agents and physical stirring act on the quartz sand filter material at the same time, the backwashing regeneration strength of the quartz sand filter material is improved, backwashing is more thorough, the service life of the quartz sand filter material is prolonged, and the quality of filtered water is improved.

Owner:肖云东

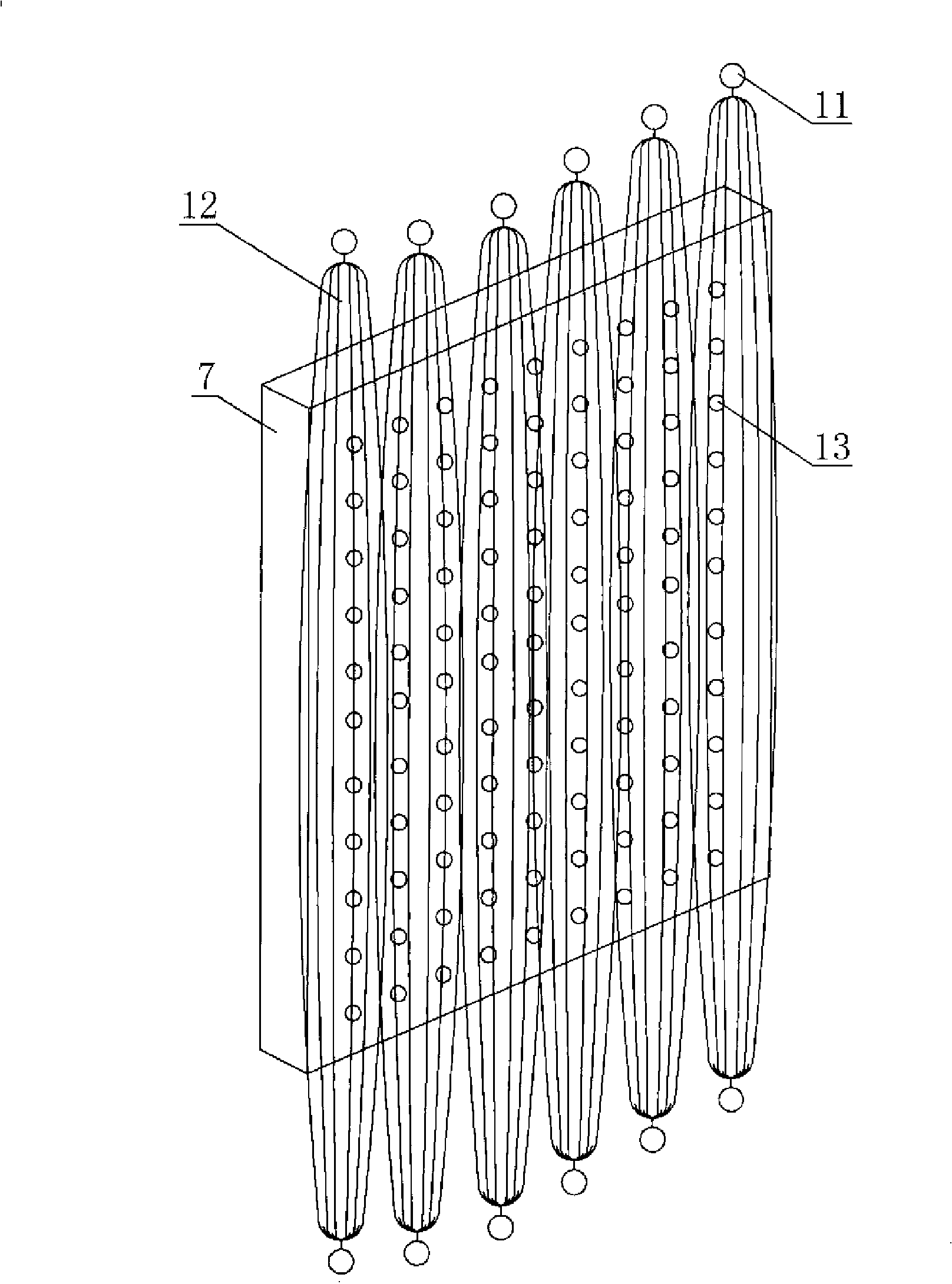

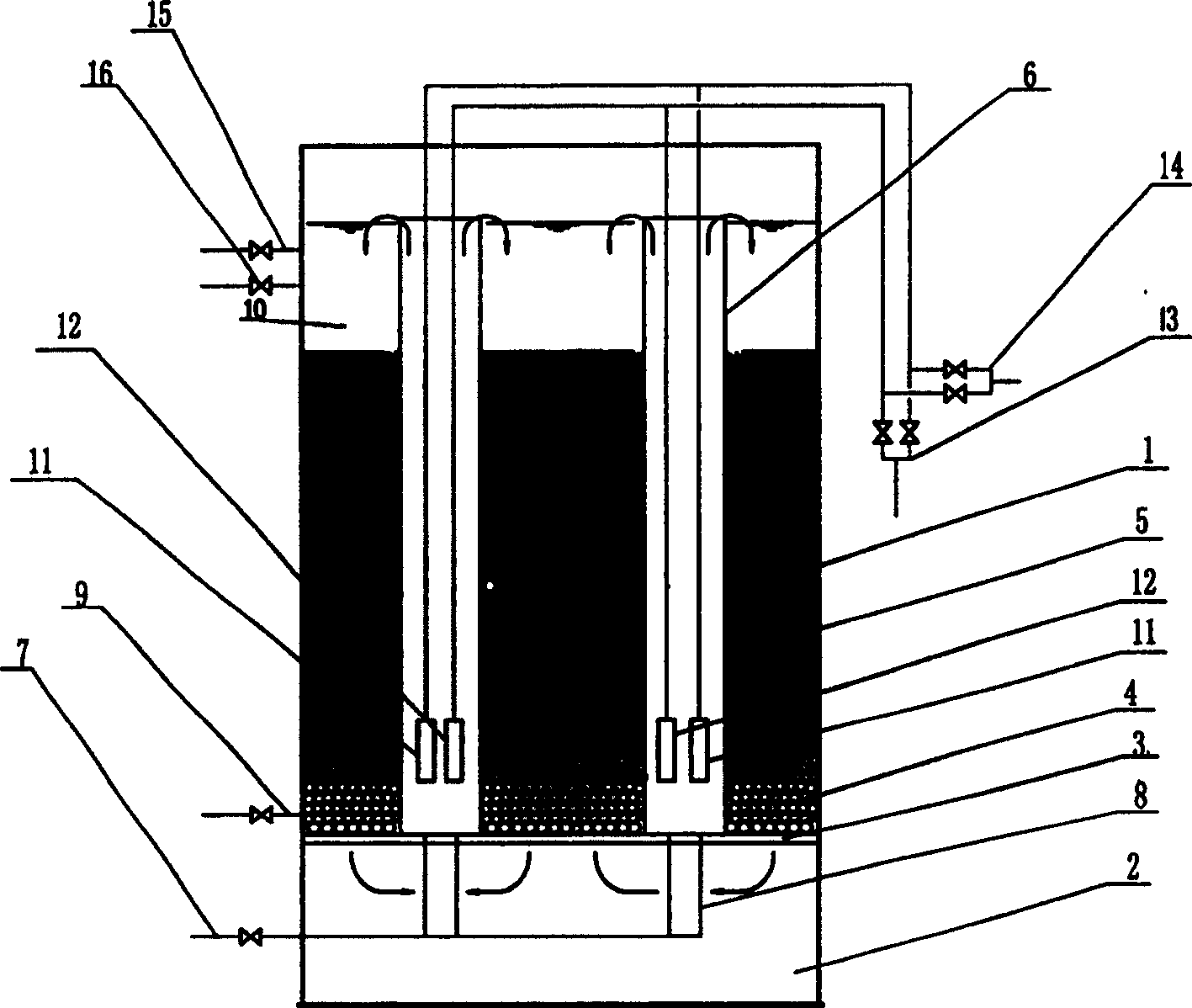

Novel fibre filter

InactiveCN101249321AOrderly rowsHigh filtration precisionLoose filtering material filtersGravity filtersFiberDrive shaft

The invention relates to a novel fiber filter, fiber beams are arranged in a pool body, the side wall of the pool body is provided with a water inlet, a water outlet and a back wash water discharge outlet, the space at the bottom part of the pool body is provided with a water collection tank of the discharged water, the side surface of the water collection tank of the discharged water is communicated with the water outlet; an upper plate surface of the water collection tank of the discharged water is connected with at least one vertical filter unit, the center of each filter unit is a hollow support body, filtration pores are distributed on the side wall of each hollow support body, the lower port of each hollow support body is communicated with the water collection tank of the discharged water, the outer surface of each hollow support body is covered with fiber beams which are vertically and tightly arranged, the lower ends of the fiber beams are connected with a wire hanging rod, the upper ends of the fiber beams and the upper ends of the hollow support bodies are connected with a wire hanging support body via a wire hanging ring and a rope, the wire hanging support body is connected with a drive device by driving via a lifting transmission shaft; the root part of each filter unit is provided with an air distributing chamber, a back wash air sparging disc is arranged on the air distributing chamber, and the air distributing chamber is communicated with a back wash air inlet pipe. The filter has small area coverage, high filtration efficiency and thorough back wash.

Owner:沙中魁

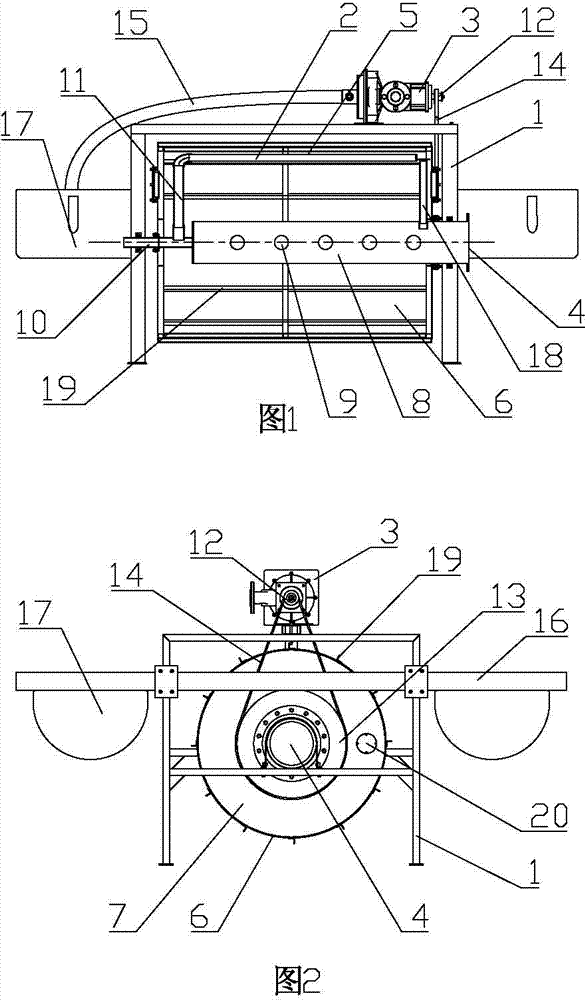

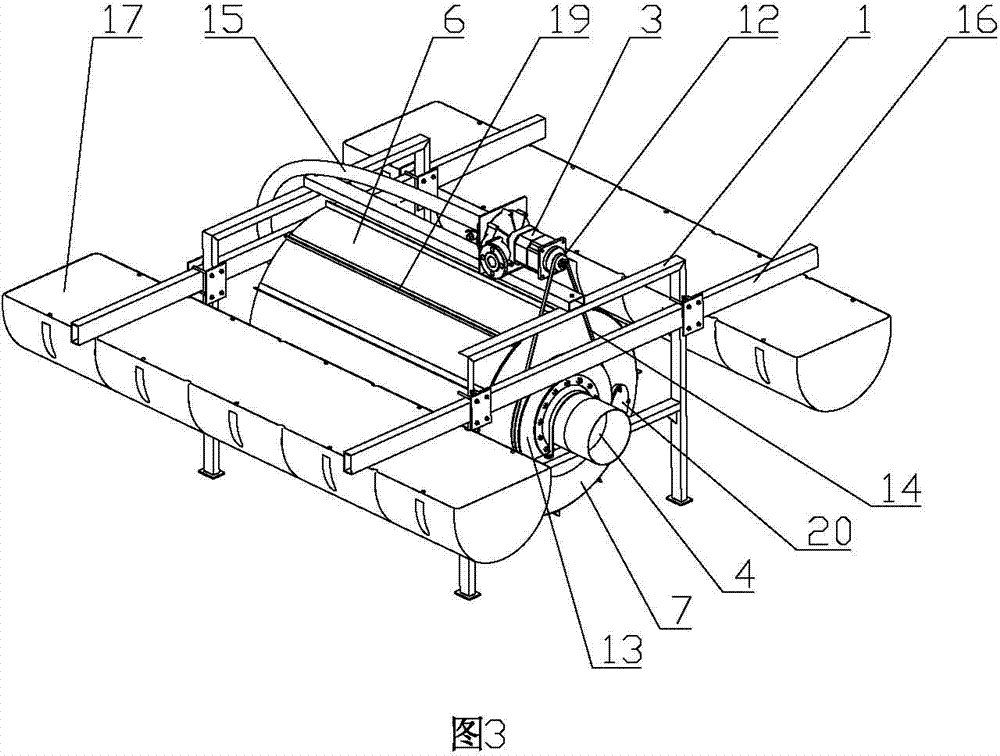

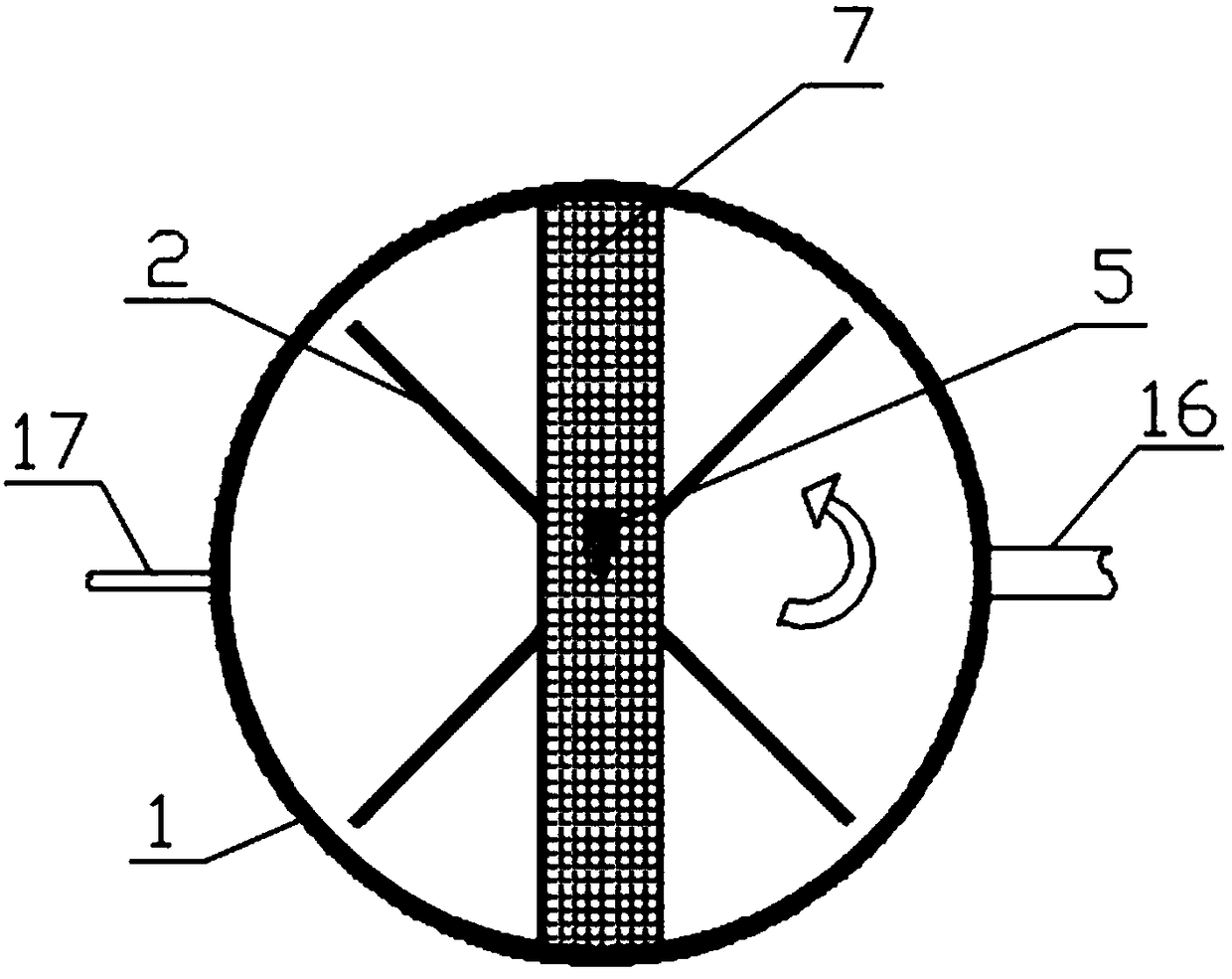

Hydroturbine propelled microfilter

ActiveCN104740924AImprove stabilityGuaranteed stabilityMoving filtering element filtersFiltrationWater source

The invention relates to the technical field of filtration equipment and relates to a hydroturbine propelled microfilter. The hydroturbine propelled microfilter comprises a holder, a filter screen component, a cleaning pipe and a hydroturbine, wherein the hydroturbine is fixedly mounted on the holder; the filter screen component which is cylindrical and can be driven by the hydroturbine to rotate around own axis is mounted on the holder; a filtered water outlet is formed in the filter screen component; the cleaning pipe located above the axis of the filter screen component is arranged in the filter screen component; water outlets all capable of jetting water in the pipe to the inner wall of the filter screen component are transversely formed in the cleaning pipe at intervals. The hydroturbine propelled microfilter is reasonable and compact in structure; the hydroturbine is capable of pushing the filter screen component to rotate around the own axis, and meanwhile, a high-pressure fluid can be input into the cleaning pipe; as a result, water returned by the hydroturbine can be effectively utilized and the utilization rate of the high-pressure water source for driving the hydroturbine is improved; besides, back washing can be completed at the same time of filtering; the filtering efficiency is high, the back washing is thorough and blockage can be avoided.

Owner:新疆一源节水设备有限公司

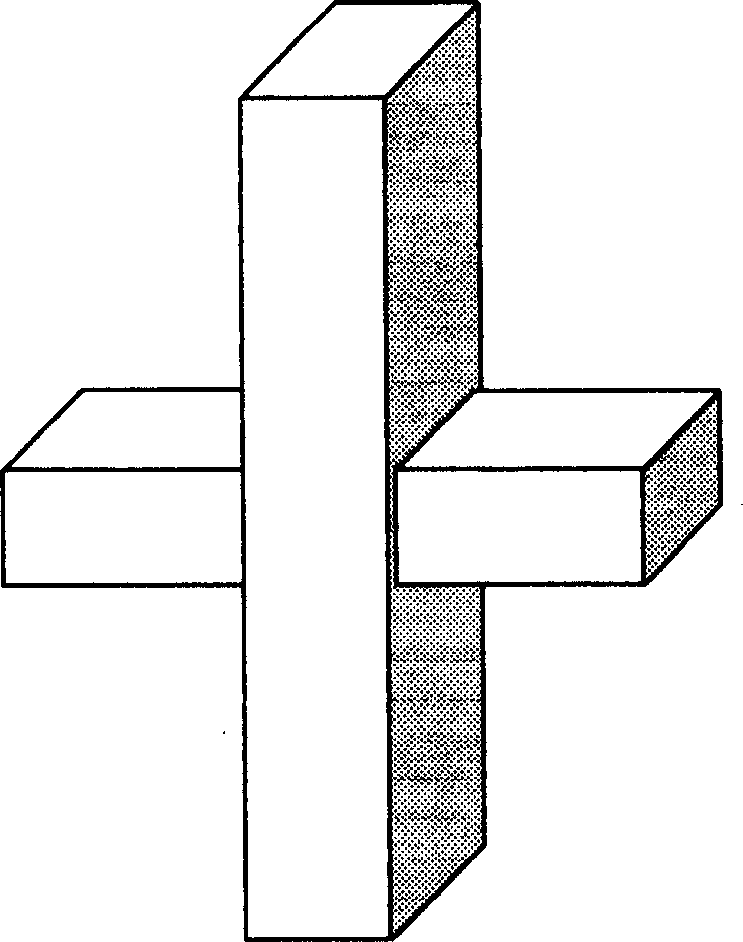

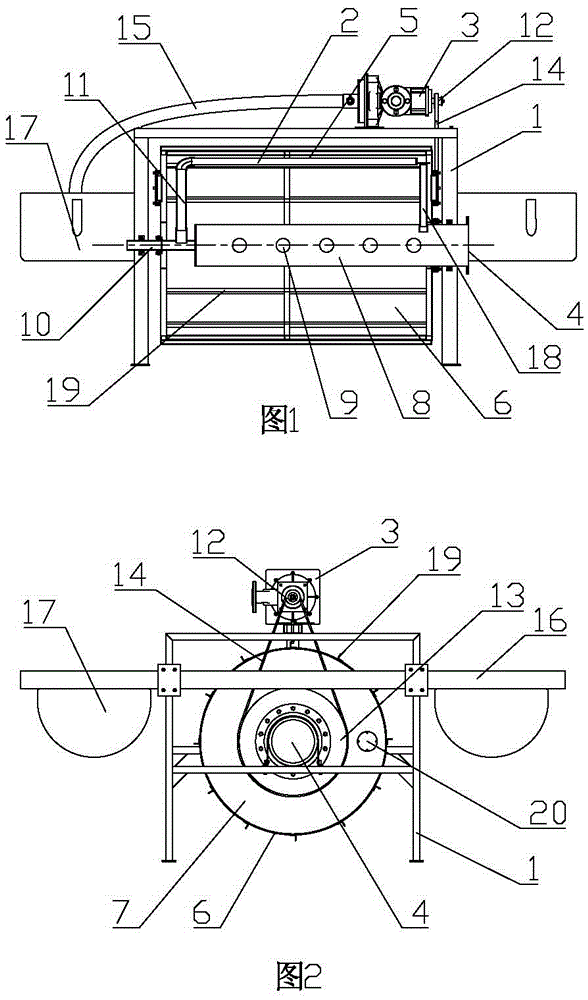

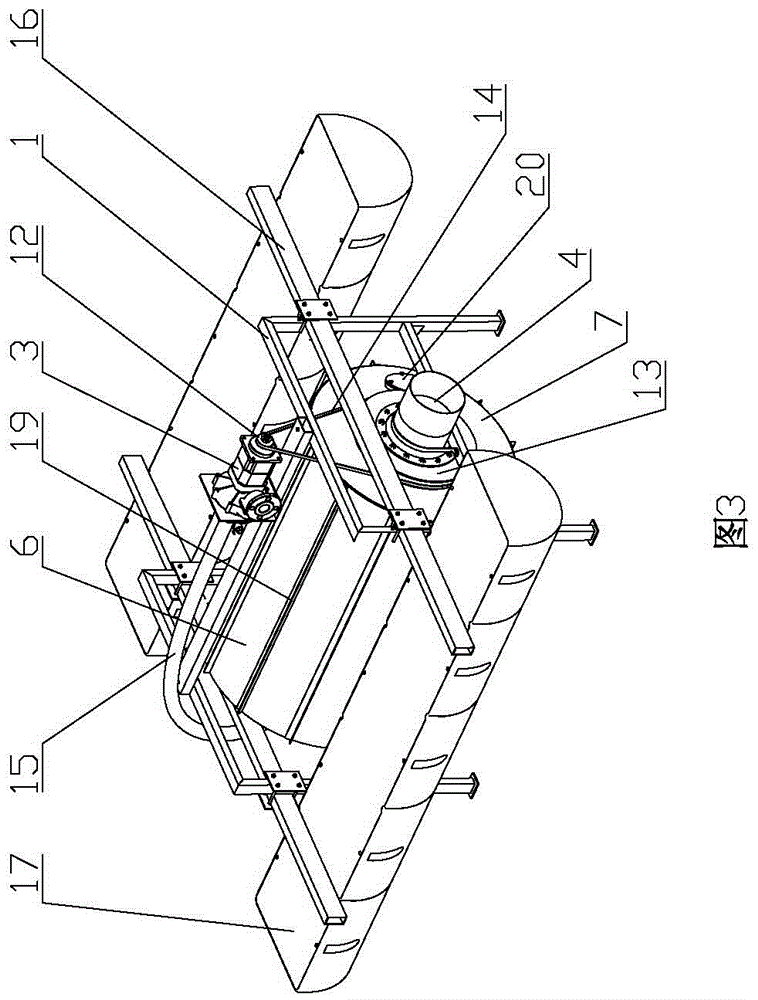

Back-flushing cutting module for ceramic bio-filter and three-dimensional back-flushing technology of back-flushing cutting module

InactiveCN108101190AWash out quicklySmall cutting resistanceSpecific water treatment objectivesBiological treatment apparatusMotor driveFilter material

The invention provides a back-flushing cutting module for a ceramic bio-filter and a three-dimensional back-flushing technology of the back-flushing cutting module. The adopted three-dimensional back-flushing technology is realized mainly by depending on the back-flushing cutting module. The back-flushing cutting module for a ceramic bio-filter comprises a cutting framework, a cutting skeleton, asecond back-flushing water inlet pipe, a second back-flushing water inlet branch pipe, a rotating shaft, a frame plate and a transmission motor, wherein the transmission motor drives the back-flushingcutting module to perform transverse filter material cutting through horizontal rotation of the rotating shaft; and the ceramic bio-filter performs longitudinal back-flushing upwards through back-flushing water which enters through a first back-flushing water inlet pipe. The three-dimensional back-flushing technology adopting three process of a 'independent gas back-flushing mode' to a 'gas-watercombined back-flushing mode' to a 'dependent water three-dimensional back-flushing mode' is provided, so that sufficient friction and movement of a filter material on a longitudinal face and a transverse face are performed, and accordingly, the bio-filter is radically prevented from blockage and caking of the filter material.

Owner:杭州达康环境工程有限公司

Water turbine driven microfilter

ActiveCN104740924BImprove stabilityGuaranteed stabilityMoving filtering element filtersWater turbineWater source

Owner:新疆一源节水设备有限公司

Backwash spray nozzle for granular filter material filter device

ActiveCN103611343BSimple structureDoes not cause excessive wearLoose filtering material filtersGravity filtersProduct gasFilter material

Owner:武汉市汉江石油物资技术开发有限责任公司

Biological reactor of internal circulating and double filtering

InactiveCN100494088CImprove dirt holding capacityIncrease shock loadTreatment using aerobic processesSustainable biological treatmentActivated sludgeWater quality

A bioreactor with internal with internal circulation and dual filters for treating sewage is composed of water distributing chamber with water distributor, bearing plate, bearing layer, fitlering layer and cyclic aerating cylinder with filter-water outlet unit. The sewage is circulating through said water distributor, cycle aerating cylinder and filter layer, and is filtered by filter layer and the filter-water outlet unit.

Owner:魏刚 +2

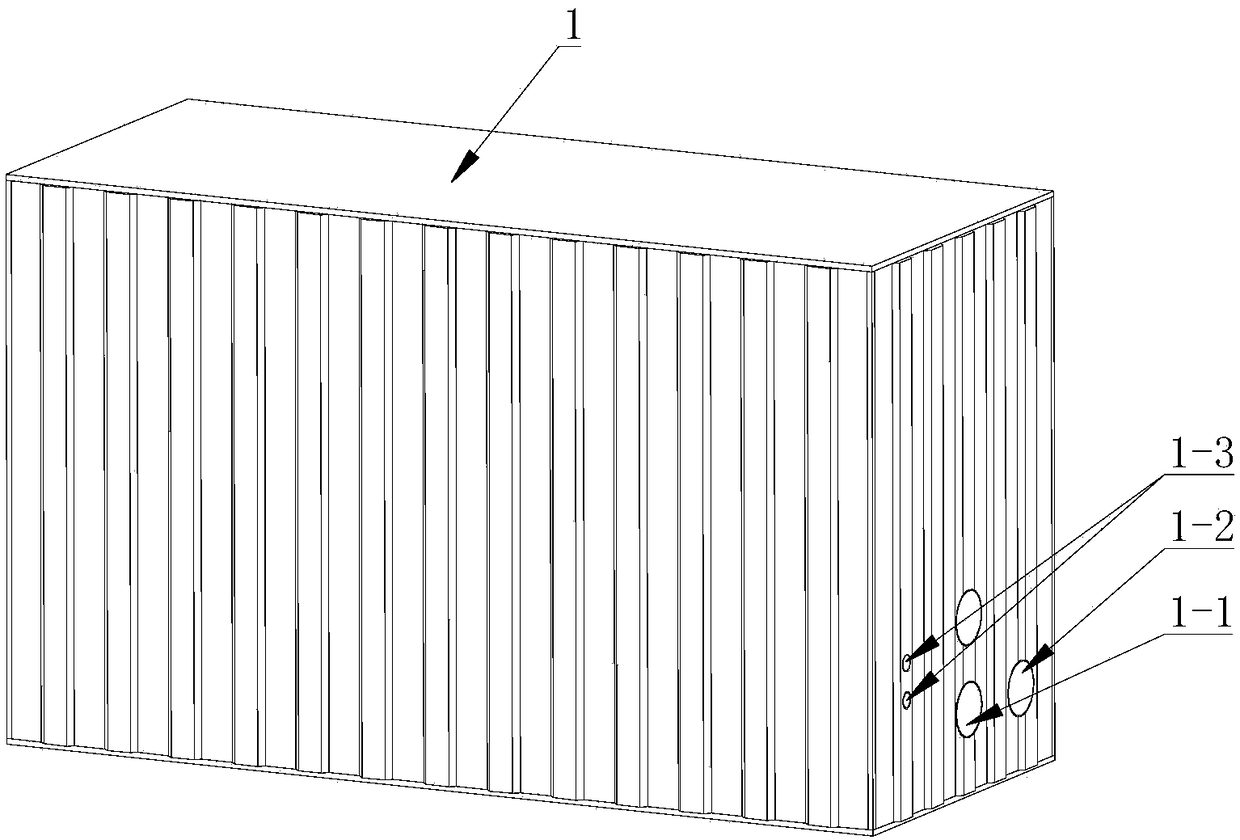

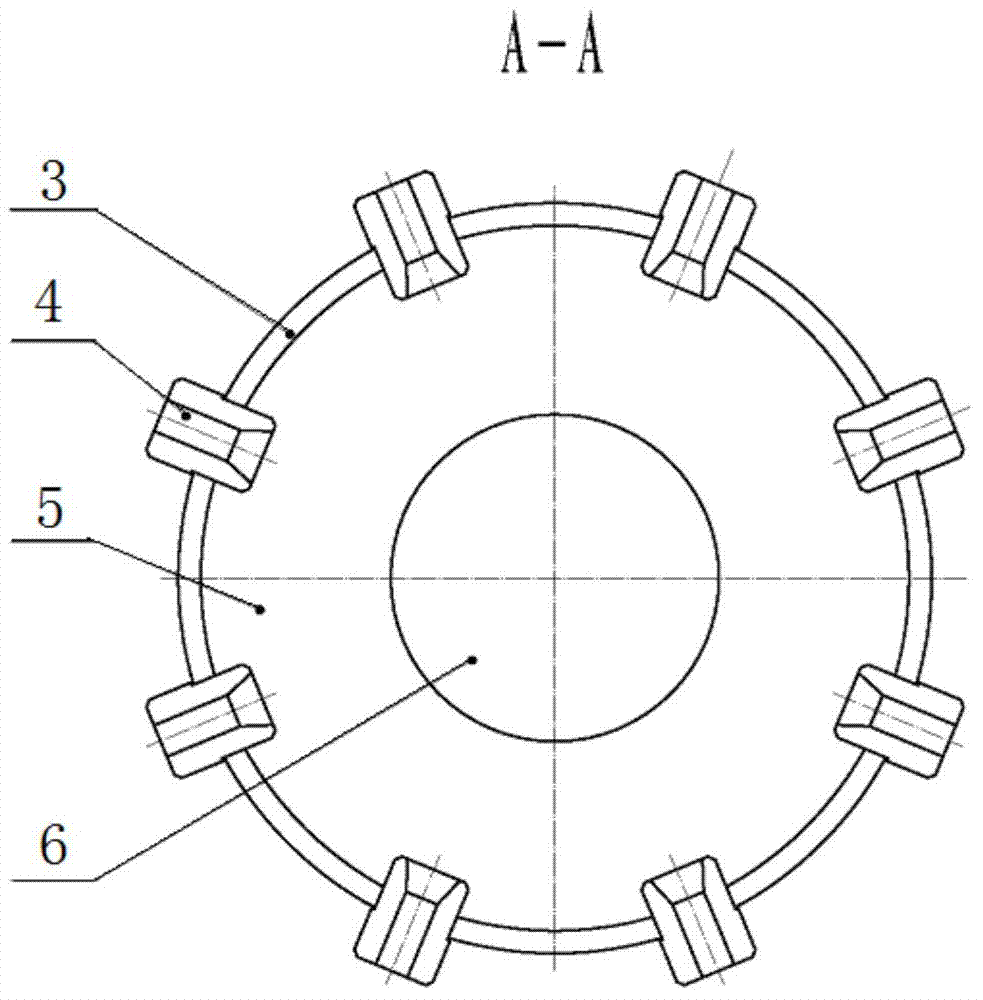

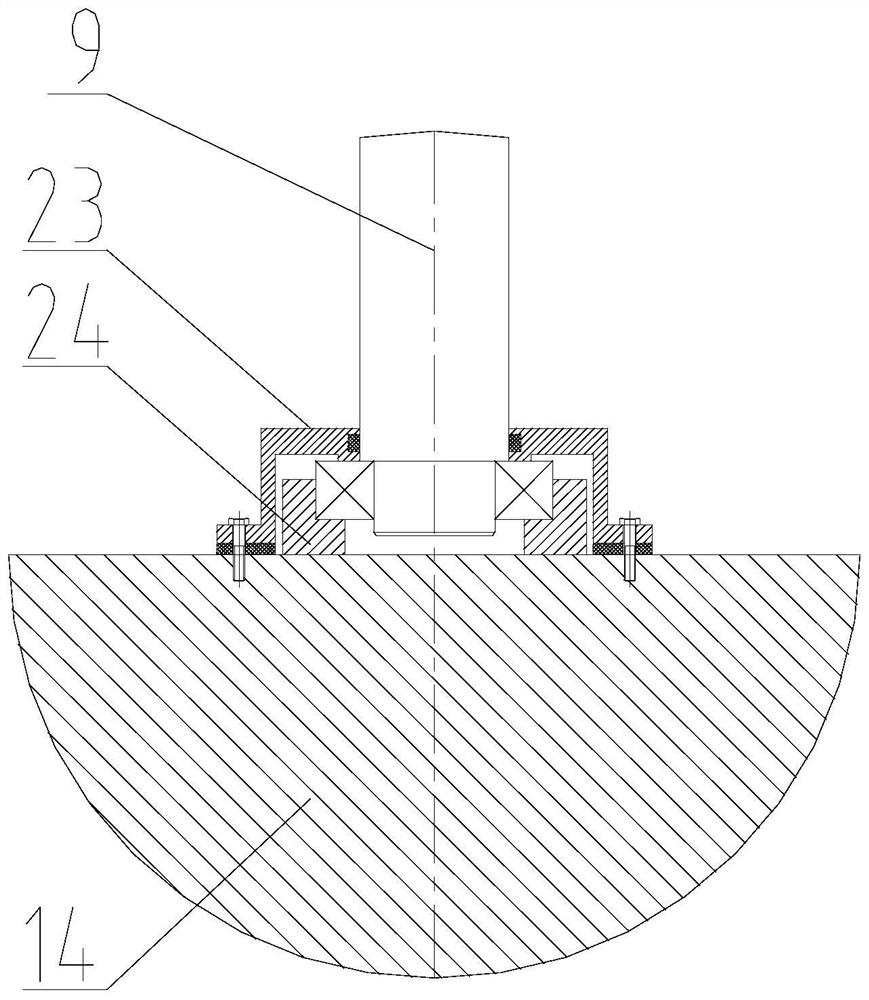

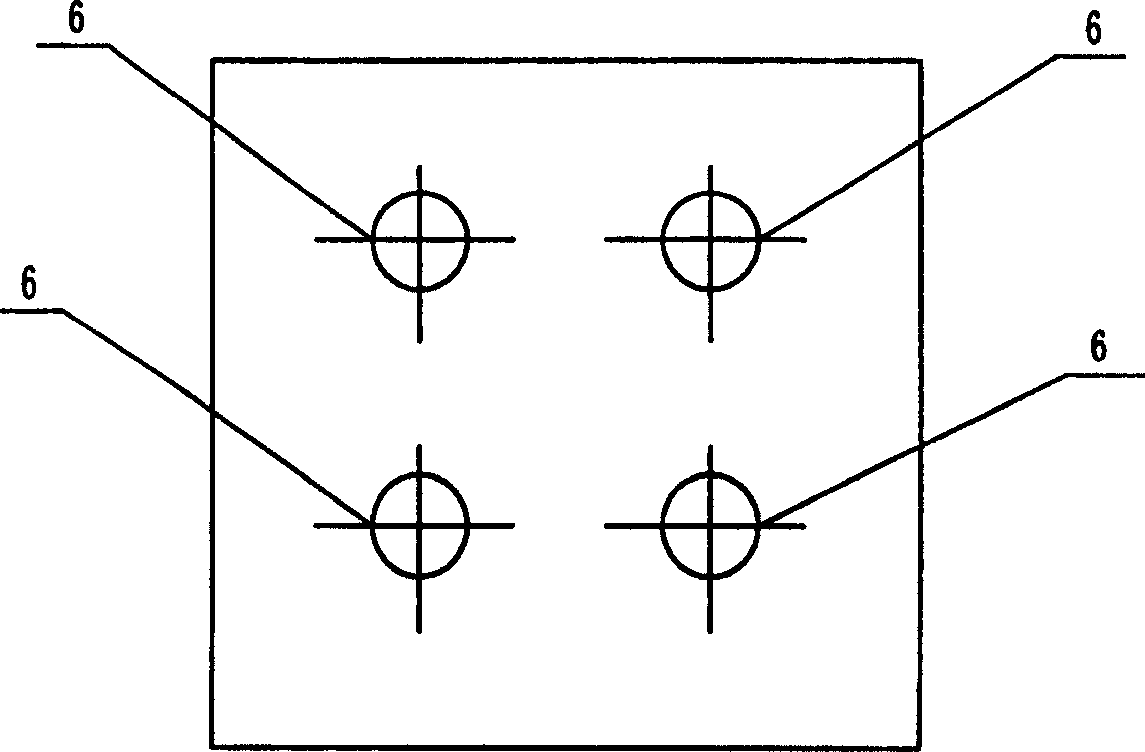

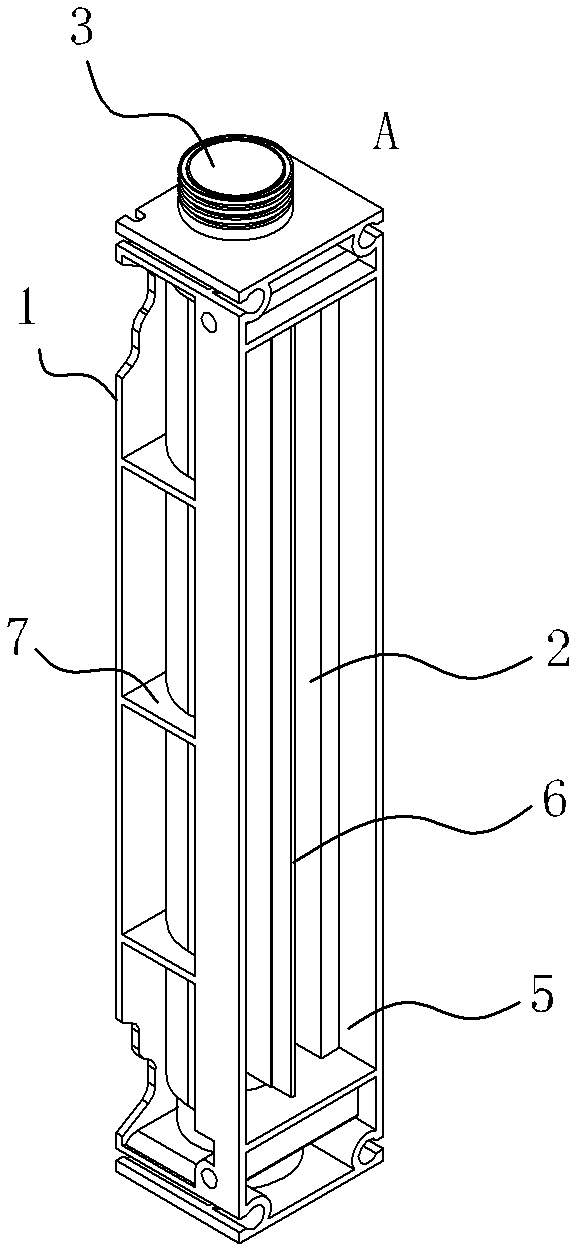

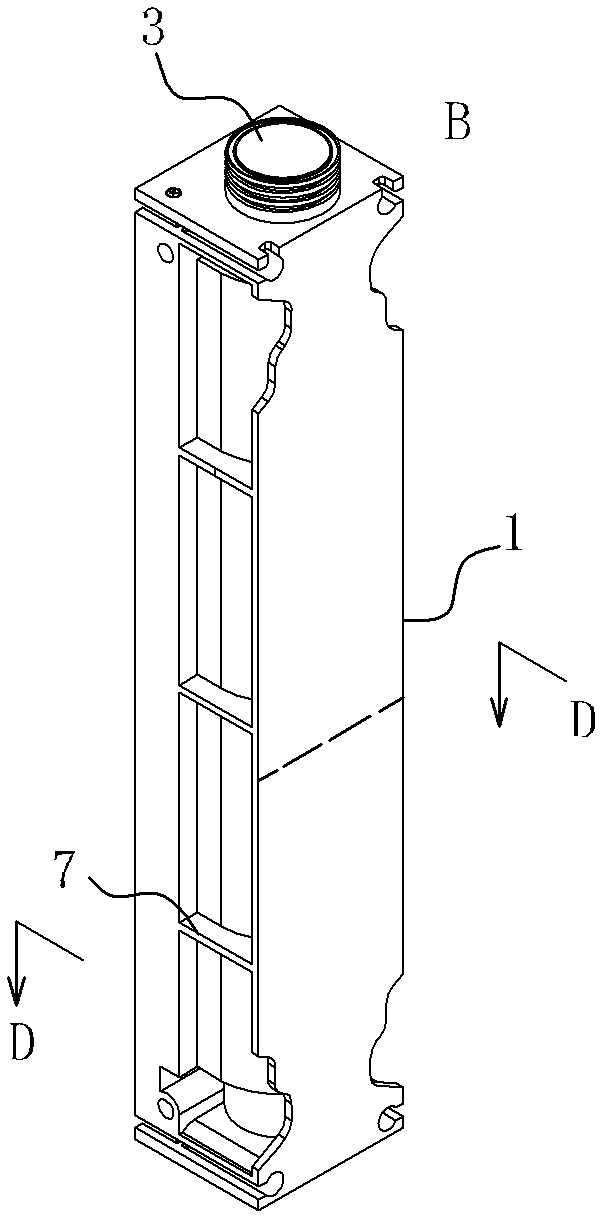

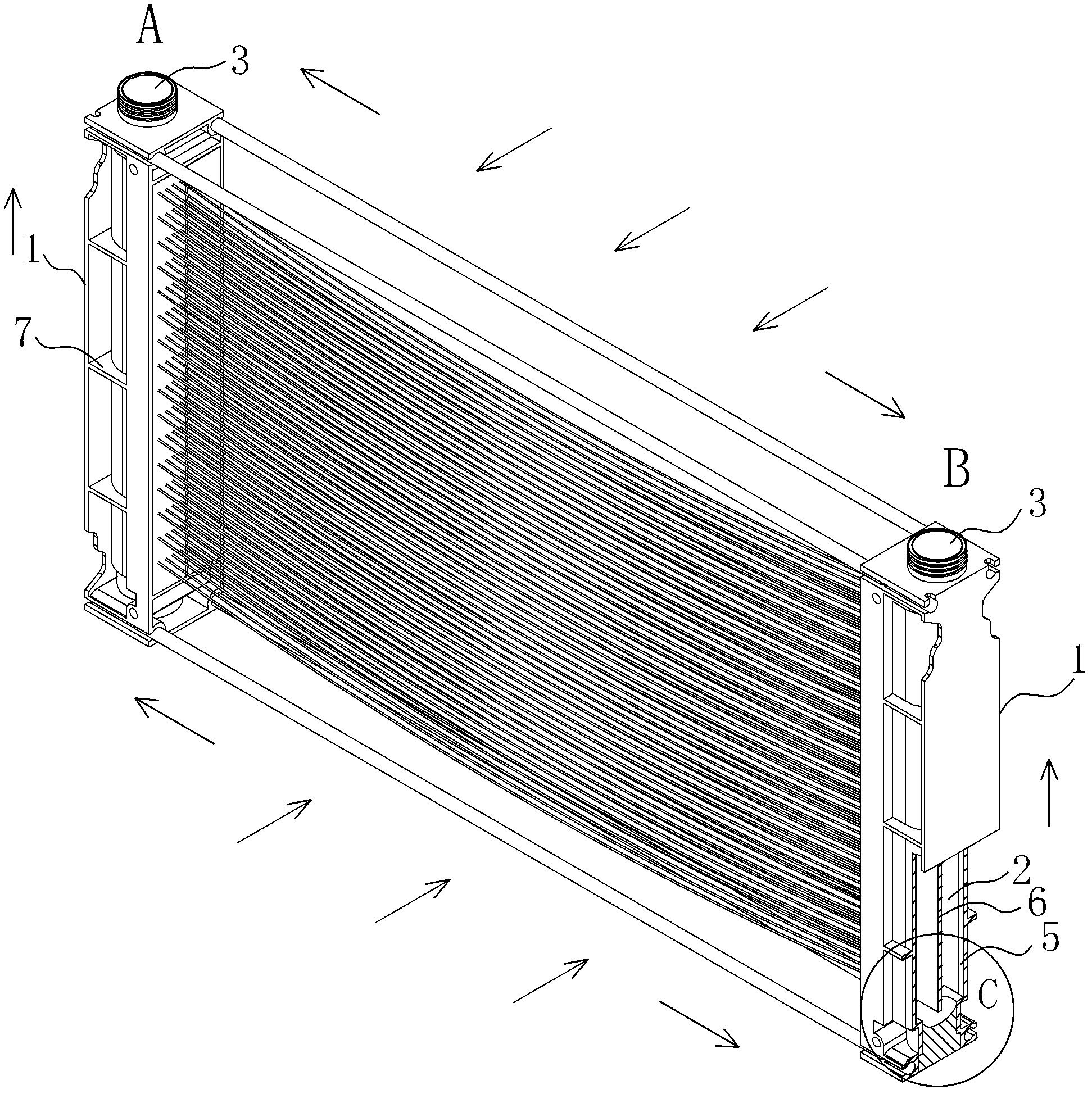

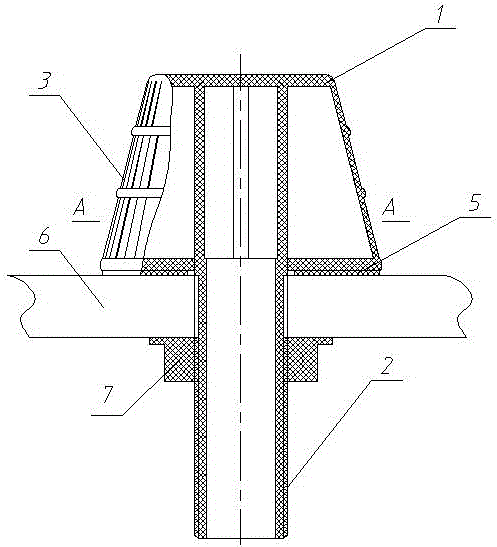

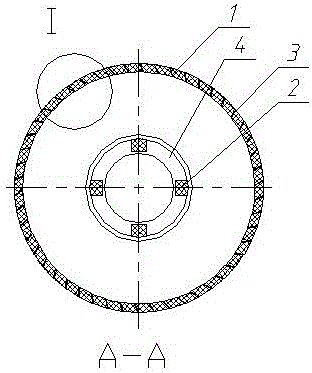

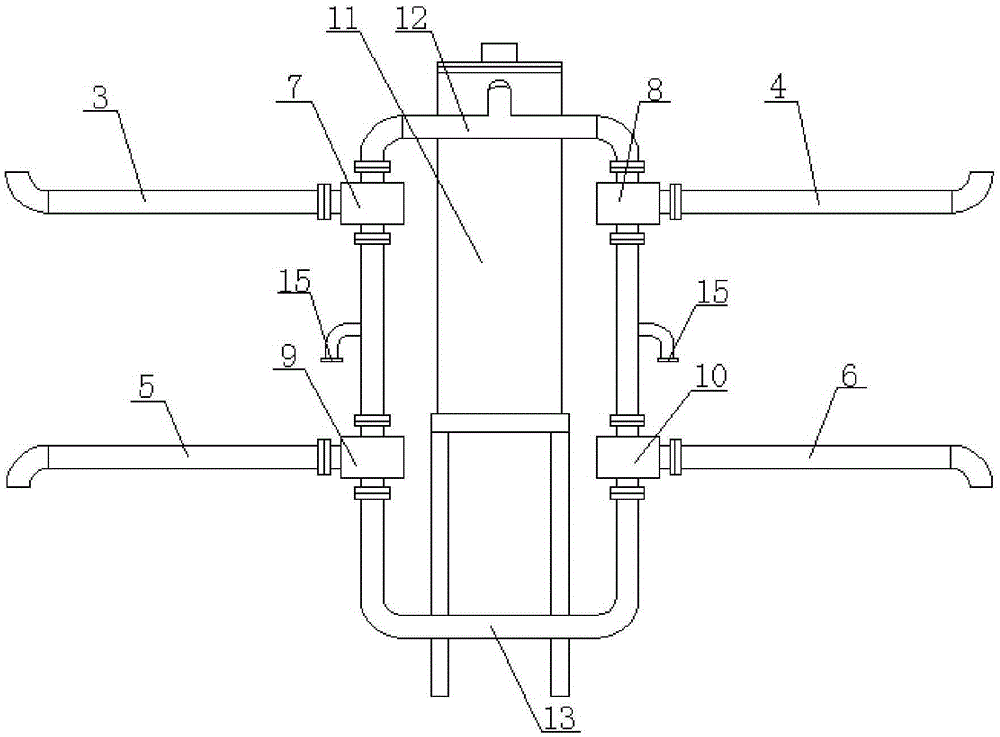

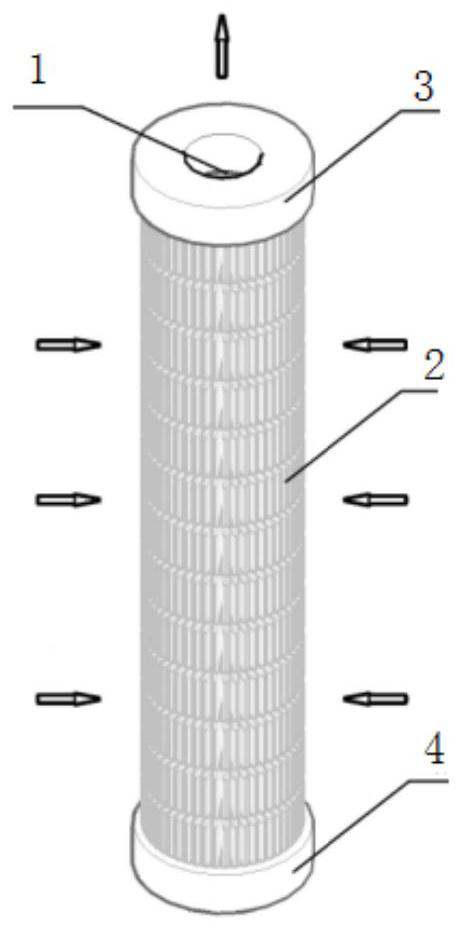

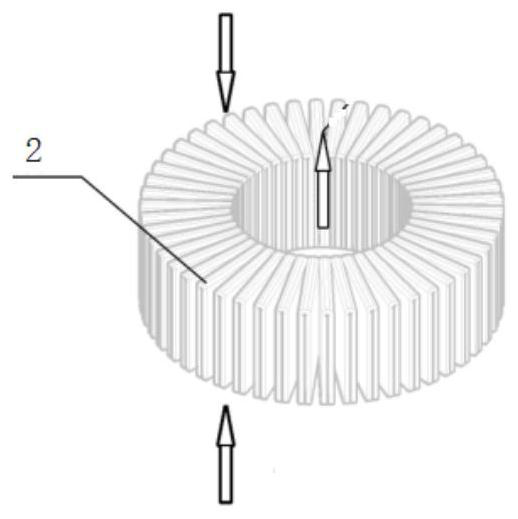

Sanitary external pressure hollow fiber membrane assembly water collecting device

ActiveCN102527242ABackwash thoroughlyWash thoroughlySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater flowBiomedical engineering

The invention discloses a sanitary external pressure hollow fiber membrane assembly water collecting device, which is characterized by being provided with a cylindrical shell (1), wherein a cylindrical hollow cavity (2) is formed inside the shell (1), and forms a water flow channel; the top end of the shell (1) is provided with a water inlet / outlet (3); the water inlet / outlet (3) is communicated with the cylindrical hollow cavity (2); the inner wall of the cylindrical hollow cavity (2) is a smooth circular-arc curved surface; the bottom end (4) of the cylindrical hollow cavity is a concave semispherical surface; the outer side wall of the shell (1) is provided with a cementing port (5) for fixing the membrane end of a hollow fiber membrane along a cylindrical length direction; and the distance between the bottom end of the cementing port (5) and the bottom end (4) of the cylindrical hollow cavity is smaller than or equal to 1.5 times the diameter of the cylindrical hollow cavity (2). The water collecting device does not encourage the growth of bacteria, does not leave harmful substances, and has a simple structure and low cost.

Owner:苏州普滤得净化股份有限公司

Method of treating saline industrial wastewater

InactiveCN107804929AImprove dirt holding capacityEfficient removalWater contaminantsTreatment involving filtrationFiberHollow fibre

The invention relates to a method of treating saline industrial wastewater, comprising the steps of (1) pretreating, to be specific, delivering wastewater into a filter tank to remove suspended matters; (2) ultrafiltering, to be specific, delivering the wastewater of step (1) into an external pressure ultrafiltration system to perform ultrafiltering; (3) performing reverse osmosis, to be specific,delivering the wastewater of step (2) to a reverse osmosis system, and removing salt; (4), performing stripping, to be specific, delivering the produced water of reverse osmosis of step (3) into a stripping column, performing stripping, and adjusting pH to meet reuse needs. The method has the advantages that a multistage quartz sand filter tank can be used to effectively remove suspended matterswith blockage rarely occurring; the external pressure ultrafiltration system used herein has good applicability and is available for full-flow filtration; ultrafiltration membranes are of hollow fiber, having good strength, backflushing is more thorough, and the membranes can restore their performance well; BW30XFR-400 / 34i or PROC10 reverse osmosis membrane components can provide high salt removalrate, reaching 98% and above, and the comprehensive recovery rate of wastewater is high, reaching 85% and above.

Owner:NORTHEAST GASOLINEEUM UNIV

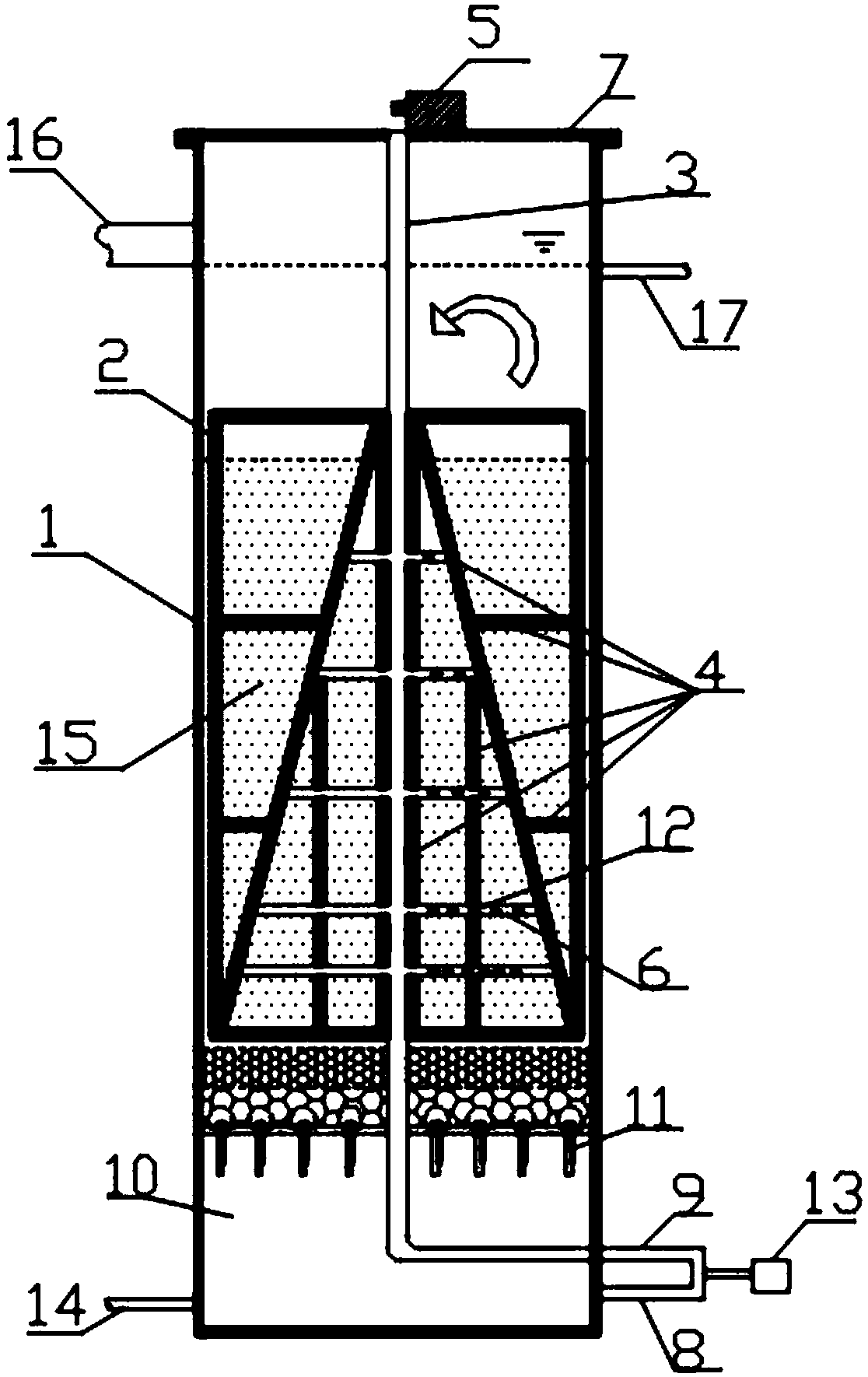

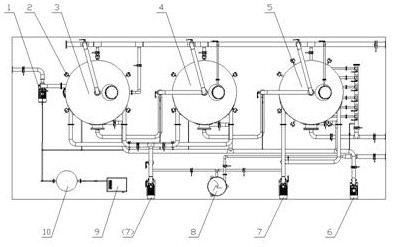

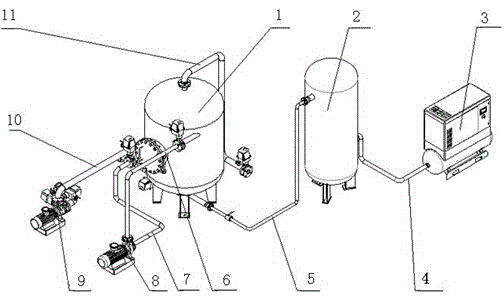

Rainwater comprehensive treatment integrated equipment

ActiveCN104003547AReduce weightEasy to transportMultistage water/sewage treatmentFiltrationWater quality

The invention discloses rainwater comprehensive treatment integrated equipment. The rainwater comprehensive treatment integrated equipment comprises a vertical tank, wherein the inner part of the tank is a closed space, the bottom space of the tank is a water distribution chamber, a heavy type light filter material is filled in the lower space of the tank and is located above the water distribution chamber, the upper space of the tank is a clear water chamber for containing filtered water, an automatic chlorine adding and pH value adjusting device is arranged in the clear water chamber, a water inlet and a sewage draining outlet are formed in the wall of the water distribution chamber of the tank, and a water outlet is formed in the wall of the clear water chamber of the tank. The rainwater comprehensive treatment integrated equipment has the advantages that the heavy type light filter material has good filtration and absorption effects on impurities in rainwater so as to ensure the quality of yielding water; the weight of the equipment can be reduced, and the equipment is suitable for occasions having requirements on bearing and is also convenient to transport and install; as the automatic chlorine adding and pH value adjusting device is arranged in the tank, an external chlorine adding disinfection system and a Ph value adjusting system are omitted, treatment technological processes are simplified, and the equipment is convenient to maintain; rainwater treatment processes are integrated in the integrated equipment, and the rainwater comprehensive treatment integrated equipment is simple in structure, low in cost and convenient to manage and maintain and occupies a small area.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Three-in-one treatment device for turbulence air flotation, filtration and electrodeionization of cations

PendingCN112759159AReduce cation contentAvoid destructionWaste water treatment from quariesWater/sewage treatment by centrifugal separationOil fieldSewage

The invention discloses a three-in-one treatment device for turbulence air floatation, filtration and electroelimination of cations. The device comprises a coarse treater, a fine treater and a precise treater, a lifting pump is connected with the liquid inlet of the coarse treater through a pipeline; the outlet of the coarse treater is connected with the inlet of the fine treater through a pipeline, and the outlet of the fine treater is connected with a liquid inlet pipe orifice of the precise processor through a pipeline; the treatment process flow is complete, the whole-process treatment of the oil field sewage can be independently completed, oil and suspended solids in the oil field sewage are removed, the water quality is subjected to electrodeionization treatment, the cation content in the water quality is reduced, scaling is prevented from damaging the original scale layer, the corrosion of the water quality to equipment is slowed down, the dissolved oxygen content is reduced, and harmful bacteria in the sewage are reduced; the external circulation scrubbing and thorough backwashing of the filter material can be realized, in the operation process, only gas and electricity are added, and no chemicals are added, so that the device is green, environment-friendly, safe, pollution-free and good in treatment effect, and can be widely applied to oil and suspended matter removal polarization treatment of oilfield sewage.

Owner:张后继

Washing and regenerating method of particle filter material filter tank for preventing filter material from scaling and hardening

InactiveCN104826373AEasy to operateBackwash thoroughlyLoose filtering material filtersGravity filtersExtracorporeal circulationFilter material

The invention discloses a washing and regenerating method of a particle filter material filter tank for preventing the filter material from scaling and hardening. When the filter tank is back-washed, the method is as follows: performing air blast with compressed gas; loosening the filter compressed during filtering; starting a backwash pump to back wash after the gas is stopped and the pressure is released, wherein the particle filter material is fluidized by water through the backwash pump; and starting a filter material circulating pump to perform external circulating and back bashing on the filter material till the filter material is clean. When the back wash is completed, the filter material is stopped first and then the backwash pump is stopped; the method is thorough in back wash; no dead corner is left in the tank; meanwhile, the back washing intensity is small, the water usage is little and the effect is good; and the particle filter material is effectively prevented from scaling and hardening and the method can be widely applied for washing and regenerating the particle filter material filter tank.

Owner:SHANDONG HYGIYA ENVIRONMENTAL PROTECTION EQUIP

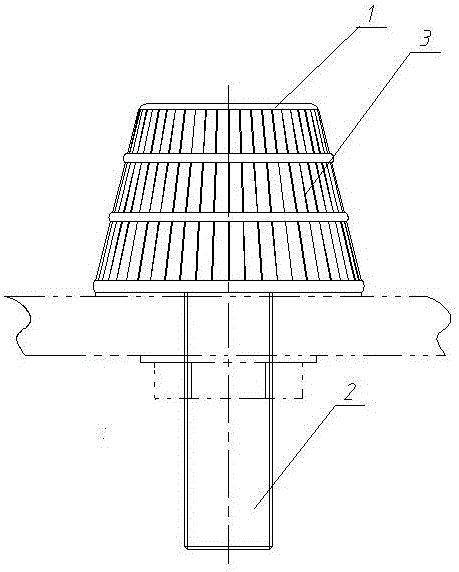

Spiral-flow type water cap

InactiveCN105833576ANot easy to looseFirmly connectedMembrane filtersLoose filtering material filtersEnvironmental engineeringSpiral flow

The invention provides a spiral-flow type water cap, which comprises a conical water cap body and a center water pipe. The spiral-flow type water cap is characterized in that a plurality of water outlets inclined in the vertical direction are formed in the conical water cap body; the center water pipe is arranged in the conical water cap body; a water passing opening is formed in the center water pipe; the plurality of water openings inclined in the vertical direction and the center water pipe form a water spiral flow passage. The conical water cap body and the center water pipe are integrally formed by plastics. The spiral-flow type water cap has the advantages that the structure is reasonable; the filtering efficiency is high; the reverse flushing effect is good; the service life is long, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

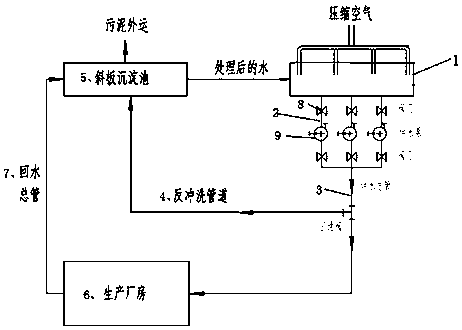

Industrial production water pool apparatus capable of performing online backwashing

InactiveCN109626606AGuaranteed uptimeAvoid offline dredgingSpecific water treatment objectivesScale removal and water softeningMarine engineeringPrecipitation

The invention belongs to the field of water treatment equipment, and particularly relates to an industrial production water pool apparatus capable of performing online backwashing. The industrial production water pool apparatus comprises a production water pool, wherein the top portion of the production water pool is provided with a compressed air total pipe, the compressed air total pipe is connected to four vertical and downward compressed air branch pipes arranged side by side, the compressed air branch pipes are arranged in the production water pool, the bottom portion of the production water pool is provided with three branch pipes, the three branch pipes are connected in parallel and are connected to a water supply total pipe, the water supply total pipe is connected to a backwashingpipeline, the other end of the backwashing pipeline is connected to an inclined plate precipitation pool, the inclined plate precipitation pool is connected to the production water pool through a pipeline, the branch pipe of the water supply total pipe is connected to a production workshop, and the production workshop is connected to the inclined plate precipitation pool through a water return total pipe.

Owner:RIZHAO STEEL HLDG GROUP

Backwashing method and device of filter

InactiveCN101982216BStrong scrubbing actionPowerful centrifugal separationFatty/oily/floating substances removal devicesLoose filtering material filtersFilter mediaEngineering

The invention discloses a backwashing method of a filter, which solves a problem of low backwashing efficiency of traditional filters, a specific method is that a whirl cavity, a water collection cavity, a filtering medium collection and transfer cavity and a discharge cavity are all installed in the filter, so that a mixed liquor generates a strong centrifugal separation acting force after passing through the whirl cavity, the acting force results in not only applying a rubbing force on the filtering medium, but also effectively separating the filtering medium from oil and suspending impurities through their channels, namely, the oil and the suspending impurities are discharged from a tank via the water collection cavity, the washed filtering medium is sequentially returned back to the tank via the collection and transfer cavity and the discharge cavity, repeating in this cycle, the filtering medium can be completely washed; the invention also provides a device capable of implementing the method.

Owner:NORTHEAST GASOLINEEUM UNIV

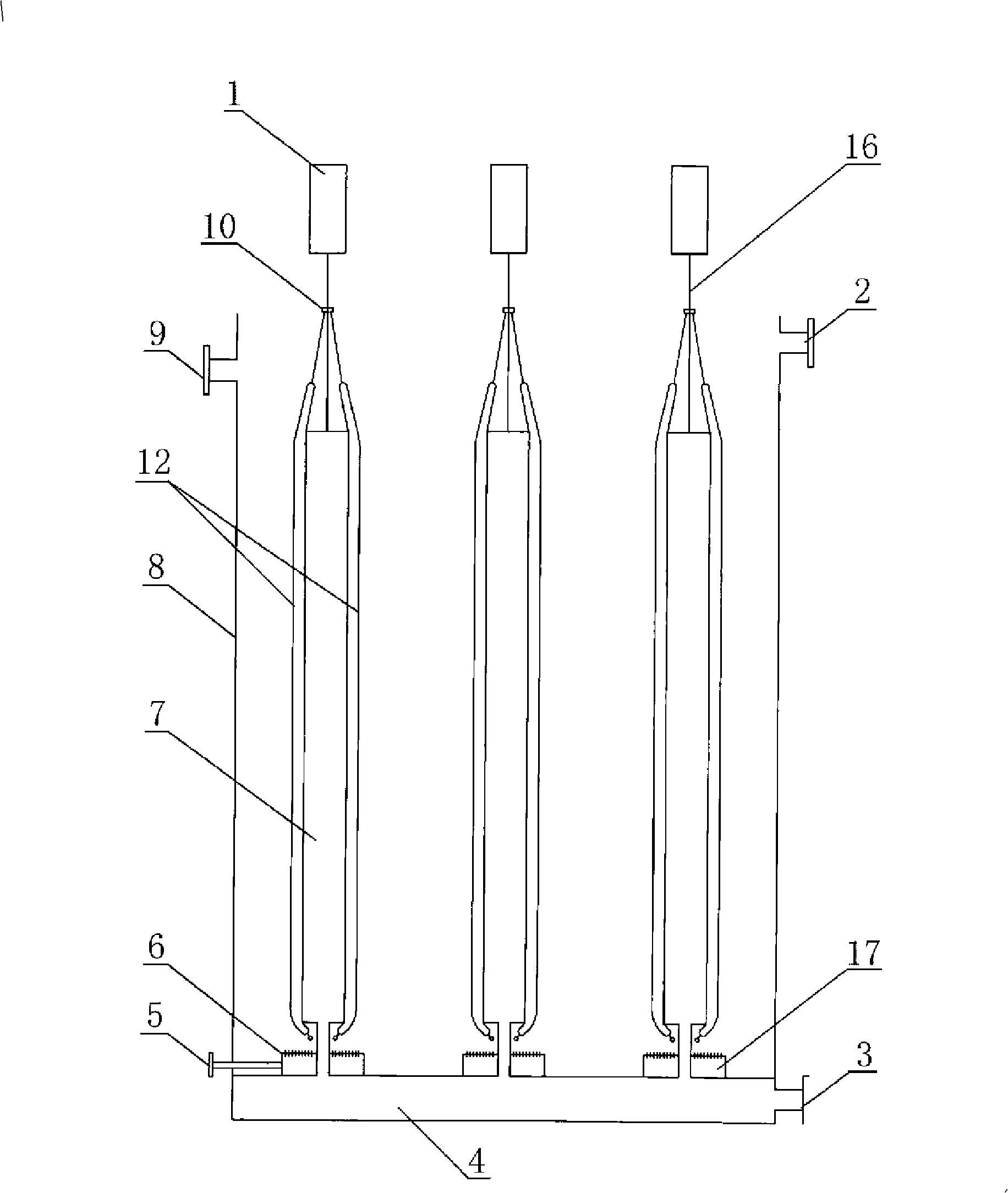

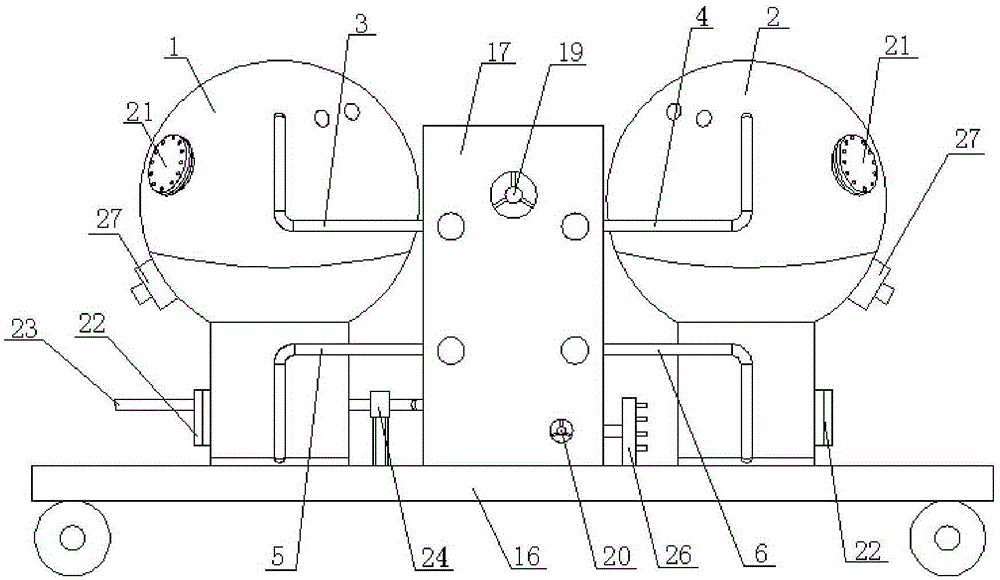

Water purification station for underground mine

InactiveCN105311877AEnsure efficient productionGuaranteed cleanlinessFiltration circuitsEmulsionSewage

The invention discloses a water purification station for an underground mine. The water purification station comprises two same tank bodies, wherein the upper half parts of the tank bodies are spheres, and the lower half parts are barrels; the diameters of the spheres are larger than the diameters of the barrels; water inlet pipes and water outlet pipes are respectively arranged at the tops and the bottoms of the tank bodies; a 3-way ball valve is arranged on each of the water inlet pipes and each of the water outlet pipes; pipelines are connected between the 3-way ball valves on the same sides; a sewage draining exit is formed in each of the two pipelines; the water inlet pipes are connected with a gap type screen drum; the water inlet of the gap type screen drum is connected with an original water inlet; the water outlet pipes are connected with a water outlet end; a fiber filter material is arranged in each of the inner cavities of the two tank bodies; an emulsion motor is arranged in each of the two tank bodies; each emulsion motor is connected with a liquid supply device through a liquid supply pipeline and a liquid returning pipeline. According to the water purification station, the structure is simple, and the backwashing of the two tank bodies is more complete through the stirring function of the emulsion motors; the emulsion motors are driven through an emulsion, so that the electric power is not consumed, the safety is guaranteed, the cost is reduced, and the efficient production of a coal mine is guaranteed.

Owner:HUAINAN RUNCHENG TECH

Butterfly type water filtration backwashing filter element

PendingCN112807772AMake up for the problem of small fluxSolve the problem of constant replacementMembrane filtersStationary filtering element filtersAgricultural engineeringWater flow

The invention discloses a butterfly type water filtration backwashing filter element which comprises a plurality of butterfly type filter materials, an inner framework, an end cover and a tail cover, the end cover and the tail cover are arranged on the two sides of the butterfly type filter materials respectively, the butterfly type filter materials form a circle through a pleating technology, the interiors of the pleated and looped butterfly type filter materials are connected with the surface of the inner framework in a welded mode, and through holes for water flowing are distributed in the surface of the inner framework. The outer side surface of the butterfly filter material is welded and sealed; and the butterfly type filter material structures are relatively independent, are mutually stacked and are welded with the inner framework to form the whole butterfly type filter element. The end cover is a water outlet or backwashing water inlet end cover, water can flow out through the end cover after being filtered, and the filtered water can also flow in through the end cover reversely for backwashing from inside to outside. The butterfly type filter element disclosed by the invention is greatly superior to various traditional backwashing filter elements in filter area, and a plurality of butterfly type filter materials operate independently and are stacked for mutual support, so that the backwashing strength of the filter materials is enhanced, and the filter capacity and the backwashing recovery capacity are improved.

Owner:联合滤洁过滤技术(武汉)有限公司

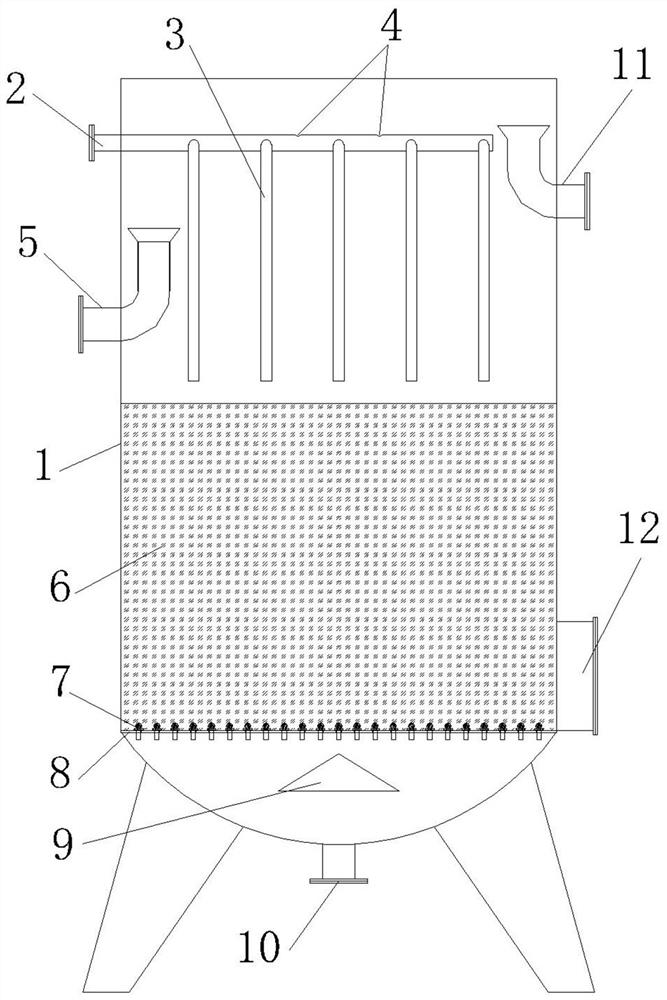

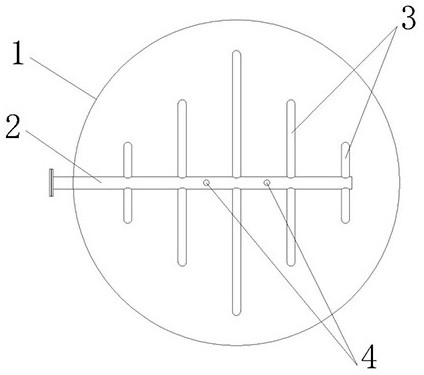

Gravity flow denitrification filter

PendingCN112624522AAvoid destructionReduce wasteSpecific water treatment objectivesWater contaminantsNitrogen removalFilter system

The invention belongs to the technical field of sewage treatment equipment for environmental engineering and municipal engineering, and particularly relates to a patent application of a gravity flow denitrification filter. The filter specifically comprises a filter body, a water distribution system arranged at the upper part in the filter body, a filter system arranged at the lower part in the filter body, and a drain pipe positioned at the bottom of the filter body and used for draining treated water; the water distribution system comprises a water distribution main pipe and water distribution branch pipes extending downwards on the water distribution main pipe. The filter system comprises a filter material layer which is positioned above a filter plate and consists of a filter material, and filter heads arranged on the filter plate; the filter heads are uniformly distributed on the filter plate and consist of umbrella-shaped filter caps with filter holes and hollow filter rods which penetrate through the filter plate and are arranged below the filter caps; and the filter material is naturally laid. By improving the water inlet and distribution system of the denitrification filter, the anoxic environment of denitrification nitrogen removal is effectively guaranteed, carbon source waste is reduced, and the operation cost is saved.

Owner:河南冠宇环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com