Back-flushing cutting module for ceramic bio-filter and three-dimensional back-flushing technology of back-flushing cutting module

A biological filter and backwashing technology, applied in the field of backwashing, can solve the problems of hardening, filter material clogging, etc., and achieve the effects of reducing cutting resistance, thorough backwashing, and saving backwash water volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

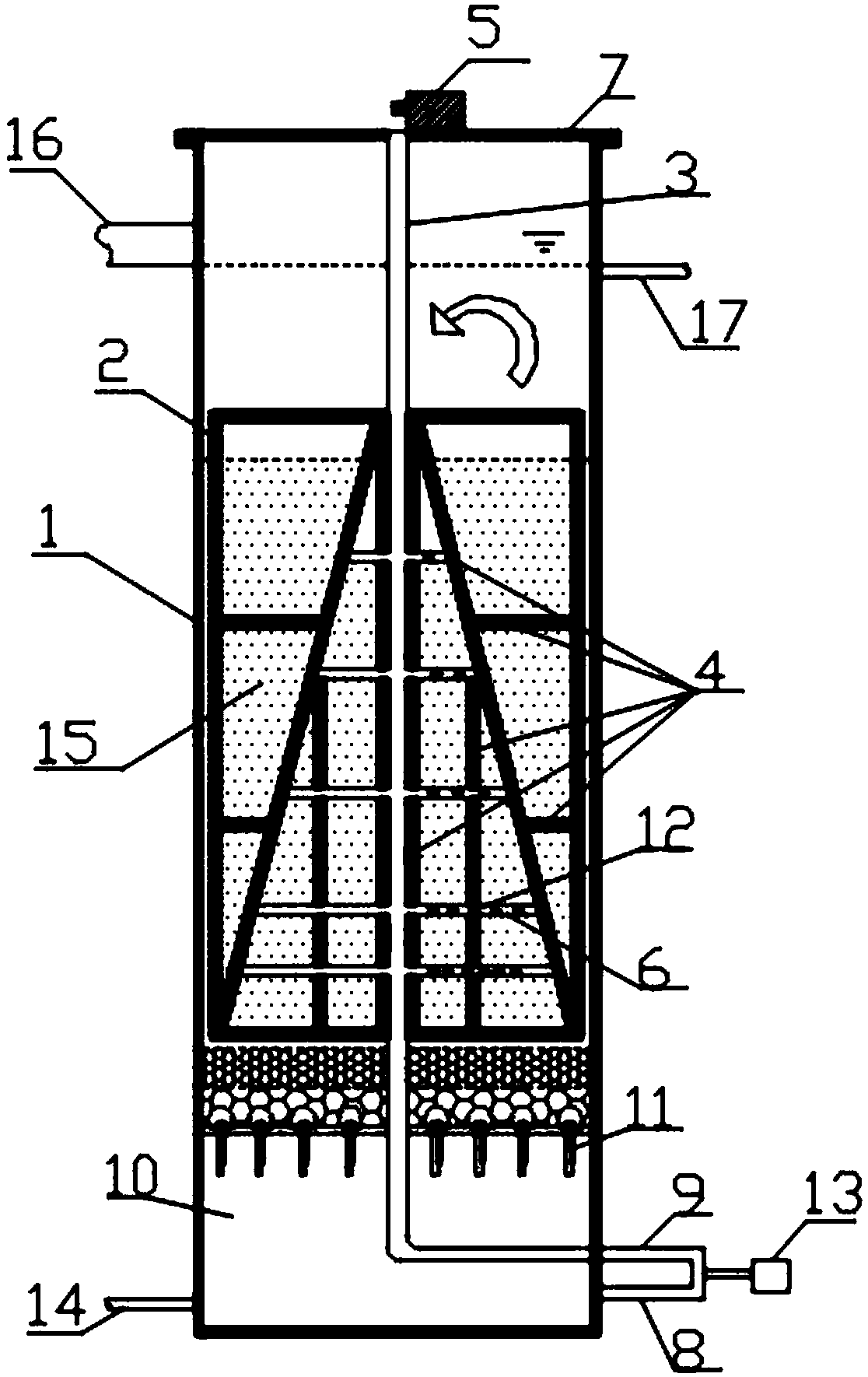

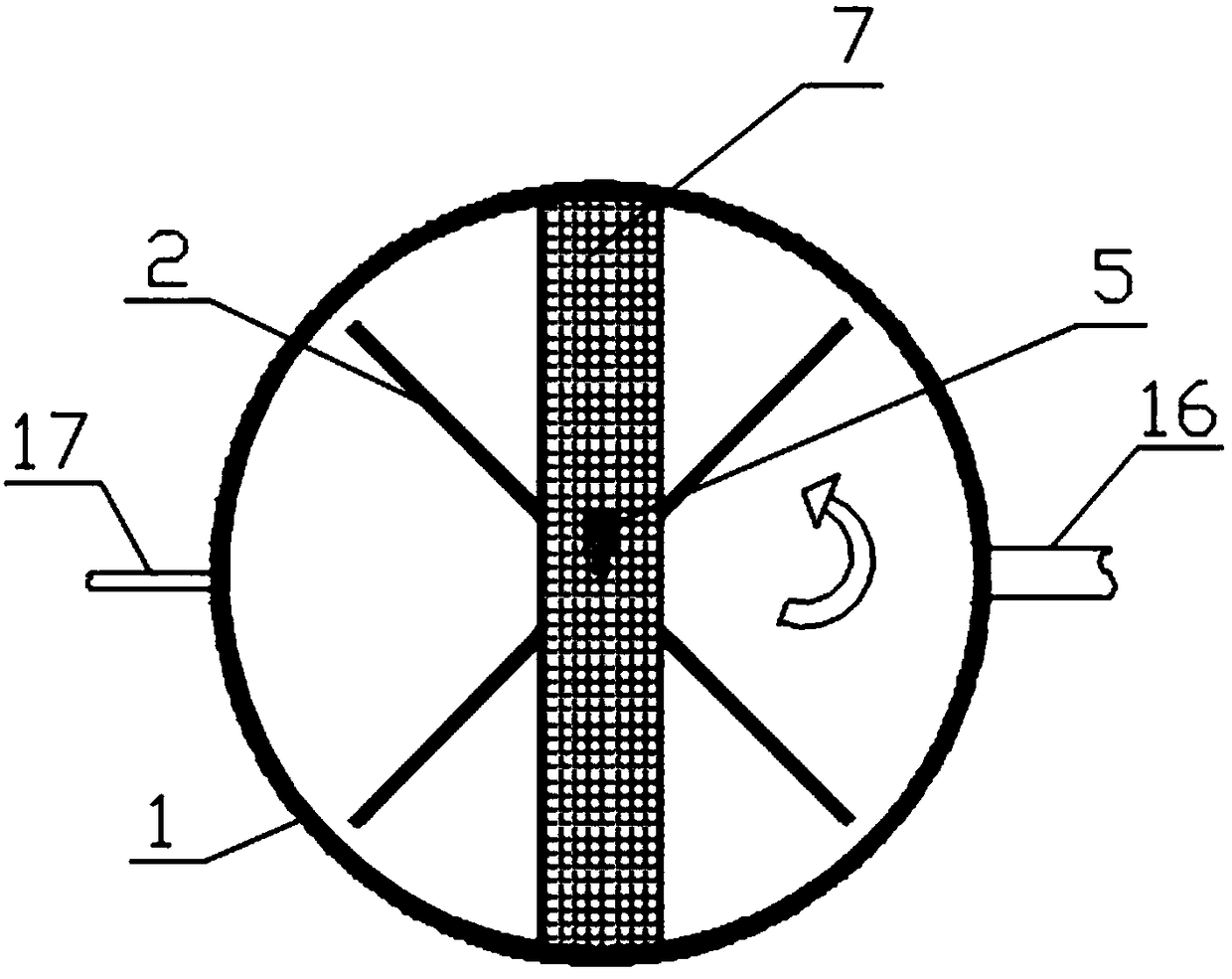

[0028] Such as figure 1 , 2 , 3, the ceramsite biofilter backwash cutting module of the present invention includes a ceramsite biofilter and a backwash cutting module, and the ceramsite biofilter includes a biofilter pool body 1, a high-pressure pulse water pump 13, The first backwash water inlet pipe 8, air inlet pipe 14, water distribution layer 10, water and air distribution pipeline 11, ceramsite filter material area 15, water outlet pipe 16, backwash water outlet pipe 17; the backwash cutting module is installed in the biological The interior of the ceramsite filter material area of the filter is perpendicular to the horizontal plane, including the cutting frame 2, the cutting frame 4, the second backwash water inlet pipe 9, the second backwash water inlet branch pipe 6, the rotating shaft 3, the frame plate 7, the transmission The motor 5, the second backwashing water inlet pipe 9 are connected to the upper part of the ceramsite filter material area 15, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com