Organic functional porous isolating membrane, preparation method and lithium ion battery

A separator and porosity technology, which is applied in the field of organic functional porous separator and its preparation, can solve the problems affecting the functionality of the coating, and achieve the effects of improving quality, excellent adhesion, and maintaining rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

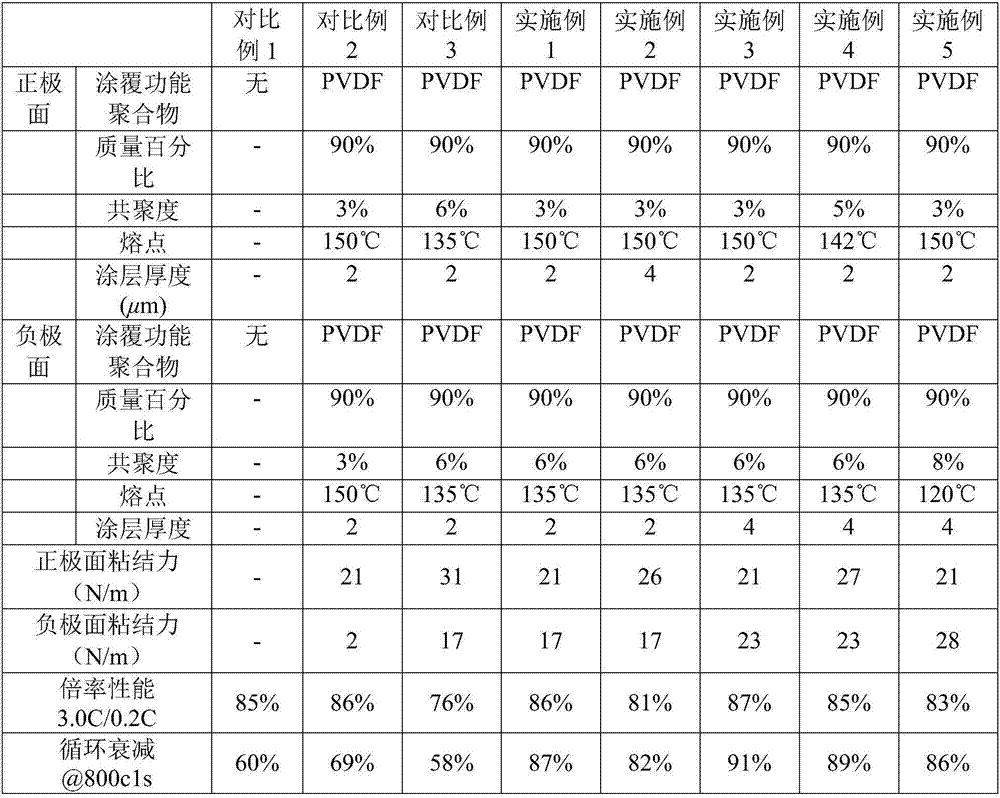

Examples

Embodiment 1

[0045] A kind of organic functionalized porous separator

[0046] The coating slurry formulation on the positive electrode surface of the lithium battery on the porous separator is in dry weight percentage, and the coating slurry consists of 8wt% styrene / acrylate copolymer emulsion, 2wt% carboxymethylcellulose sodium, 90wt% poly Vinylidene fluoride consists of three parts, among which polyvinylidene fluoride is selected from hexafluoropropylene and vinylidene fluoride copolymerization high molecular polymer with a degree of copolymerization of 3% and a melting temperature of 150°C. For polyvinylidene fluoride, the average particle diameter D50 is 0.15-1.0 μm. The water-based polymer binder is selected from styrene / acrylate copolymer emulsion, and the water-based polymer thickener is selected from sodium carboxymethyl cellulose. During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for 30wt% of the total weight of t...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 lies in the thickness specifications of the coating slurry on the positive electrode surface of the lithium battery on the porous separator:

[0051] Wherein, the coating slurry on the positive electrode surface of the lithium battery is used on the porous separator to coat the surface of the separator, and the coating thickness is 4 μm; then, the coating slurry on the negative electrode surface of the lithium battery is carried out on the porous separator. The other surface of the separator was coated with a coating thickness of 2 μm to obtain an organic functionalized porous separator with a total thickness of 18 μm.

[0052] The rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1 lies in the thickness specifications of the coating slurry on the negative electrode surface of the lithium battery on the porous separator:

[0054] Wherein, use the coating slurry on the positive electrode surface of the lithium battery on the porous separator to coat the surface of the separator, and the coating thickness is 2 μm; then, use the coating slurry on the negative electrode surface of the lithium battery on the porous separator. The other surface of the separator was coated with a coating thickness of 4 μm to obtain an organic functionalized porous separator with a total thickness of 18 μm.

[0055] The rest are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com