Novel tyre renovating sander

A tire retreading and grinding machine technology, applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problem of increasing the operating strength and affecting the bonding quality of new treads, economical and practical Sexuality is not good and other problems, to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

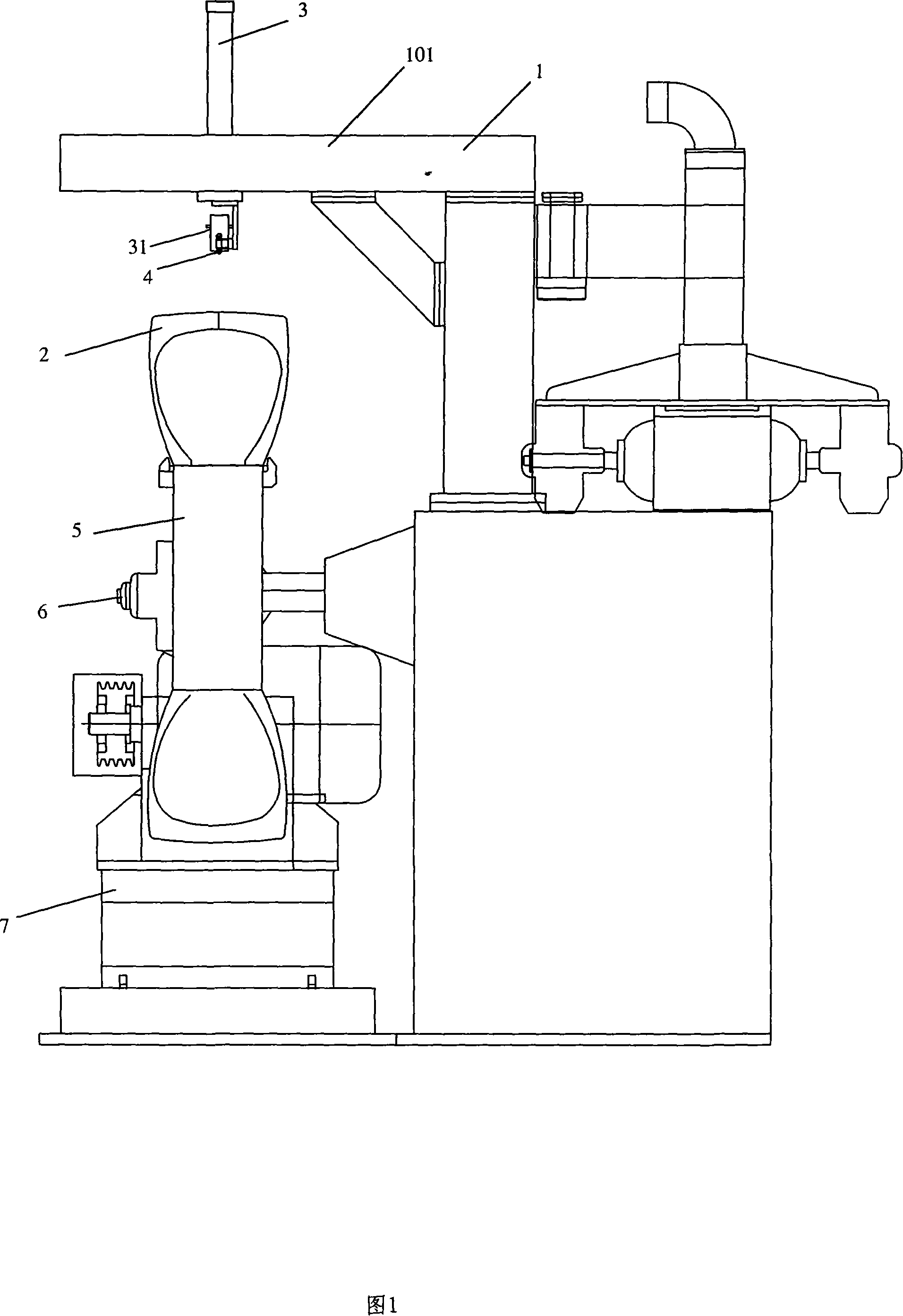

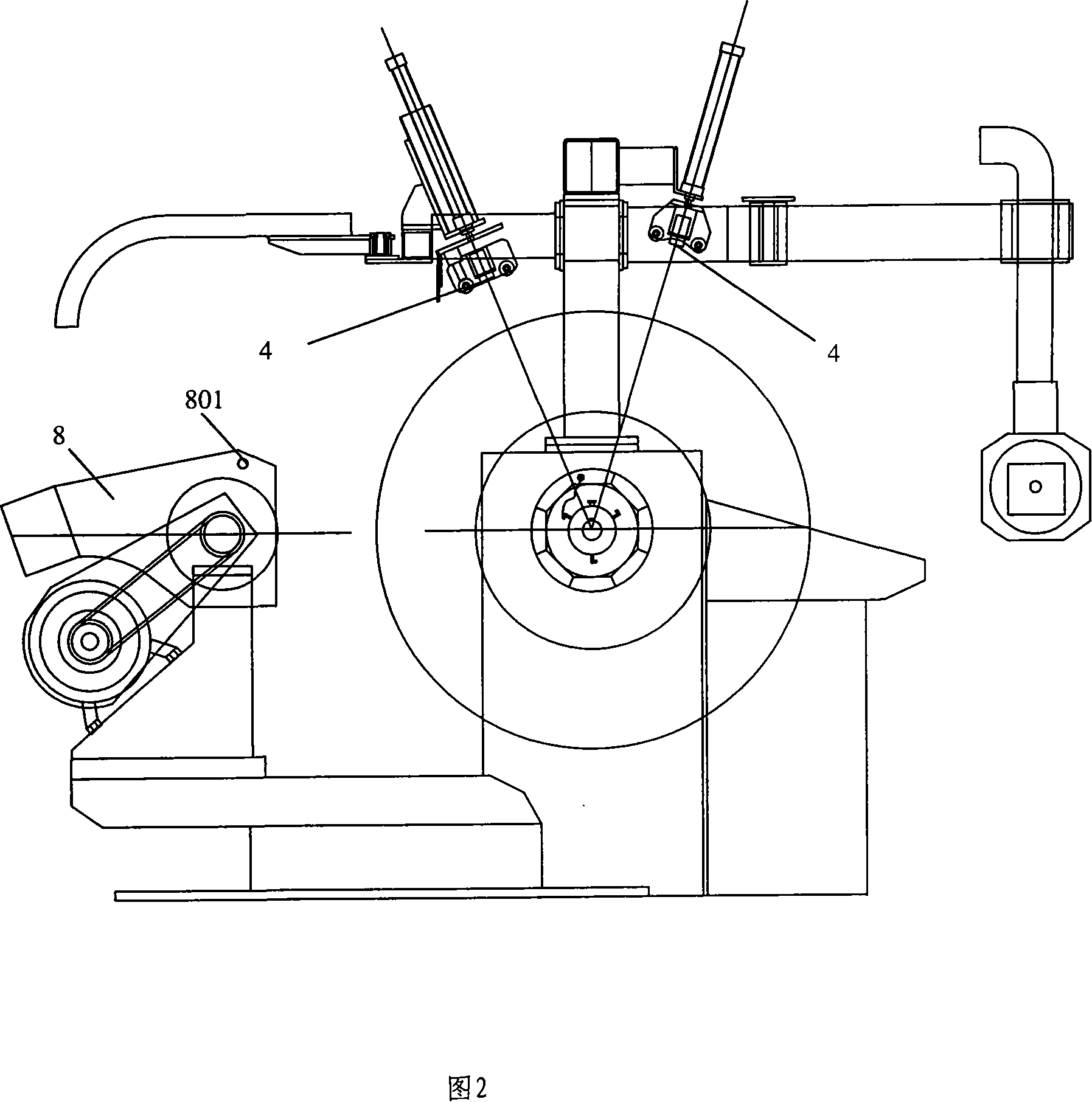

[0028] As shown in Figure 1, it is a schematic structural diagram of the present invention. Fig. 2 is a left side view of Fig. 1 .

[0029] The tire 2 to be polished is fixed on the expansion drum 5, and is installed on the axle 6 together with the expansion drum 5 and fastened.

[0030] A cylinder 3 is fixed on the body cantilever 101 above the tire 2, and the cylinder drives the frame body 31 to move. A group of detection probes 4 is arranged at the end of the frame body 31. The group of detection probes 4 includes at least a temperature measurement probe and a detection device for detecting the radial size of the tire. The probe and the detection probe of the base rubber thickness, wherein the temperature measurement probe can be fixed on the body by using a photoelectric temperature measurement probe, and the detection probe for detecting the radial size of the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com