Vertical deflector combined Filtration type dephosphorization and nitrogen rejection facility

A filtering and vertical technology, applied in the field of environmental protection and sewage treatment, can solve problems such as short operation period, difficulty in meeting discharge standards, complex operation and management, etc., achieve low equipment investment and operation costs, save water and energy consumption , the effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

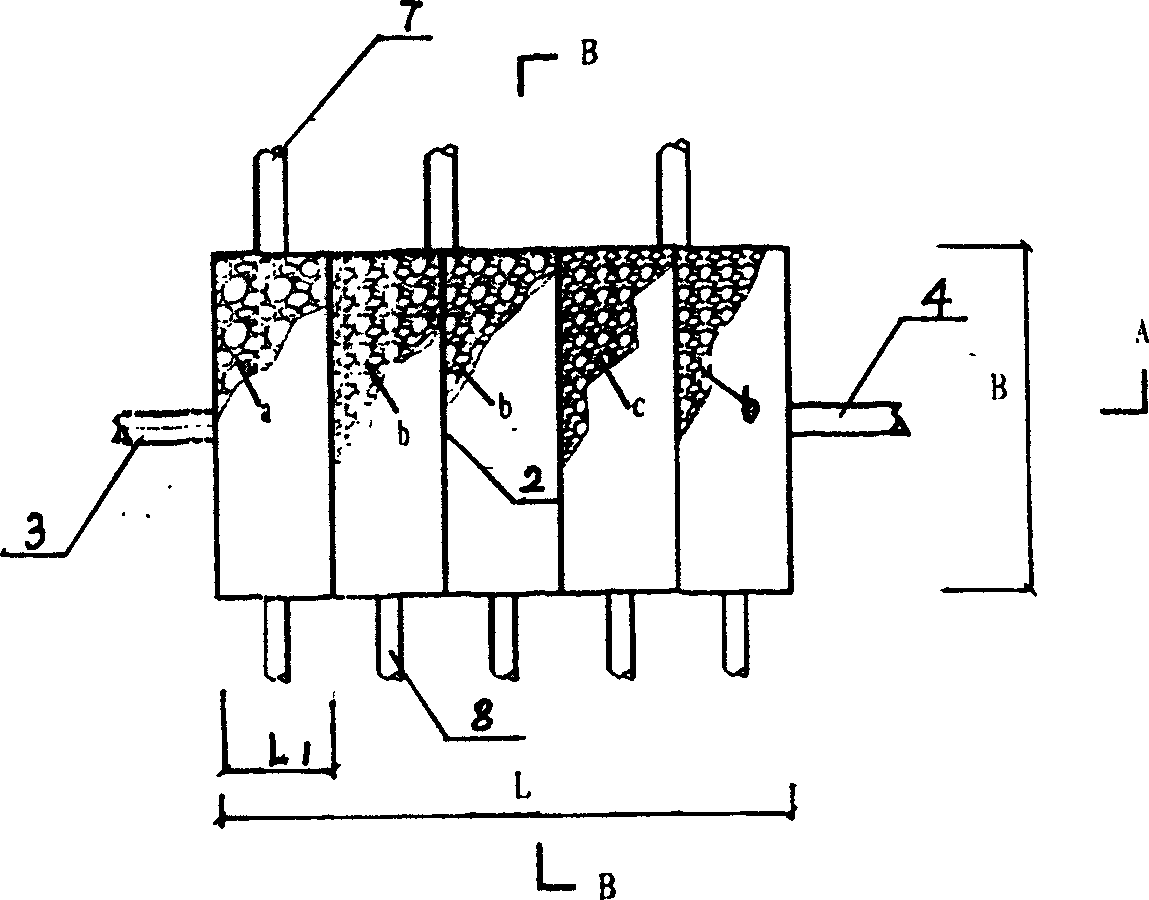

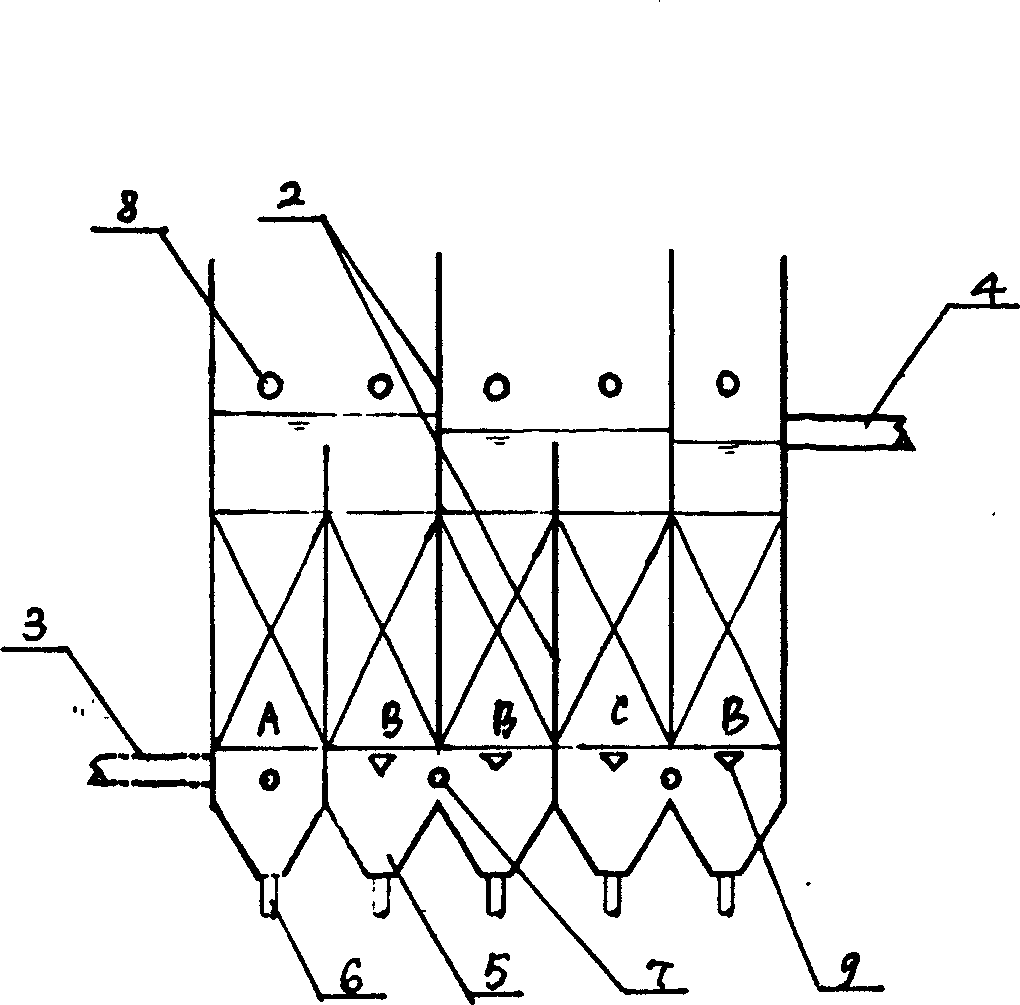

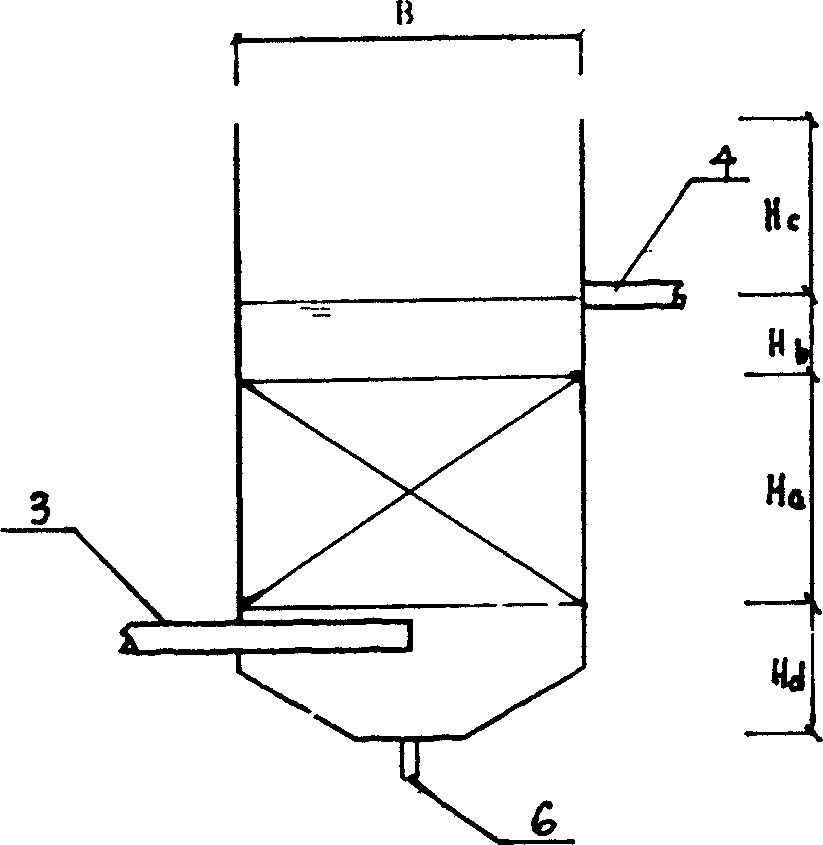

[0025] see figure 1 , 2 and image 3 , the main body of this device is divided into five relatively independent and interconnected 5 single filter tanks 1 divided by clapboards, each single filter tank is separated by clapboards 2 staggered up and down, leaving a sewage baffle channel up and down, see Figure 4 indicated by the arrow in . The water inlet pipe 3 is connected to the first single filter tank, and the last single filter tank is connected to the water outlet pipe 4 . The bottom of each single filter tank is provided with a mud collecting bucket 5 and a mud discharge pipe 6, and at the same time, a backwash water inlet pipe 7 is also provided at the bottom of each single filter tank, (two single pools connected at the bottom are combined to establish a mud collecting bucket and - backwash water inlet pipe), the top has a backwash water outlet pipe 8. There is a packing layer in the middle of each single filter tank, the first single filter tank is equipped with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com