Industrial production water pool apparatus capable of performing online backwashing

A backwashing, industrial technology, applied in descaling and water softening, water/sludge/sewage treatment, sedimentation tank, etc., can solve the problem of consuming a lot of manpower and material resources, reducing the operation rate of the main production equipment, and long cleaning cycle, etc. problems, to achieve the effect of improving operation rate, reducing occupational hazards, and reducing dredging manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

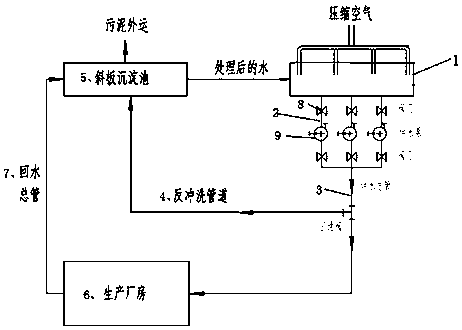

[0017] An industrial production pool device capable of backwashing on-line, comprising a production pool 1, a compressed air main pipe is provided on the top of the production water pool 1, and the compressed air main pipe is connected with four vertically downward and parallel compressed air branch pipes, The outlet of the compressed air branch pipe is set in the production pool 1, and the bottom of the production pool 1 is provided with three branch pipes 2, and the three branch pipes 2 are connected in parallel to the water supply main pipe 3, and the water supply main pipe 3 is connected to the backwash pipe 4 , the other end of the backwash pipeline 4 is connected with the inclined plate sedimentation tank 5, the inclined plate sedimentation tank 5 is connected with the production pool 1 through pipelines, and the branch pipe of the water supply main pipe 3 is connected with the production plant 6, and the The production plant 6 is connected with the inclined plate sedimen...

Embodiment 2

[0019] On the basis of Embodiment 1, two valves are provided on the branch pipe 2, and a water supply pump 9 is provided on the branch pipe between the two valves.

Embodiment 3

[0021] On the basis of Embodiment 2, at least three vertical sand retaining nets are arranged at equal intervals in the backwash pipeline 4, and the backwash pipeline 4 on the left and right sides of the sand retaining net is provided with sand discharge mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com