Preparation device of indoor single-cracked rock specimen

A technology for preparing devices and rock samples, which is applied in the field of geotechnical engineering, can solve the problems of difficult precise control of concentricity, parallelism and thickness of bonding layer, constraints on the design basis of mechanical tests, and inability to accurately simulate the actual situation on site. The effect of strong practicability, easy manufacture and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

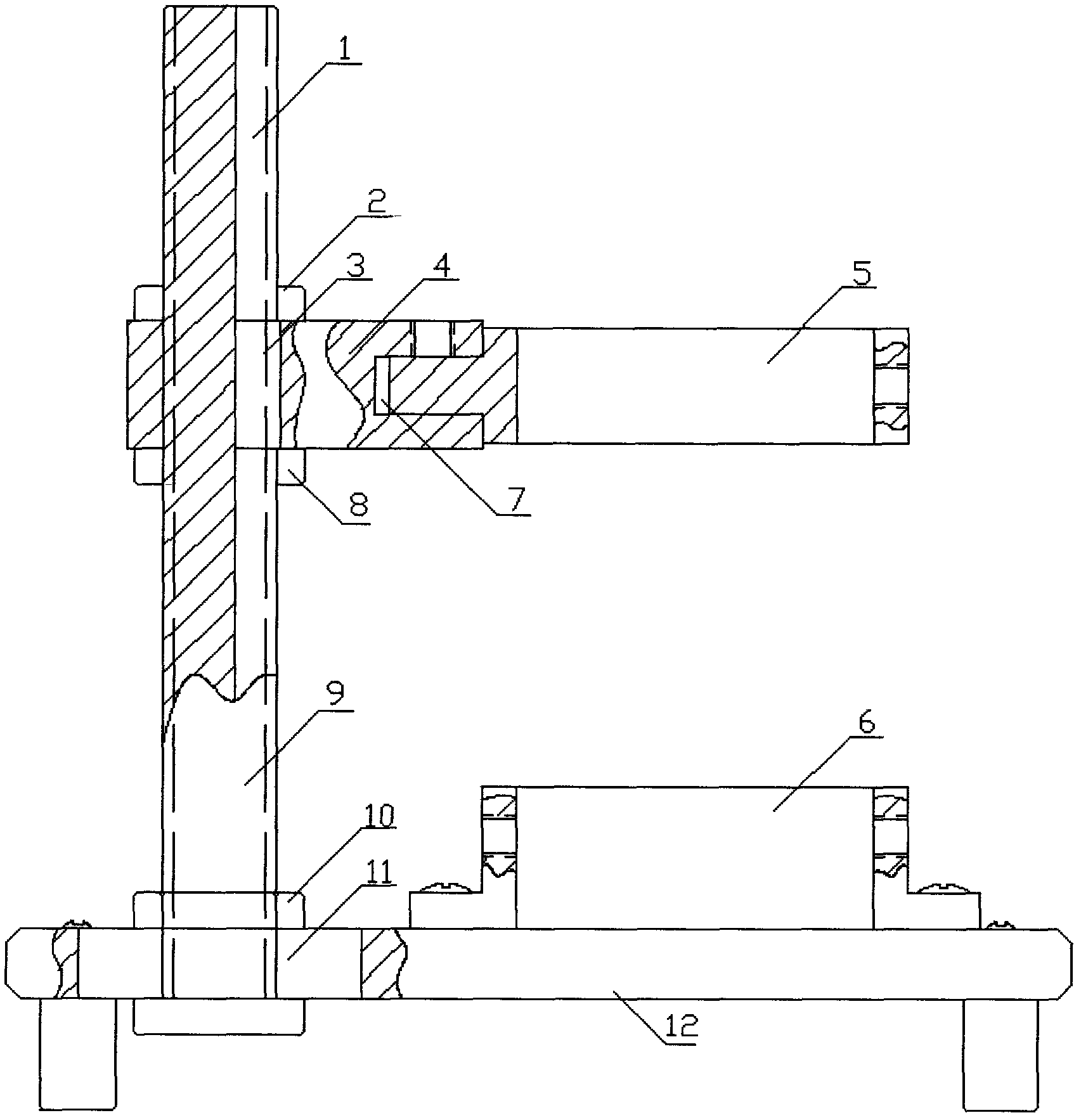

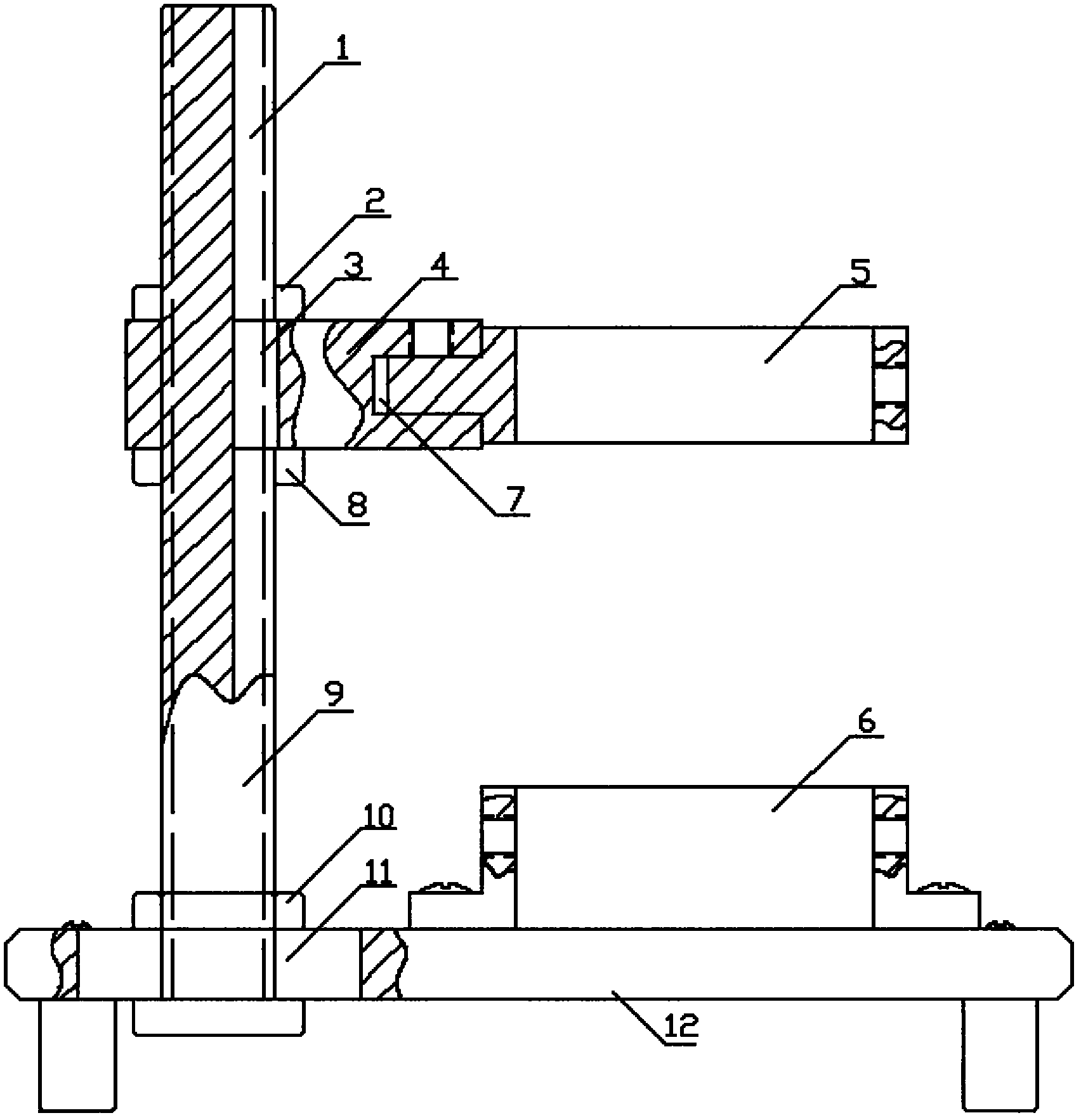

[0015] See accompanying drawing, a kind of indoor single crack rock sample preparation device is made of base 12, movable upper seat 4, lower rock core fixing collar 6, upper rock core fixing collar 5, threaded main shaft 9, adjusting nut 8, fastening screw Cap 2 constitutes. One end of the base 12 is provided with a through groove 11 that runs through the upper and lower surfaces. The lower end of the threaded main shaft 9 is connected with a fixed cap, and the upper end of the threaded main shaft 9 passes through the through groove 11. The position of the main shaft 9 and the through groove 11 regulates the left and right movement of the upper rock core fixing collar 5. The threaded spindle 9 is provided with a through keyway 1 along the axial direction, and a round hole is opened at one end of the movable upper seat 4, and a keyway is opened in the round hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com