Patents

Literature

44results about How to "Save backwash water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

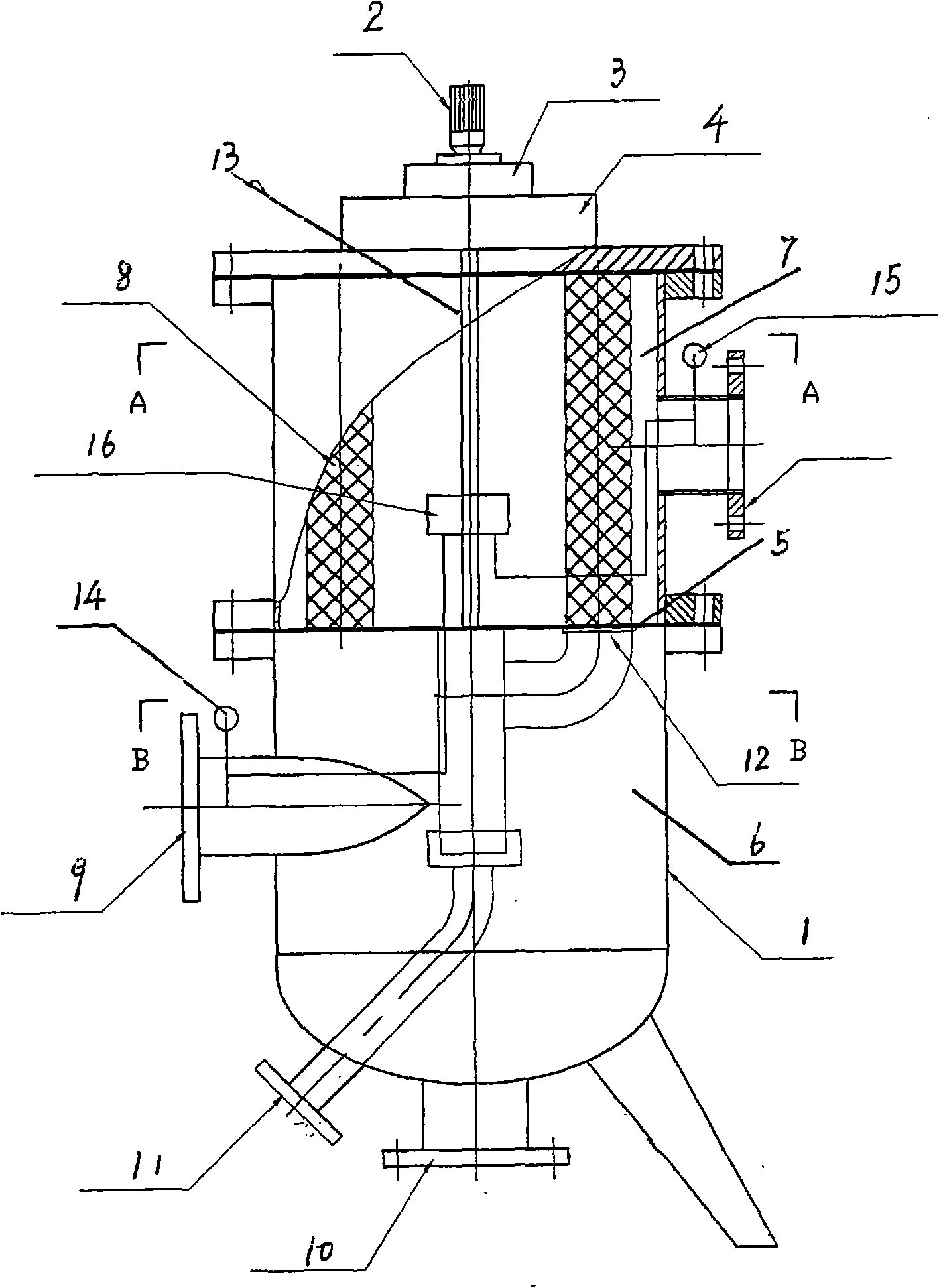

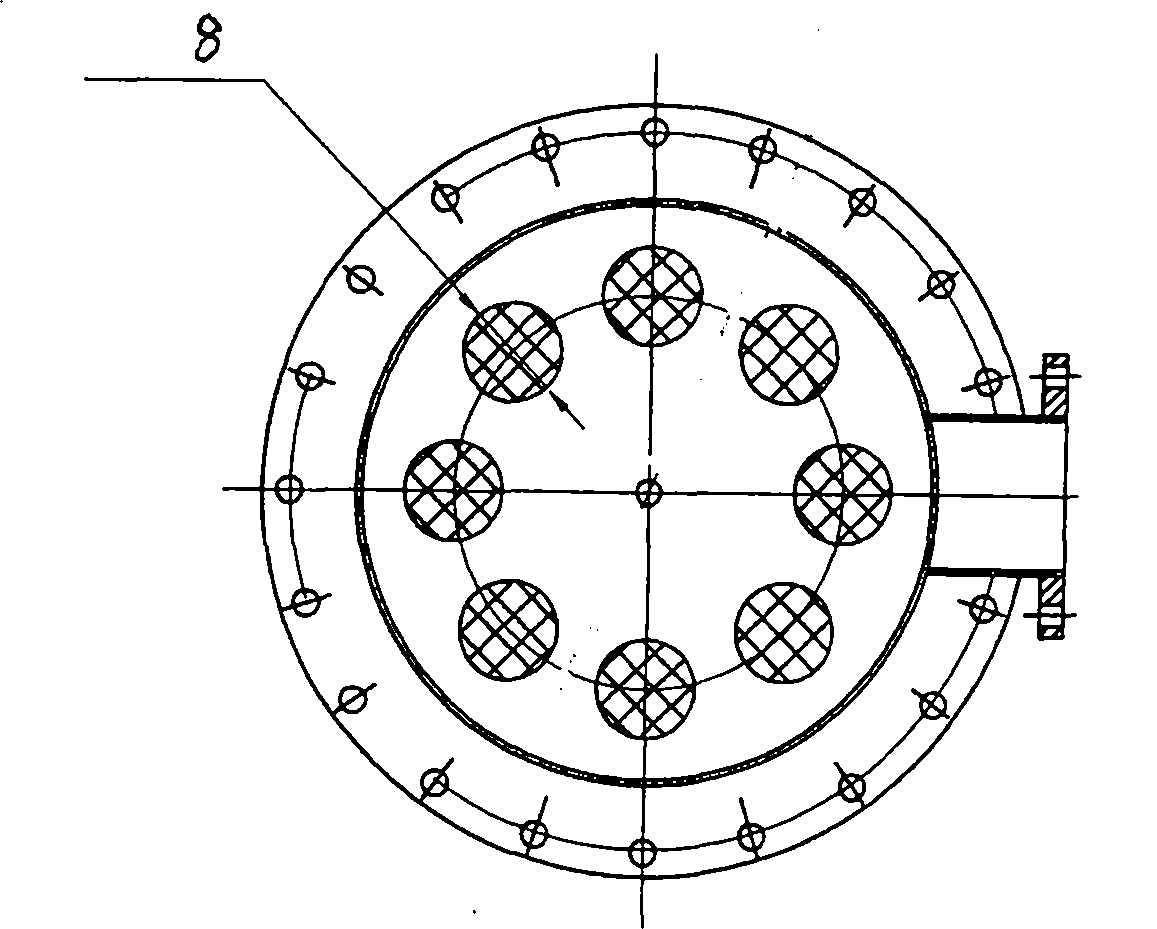

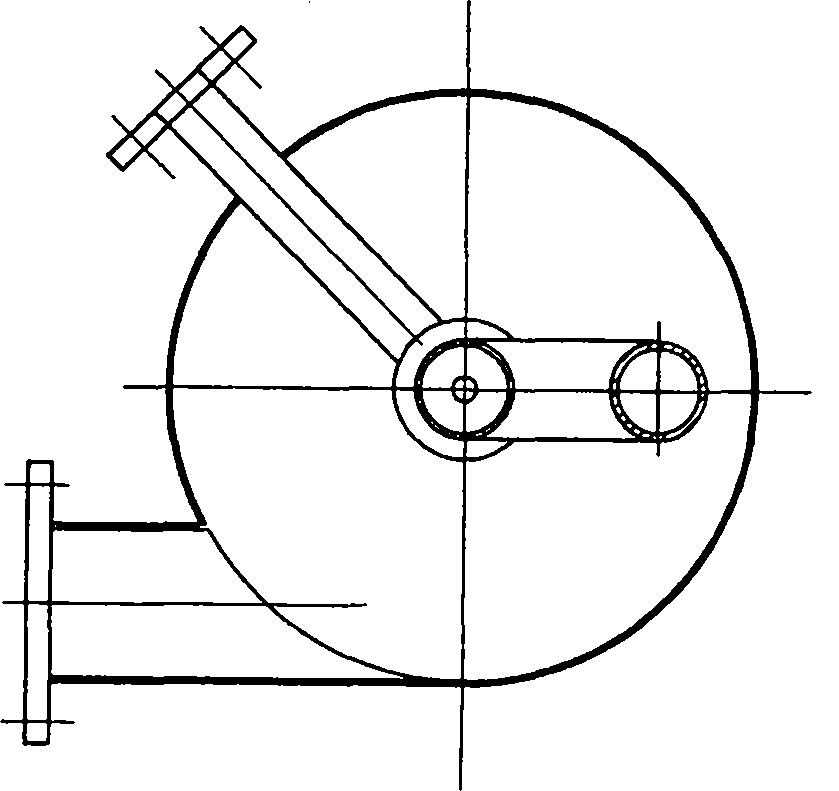

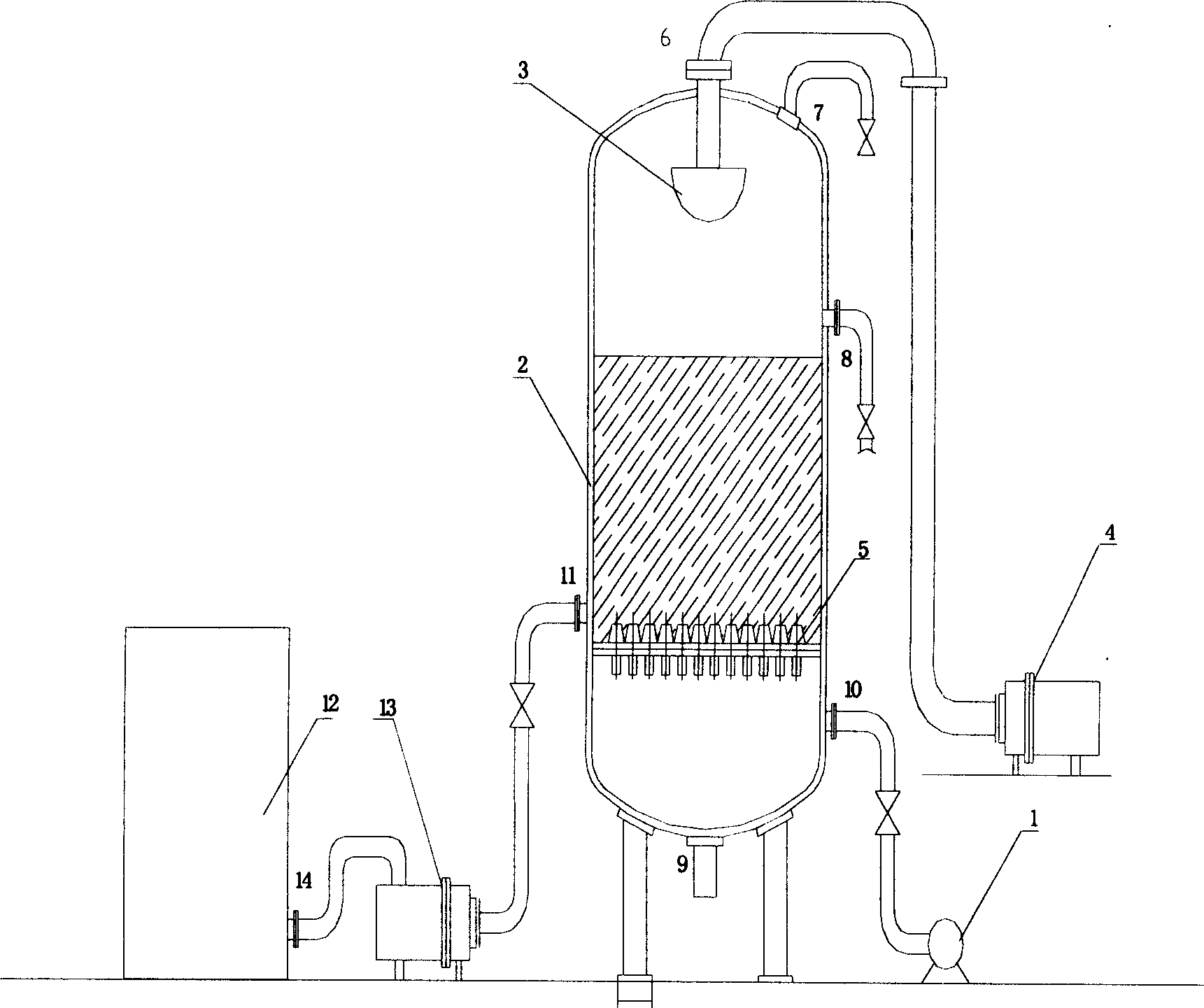

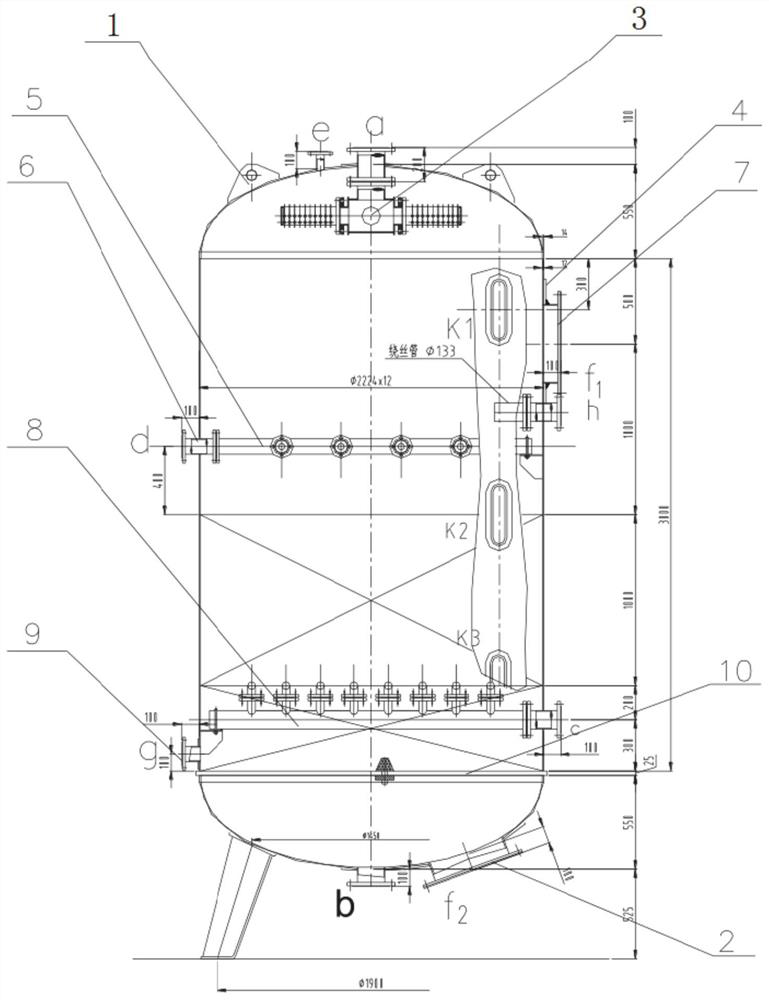

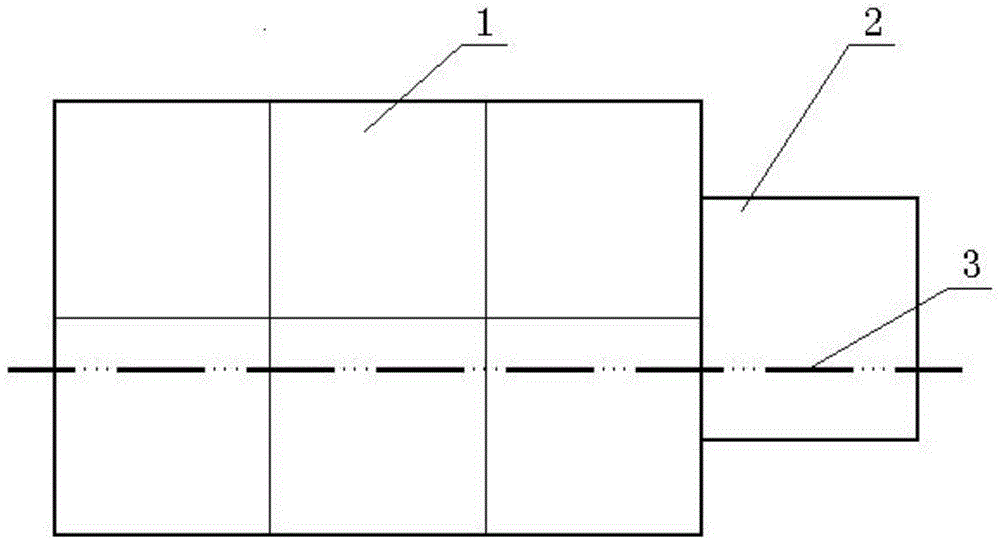

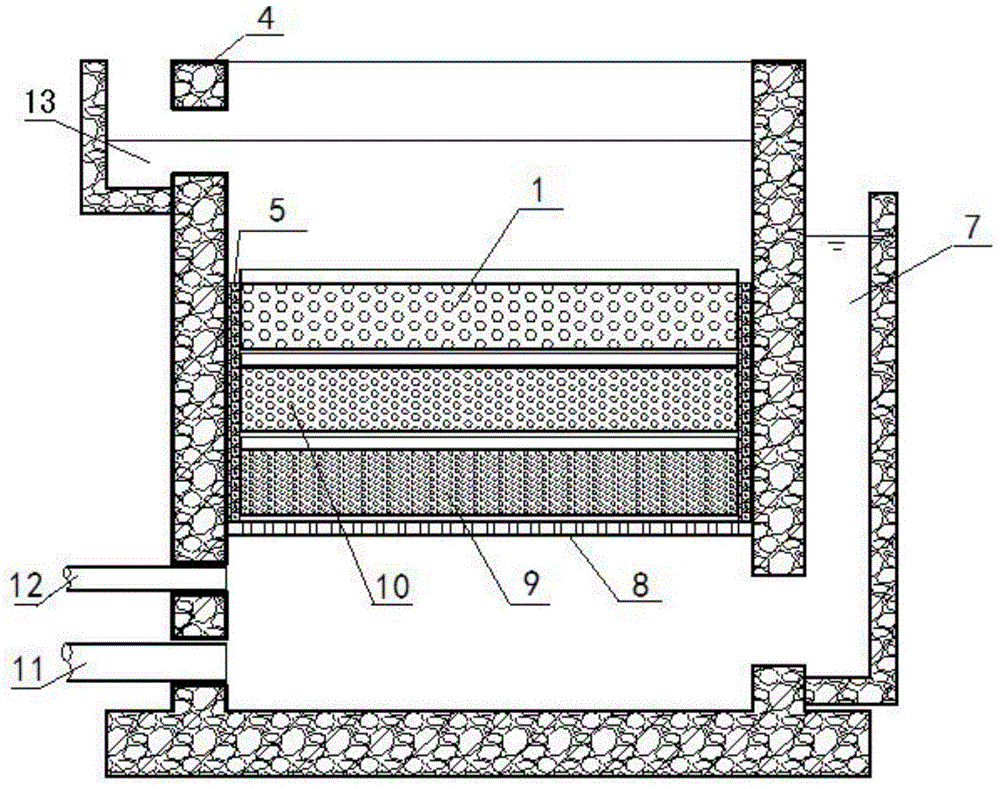

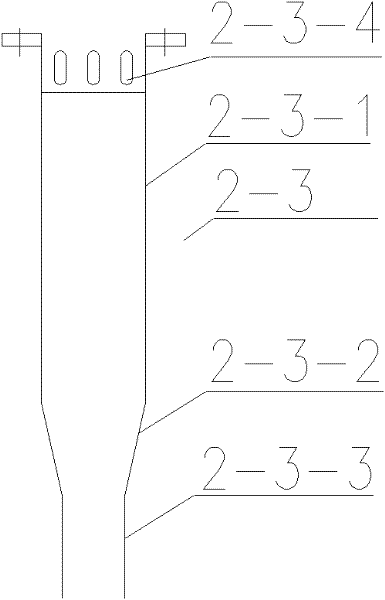

Differential-pressure swirl-type backwashing filtration system

InactiveCN102107100ANot easy to bruiseExtend your lifeStationary filtering element filtersFiltrationDrive shaft

A differential-pressure swirl-type backwashing filtration system. An indexing mechanism and a transmission mechanism are disposed on the top of a filter cylinder body; the internal cylinder body is divided into a water-inlet chamber and a water-outlet chamber by a clapboard; eight filter cores are disposed in the water-outlet chamber and are distributed uniformly and circumferentially; a water inlet is disposed along a tangent of the cylinder wall of the water-outlet chamber; a sewage draining exit and a dirt discharging exit are disposed in the water-inlet chamber; a sucking disc is disposed between the dirt discharging exit and the clapboard, and is driven to rotate by a transmission shaft of the transmission mechanism. The device adopts eight groups of filter core structures, and by using the hydrodynamics principle, the device has the advantages of less no-load pressure loss, less backwashing water consumption, good filtering effect, compact structure, and reliable operation, and can perform backwashing under low differential pressure.

Owner:天津富斯特环保设备有限公司

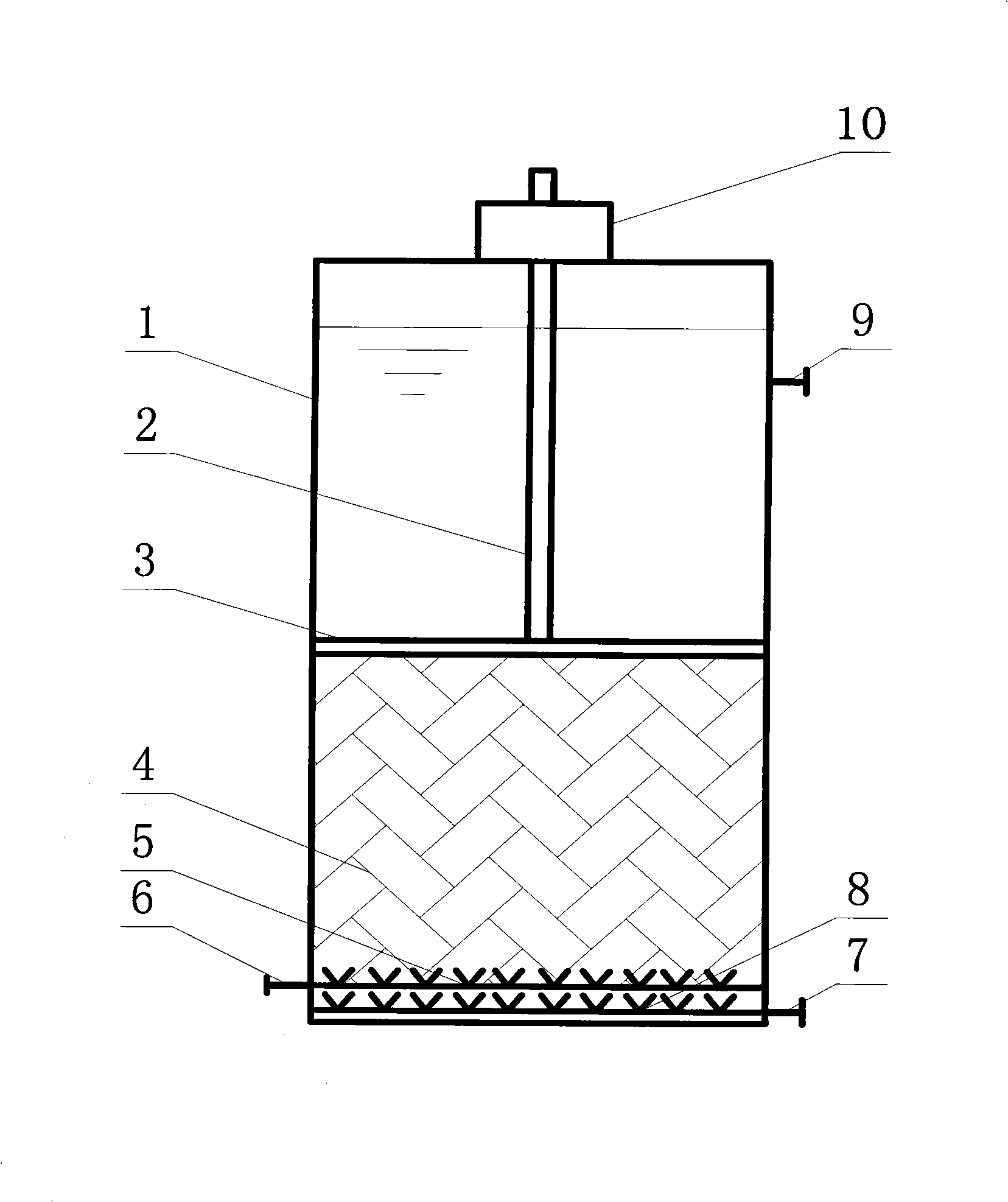

Lightweight highly effective filtering material for biology and its preparation method

InactiveCN1876579AImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The lightweight and highly effective biology filtering material comprises 65wt%-80wt% red earth ore, 10wt%-30wt% coal ash and 5wt%-15wt% pore-forming agent. The method comprises the following steps: breaking the 65wt%-80wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

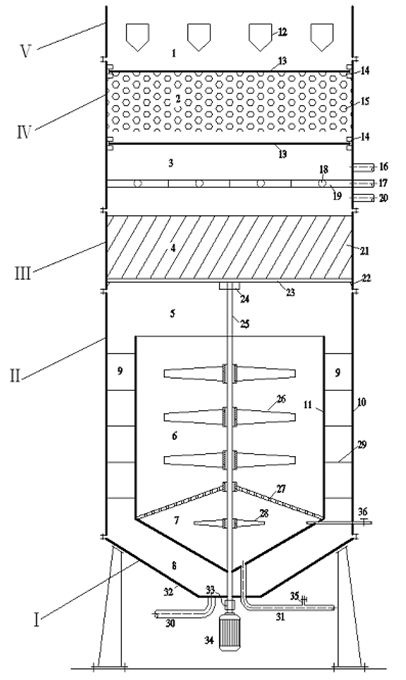

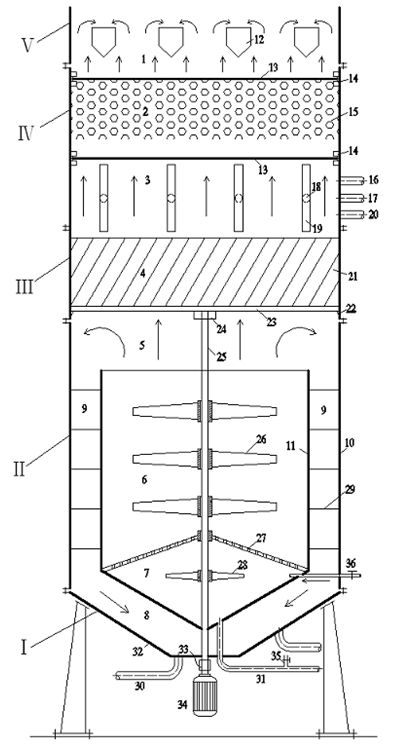

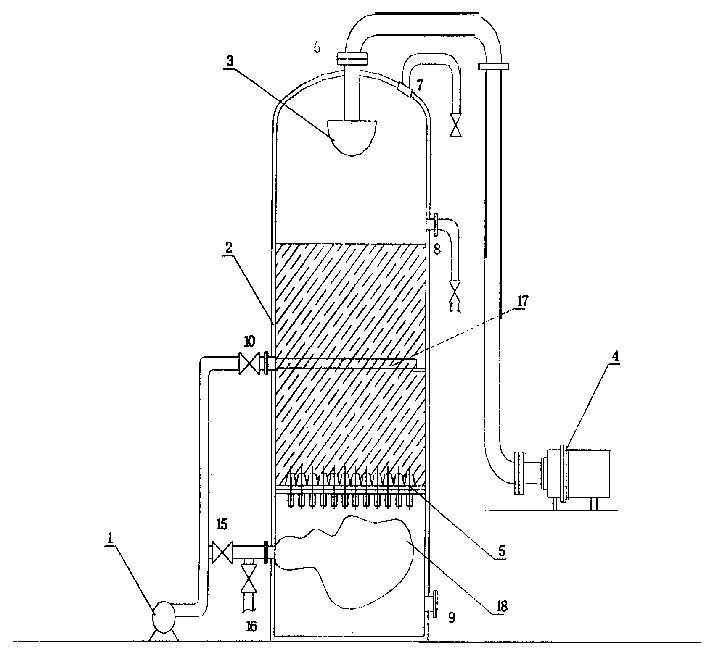

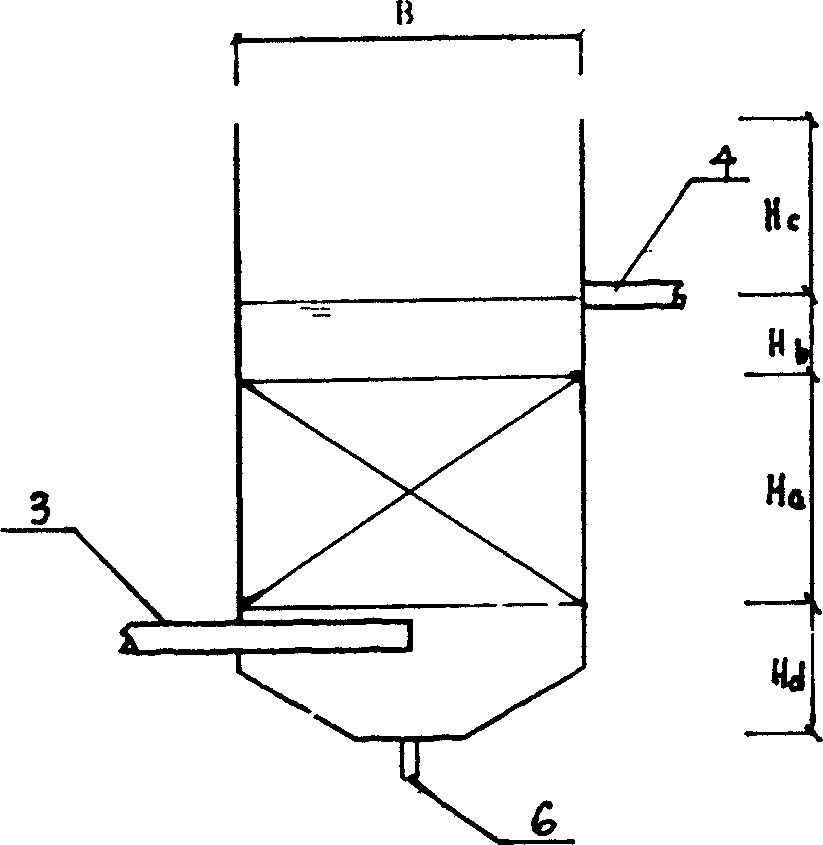

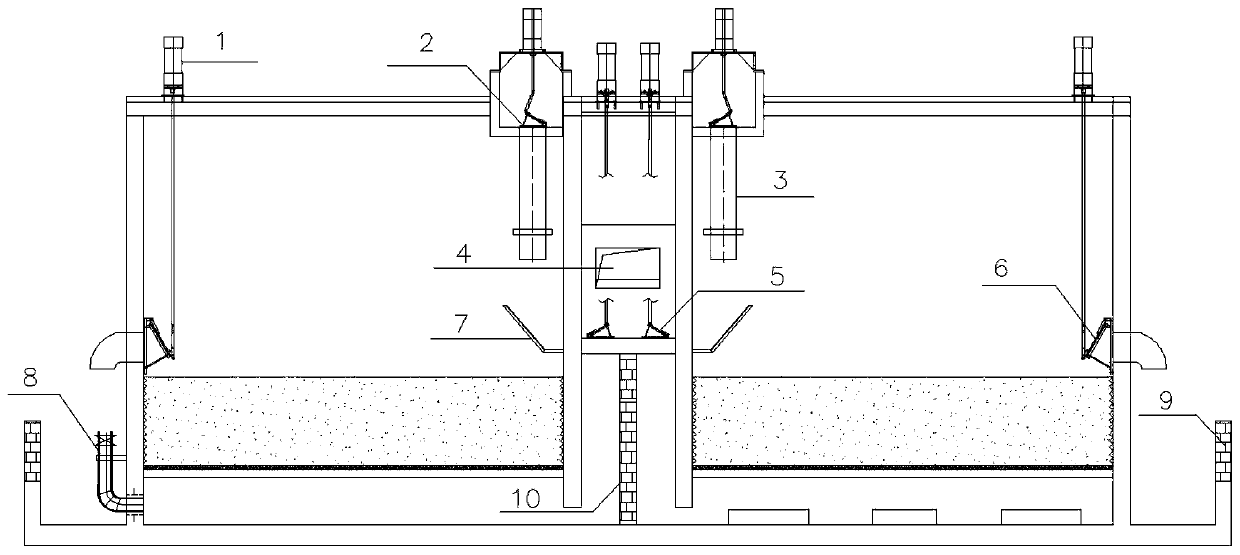

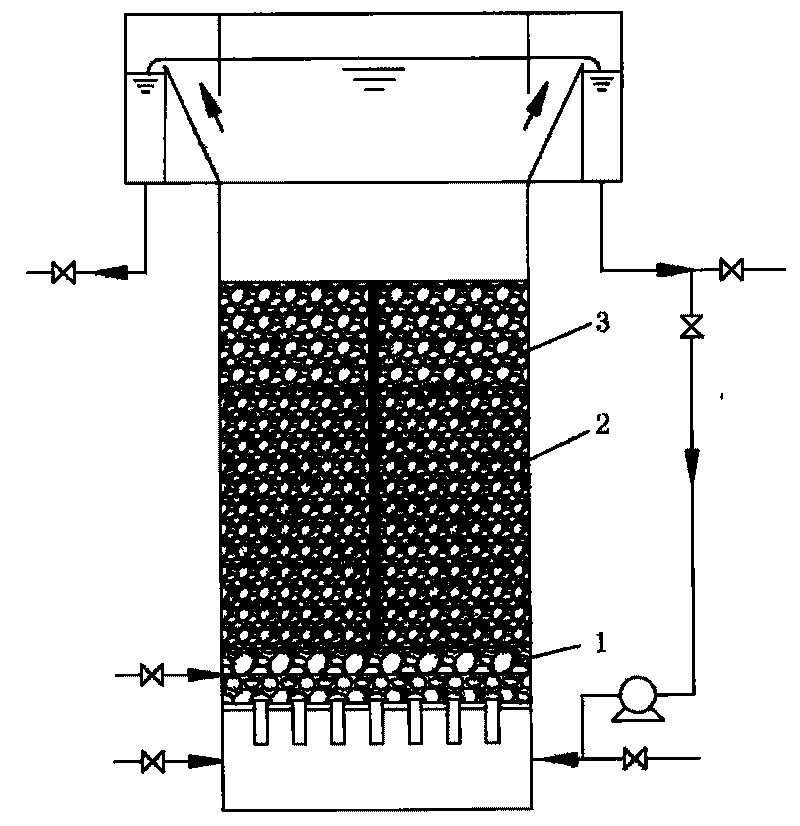

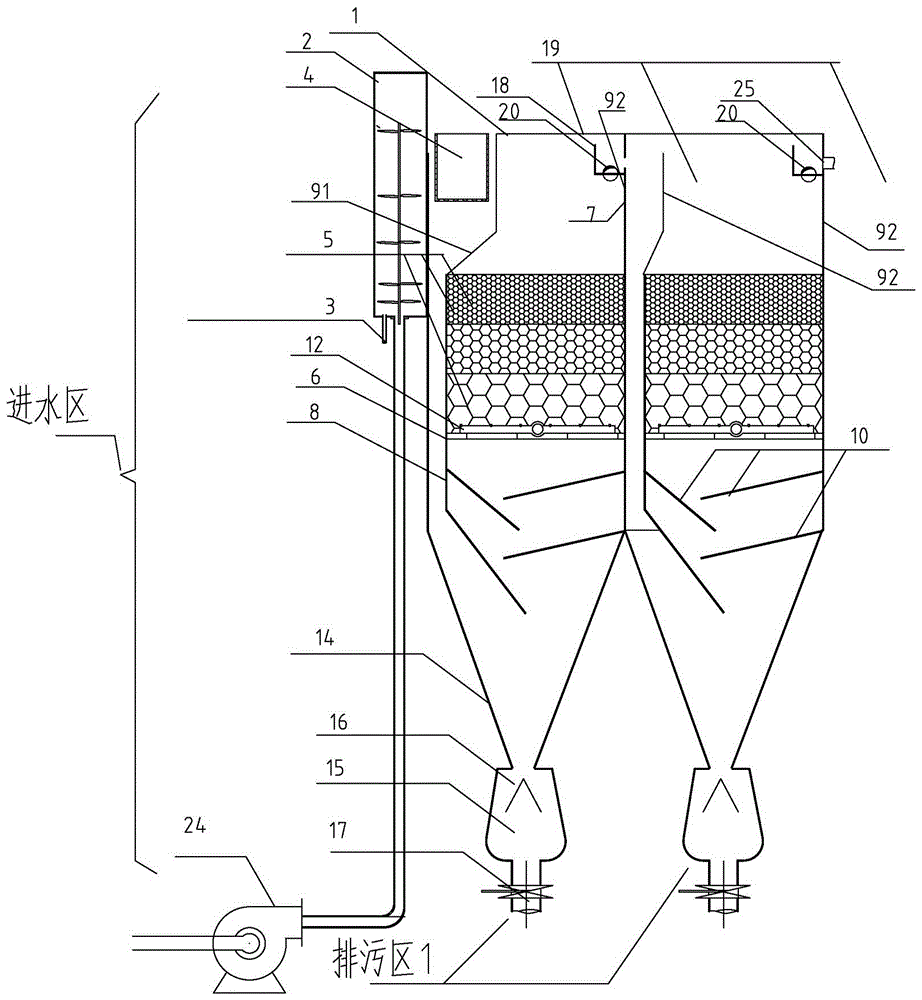

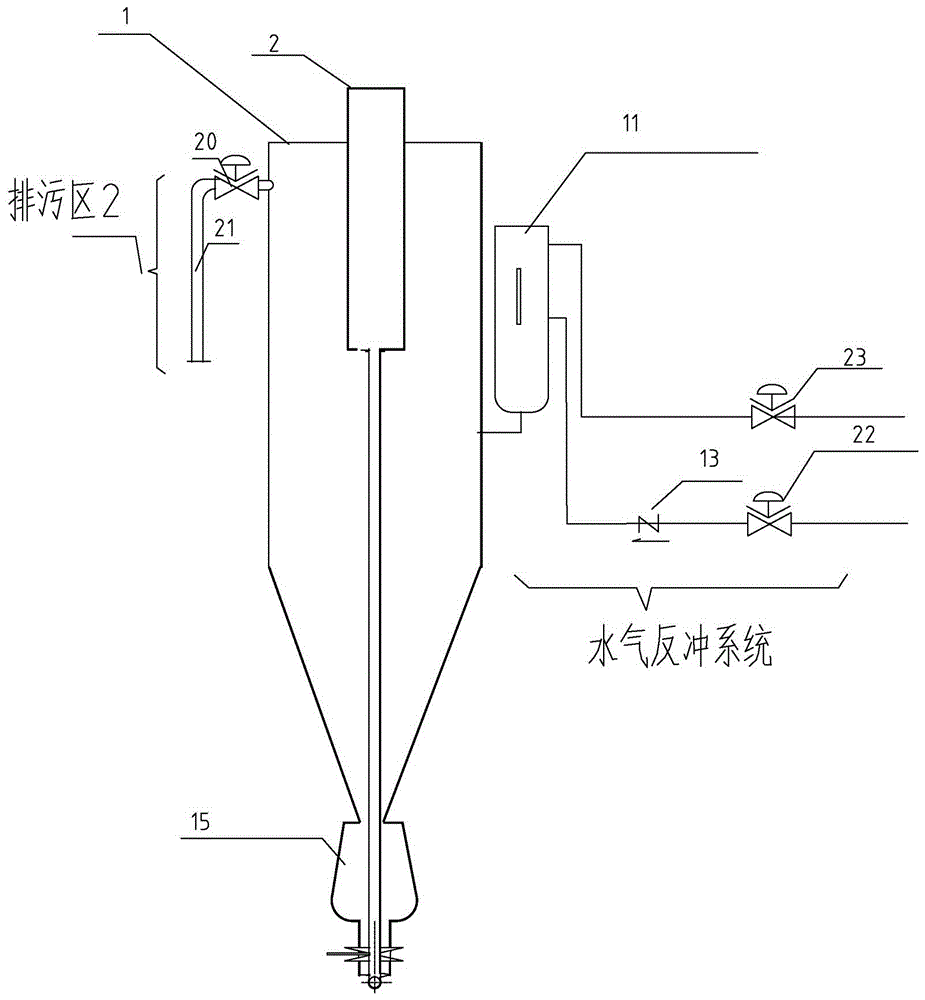

Intensive integrated water purification equipment

InactiveCN102120655ASmall footprintImprove land utilizationMultistage water/sewage treatmentFlocculationSludge

The invention discloses intensive integrated water purification equipment. The equipment is separated into five sections according to difference of water purification units, and the five sections are connected through flanges; and the equipment is provided with a mud collecting area, a primary flocculation area, an inner-cylinder clustering flocculation area / and an outer-cylinder sludge concentration area, a sludge separation area, an inclined tube sedimentation area, a backwashing gas distribution area, a filtration area, and a clear water area from bottom to top. The equipment is provided with devices such as an agitator blade used for particles to form agglomerated floc, a rotary gas distribution plate used for gas-water backwashing of a filter material, small-space spiral sloping panels used for concentrating sludge and the like; and the whole equipment is simple in structure, water purification functional units are compactly connected, the flat plane utilization rate is high, and the equipment is convenient to operate, can maximize the water purification function, and has important practical significance for medium and small water supply systems.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Variable-volume sewage interception and acceptance solid-liquid separator and method thereof

InactiveCN101337138AFast fermentation rateHigh interception capacityLoose filtering material filtersGravity filtersAutomatic controlFilter media

The present invention discloses a volume-variable solid-liquid separating device with functions of sewage capturing and dirt accepting, and a separating method thereof. The solid-liquid mixture to be separated flows(down-to-up or up-to-down) through the filtering medium which is compressed to have a height equal to 60% to 90% of the natural filling height. With the increase of captured solid phases, a shaft lifting driver drives a lifting shaft to lift a compress screen, and the height of the filtering medium increases gradually. When the height of the filtering medium reaches 90% of the natural filling height, the compress screen is lifted to the highest position, the filtering medium is loosened completely, at the same time, reverse flushing gas is charged from the intake pipe for a period of 10 to 15 minutes, after the reverse flushing, the compress screen is lowered to compress the filtering medium for refiltration. As a result, the invention has a fast filtering speed reaching a level of 45m / h, sewage capturing speed is increased while the pressure drop loss is decreased; the reverse flushing is complete while the water consuming is less; the operation is simple, and complete auto-control can be realized.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Flap valve and flap filter tank

InactiveCN1660466AReduce the cost of civil constructionLess investment in infrastructureLoose filtering material filtersGravity filtersPipingPush pull

A turn-over plate type filter pool is composed of pool body, filtering tubes, water collecting chamber, water draining pipe, back flushing pipe, filtering material layer, the canal and overflow dam for draining the black flushing water, and the flap valve consisting of valve frame, flap, sealing rubber ring and drive mechanism which comprises drive cylinder and push-pull connecting rod.

Owner:珠海市沃特金水处理技术有限公司

Pressure sand filter and reverse flushing method

InactiveCN1424129AIncrease profitLess investmentLoose filtering material filtersGravity filtersAir pumpWater quality

A pressure sand filter is composed of cylindrical body, raw water pump and air pump. Said cylindrical body contains a lower air bag in water collecting chamber. The water collecting chamber also plays the role of back washing box and the blower plays the role of back washing pump. Its advantages are less water consumption, low cost and high water utilization rate.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

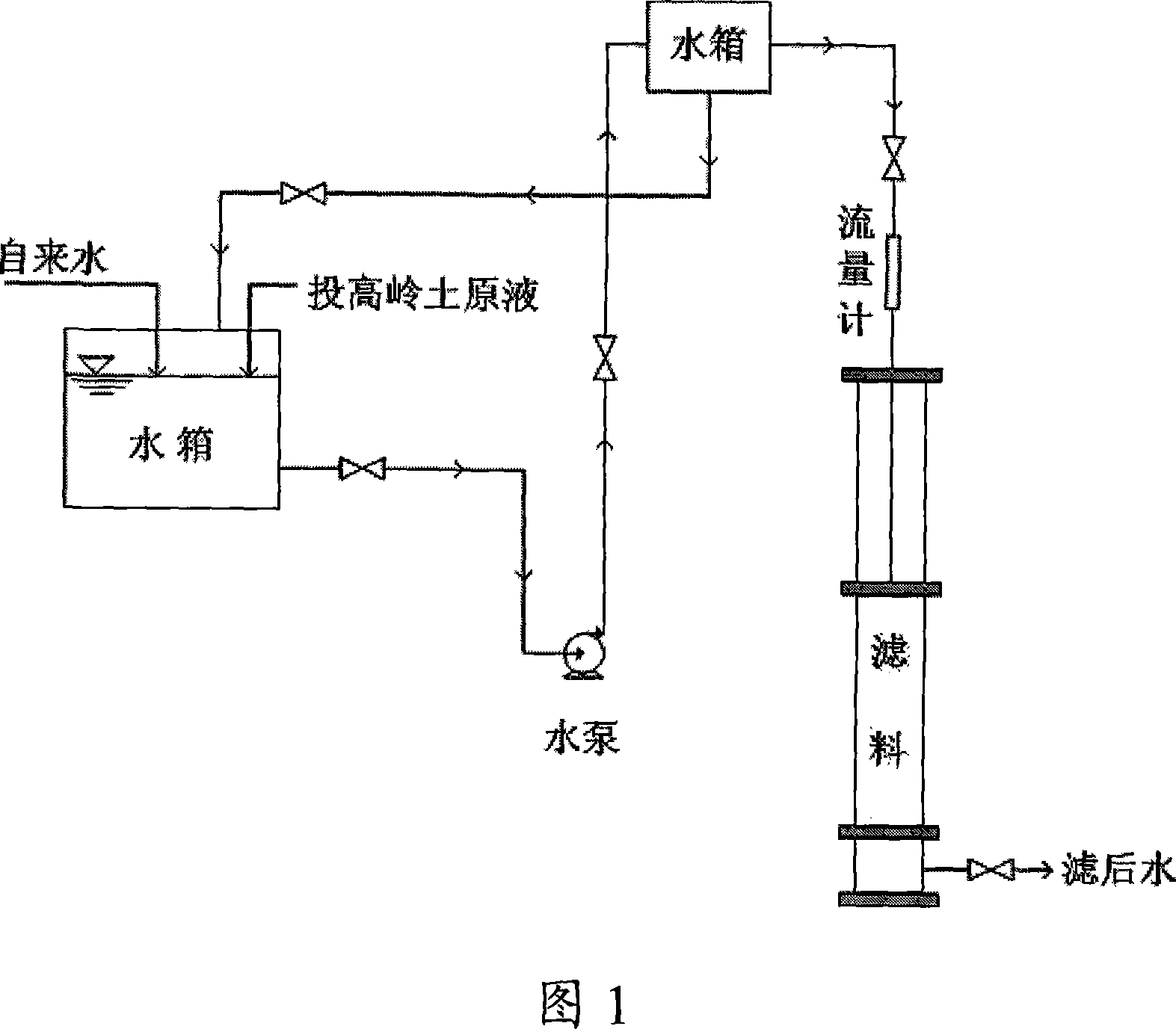

Filtering mode with pressurizing altered porosity of elastic filter material layer

InactiveCN101066511ARelieve pressureReduced dirt holding capacityLoose filtering material filtersGravity filtersPorosityPolyester

The present invention relates to filtering method with pressurizing altered porosity of elastic filter material layer, and belongs to the field of sewage treating technology. The present invention features that in the upper part of the filter material layer inside the filtering column, is set one filter material compressing device. The filter material compressing device is one pressurizing plate capable of moving up and down, and the elastic filter material is sponge, fiber bundles or fiber balls. During filtering sewage, the filter material is compressed in the compression ratio of 75-85 % and the flow rate is controlled with a flowmeter, so as to reach certain treating effect.

Owner:SHANGHAI UNIV

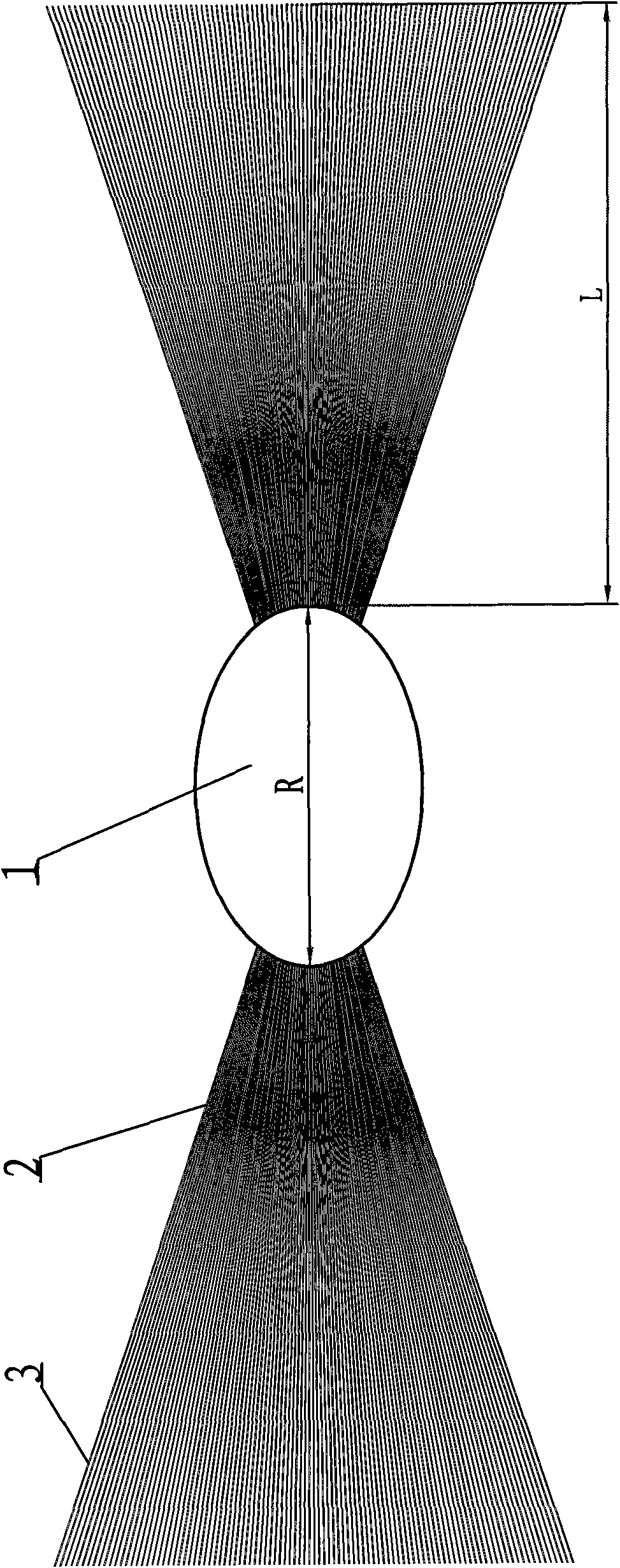

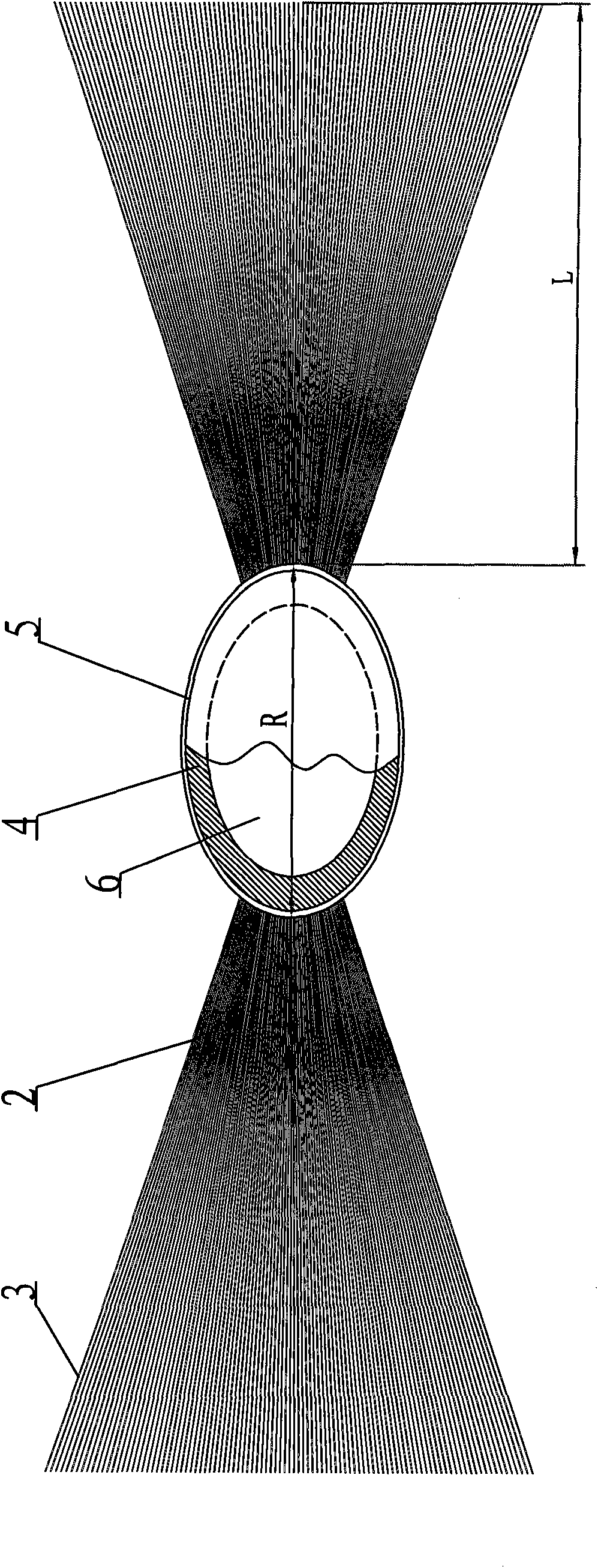

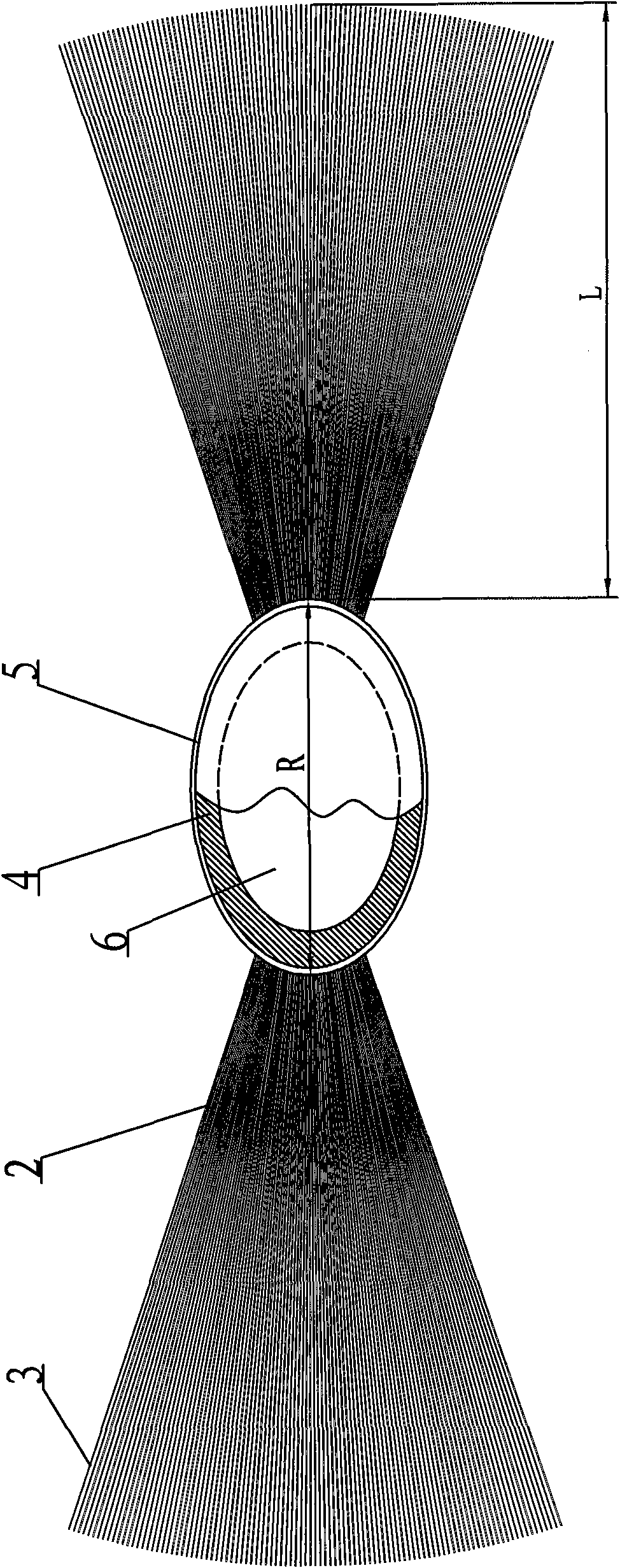

Butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter

ActiveCN101884860AHigh interception capacityHigh filtration precisionFiltration separationCorrosion resistantSmall footprint

The invention discloses a butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter. The filter consists of filter material monomers, wherein each filter material monomer is formed by connecting a weight-balancing core body and paired corrosion-resistant balancing filtering wing bodies in a matching way; the surface of the weight-balancing core body is made of plastic; the weight-balancing core body is ellipsoidal; the threshold of the average density p0 of the weight-balancing core body is between 1.30 and 1.50 g / cm<3>; the two ends of a long axis of the ellipsoidal weight-balancing core body are provided with balancing wing bodies respectively; each balancing wing body is made from fiber bundles consisting of artificial fiber yarns; and the inner ends of the artificial fiber yarns constituting each fiber bundle are fixedly connected to each end of the long axis of the weight-balancing core body and the other ends of the artificial fiber yarns are in a diffused state so as to form a whisker form. The filter has the technical advantages of high porosity, high filtering speed, high filtering accuracy, low resistance, high filth holding capacity, small backwashing water using amount, high periodic water yield, low operating cost, small floor area and high anti-load impact capacity.

Owner:新疆德安环保科技股份有限公司

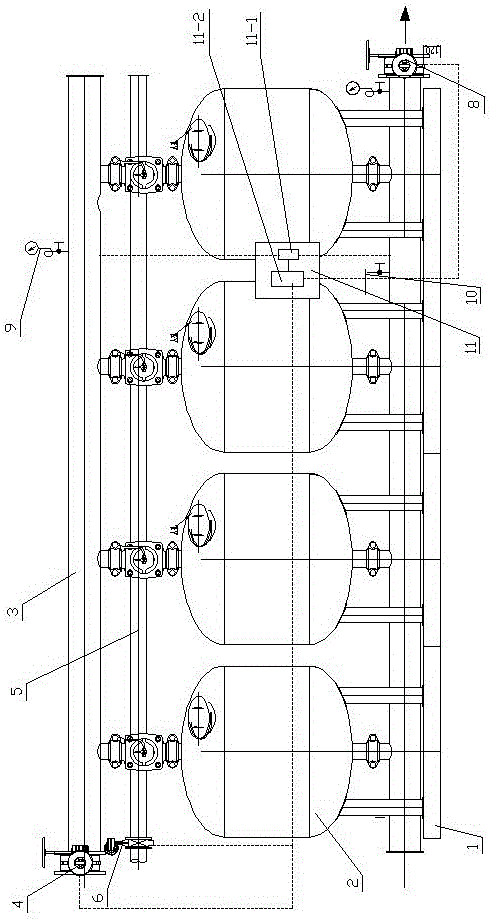

Automatic continuous quick filtering system

InactiveCN106362458AReduce volumeSmall footprintMembrane filtersLoose filtering material filtersWater flowWater quality

The invention discloses an automatic continuous quick filtering system and relates to the field of filtering equipment. The automatic continuous quick filtering system comprises a plurality of same filtering tanks and a control device, wherein each filtering tank comprise a tank body; a water distributor, a filtering filler layer and a water collector are sequentially arranged in each tank body from top to bottom; a three-way valve is arranged at the top of each tank body; each three-way valve comprises a water inlet, a first water outlet and a second water outlet; the first water outlet of each three-way valve is connected with a water inlet of each water distributor; the outlet end of each water collector outward extends out of the corresponding filtering tank; the water inlets of the three-way valves are connected by a water inlet manifold to form a whole; the second water outlets of the three-way valves are connected by a backwash water outlet manifold to form a whole; the outlet ends of the water collectors are connected by a water outlet manifold to form a whole. According to the automatic continuous quick filtering system disclosed by the invention, a backwash process and a filtering process are simultaneously performed, and the system usually supplies water; by adopting unique water distributors and water collectors, water flow becomes laminar flow in the whole filtering process, and the quality of effluent is stable.

Owner:BROTHER ENVIRONMENTAL PROTECTION EQUIP ENG

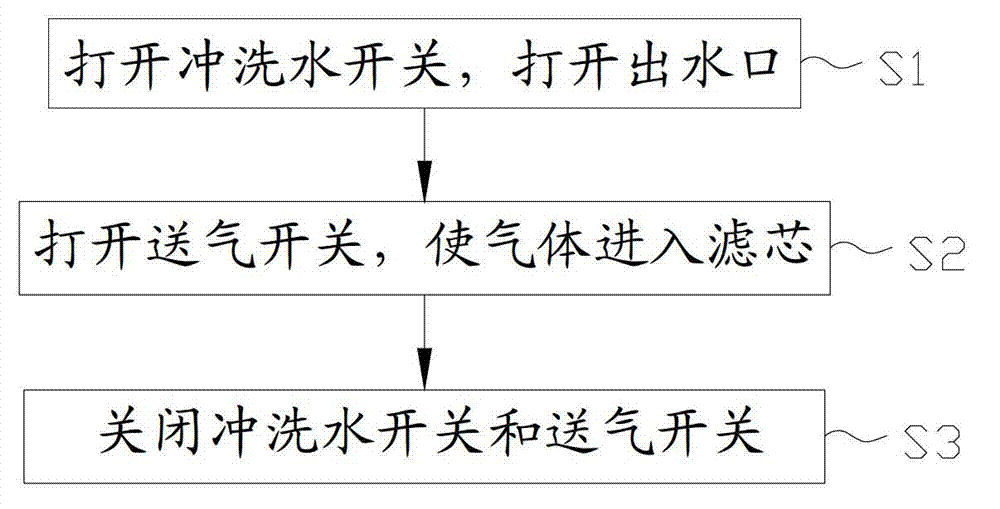

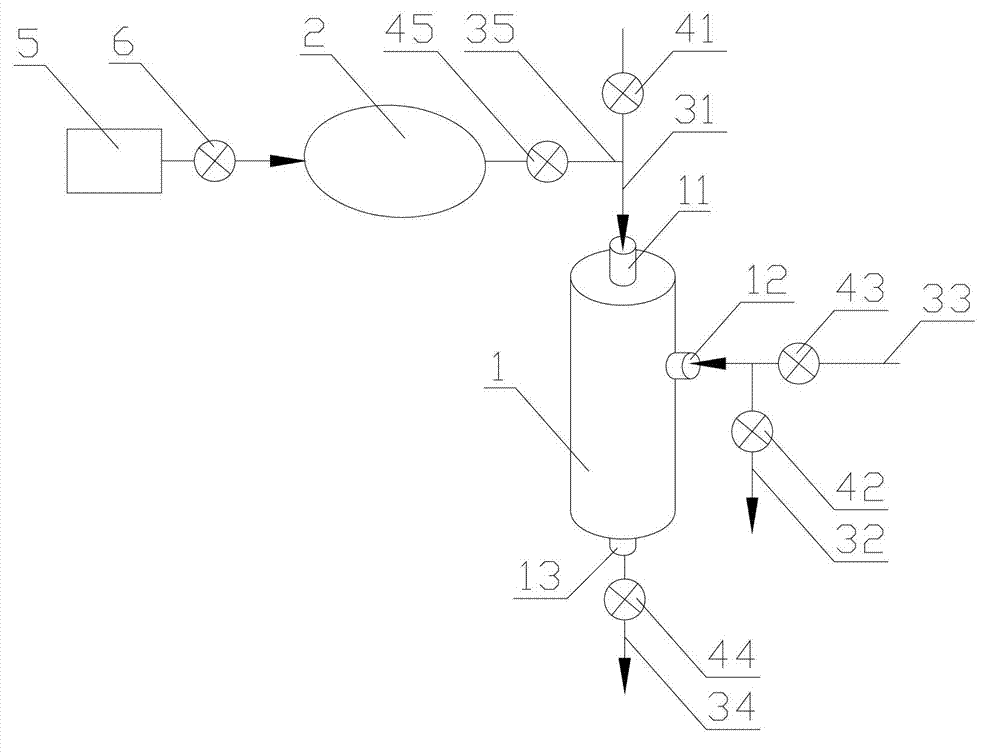

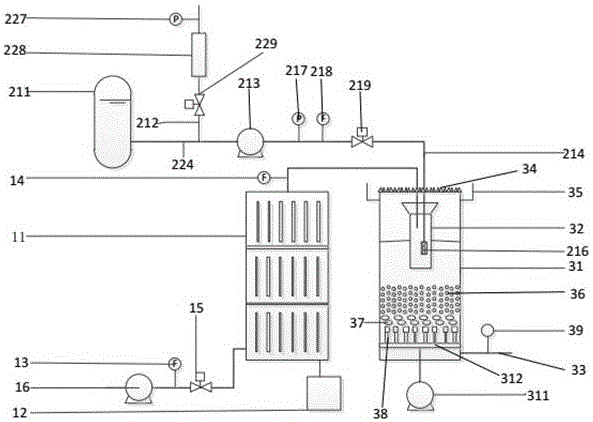

Internal-pressure type ultrafiltration membrane flusher and flushing method

InactiveCN103084069AReduce cloggingIncrease water fluxSemi-permeable membranesFlushing timeInternal pressure

The invention discloses an internal-pressure type ultrafiltration membrane flushing method and a flusher. The flusher provided by the invention comprises a flushing water pipe and a flushing water switch, a sewage discharge pipe and a sewage discharge switch, and further comprises an air storage tank and an air supply pipe, as well as an air supply switch arranged on the air supply pipe, wherein the air supply pipe is connected to the water inlet of a filter element. Under the action of pressure, the air in the air storage tank passes through the filter element and gaseous-liquid two phase flows are formed in the filter element; and the acting manner and the acting intensity of the single water phase with the attachments inside the membrane filaments are changed; therefore, flushing of the filter element can be finished well. Compared with the traditional flushing way, the flusher is capable of completing back flushing of the filter element better and more thoroughly; therefore, the water flux of the filter element after flushing is improved, stoppage of the ultrafiltration membrane is retarded, the service lives of the ultrafiltration membrane and the filter element are prolonged, the total water flux of the filter element is improved, and simultaneously, the flushing time is saved and the back flushing water is saved.

Owner:SHENZHEN CHENGDELAI IND CO LTD

Highly effective filtering material for biology and its preparation method

ActiveCN1876580AImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The highly effective biology filtering material comprises 70wt%-90wt% red earth ore and 10wt%-30wt% coal ash. The filtering material is out-of-shape, and the grain diameter is between 3mm and 8mm. The method comprises the following steps: breaking the 70wt%-90wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

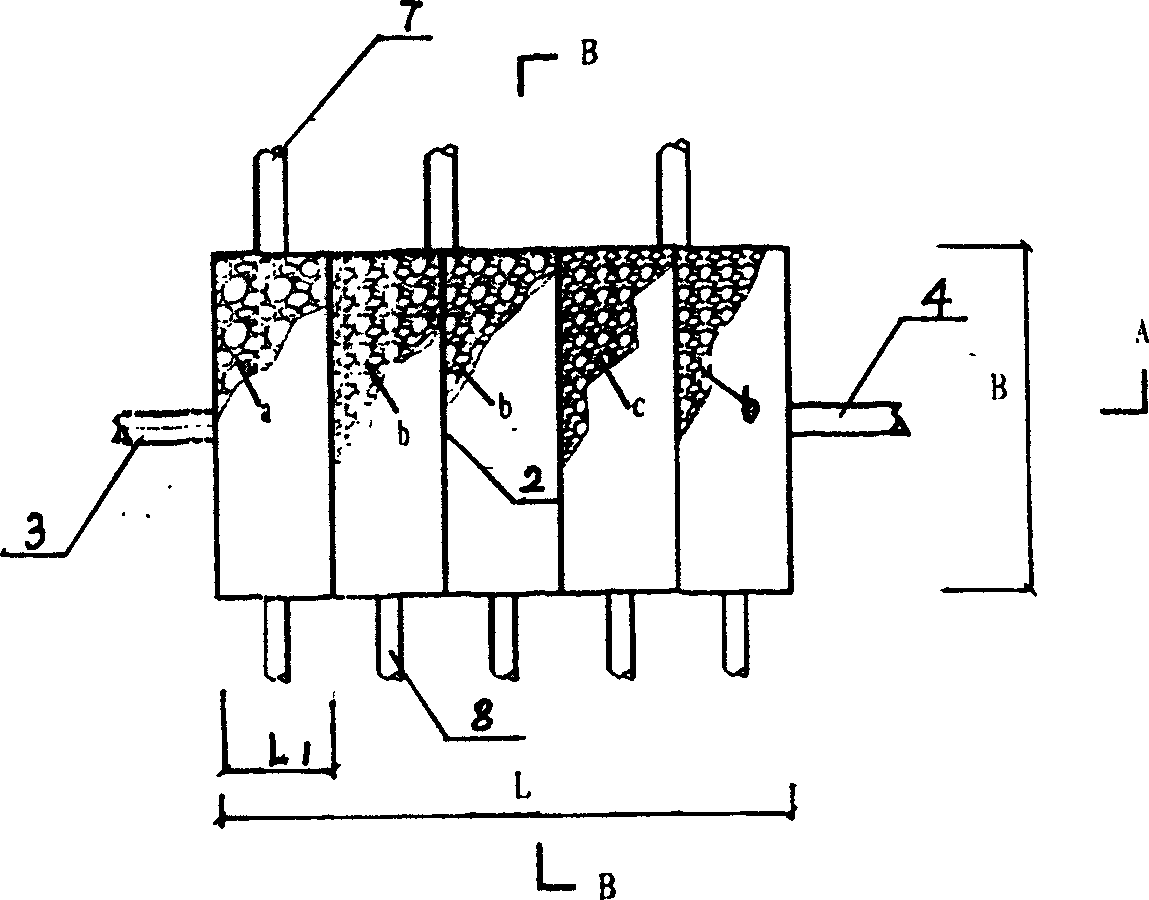

Vertical deflector combined Filtration type dephosphorization and nitrogen rejection facility

InactiveCN1562802AGuaranteed thicknessGuaranteed process lengthSustainable biological treatmentBiological water/sewage treatmentFiltrationNitrogen

The device contains at least two single filter tanks connected each other, water entrance pipe connected with first single filter tank and water exit pipe connected with last single filter tank, devision plates are used to separate the single filter tanks up and down crisscrossed, sewage up and down baffling passageway is preset. Bottom of single filter tank are mud collector, mud sludging pipe and filling layer is the middle part, the fillings are anaerobic filling, aerobic filling and high-grad iron filling, at least two of them are combined to put into the filter tanks, each fillings combination is put to one filter tank to form different function area. The design of sewage up and down baffling passageway is to ensure obtaining length of flow path required by process, the combination of mutiple fillings is suited for requirements of different water quality.

Owner:CHONGQING UNIV

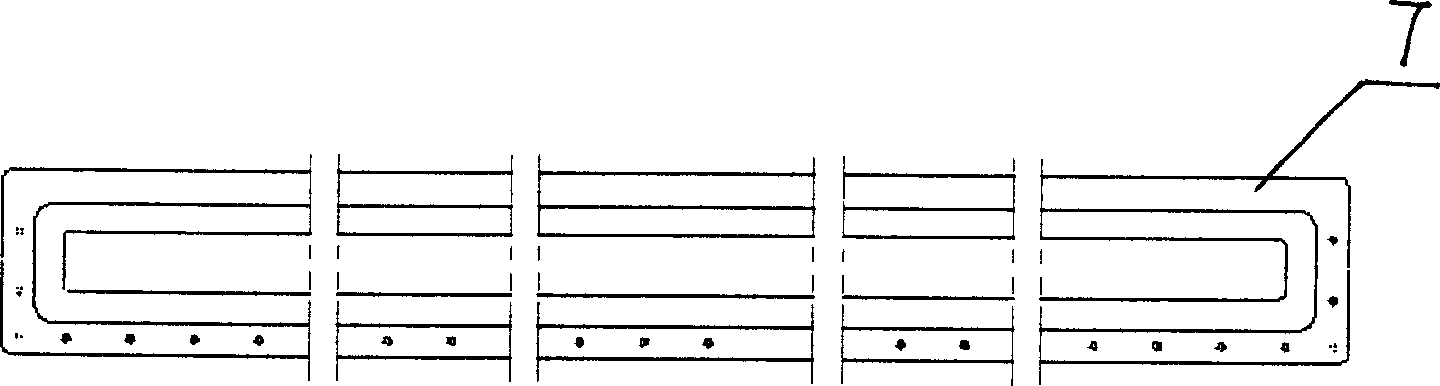

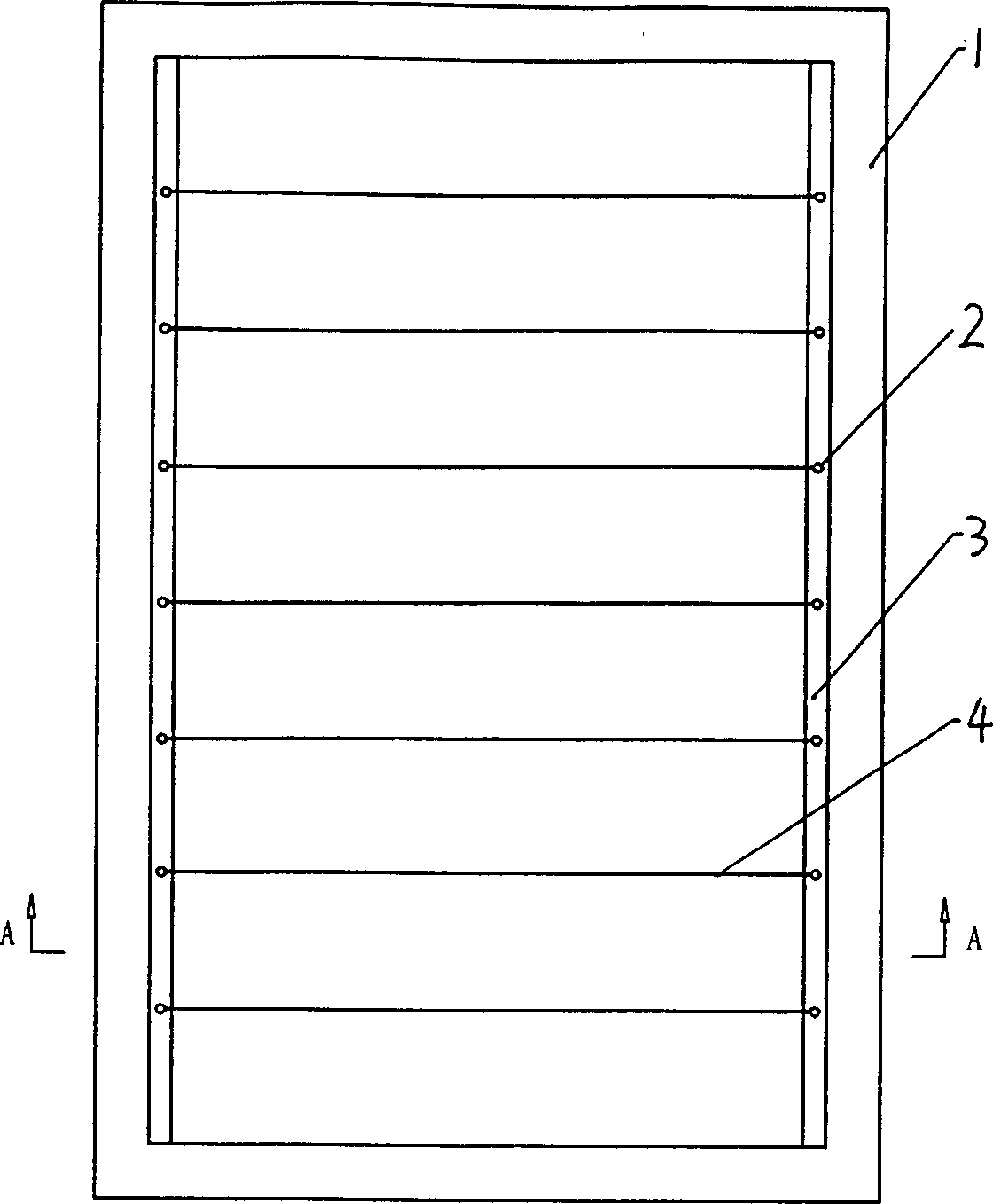

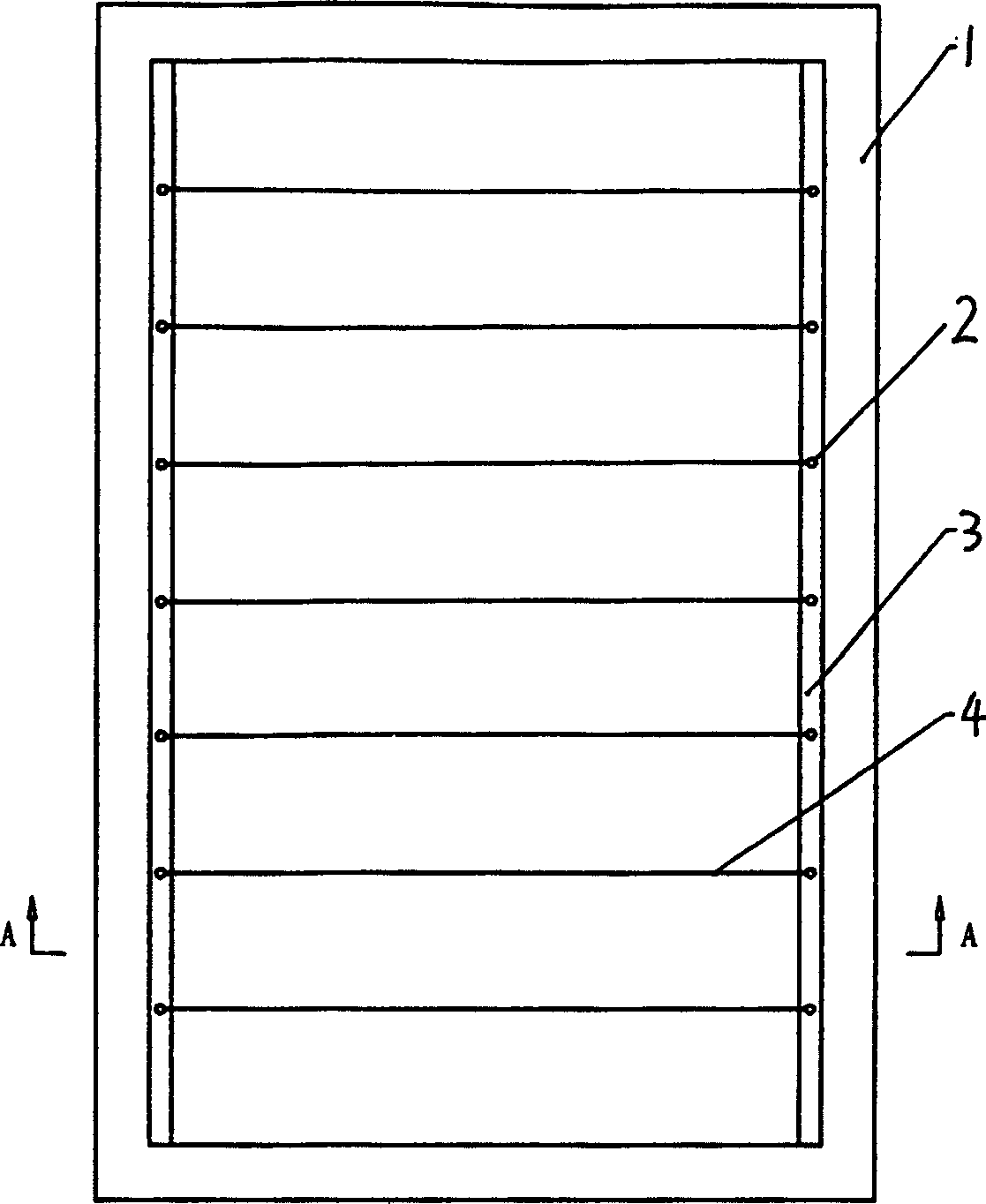

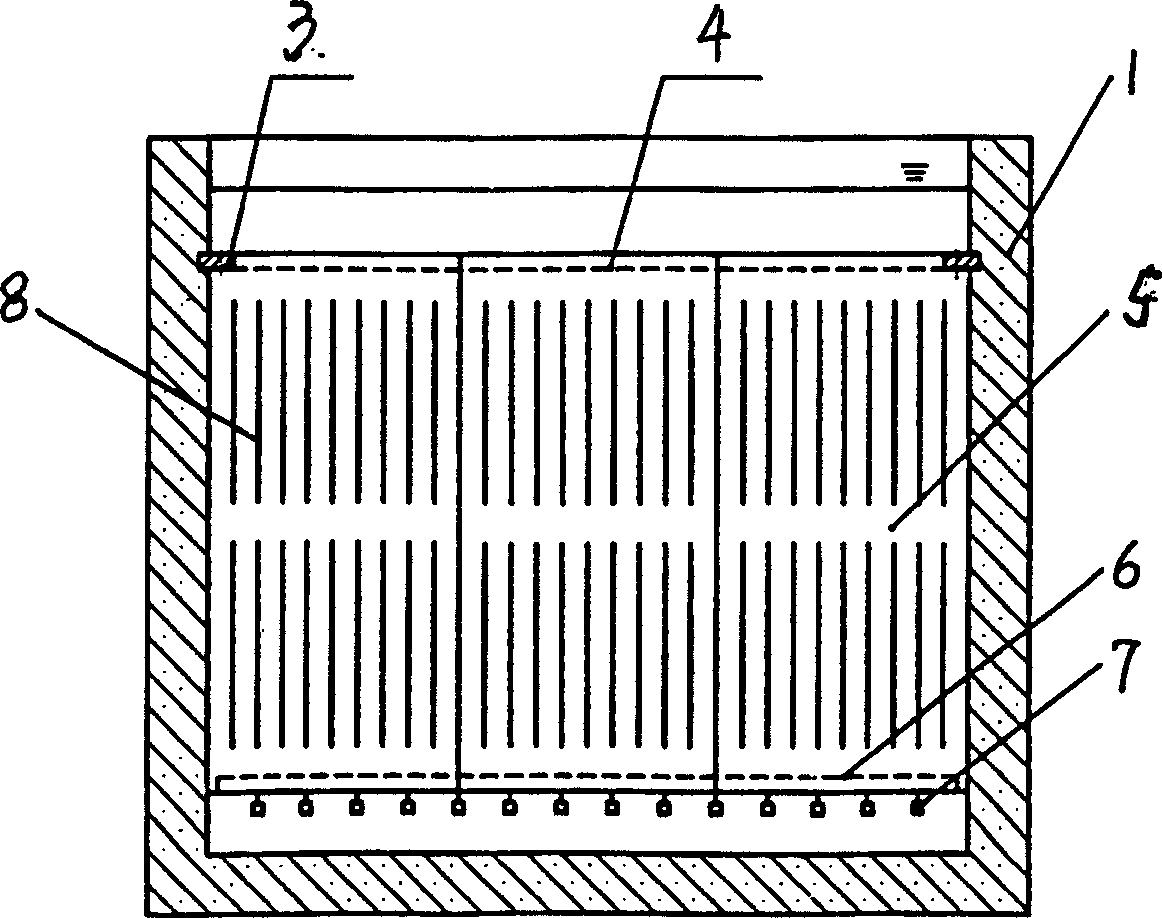

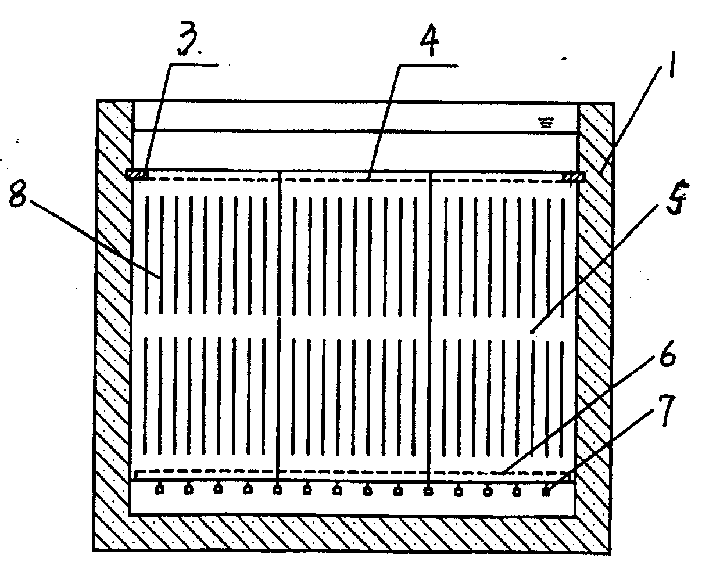

Multifunction sea-water purifying device and treatment method

InactiveCN1405097AReduce organic contentReduce BODTreatment using aerobic processesClimate change adaptationEnvironmental engineeringOxygen

The multifunctional sea water purification equipment comprises the purification pool and filter material placed in the purification pool, and the described filter material is formed from several pieces of water-cleaning clohtes which are parallelly sepaced and suspended, and the purification pool is divided into several purification filtering chambers by means of water-cleaning clothes. Said water-cleaning cloth has a row of vertical gaps which are cut according to a spaced width, and its two end portions and middle portion are equipped with connecting portion with a certain width, said water-cleaning cloth is a punched non-woven fabric, and its specific surface area is above 2000 sq.m / cu.m. Its purification process includes: fish farming pool, air float pool, multifunctional sea water purificiation equipment, oxygen-dissolving tank and fish farming pool.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

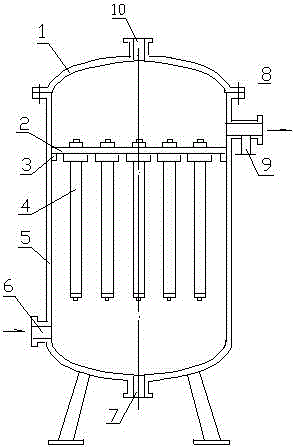

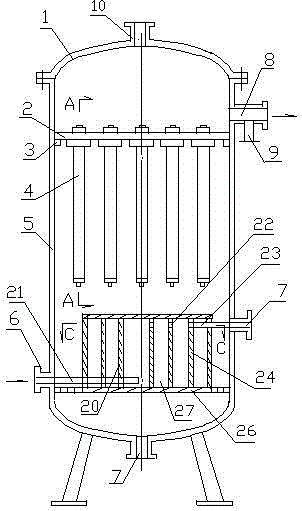

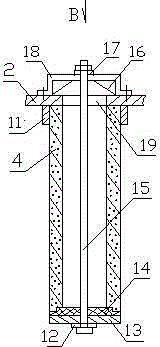

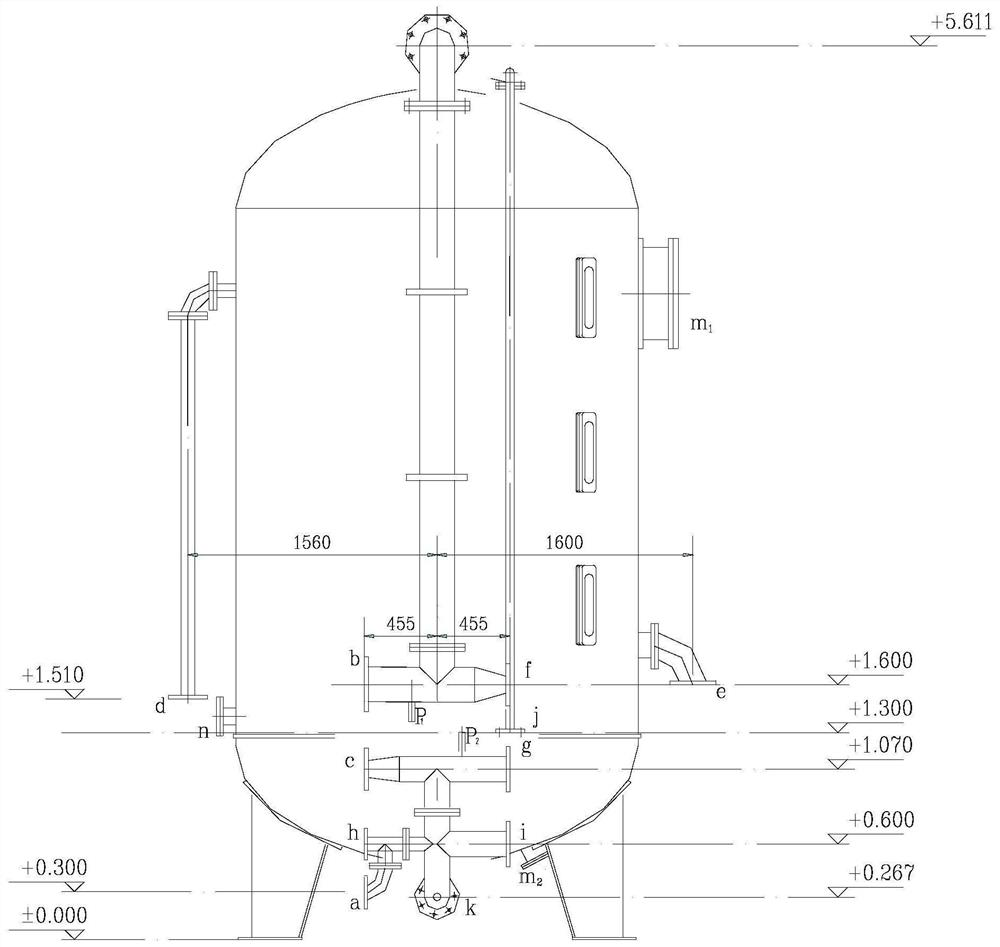

High-efficiency desulfurization waste liquor salt extraction recycling device

ActiveCN104645830AIncreased Filtration ThroughputIncreased filtration surface areaDispersed particle separationFiltration circuitsLiquid wasteDevice form

The invention discloses a high-efficiency desulfurization waste liquor salt extraction recycling device. The device comprises a two-stage filtering device formed by connecting two micro-porous ceramic filtering devices with each other, wherein each micro-porous ceramic filtering device comprises a tank body (5) and a seal head (1); a liquid inlet (6) is formed in the lower part of the tank body; a liquid outlet (8) is formed in the upper part of the tank body; a backwash opening (9) is formed in the liquid outlet; a supporting disc (2) is arranged in the tank body; liquid outlet holes (19) are formed in the supporting disc at intervals; limiting sleeves (3) are fixedly arranged on the lower bottom surface of the supporting disc at intervals; the limiting sleeves are tightly connected with the outer diameters at the upper ends of micro-porous ceramic pipes in a matched mode; the micro-porous ceramic pipes are connected with a pressing plate (13); a riding fixing rack (18) is fixedly arranged on the supporting disc; and pull rods (15) through which the micro-porous ceramic pipes can be fixedly arranged on the supporting disc in a suspended mode at the intervals are arranged between the riding fixing rack and the pressing plate. According to the device disclosed by the invention, the occupied space can be reduced, the construction cost is saved, the filtering effect of desulfurization waste liquor can be improved, desulfurization liquor is conveniently filtered, and the backwash is conveniently performed.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Mixed bed regeneration improvement process, system and application

ActiveCN112295611AImprove backwashing effectEasy to backwashGeneral water supply conservationFeed water supplyWater productionProcess engineering

The invention belongs to the field of water production, and relates to a mixed bed regeneration improvement process, a system and application. The process comprises air scrubbing, backwashing pre-layering, primary drainage, alkali feeding failure, backwashing layering, standing, secondary drainage, pre-injection, acid and alkali feeding, replacement, after-replacement drainage, regeneration mixing, regeneration irrigation, regeneration forward washing, and operation. The backwashing effect is enhanced by compressed-air scrubbing, so that the resin is fully loosened. The subsequent backwashingis facilitated. Meanwhile, in the alkali feeding failure step, the alkali feeding mode is adjusted, a positive discharge valve is changed into a middle discharge valve, alkali can fully and only exchange with upper-layer anion resin, meanwhile, a small amount of upper-layer cation resin fails, the alkali feeding time is shortened, the alkali consumption can be reduced, and the regeneration effectis improved.

Owner:YANKUANG GRP CO LTD

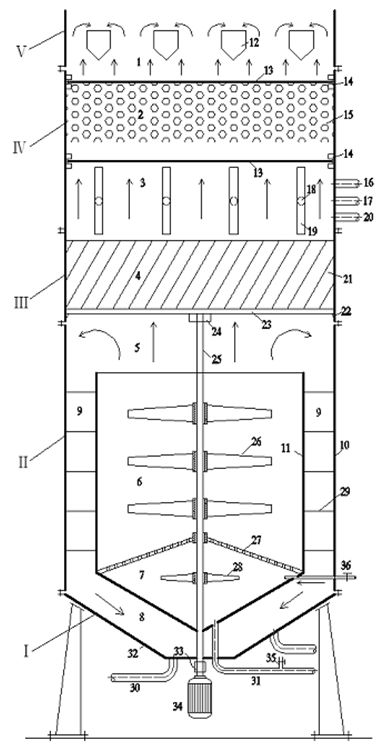

Biological aerated filter for sewage treatment

InactiveCN103466789AExtended backwash cycleReduced accumulation rateSustainable biological treatmentBiological water/sewage treatmentSurface layerBiological filter

The invention discloses a sewage biological aerated filter. A filter device of the filter comprises a supporting layer and a filter material layer which are arranged from bottom to top, wherein a large-particle-diameter light filler layer is arranged on the upper part of the filter material layer. Filter materials with different particle diameters are used in the biological aerated filter, filter materials with larger particle diameters are used in the supporting layer, filter materials with smaller particle diameters are used in an intermediate layer, and light filter materials with larger particle diameters are added in the surface layer. The light filter materials with larger particle diameters in the surface layer play an effect of pretreatment, so that the surface layer can be used for performing biological treatment and accommodating massive SS (suspending substances), the accumulation speed of the SS amount of the filter materials in the intermediate layer can be greatly retarded, and the time of flow to a critical value can be prolonged, so that the backwashing cycle of the biological filter can be prolonged, the efficiency can be improved, the backwashing water can be saved, and the operation cost can be reduced; relative positions of the structure layers of the filter are not changed after backwashing, the effluent is stable, and the quality is high.

Owner:刘岩玉

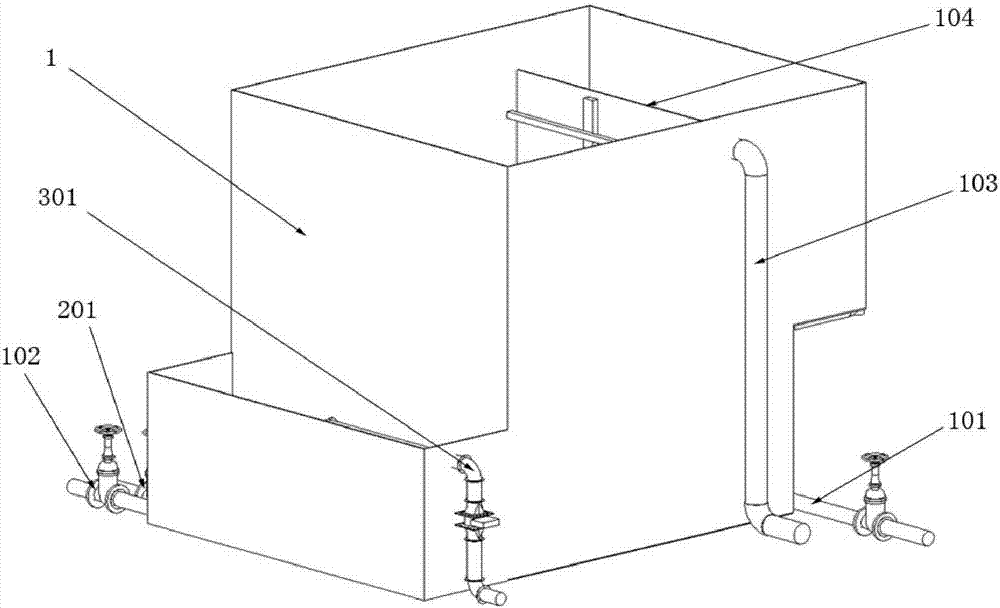

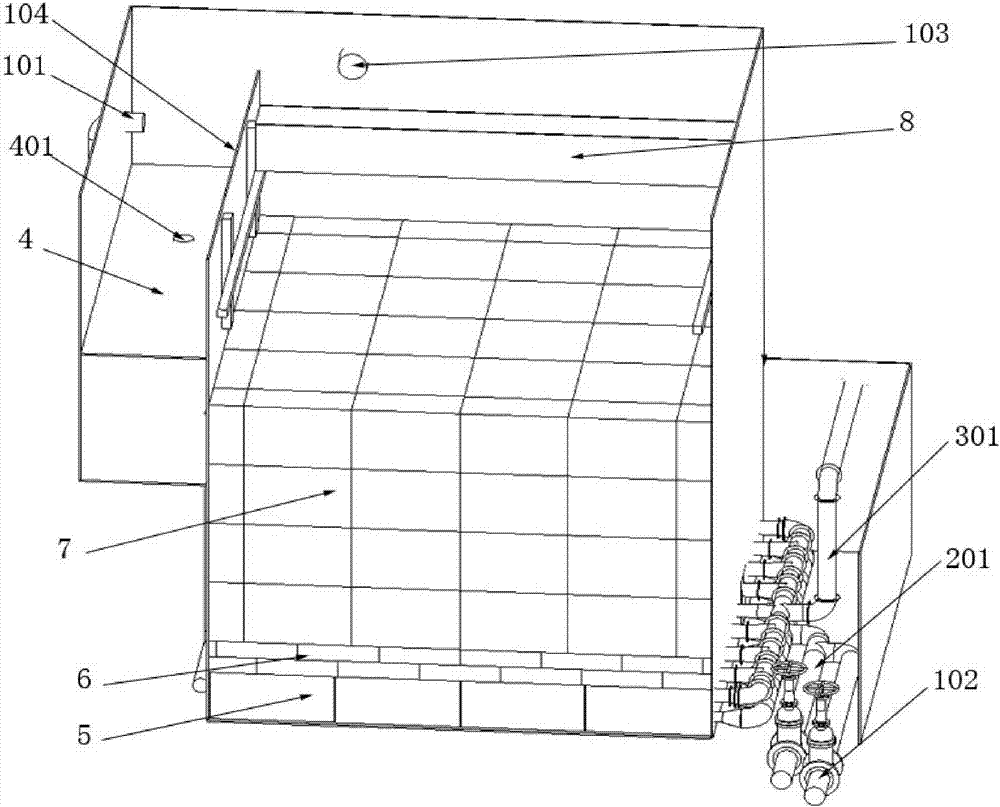

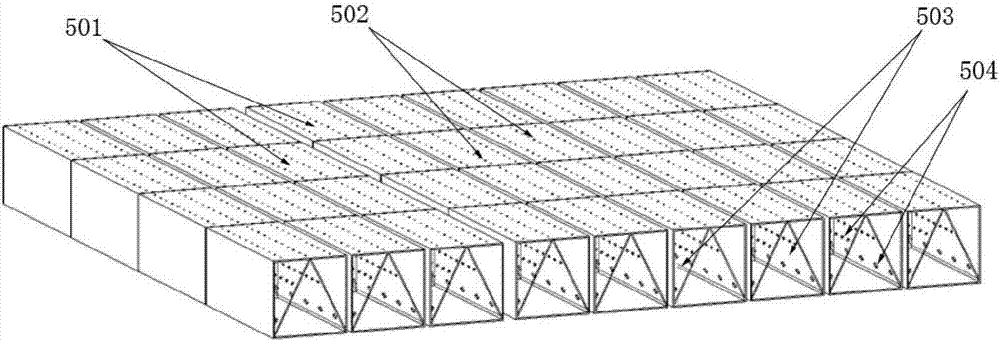

Novel denitrification deep bed filter tank reaction system

PendingCN110240270ANo maintenanceNo consumable partsWater contaminantsTreatment with anaerobic digestion processesBrickWater quality

The invention discloses a novel denitrification deep bed filter tank reaction system. The novel denitrification deep bed filter tank reaction system comprises a denitrification deep bed filter tank composed of a water inlet system, a biological filter material, sewage special-purpose water distribution gas distribution filter bricks, a gas water distribution chamber, a water outlet pipe, a backwashing system, and a carbon source adding system; a plurality of functions are achieved; a plurality of purposes can be achieved using one tank; synchronous removing is adopted to reach TN, SS, and TP three water quality index standards; the quality of discharged water is better than first grade A discharge standard or special discharge value limit standard in <Discharge standard of pollutants for municipal wastewater treatment plant> (GB18918-2002); incomplete denitrification at winter low temperature conditions is avoided; adding of a certain amount of carbon source into the denitrification deep bed filter tank plays an important role in stable reachment of TN standard, and TN discharge standard which is gradually strict in the further is achieved, and TN is ensured to be equal to or lower than 8mg / L.

Owner:盖格环境技术(杭州)有限公司

Gas-water backwashing rapid filter tank based on modification of siphon filter tank

PendingCN110613966AReasonably set the sizeSimple structureLoose filtering material filtersGravity filtersSiphonProcess equipment

The invention relates to a gas-water backwashing rapid filter tank based on modification of a siphon filter tank. A pneumatic pull plate valve is used and an air impact system is additionally arranged; a siphon filter tank only having a water flushing mode is modified into a gas-water combined backwashing efficient intensive filter tank. The filter tank comprises a water inlet pull plate valve arranged in a water distribution channel, a water outlet / water flushing pull plate valve arranged on a transverse partition plate of a clear water channel, a drainage pull plate valve arranged on the outer side tank wall of the filter tank, and an overflow pull plate valve arranged on an overflow weir wall at the tail end of the clear water channel of the filter tank, a flushing water head is formedthrough coordination and cooperation between the pneumatic pull plate valves to perform filter tank water flushing operation without a back flushing pump, so that process equipment is simplified. Herein, by adding the air flushing system, air-water combined backwashing of the filter is realized, and the operation efficiency of the traditional siphon filter is improved, the operation effect of thefilter tank can be remarkably improved, the operation period of the filter tank is prolonged, the operation cost is reduced, and certain popularization and reference values are achieved for siphon filter tank transformation of medium and small water plants.

Owner:深圳市深水龙岗水务集团有限公司

Highly effective filtering material for biology and its preparation method

ActiveCN100417605CImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The highly effective biology filtering material comprises 70wt%-90wt% red earth ore and 10wt%-30wt% coal ash. The filtering material is out-of-shape, and the grain diameter is between 3mm and 8mm. The method comprises the following steps: breaking the 70wt%-90wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

Equipment and method for enhanced coagulation and clarification treatment in emergent water supply treatment

InactiveCN106495372AEfficient coagulation effectEasy to adjustTreatment involving filtrationMultistage water/sewage treatmentMicro nanoFlocculation

The invention discloses equipment for enhanced coagulation and clarification treatment in emergent water supply treatment. The equipment comprises a coupling inductive type electric flocculation treatment unit, a micro nano bubble generation unit and a polymerization floating separation filtering unit, wherein an air inlet pipeline is communicated with a water inlet pipeline at one point; one end of an air dissolving pump is connected with the water inlet pipeline; the other end of the air dissolving pump is connected with a water outlet pipeline; one end of the water outlet pipeline is a micro nano bubble release head; a pipeline which is introduced into an inner cylinder is connected with the upper end of a coupling inductive type coagulation reactor; the micro nano release head is positioned inside the inner cylinder; the inner cylinder is positioned inside a polymerization floating separation area; the coupling inductive type coagulation reactor is further connected with a power supply control cabinet. The invention further discloses a method for enhanced coagulation and clarification treatment in emergent water supply treatment. The equipment has the advantages of being free of coagulant, good in coagulation and clarification effect, simple in process, low in cost and good in applicability.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

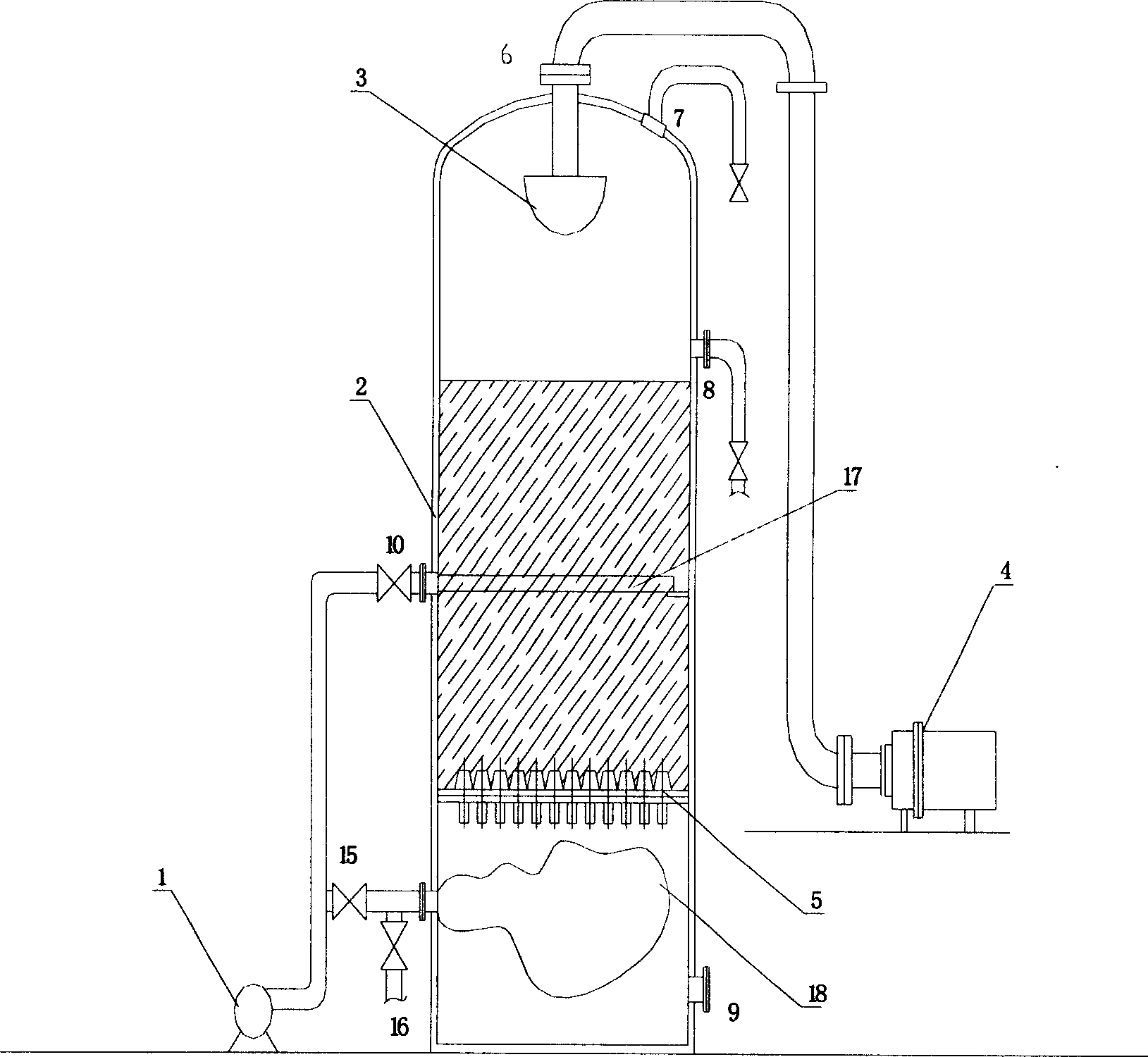

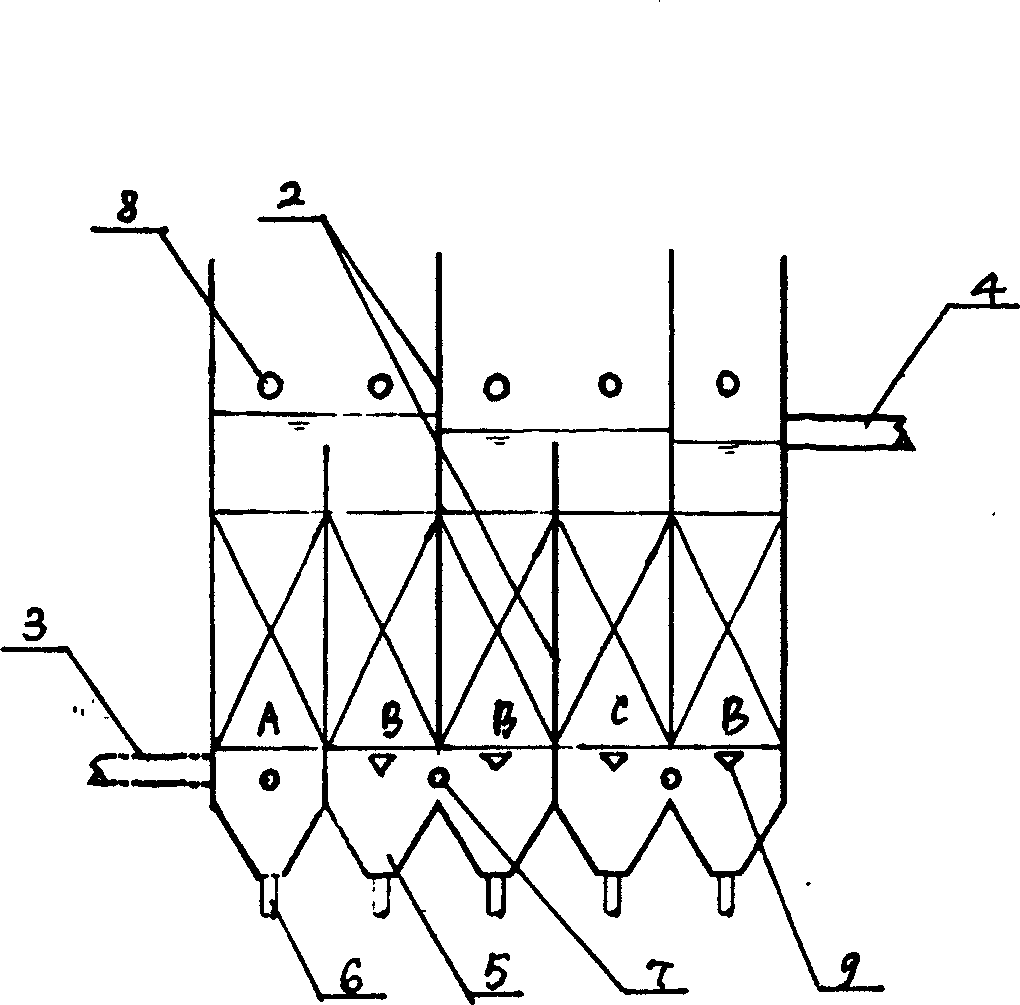

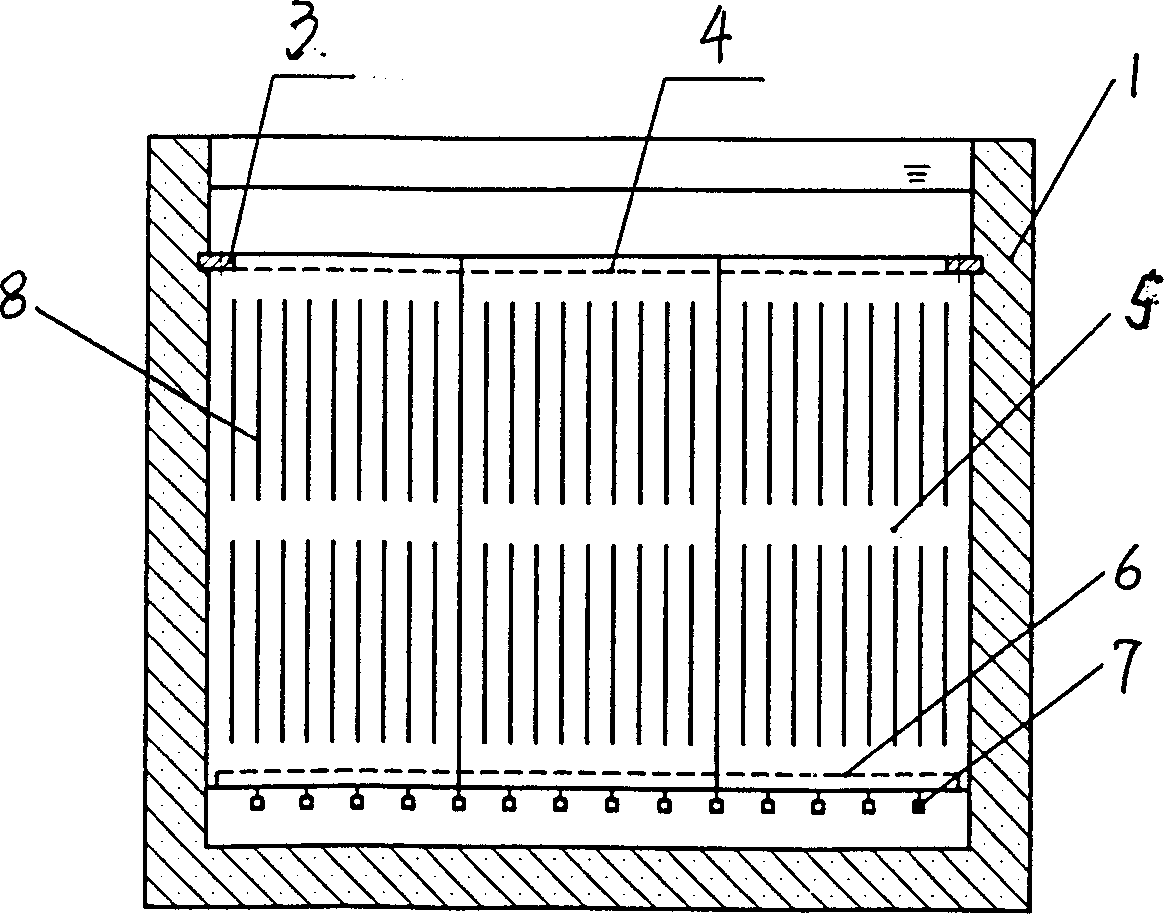

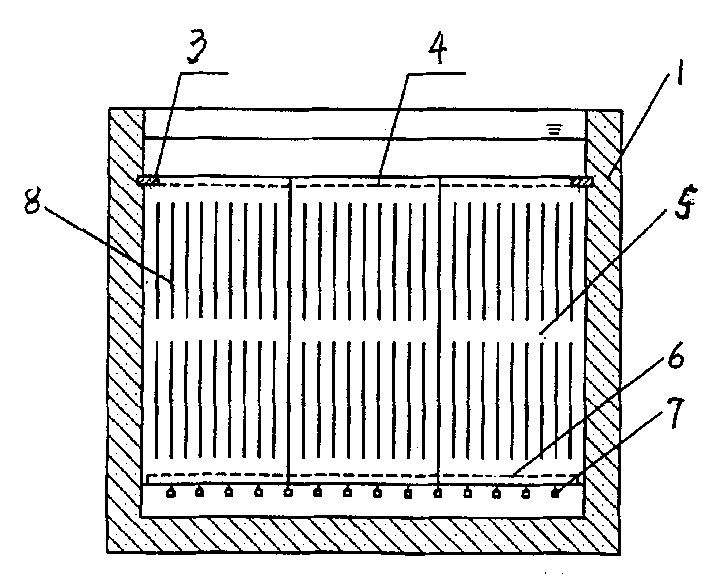

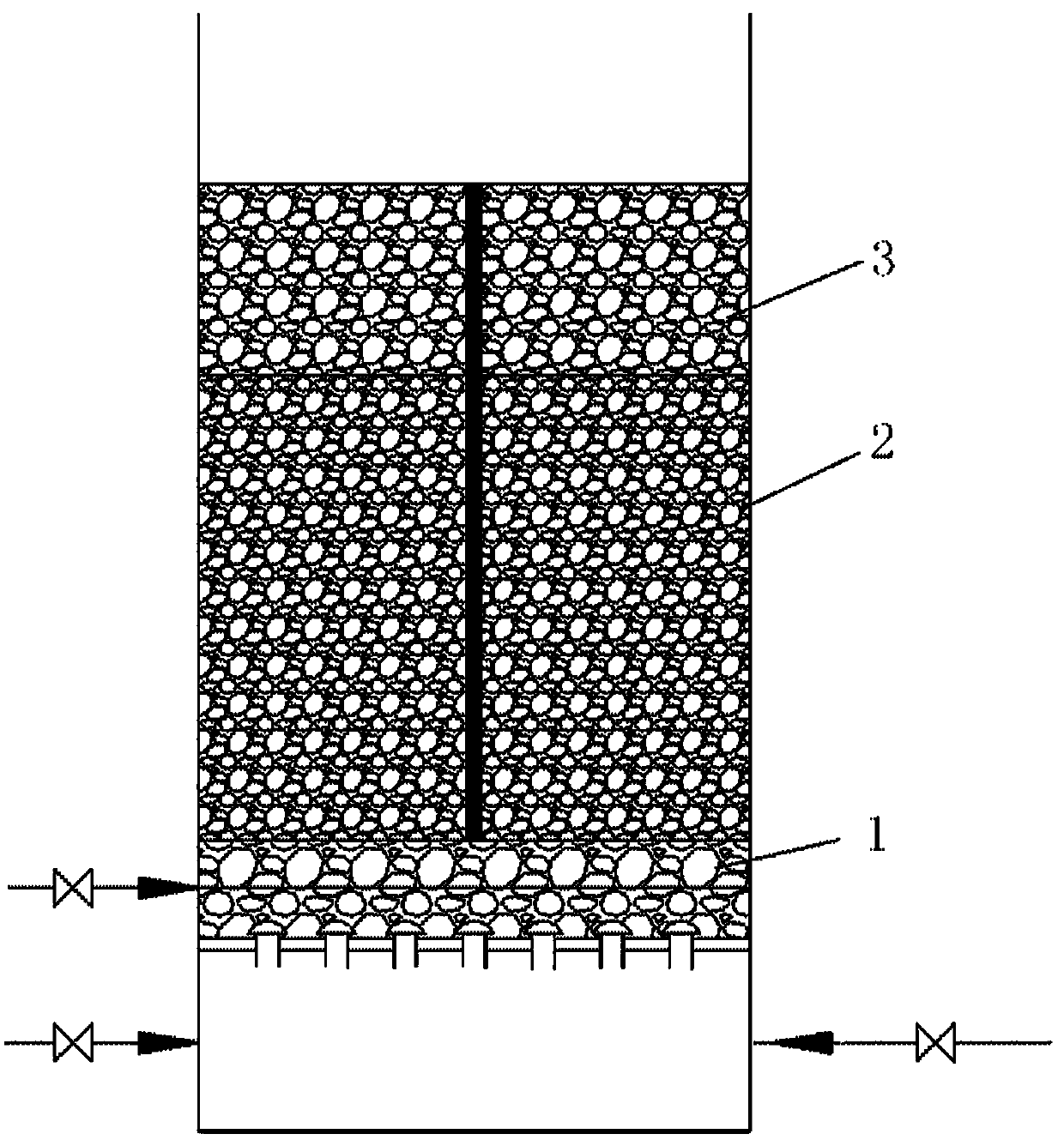

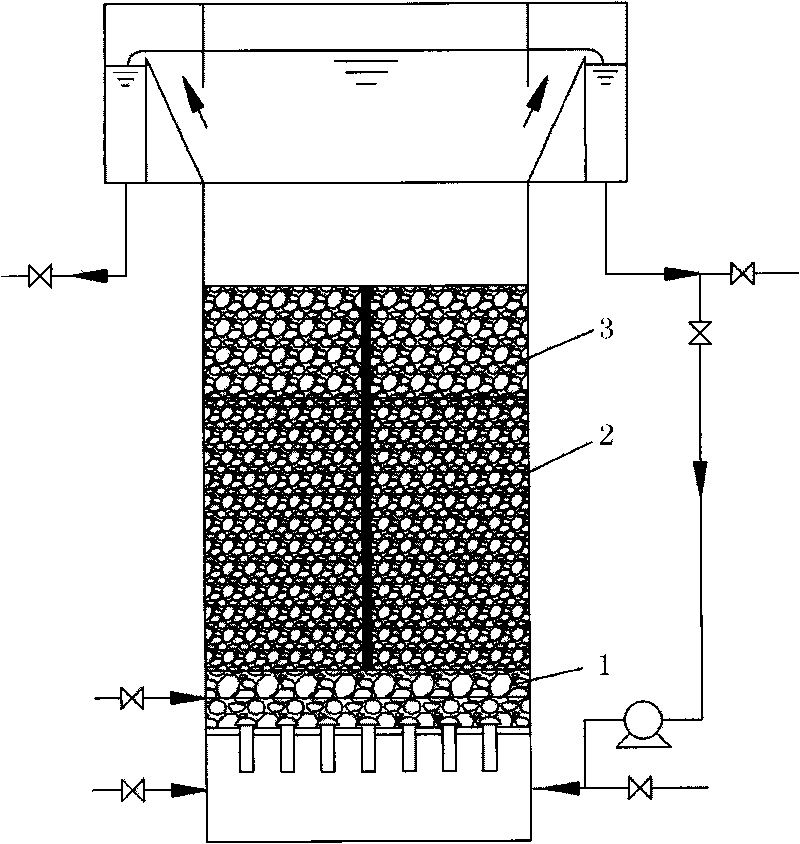

Biological aerated filter with three filter layers

InactiveCN101734786AExtended backwash cycleReduced accumulation rateSustainable biological treatmentBiological water/sewage treatmentSurface layerFilter media

The invention discloses a biological aerated filter with three filter layers. The biological aerated filter is characterized in that a filter device is provided with a supporting layer (1) with large particle size, a quartz sand filter media layer (2) with the particle size of 4 to 5mm and a light-weight filling layer (3) with the large surface particle size of 6 to 8mm from bottom to top; and the thicknesses of the three layers are respectively 800mm, 2000mm and 1000mm. A layer of light-weight filling media with larger particle size, which have the function of pretreatment, is added to the surface layer so that the surface layer can be used for carrying out biological treatment, can contain a large number of SS (suspended solids), greatly slows down the accumulation speed of the SS quantity of intermediate filter media, prolongs the time for reaching a critical value of flow and the backwashing cycle of the biological aerated filter, improves efficiency, saves water for backwashing and reduces operation costs. In addition, the relative position of the structure layers of the biological aerated filter after backwashing is not changed, and water can be supplied stably with higher quality.

Owner:大连恒基新润水务有限公司

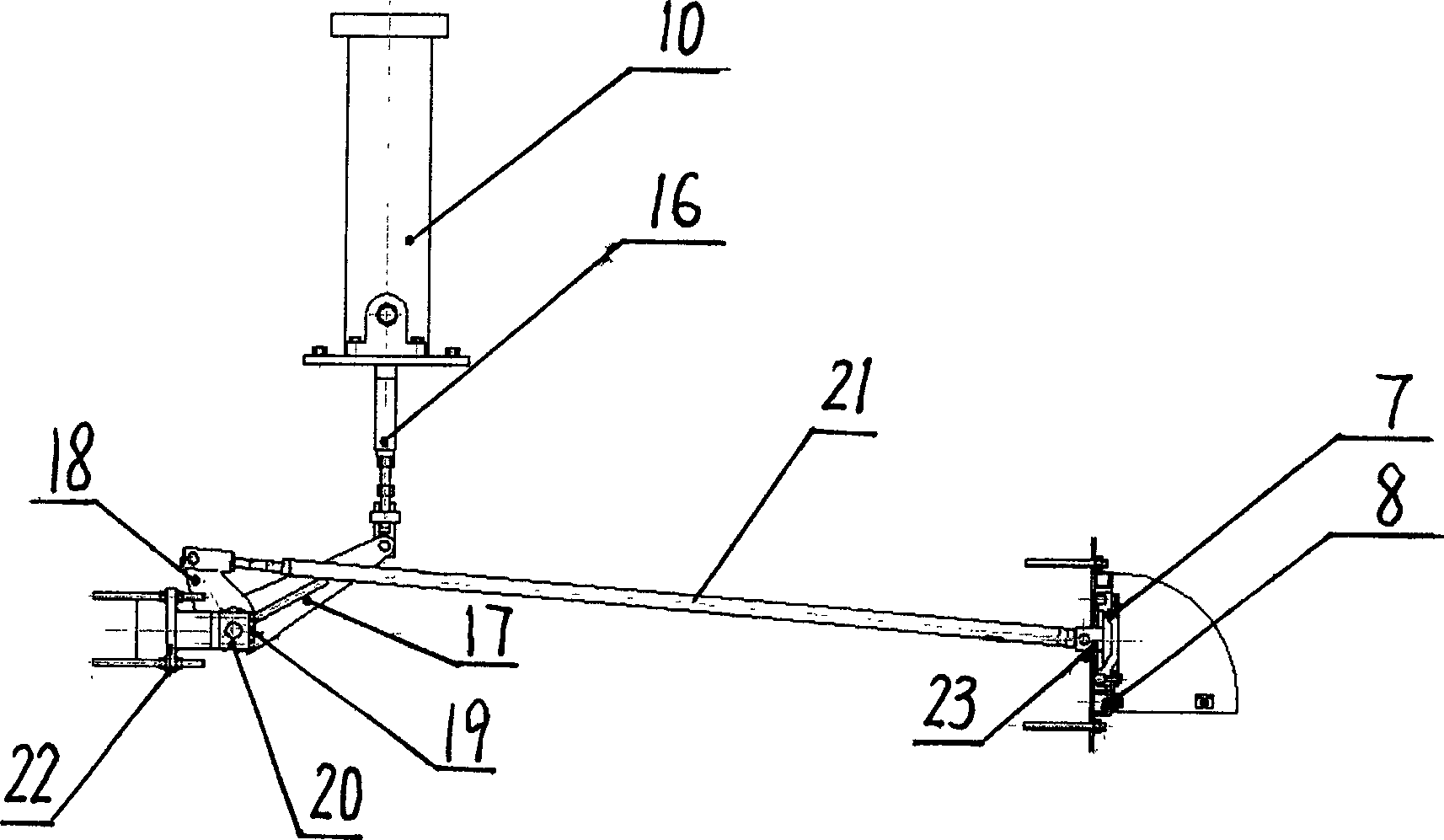

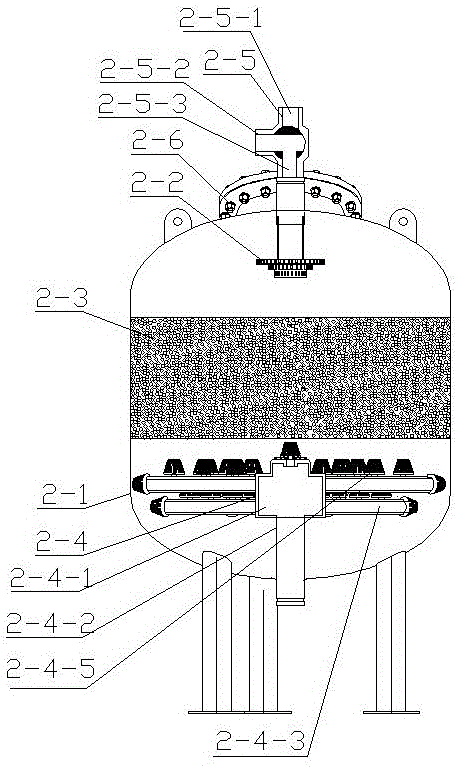

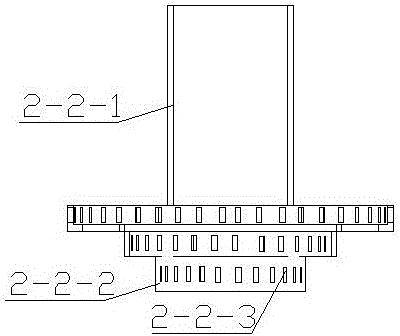

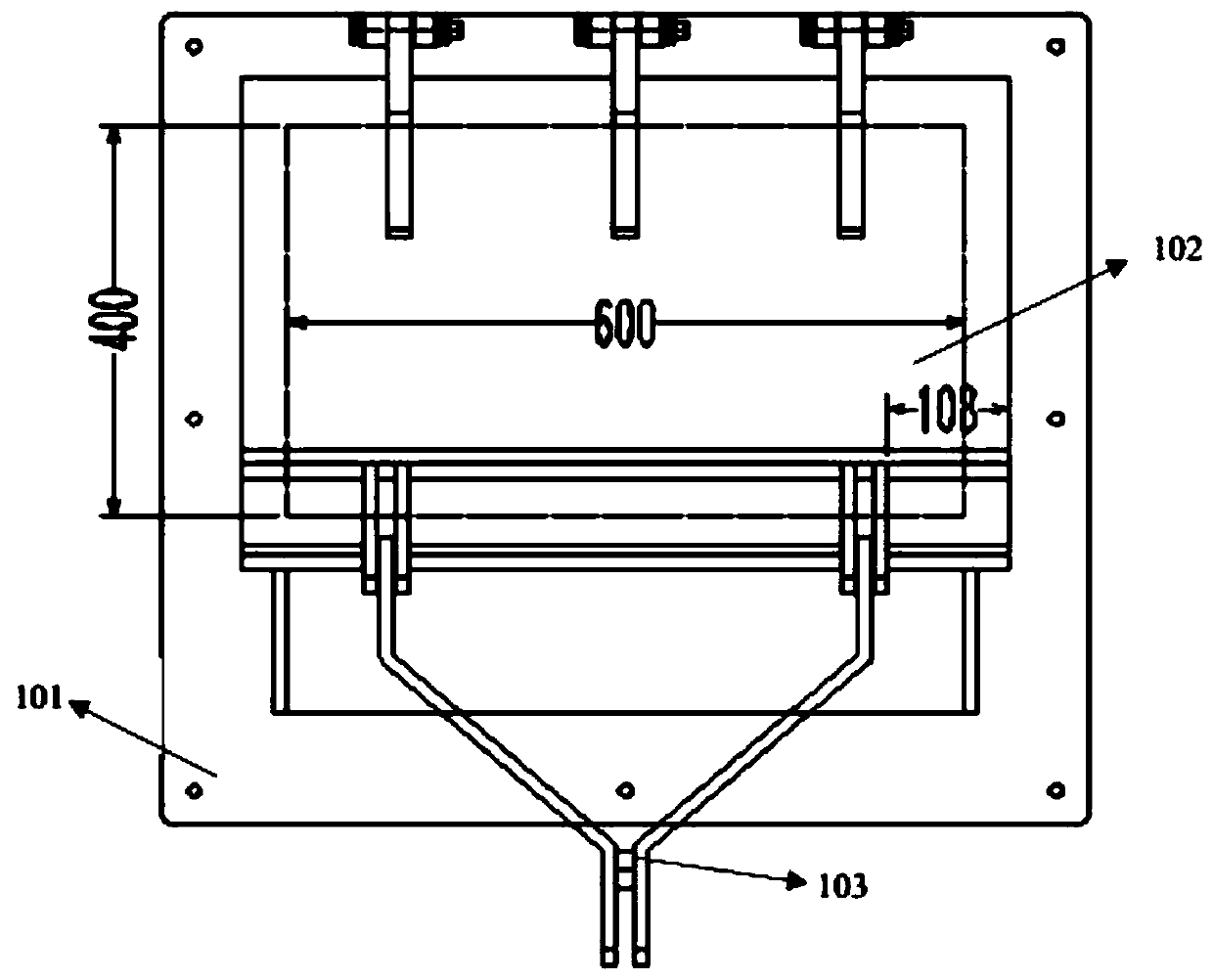

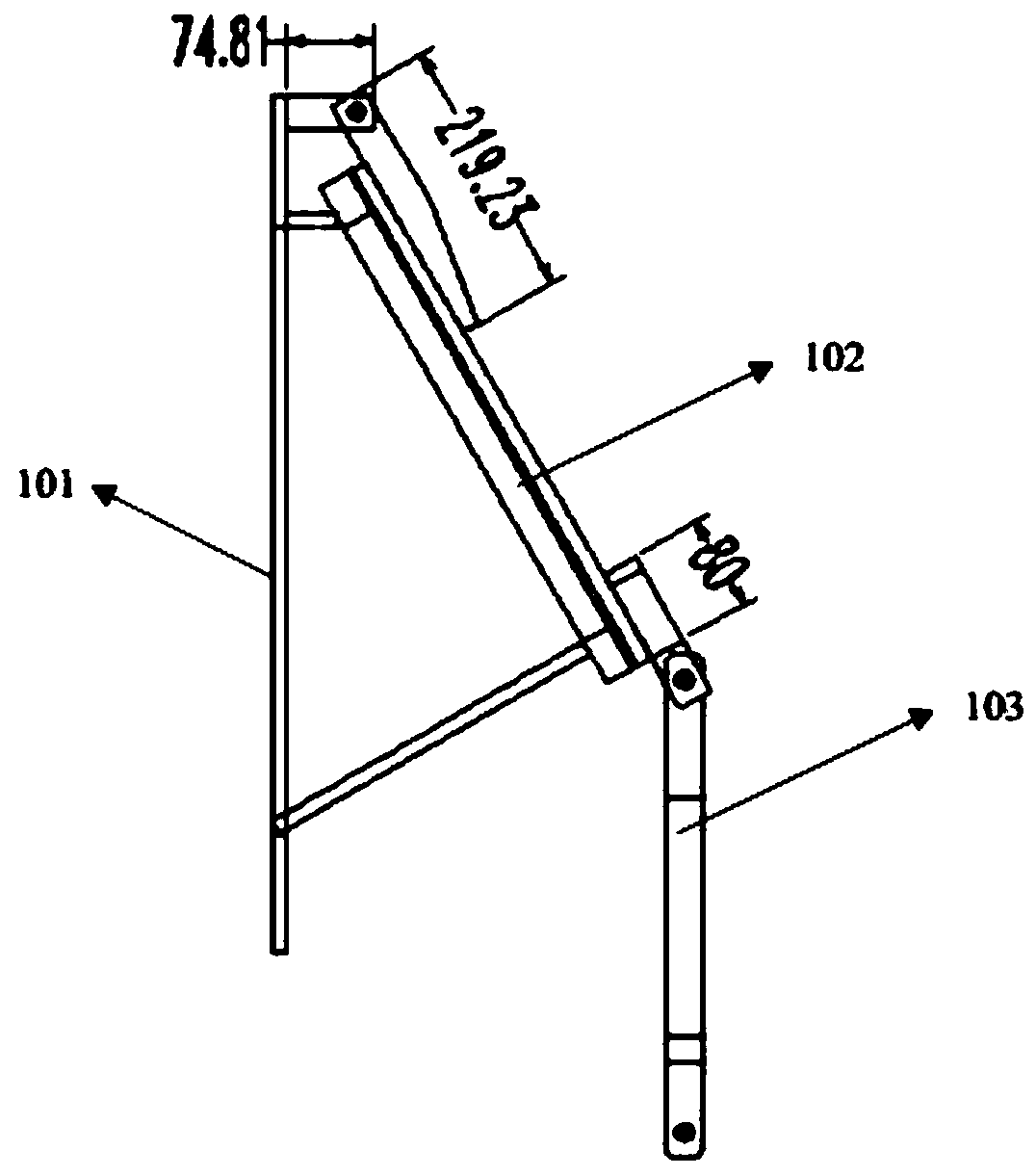

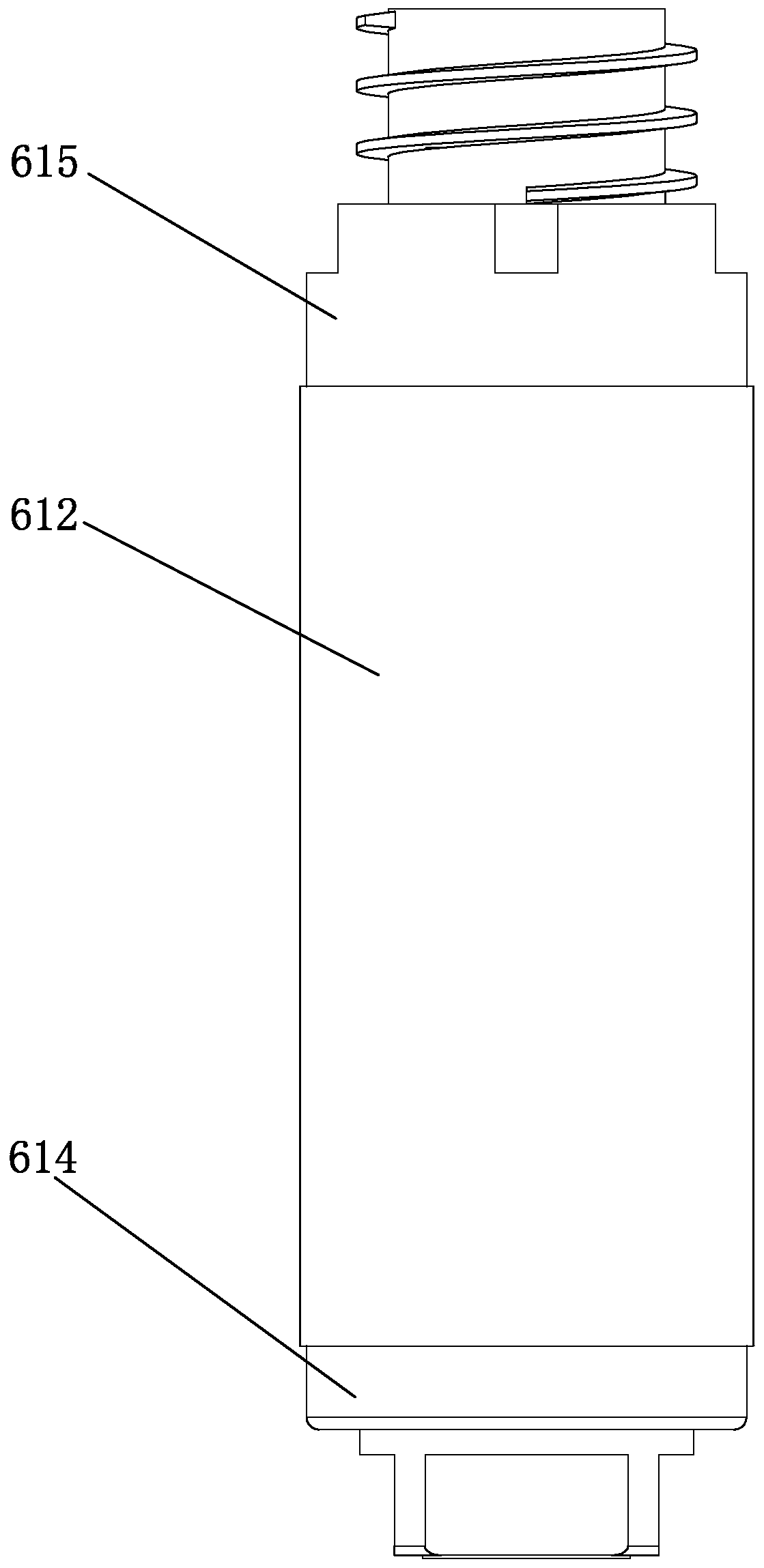

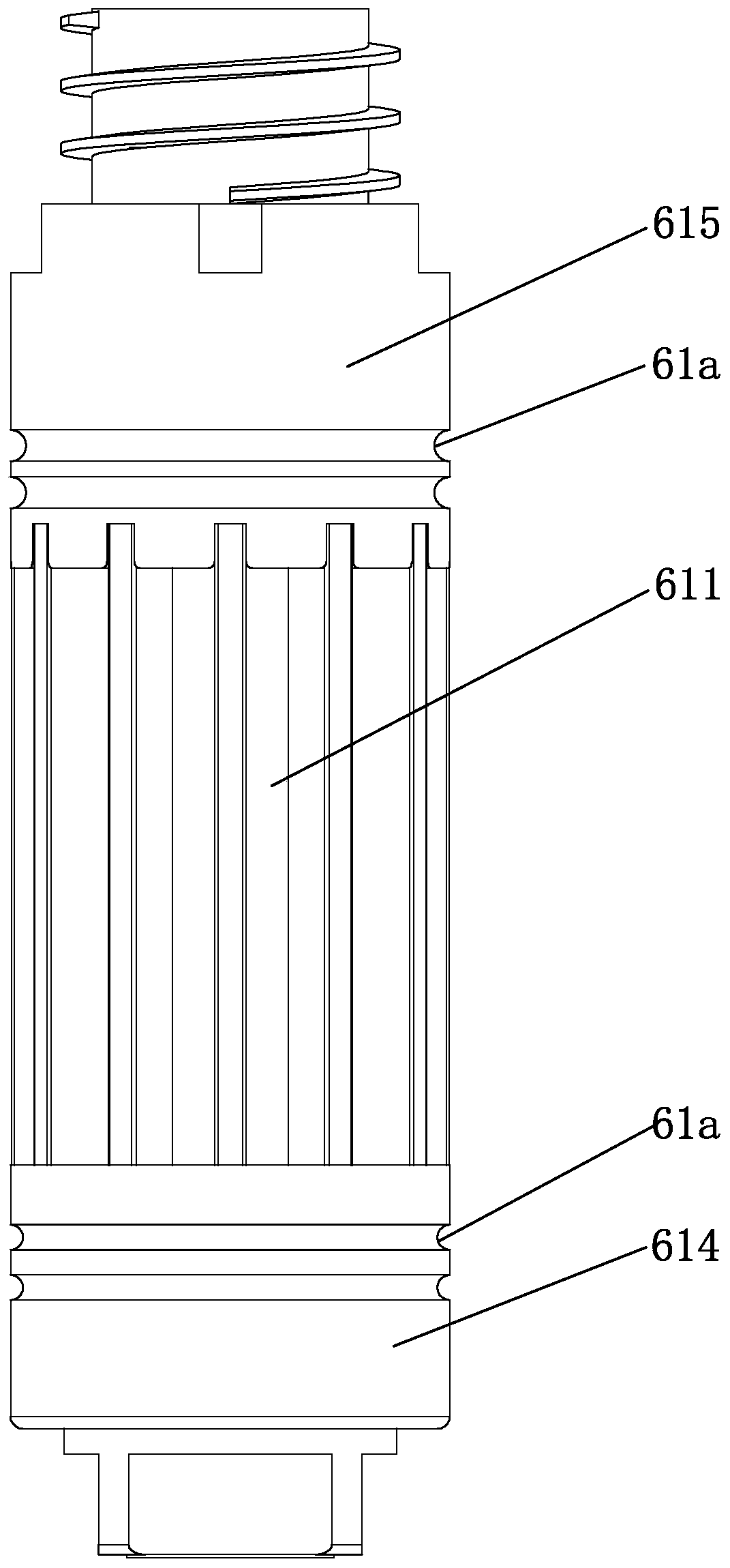

Back-flushing cutting module for ceramic bio-filter and three-dimensional back-flushing technology of back-flushing cutting module

InactiveCN108101190AWash out quicklySmall cutting resistanceSpecific water treatment objectivesBiological treatment apparatusMotor driveFilter material

The invention provides a back-flushing cutting module for a ceramic bio-filter and a three-dimensional back-flushing technology of the back-flushing cutting module. The adopted three-dimensional back-flushing technology is realized mainly by depending on the back-flushing cutting module. The back-flushing cutting module for a ceramic bio-filter comprises a cutting framework, a cutting skeleton, asecond back-flushing water inlet pipe, a second back-flushing water inlet branch pipe, a rotating shaft, a frame plate and a transmission motor, wherein the transmission motor drives the back-flushingcutting module to perform transverse filter material cutting through horizontal rotation of the rotating shaft; and the ceramic bio-filter performs longitudinal back-flushing upwards through back-flushing water which enters through a first back-flushing water inlet pipe. The three-dimensional back-flushing technology adopting three process of a 'independent gas back-flushing mode' to a 'gas-watercombined back-flushing mode' to a 'dependent water three-dimensional back-flushing mode' is provided, so that sufficient friction and movement of a filter material on a longitudinal face and a transverse face are performed, and accordingly, the bio-filter is radically prevented from blockage and caking of the filter material.

Owner:杭州达康环境工程有限公司

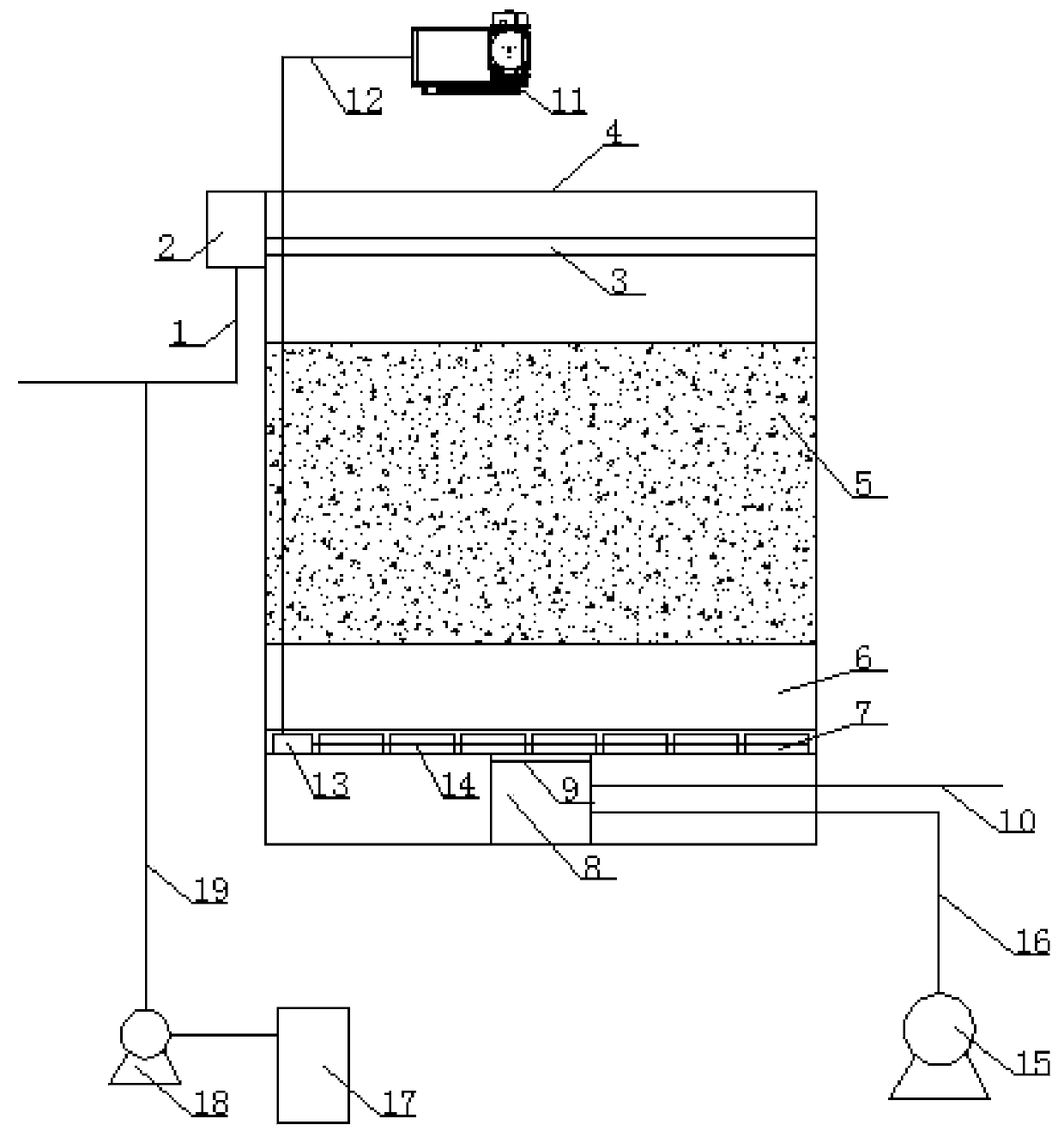

Ultrasonic air-water backwash filter

ActiveCN106902556ASpeed up the flowPromote sheddingSpecific water treatment objectivesTreatment involving filtrationParticulatesMegasonic cleaning

The invention discloses an ultrasonic air-water backwash filter which comprises a tank body. A water inlet and outlet chamber is formed in the outer wall of the tank body and used for discharging sewage and feeding original water, an air-water backwash device is arranged at the bottom of the tank body and communicated with a clean water tank and an air supply device so that water and air used for backwash are provided, the air-water backwash device is connected with a clean water outlet pipe so that clean water is discharged, a supporting layer is arranged on the upper surface of the air-water backwash device, a filter material layer is arranged on the upper surface of the supporting layer, and an ultrasonic vibration device for washing surfaces of filter materials is arranged above the filter material layer. According to the ultrasonic air-water backwash filter, the filter materials are washed by the ultrasonic washing device before and in the backwash process, so that sewage on the surfaces of the filter materials falls off, surface particles are dissolved, subsequent backwash is easier, backwash water flow velocity is reduced, backwash water is saved, energy consumption is reduced, and time is shorted.

Owner:国智建筑科技有限公司

Sea water, fresh water culture tail water processing up-to-standard discharging recycling system, and purifying method

PendingCN109879497ASimple structureEasy maintenanceWater contaminantsWaste water treatment from animal husbandrySeawaterWater treatment

The invention belongs to the technical field of sewage processing up-to-standard discharging and recycling, and especially relates to a sea water, fresh water culture tail water processing up-to-standard discharging recycling system. The sea water, fresh water culture tail water processing up-to-standard discharging recycling system comprises a phosphorus removing water tank, a filter, and a smallmolecule sterilizer; the phosphorus removing water tank is connected with the filter through a first water pipe; a filtering structure is arranged in the filter; the filtering structure is connectedwith the small molecule sterilizer through a fourth water pipe; the filtering structure comprises a plurality of filter cores; each filter core comprises an outer sleeve; each outer sleeve is sleevedwith cylindrical filter cloth; an inner tube is sleeved by each outer sleeve; the side surface of each inner tube is provided with water flow holes. According to the sea water, fresh water culture tail water processing up-to-standard discharging recycling system, simple technology equipment is adopted to realize technical improvement of a conventional culture system, sea water and fresh water fishculture industry structure restructuring is promoted, limit water resource is saved, pollution of aquatic product culture on the environment is reduced, and active promotion effect on development offish culture industry with high requirements on water quality is achieved.

Owner:无锡市江南给排水设备有限公司

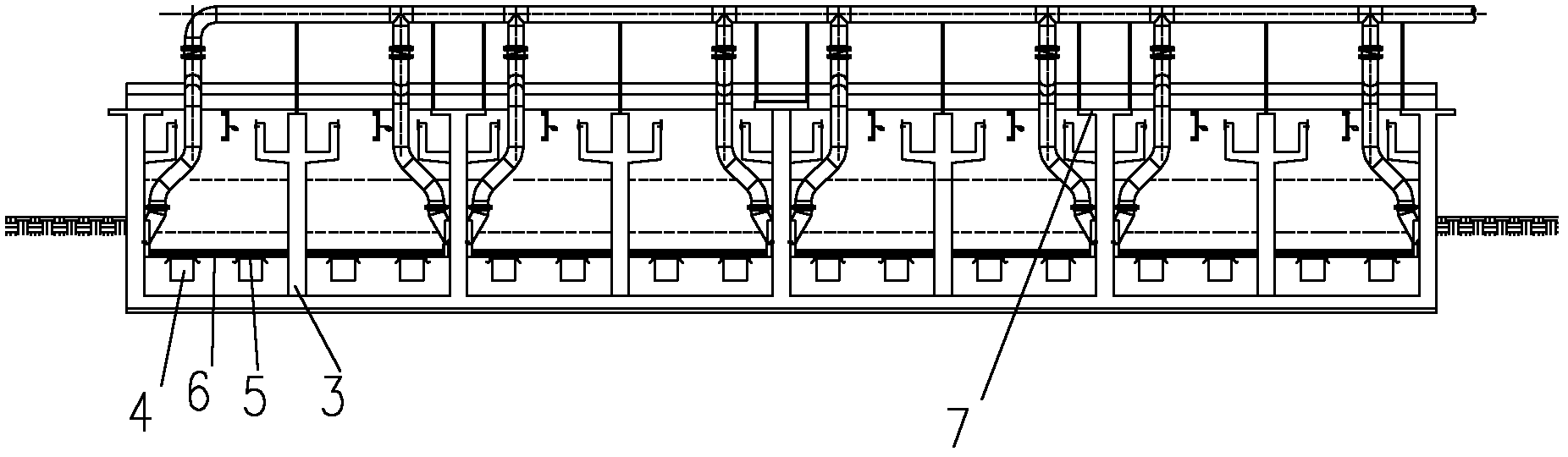

Denitrified deep bed biological filter tank

ActiveCN102491512BIncrease lossPrevents affecting backwash frequencyWaste based fuelTreatment with anaerobic digestion processesFlocculationWater volume

The invention relates to a denitrified deep bed biological filter tank, which comprises a tank body of a flocculation sedimentation tank which is divided into four groups of sedimentation tanks. The invention is characterized in that tank walls are additionally installed at the central position of the front part of each group of the sedimentation tank to form eight groups of filter tanks, a collecting tank is provided at the bottom of the filter tank, a cover plate is provided on the collecting tank, an interval part capable of penetrating water is provided between the cover plate and the collecting tank, an aeration head and an aeration pipe are uniformly distributed on the cover plate, a gas and water distribution block is additionally installed on the aeration pipe, a distribution tank is additionally installed at the upper part of each group of the filter tank. The invention has the advantages that the land occupation is less, the filter tank can be taken as the deep bed filter tank or the denitrified deep bed biological filter tank for removing SS, TN and TP. According to the invention, the gas and water distribution is employed; the water distribution and the gas distribution are uniform, maintenance-free for lifetime in the filter tank is provided. The water volume for backwashing is little with 4% and no exceeding of 2% generally. The filling material uses quartz sand which possesses hard quality, no loss or damage can be generated, no replacement is required. The standard of urban reclaimed water can be reached, and the water from the filter tank of the invention can be reused as wash water for plant area greening and road flushing.

Owner:天津泰达新水源科技开发有限公司

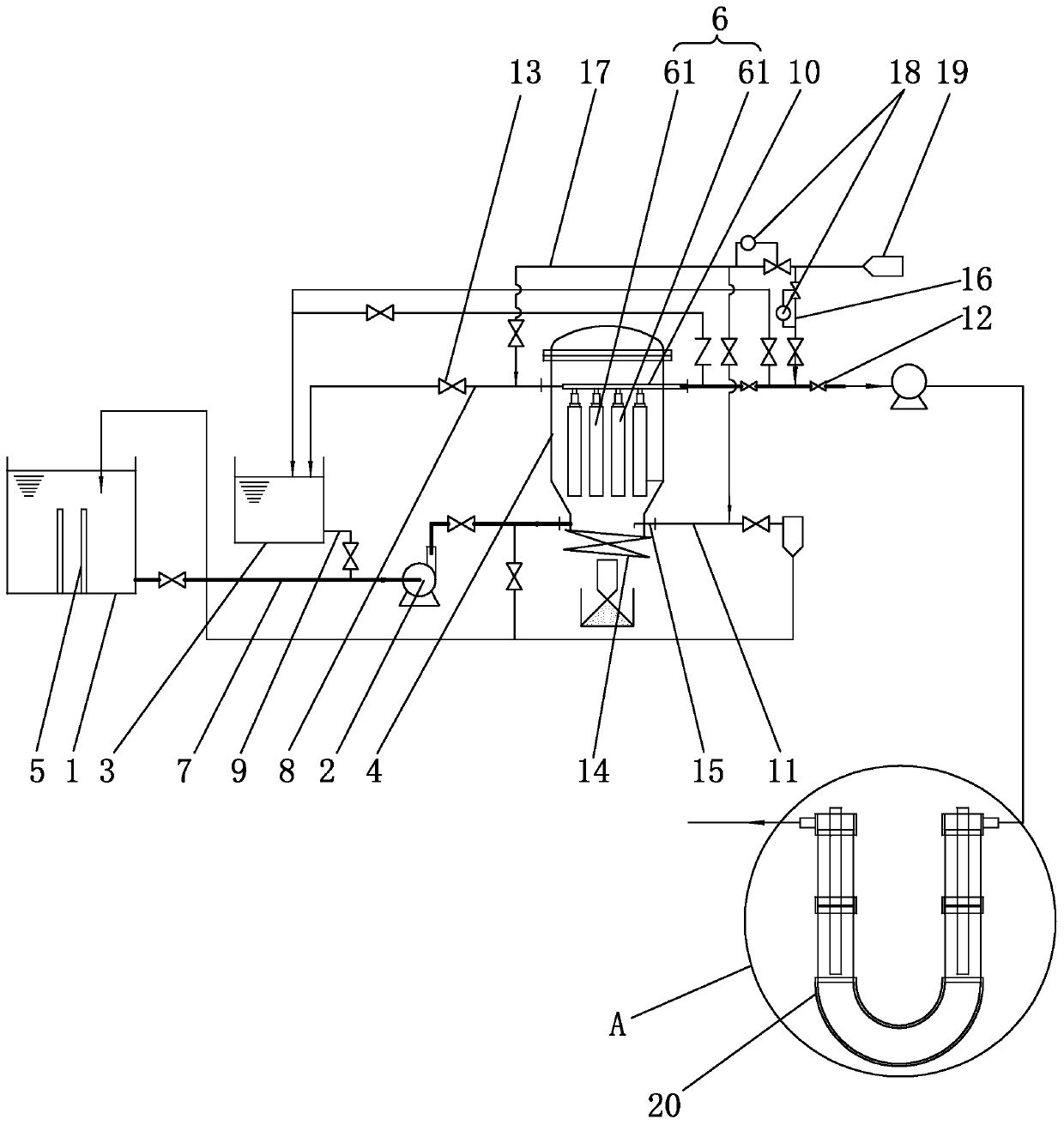

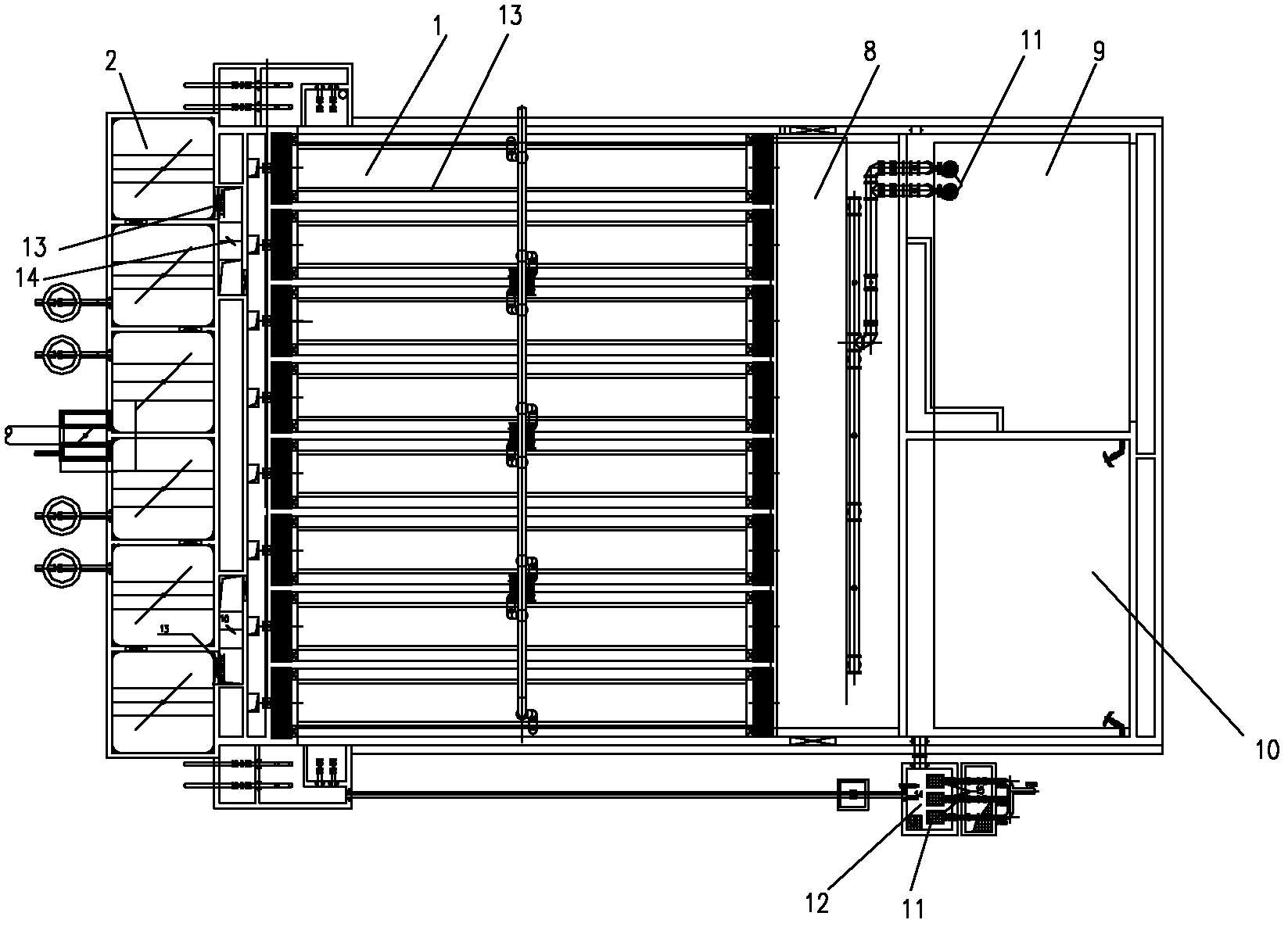

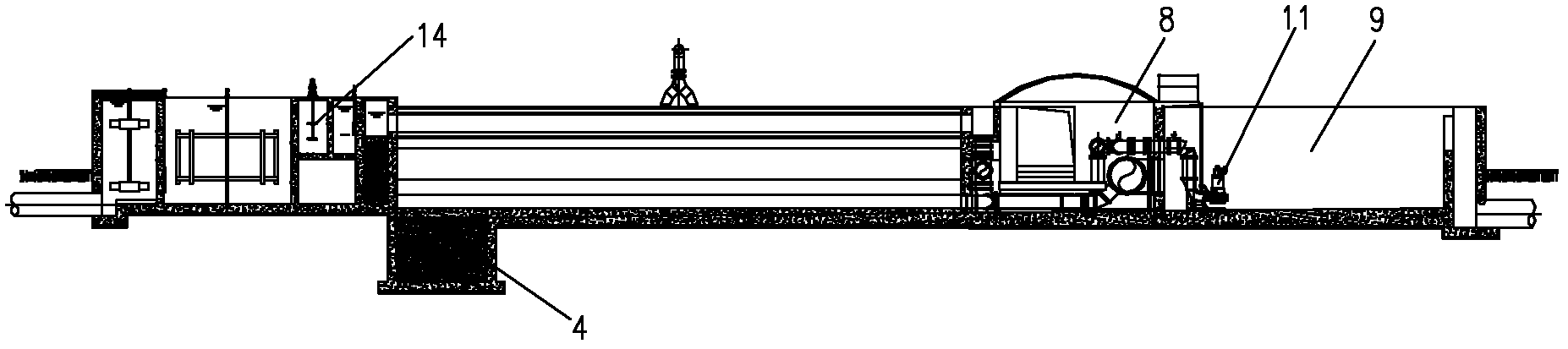

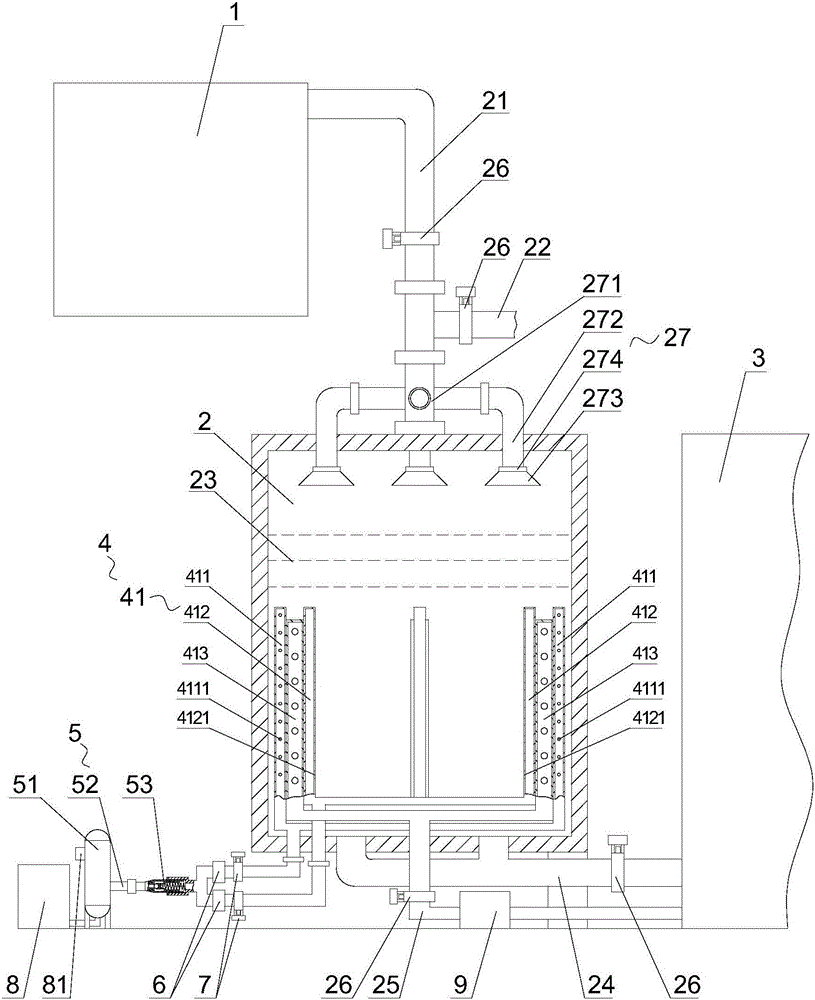

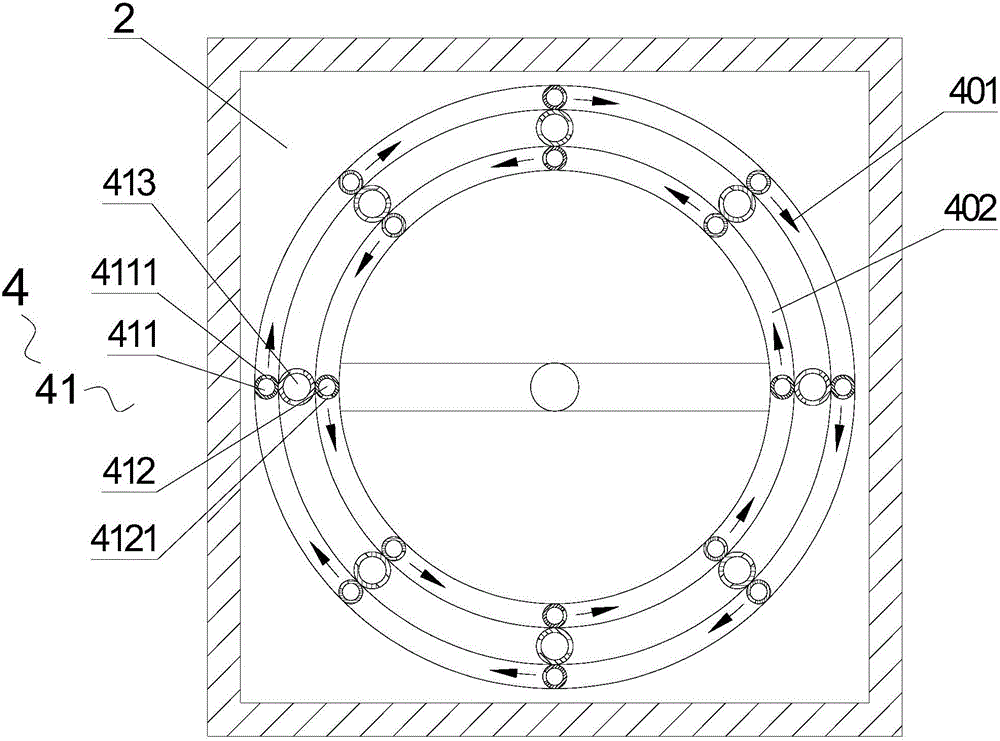

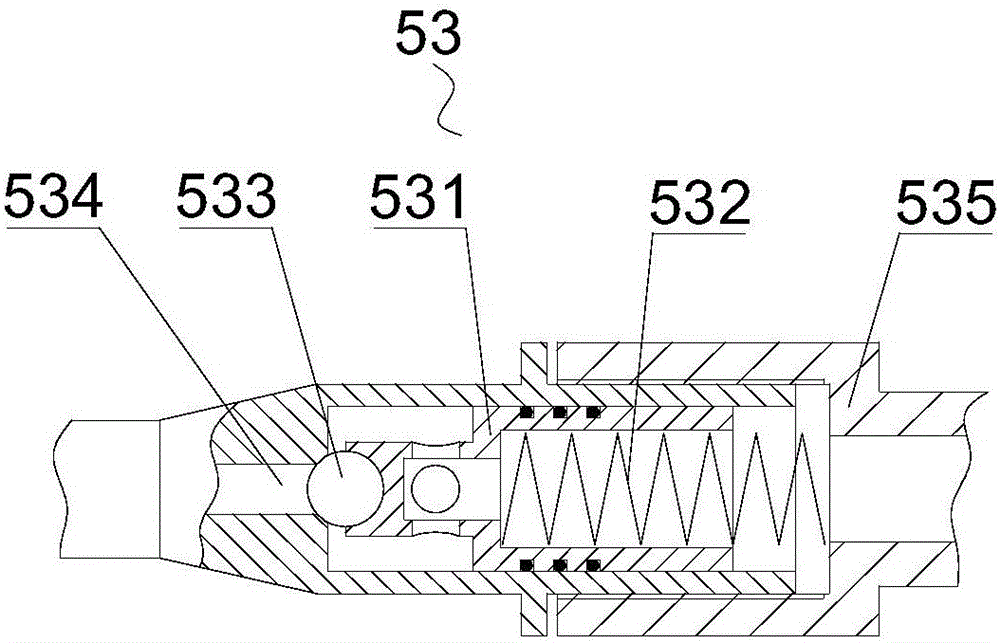

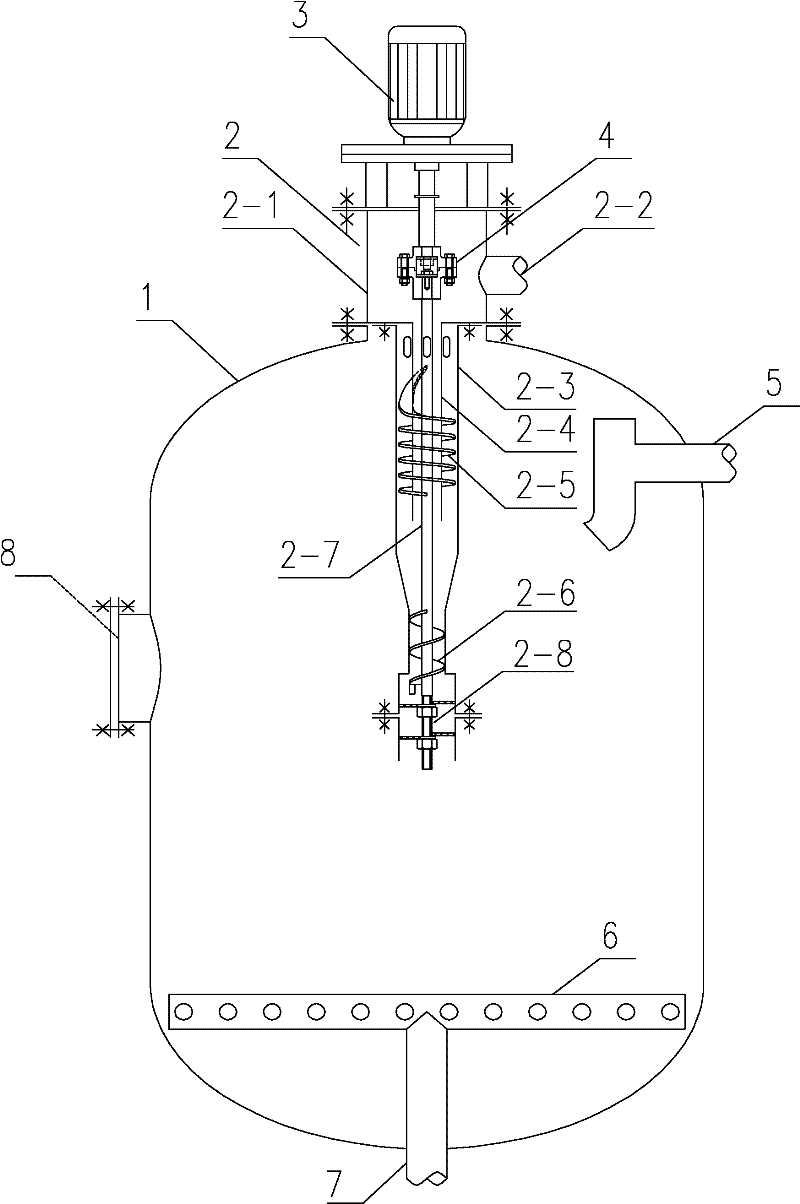

Spiral pulse gas-water composite backflushing system

PendingCN106310776AShort backwash timeSave backwash waterLoose filtering material filtersGravity filtersFilter mediaEngineering

The invention discloses a spiral pulse gas-water composite backflushing system which includes a filter tank, gas-water mixing jet pipes are in circumference array arrangement in the filter tank, independent first and second pulse gas jet branch pipes and a backflushing water jet pipe are arranged in each gas-water mixing jet pipe, the out-jet direction of jet ports of the first pulse gas jet branch pipes are in clockwise arrangement according to the circumference array to form a positive spiral pulse gas-water mixing jet system, the out-jet direction of gas-water jet ports of the second pulse gas jet branch pipes are in anticlockwise arrangement according to the circumference array to form a negative spiral pulse gas-water mixing jet system, and the first and second pulse gas jet branch pipes are connected with a pulse gas source input device. A filter media in the filter tank can be stirred at a high speed by spiral pulse compound gas and water, the filter media can intensely collide and move in the filter tank, discharge of impurities in the filter media into water is accelerated, and the filter media can be quickly restored to the level before filtration.

Owner:ZHONGKE JIELI FUZHOU ENVIRONMENTAL PROTECTION TECH

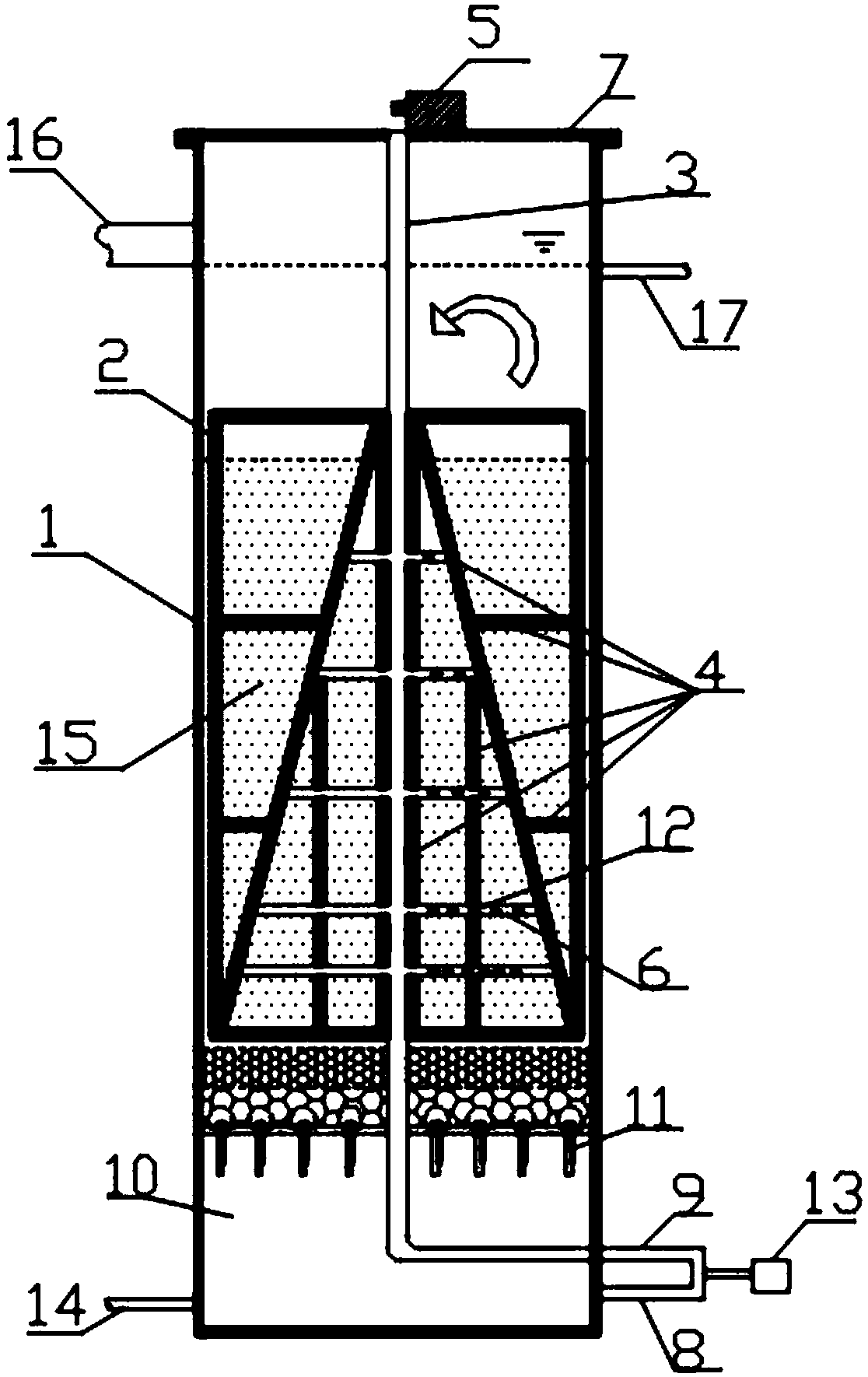

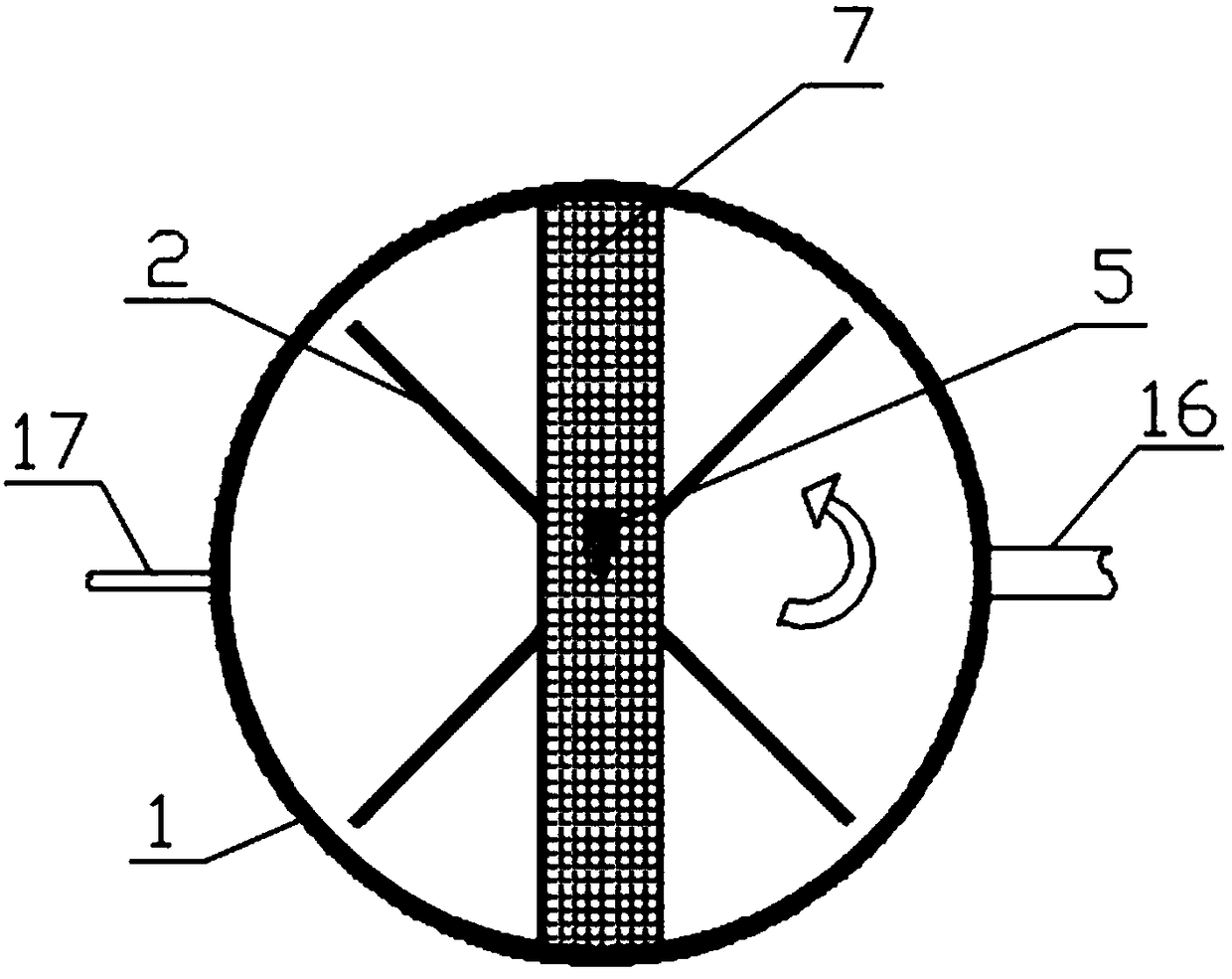

A kind of biofilter process and filter

ActiveCN104496007BSolve easy blockageSolve compactionBiological treatment apparatusBiological filterWater flow

The invention discloses a new biological filter tank process and a new biological filter tank, the new biological filter tank includes a filter tank, a backwash water pipe located at the bottom side part of the filter tank, a water intake canal located above the filter tank, an effluent weir located below the filter tank, and a filter material; all the filter material is separately put into a plurality of liftable filter material boxes, the filter material boxes vertically separate a filter bed into a plurality of layers, the plane of the filter bed is also can be divided into a plurality of cases and one overall case according to the need of practical engineering, a water swelling material is arranged between the periphery of the filter material boxes and the filter tank, a compressible and stretchable rigid frame is arranged in the swelling material; the filter material size gradually decreases along the filtering water flow direction, and enough spare height is left above the filter material in the filter material boxes. The new biological filter tank can solve many technical problems of high backwash difficulty, easy blockage or hardening, high backwash frequency, high backwash water consumption, f large power consumption, high effluent SS (suspended solids) and the like of filter tanks in the prior art.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

Pretreatment equipment for water purification

PendingCN106698752ASave backwash waterLess consumablesTreatment involving filtrationMultistage water/sewage treatmentFlocculationControl valves

The invention discloses pretreatment equipment for water purification. The pretreatment equipment comprises a casing, an inlet and an outlet formed in the casing, and further comprises an inlet water mixer arranged at the front end of the casing, a flocculation filling opening formed in the inlet water mixer, and a horizontal water distributor arranged between the inlet water mixer and the casing, wherein a plurality of multi-box areas which are communicated with one another are arranged in the casing; the multi-box areas comprise a cone depression area positioned at the lowermost part, a water outlet area positioned at the uppermost part, and a flotation filtering area positioned between the water outlet area and the depression area; a combined filtering layer is arranged in the flotation filtering area; the pretreatment equipment further comprises horizontal water outlet weir plates at the beads of the multi-box areas, floating foam lateral flow openings formed in one sides of the horizontal water outlet weir plates in lower positions, blow-off pipes connected with the floating foam lateral flow openings, and lateral flow blow-down control valves, check valves and vapor pressure backflushing devices arranged on the blow-off pipes. The pretreatment equipment belongs to a technical improvement integrating multiple functions, such as flocculation mixing, mechanical filtering, flotation and defoaming, of universal water purification pretreatment equipment, and is low in cost and high in water purification efficiency.

Owner:戚征群 +1

Multifunction sea-water purifying device and treatment method

InactiveCN1183045CReduce organic contentImprove purification effectTreatment using aerobic processesClimate change adaptationEnvironmental engineeringOxygen

The multifunctional sea water purification equipment comprises the purification pool and filter material placed in the purification pool, and the described filter material is formed from several pieces of water-cleaning clohtes which are parallelly sepaced and suspended, and the purification pool is divided into several purification filtering chambers by means of water-cleaning clothes. Said water-cleaning cloth has a row of vertical gaps which are cut according to a spaced width, and its two end portions and middle portion are equipped with connecting portion with a certain width, said water-cleaning cloth is a punched non-woven fabric, and its specific surface area is above 2000 sq.m / cu.m. Its purification process includes: fish farming pool, air float pool, multifunctional sea water purificiation equipment, oxygen-dissolving tank and fish farming pool.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

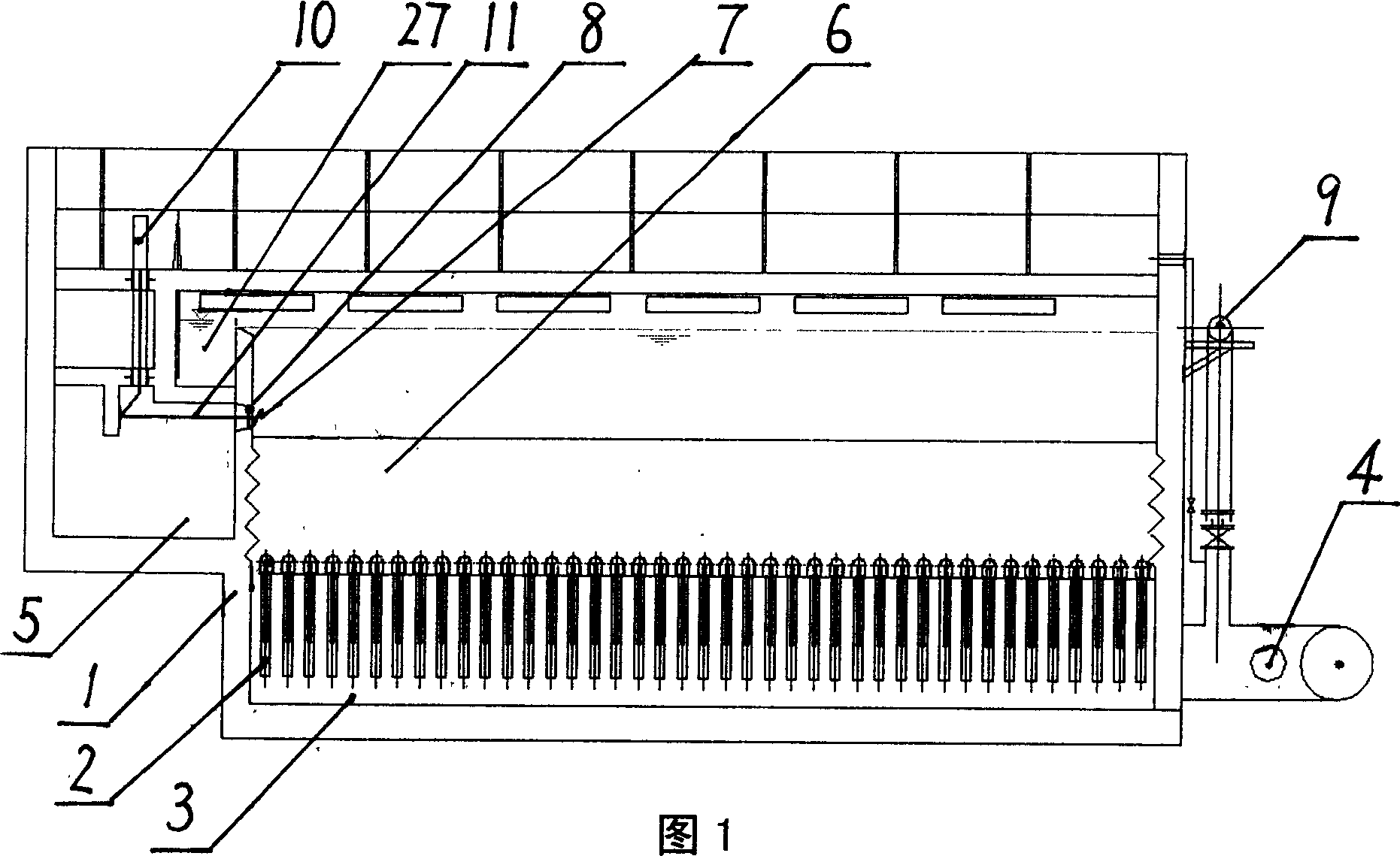

Backwashing method and device of filter

InactiveCN101982216BStrong scrubbing actionPowerful centrifugal separationFatty/oily/floating substances removal devicesLoose filtering material filtersFilter mediaEngineering

The invention discloses a backwashing method of a filter, which solves a problem of low backwashing efficiency of traditional filters, a specific method is that a whirl cavity, a water collection cavity, a filtering medium collection and transfer cavity and a discharge cavity are all installed in the filter, so that a mixed liquor generates a strong centrifugal separation acting force after passing through the whirl cavity, the acting force results in not only applying a rubbing force on the filtering medium, but also effectively separating the filtering medium from oil and suspending impurities through their channels, namely, the oil and the suspending impurities are discharged from a tank via the water collection cavity, the washed filtering medium is sequentially returned back to the tank via the collection and transfer cavity and the discharge cavity, repeating in this cycle, the filtering medium can be completely washed; the invention also provides a device capable of implementing the method.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com