A new type of magnetic separator and its application method

A magnetic separator, a new type of technology, applied in the field of magnetic separator, can solve the problems of high installation requirements, environmental impact, concentrate loss, etc., and achieve the effect of scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

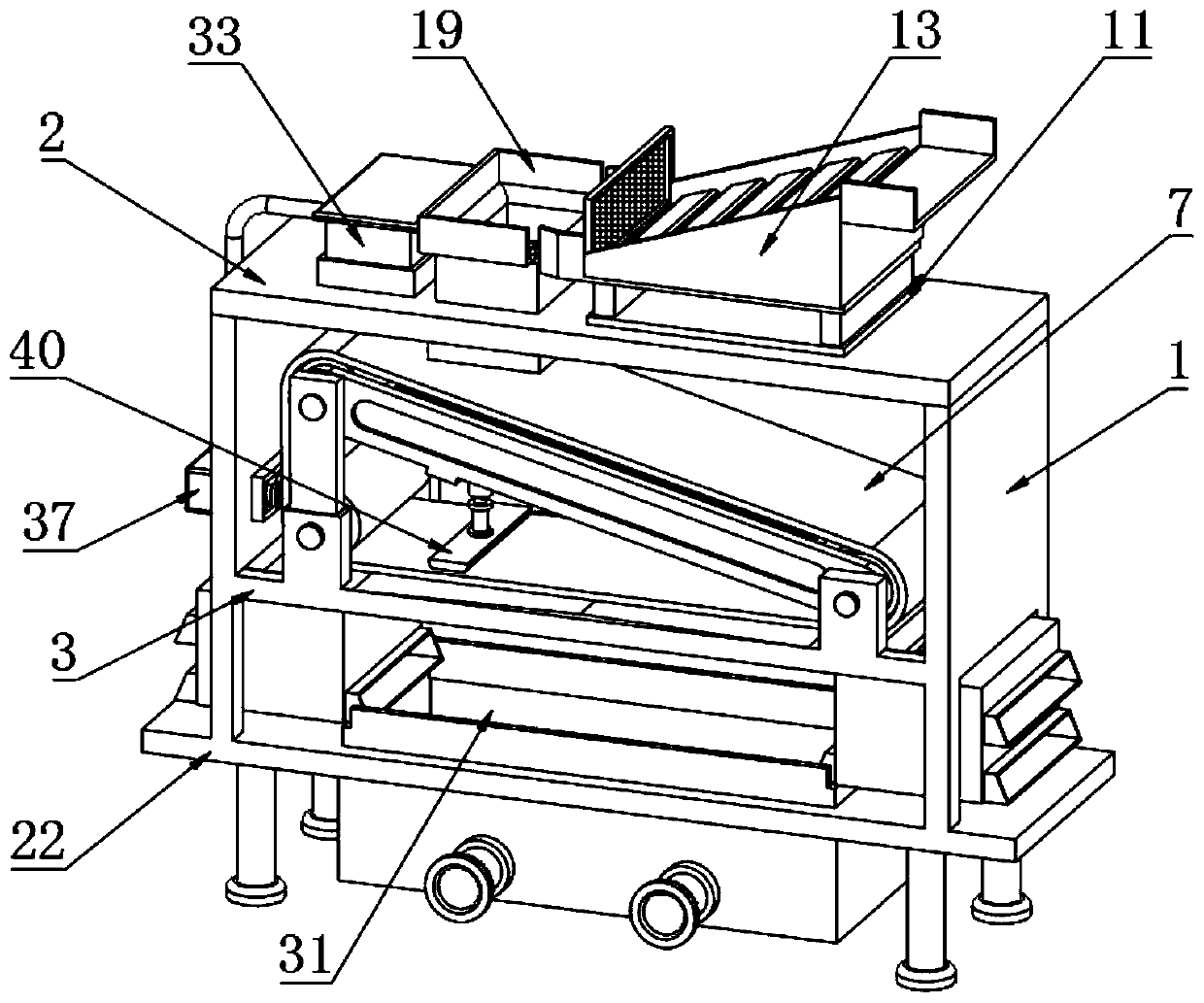

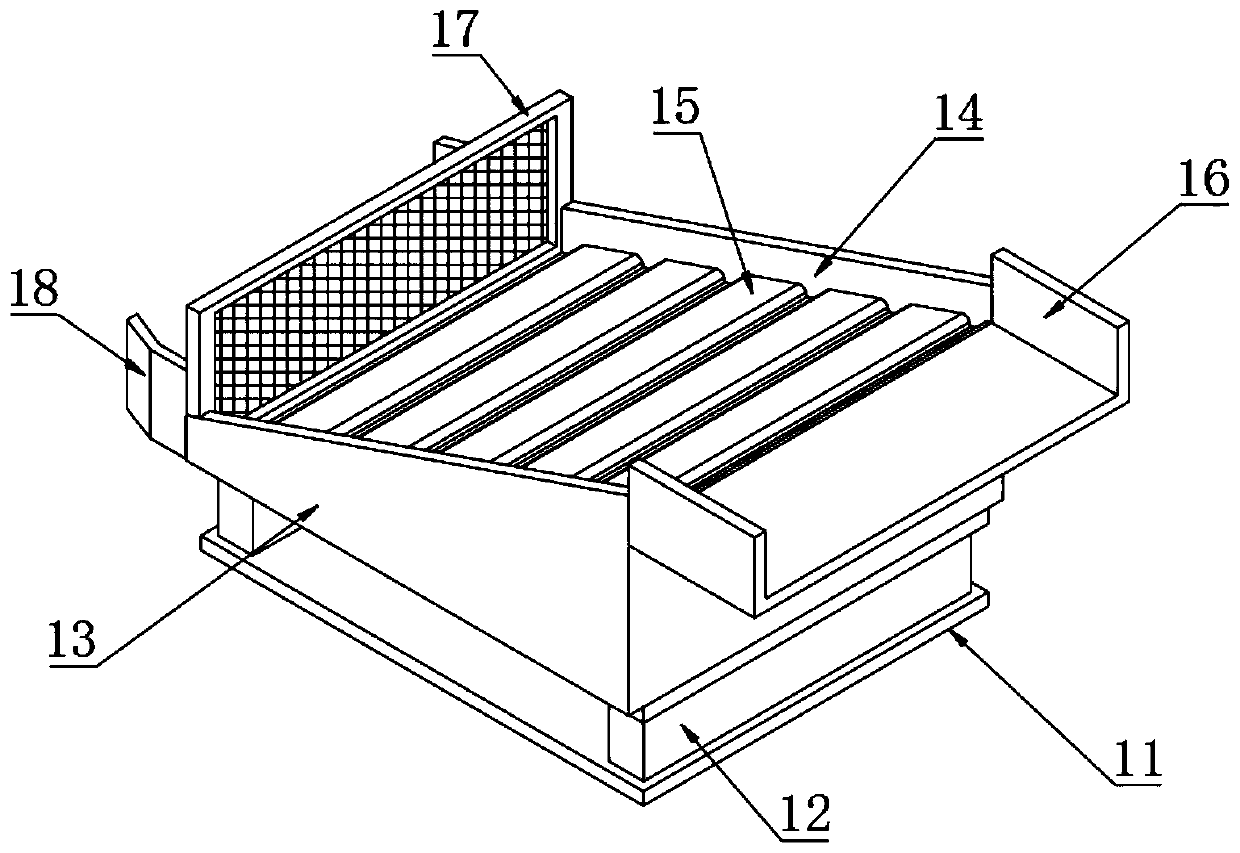

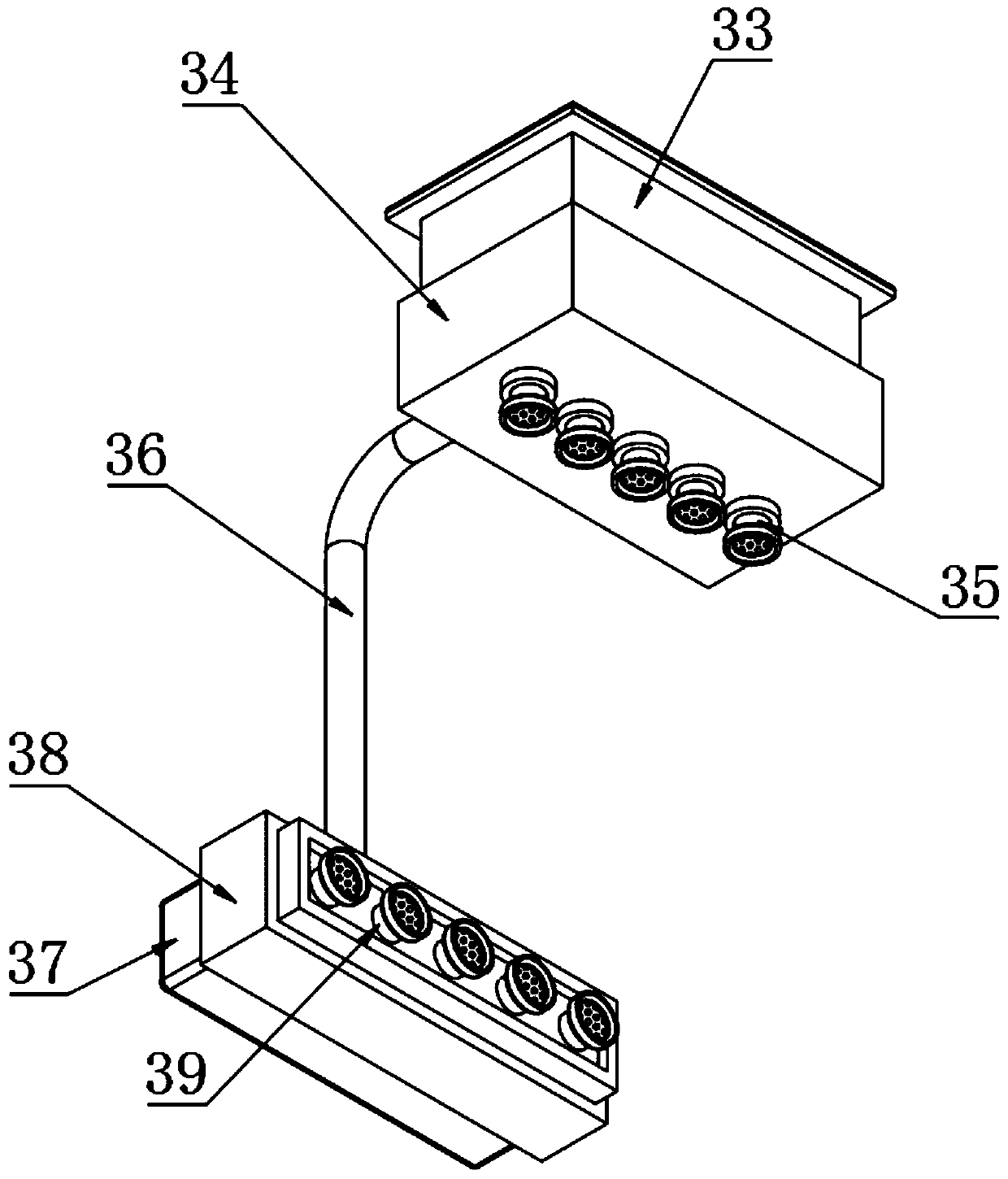

[0038] Embodiment 1: as Figure 1-8 As shown, the present invention provides a technical solution, a novel magnetic separator, comprising a mounting side plate 1, a top plate 2 is fixedly mounted on the top of the mounting side plate 1, a pressure-bearing bottom plate 3 is fixedly mounted on the bottom of the mounting side plate 1, and a bearing Mounting brackets 4 are symmetrically welded on both sides of the top of the pressure base plate 3. The top of the two mounting brackets 4 on one side of the top of the pressure base plate 3 is fixed with a support frame 5. The two mounting brackets located on both sides of the top of the pressure base plate 3 4 and the inner middle ends of the two supporting frames 5 are rotatably connected with a roller 6, and the outer sides of the three rollers 6 are all sleeved with a conveyor belt 7, and one end of the roller 6 is located on one side of the supporting frame 5 and is connected with a geared motor through a rotating shaft. And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com