Whole-membrane-process water treatment integration device

A technology of water treatment and full-membrane method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of energy-consuming design, manufacture, and commissioning of test devices, and achieve Simple internal structure, long life, easy to manufacture and install

Inactive Publication Date: 2013-02-27

NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

View PDF6 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] With the increasing development of water treatment technology, for how to formulate the treatment process of complex water sources, it is necessary to pass a series of experiments and obtain the optimal results before arriving at the final solution. At present, various units engaged in water treatment are encountering similar During the test, it is always necessary to spend energy to design, manufacture and debug the test device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

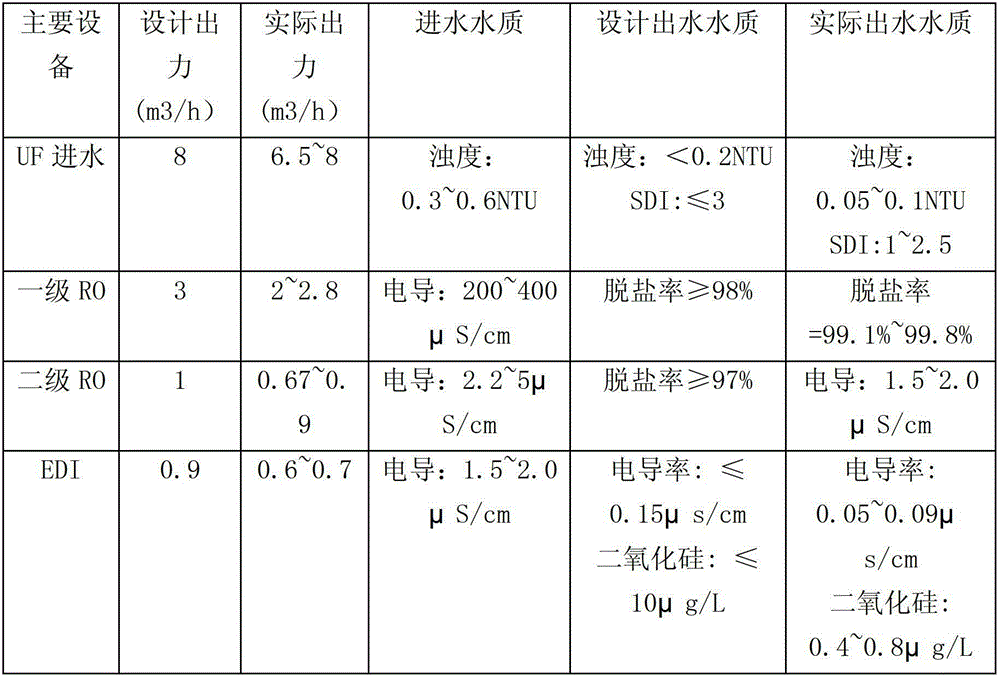

[0027] In the pilot test of boiler make-up water process selection in a certain power plant, this set of full-membrane integrated device was used, and the pilot test effect was good.

[0028] Table 1 Analysis table of a power plant boiler feed water test

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

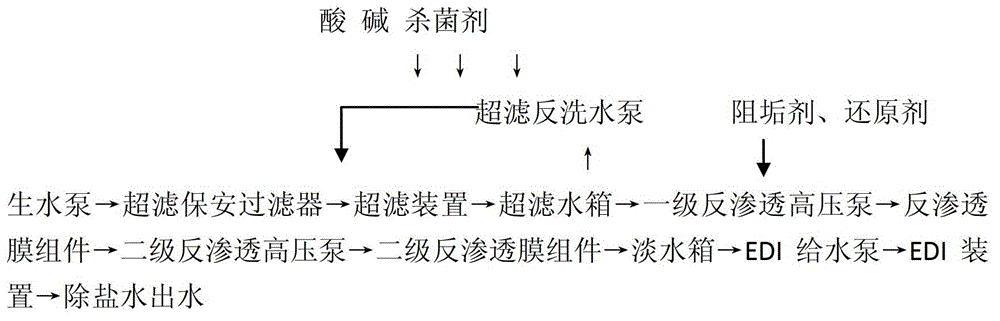

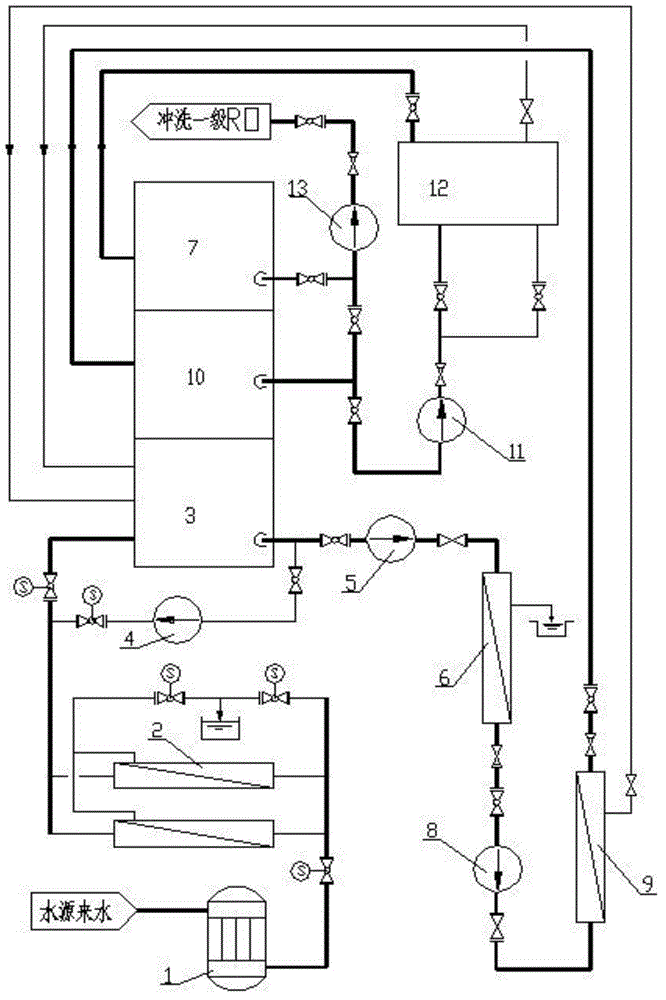

The invention discloses a whole-membrane-process water treatment integration device. The whole-membrane-process water treatment integration device is characterized in that 'whole-membrane-process' water treatment components are integrated into a small-size device, and comprise a raw water pump, an ultra-filtration safety filter, an ultra-filtration membrane component, an ultra-filtration water tank, an ultra-filtration backwashing water pump, reverse-osmosis high-pressure pumps, reverse-osmosis membrane components, a fresh-water tank, an EDI (Electrodeionization) water feeding pump, an EDI membrane block, an acid dosing device, an alkali dosing device, a bactericide device, a scale inhibitor device, a reducing-agent device, a valve, pipelines and a PLC (Programmable Logic Control) control system; the ultra-filtration device consisting of the raw water pump, the ultra-filtration safety filter and the ultra-filtration membrane component, the ultra-filtration water tank, the first-stage reverse-osmosis high-pressure pump, the reverse-osmosis membrane component, the second-stage reverse-osmosis high-pressure pump, the second-stage reverse-osmosis membrane component, the fresh-water tank, the EDI water feeding pump and the EDI device are connected by the pipelines in the following sequence till the desalting water is discharged; and the ultra-filtration backwashing waterpump is arranged to be connected with the ultra-filtration membrane component for backwashing; and the acid dosing device, the alkali dosing device and the bactericide device are respectively connected to the ultra-filtration device.

Description

technical field [0001] The invention relates to a desalinated water treatment device, which can realize automatic operation of the device through an automatic control system, remove colloids, particles, germs, dissolved solids, etc. in water, and the effluent water quality index is better than the secondary desalinated water standard (ie Conductivity (25℃)<0.1μS / cm, silicon dioxide (SiO 2 )<20μg / L). The device is mainly used for pilot tests of enterprise-level water treatment projects, laboratory research of scientific research institutions and educational institutions. Background technique [0002] With the development of science and technology, water treatment technology is no exception. On the road of water treatment technology, it has experienced three generations of water treatment process development. The first generation process is filter + cation exchanger + carbon remover + anion exchanger + mixed ion exchanger. The second-generation process is filter (doub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/04

Inventor 王静史宇涛南晓东袁劲梅

Owner NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com