Patents

Literature

30results about How to "Meet the requirements of parallelism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

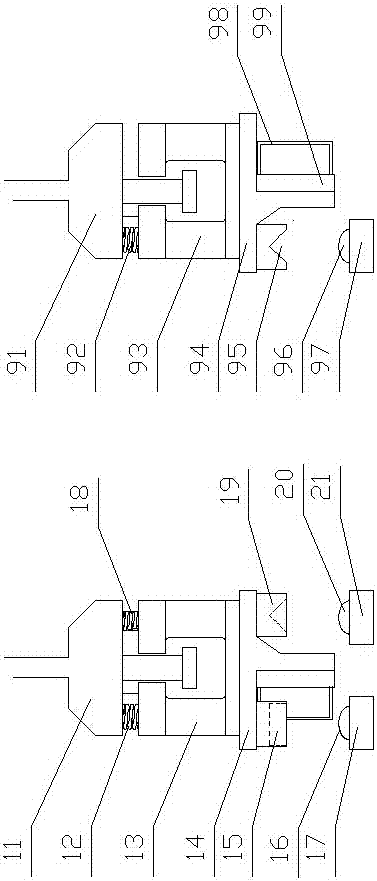

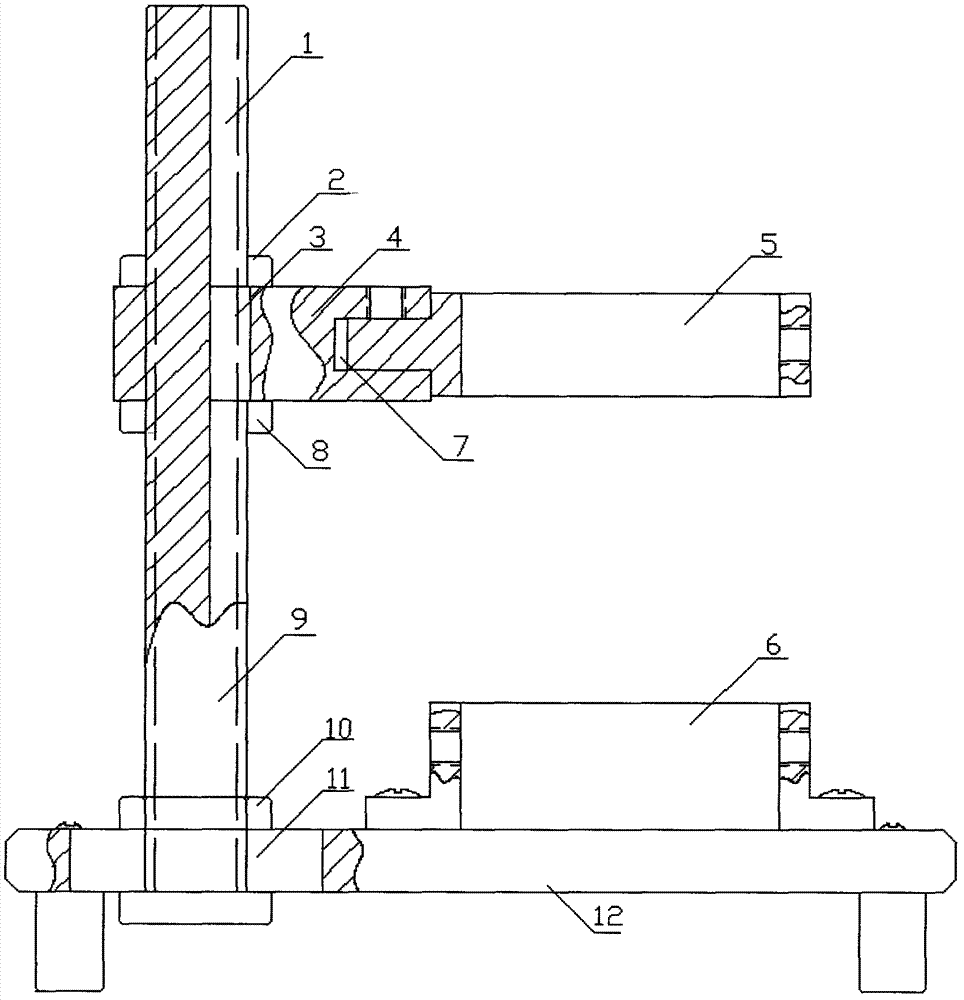

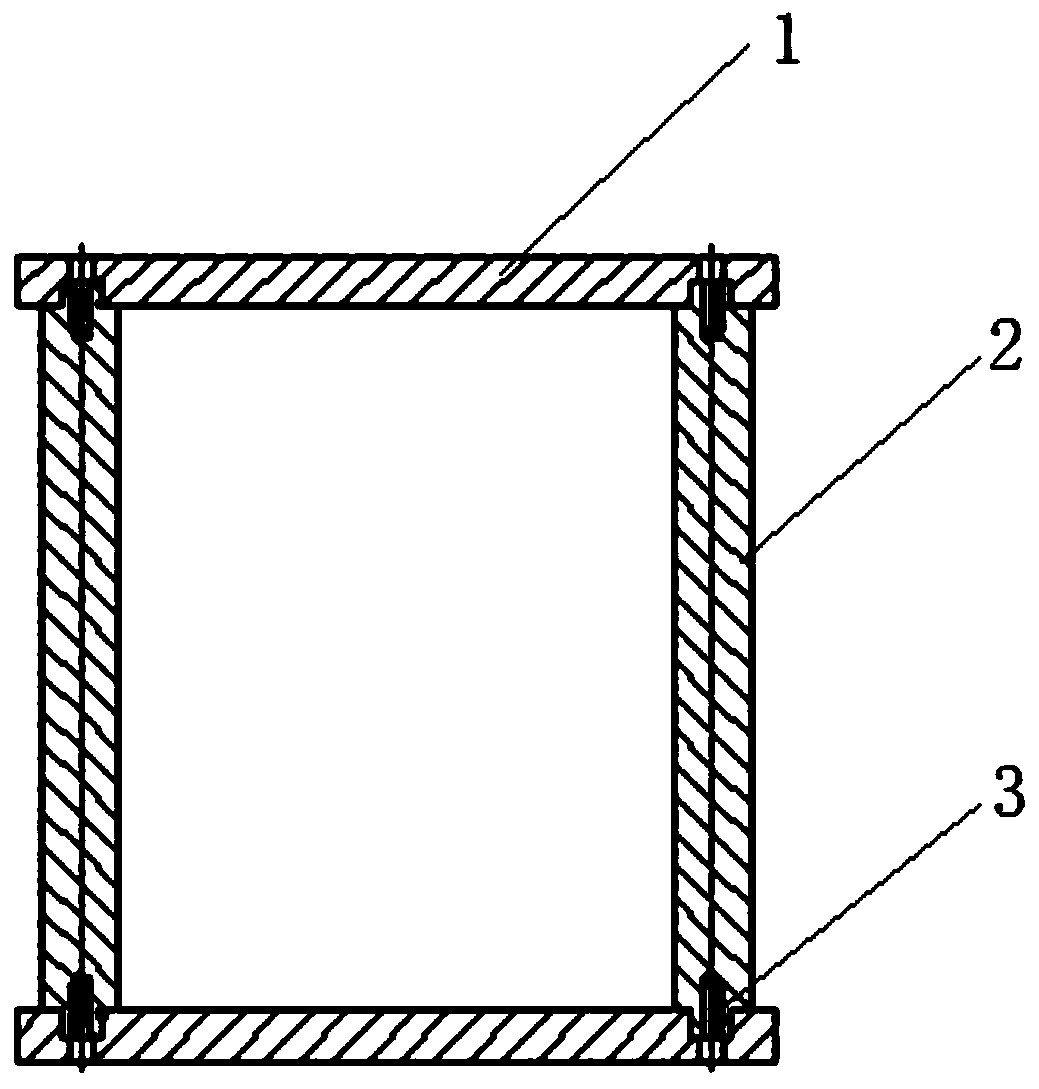

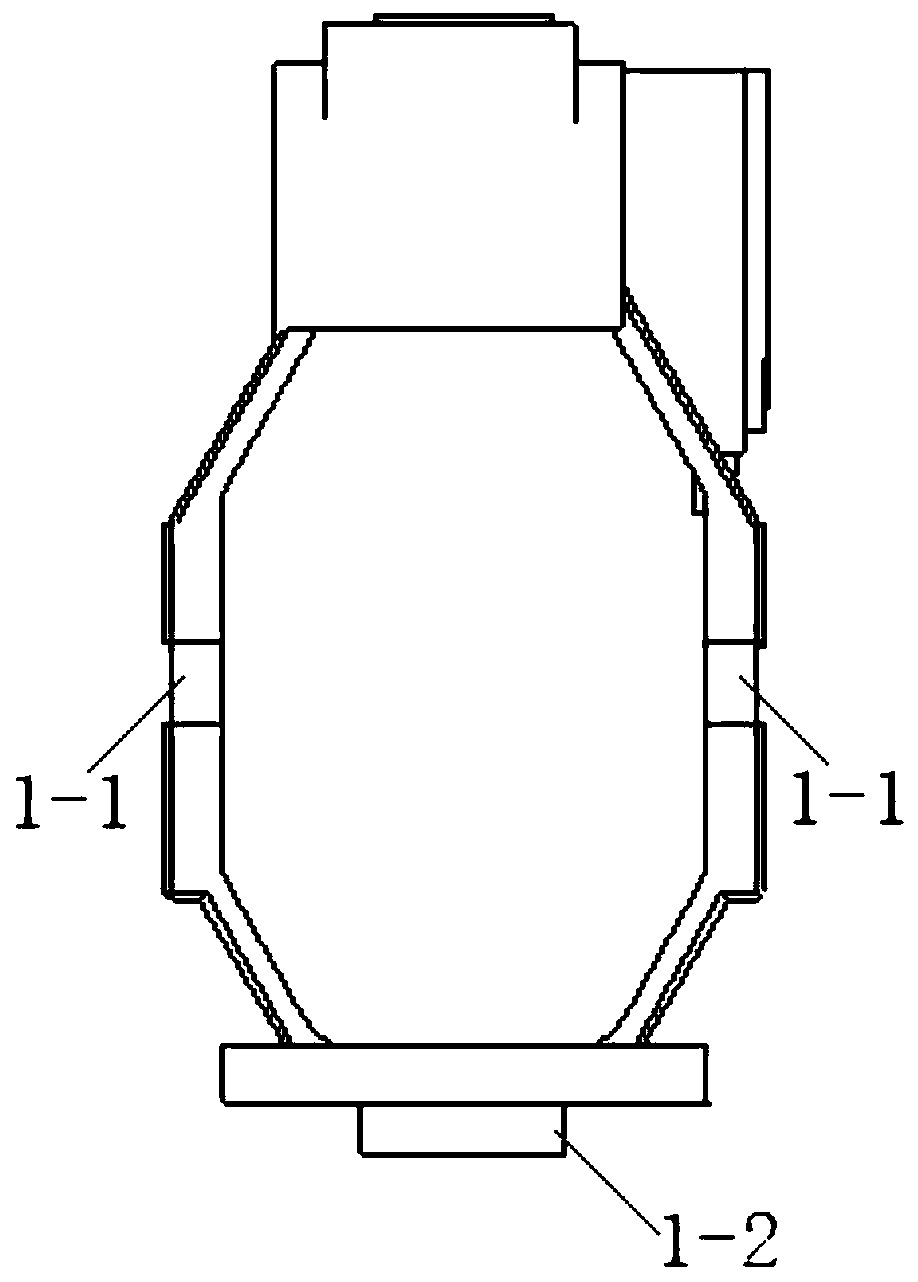

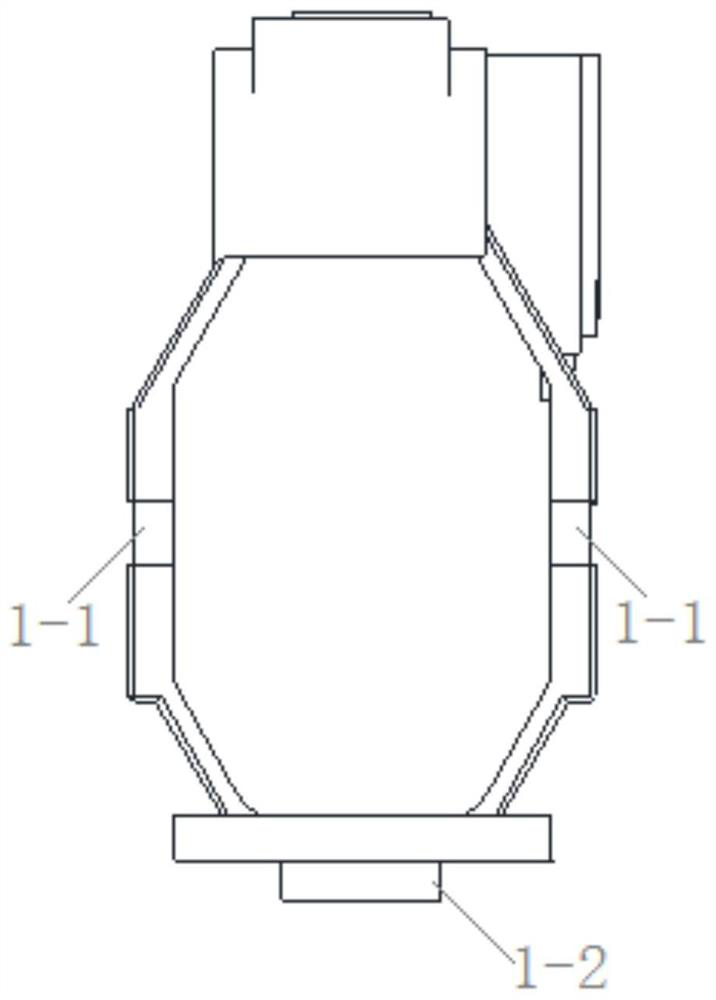

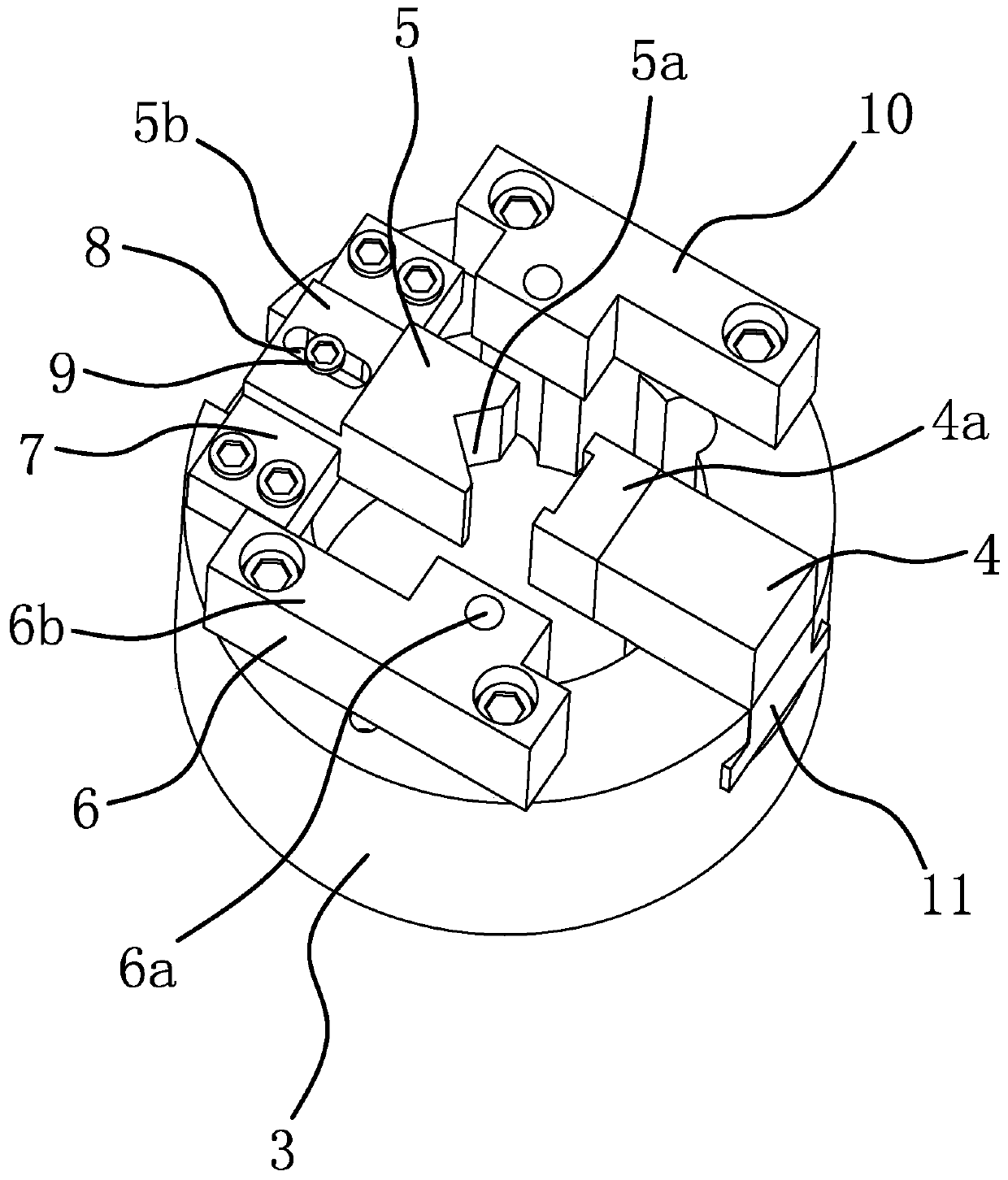

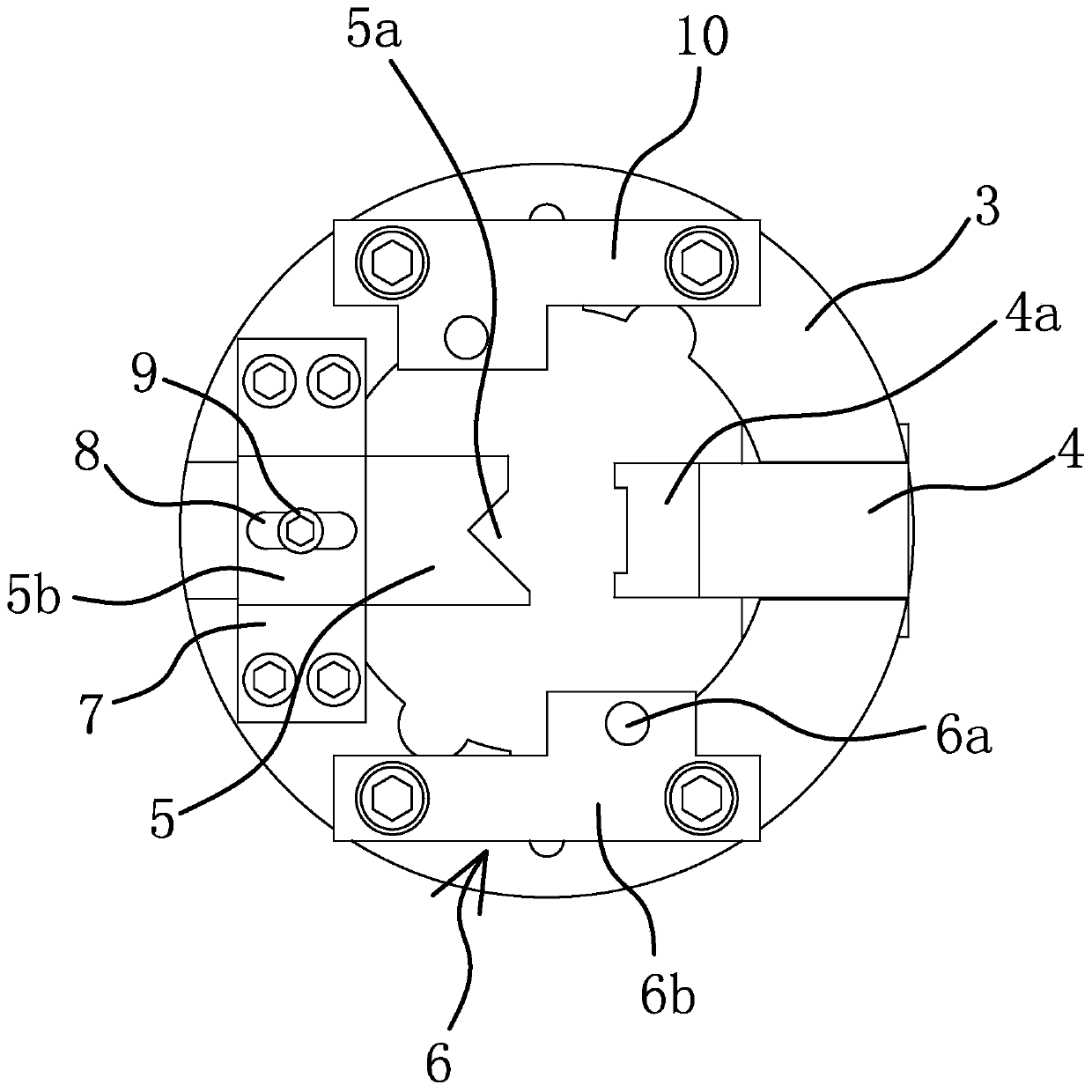

Preparation device of indoor single-cracked rock specimen

InactiveCN102435475AReasonable structureEasy to manufacturePreparing sample for investigationPetrologyButt joint

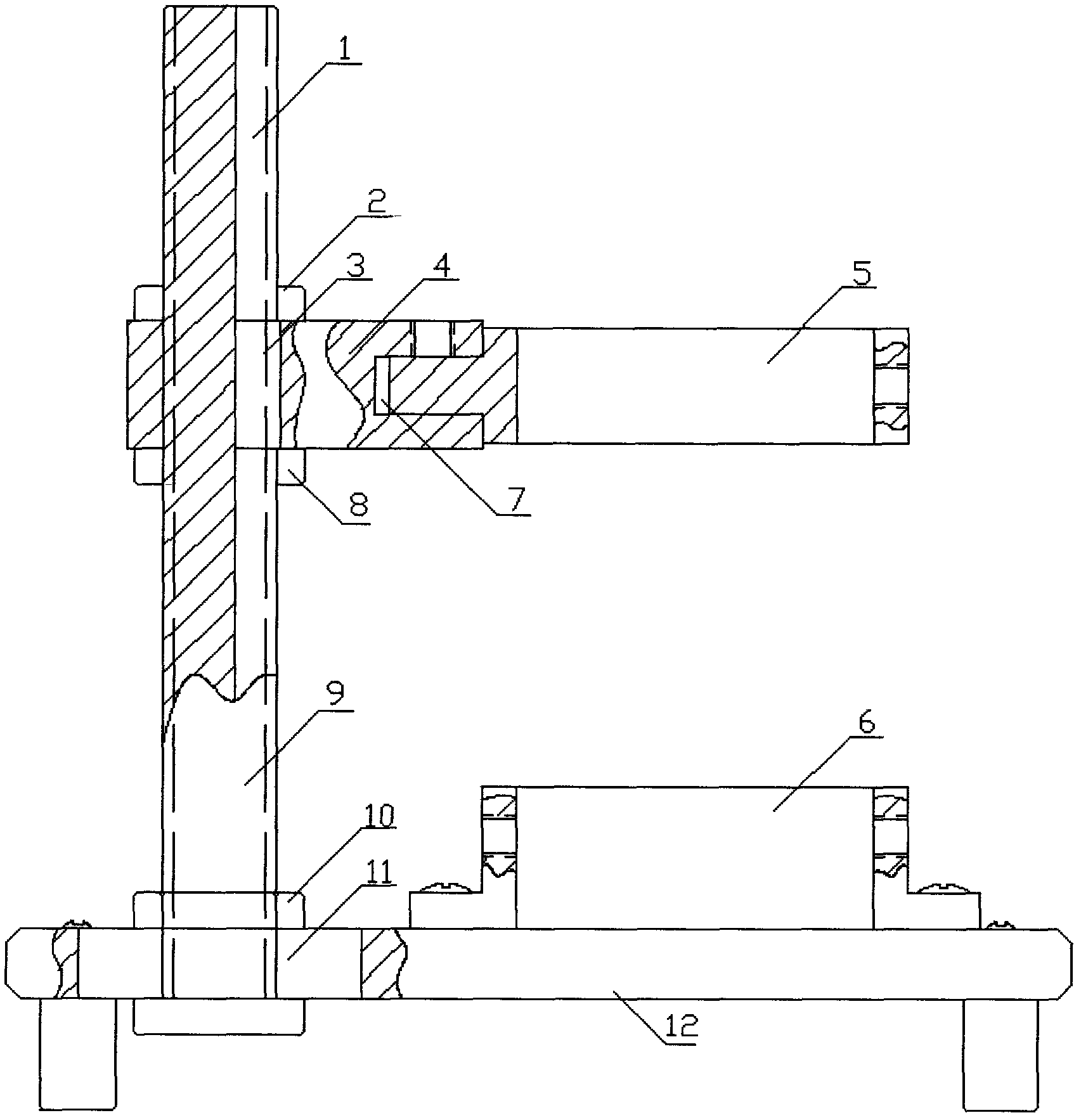

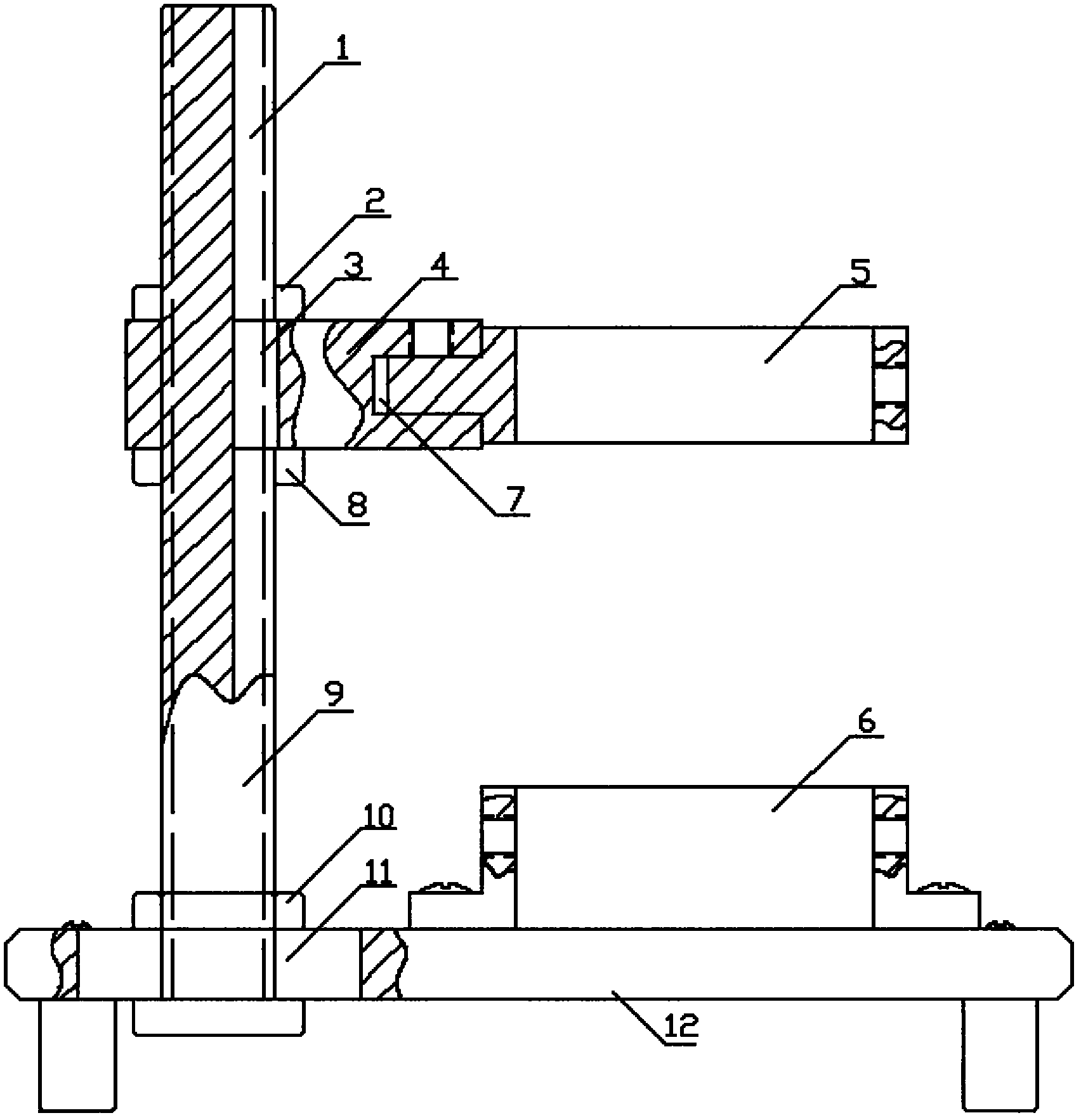

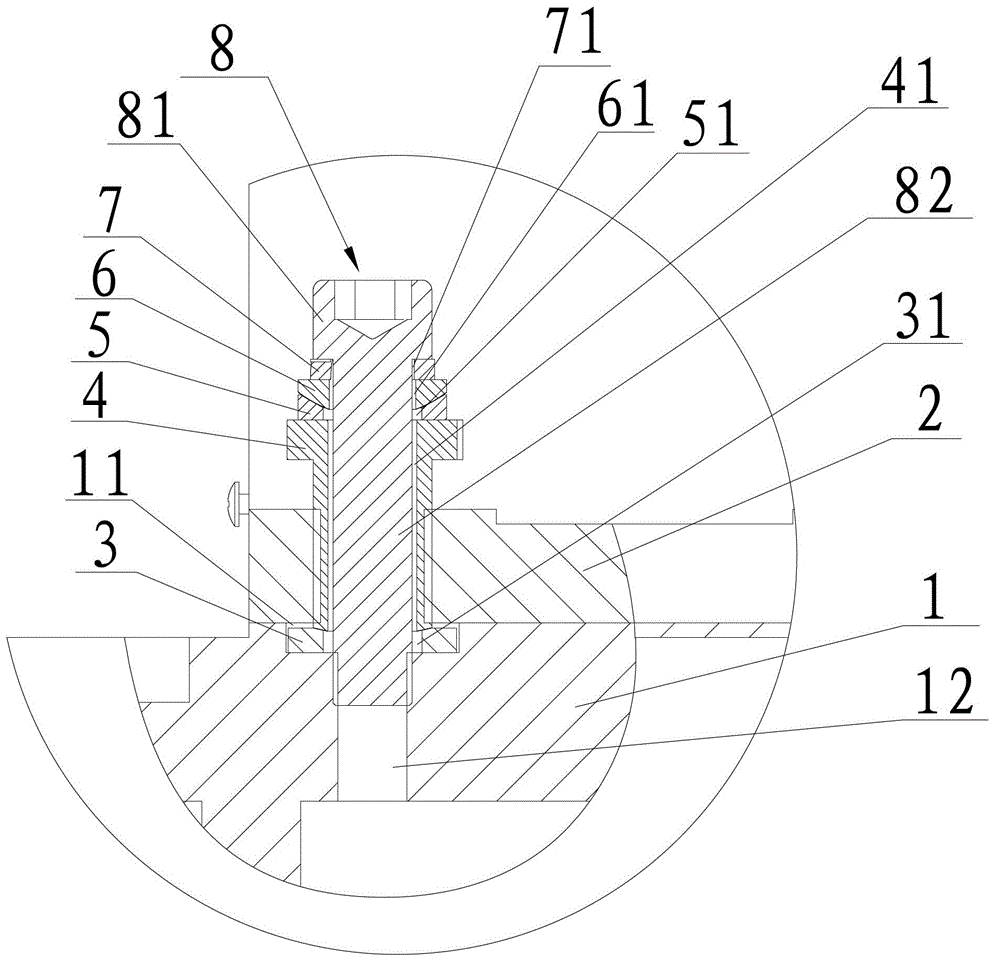

The invention relates to a preparation device of a rock cracked specimen, in particular to a preparation device of a single-cracked rock specimen filled with a binding material with a certain thickness. The preparation device comprises a base, an upper movable seat, a lower rock core fixing lantern ring, an upper rock core fixing lantern ring, a threaded spindle, an adjusting screw cap and a fastening screw cap; the concentricity of an upper rock core and a lower rock core arranged in the upper rock core fixing lantern ring and the lower rock core fixing lantern ring can be ensured through adjusting the position of the spindle relative to a through groove of the base and the position of the upper rock core fixing lantern ring relative to a horizontal through groove; the distance between the upper rock core and the lower rock core is controlled through the adjusting screw cap and the fastening screw cap; and meanwhile, the thickness of a binding layer between the upper rock core and the lower rock core is ensured so that the upper rock core and the lower rock core are coupled and butt-jointed to form a standard single-cracked rock specimen. The preparation device of the single-cracked rock specimen in the invention is easy to manufacture, simple in operation, strong in practicability and capable of being widely used for preparing single-cracked rock specimens.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

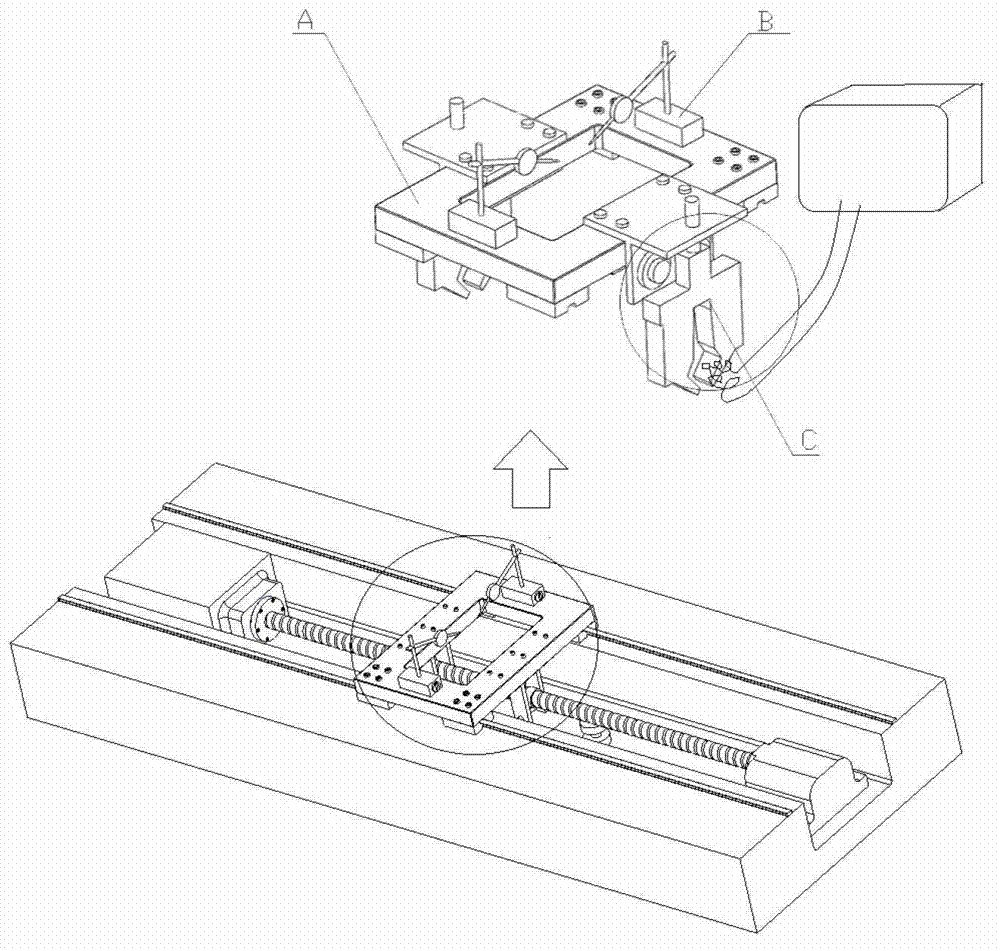

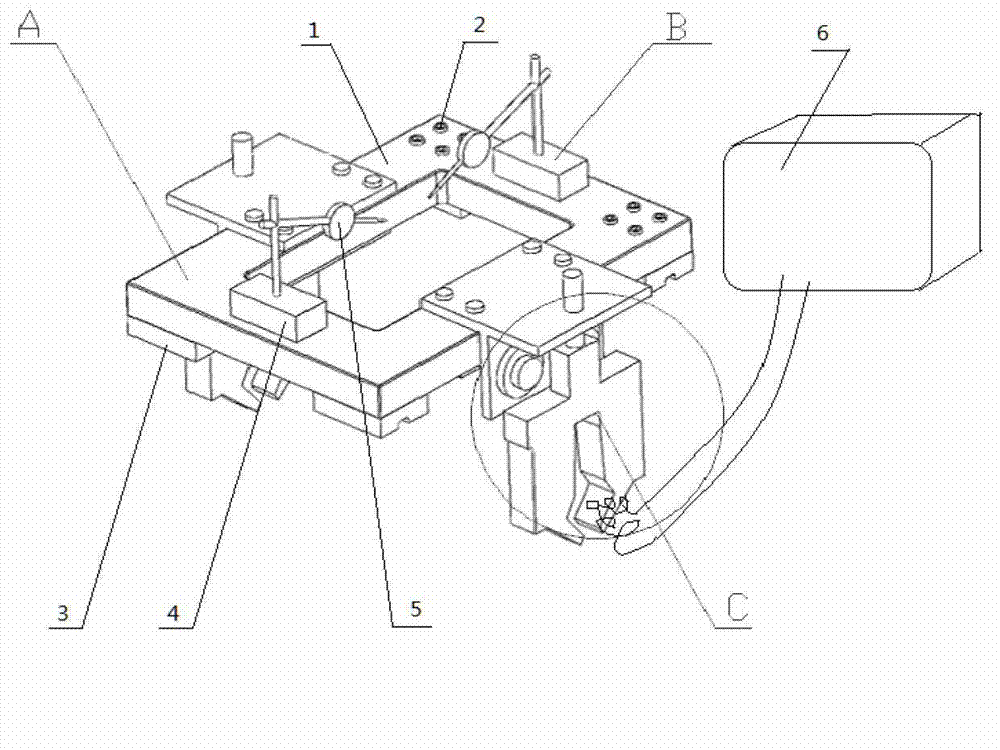

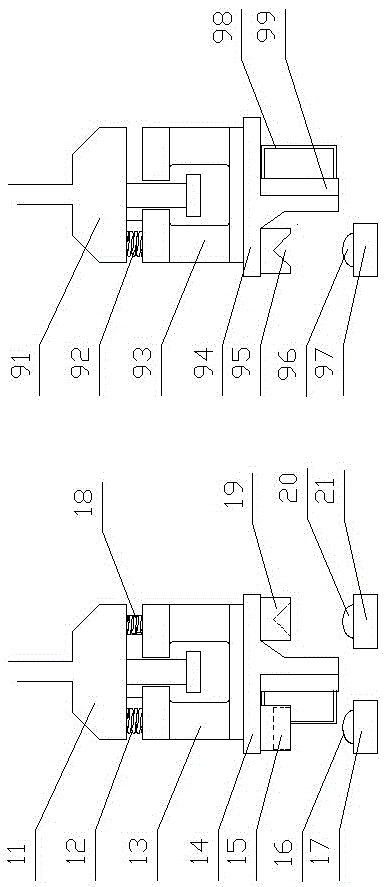

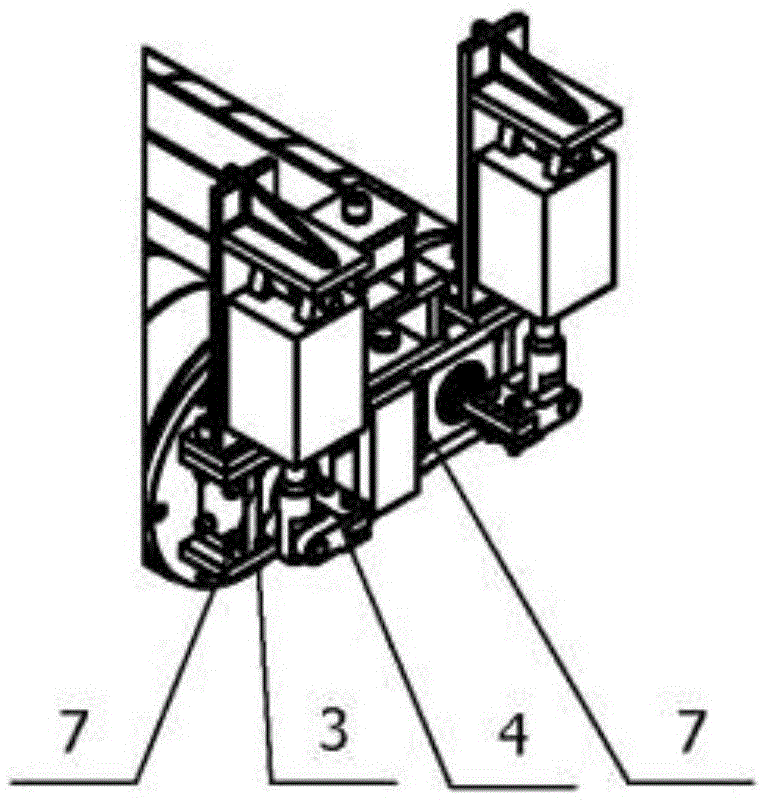

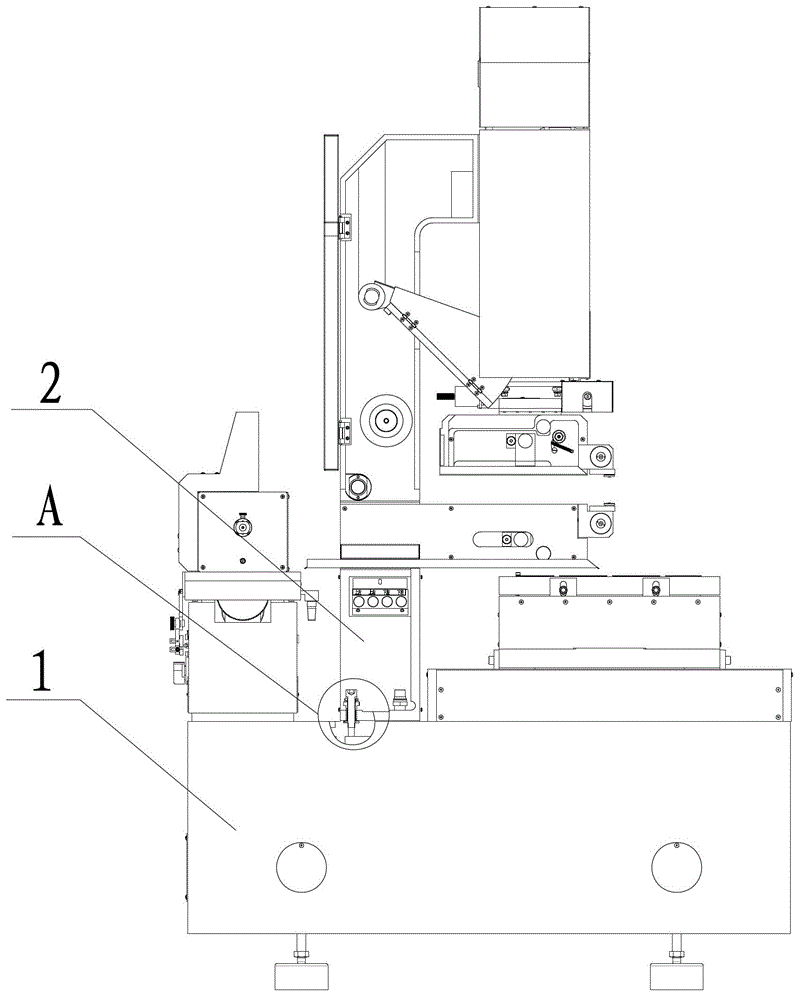

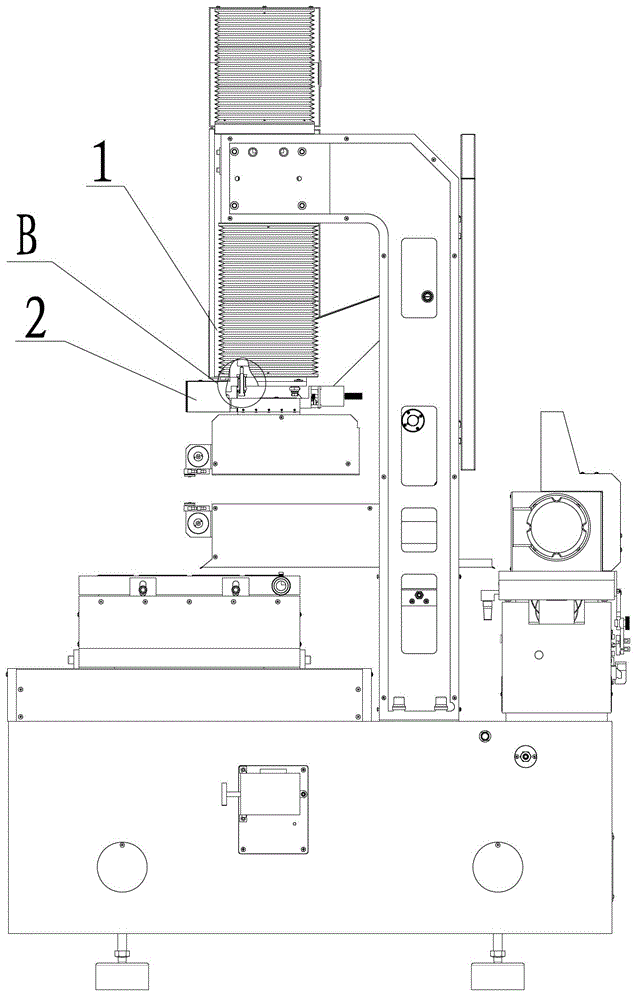

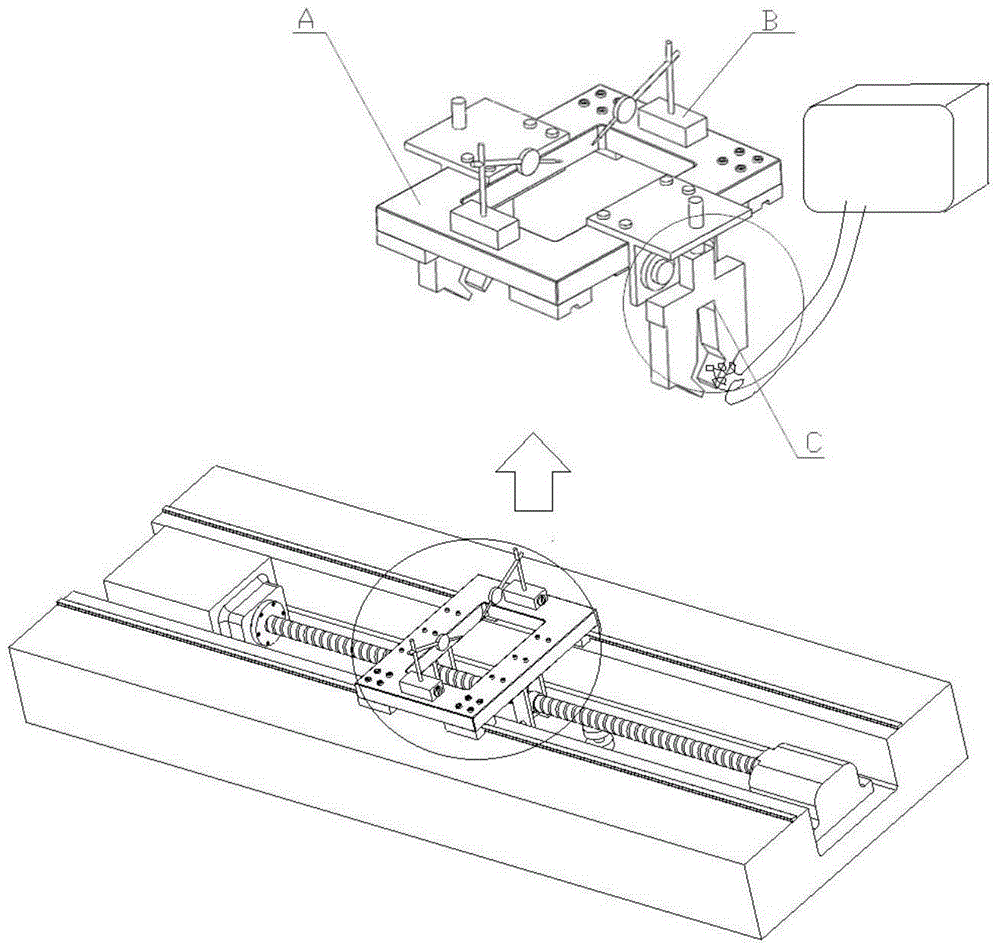

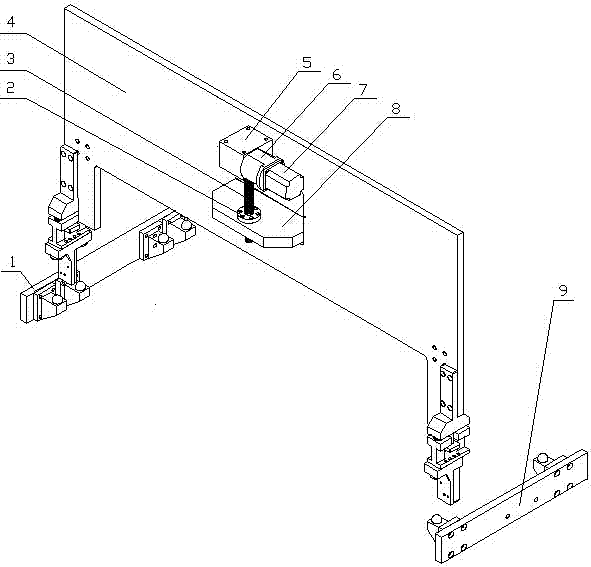

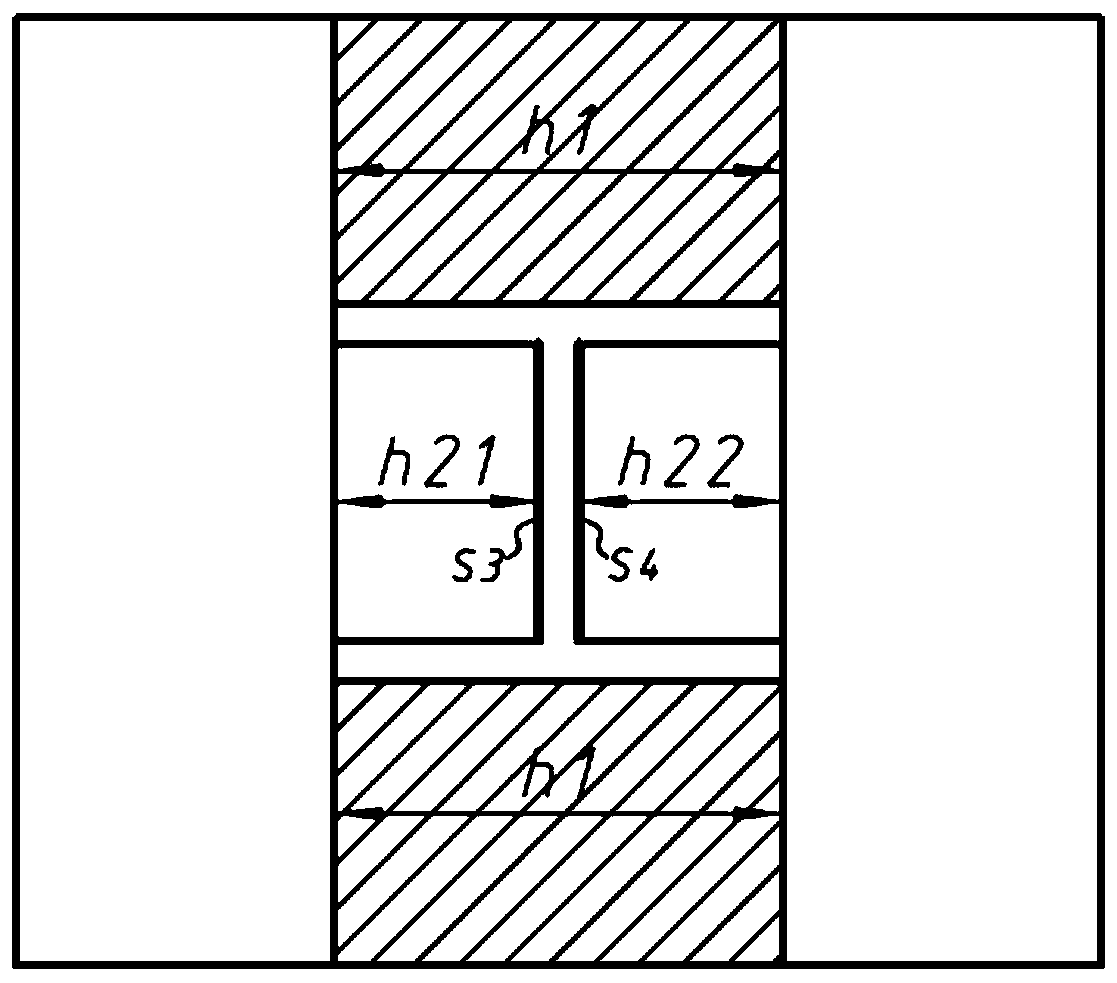

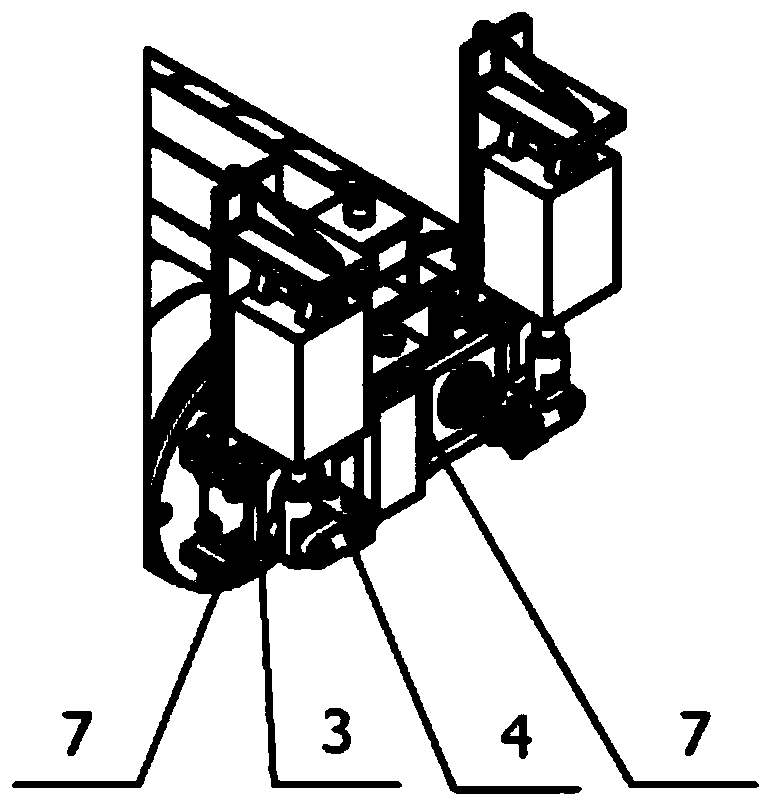

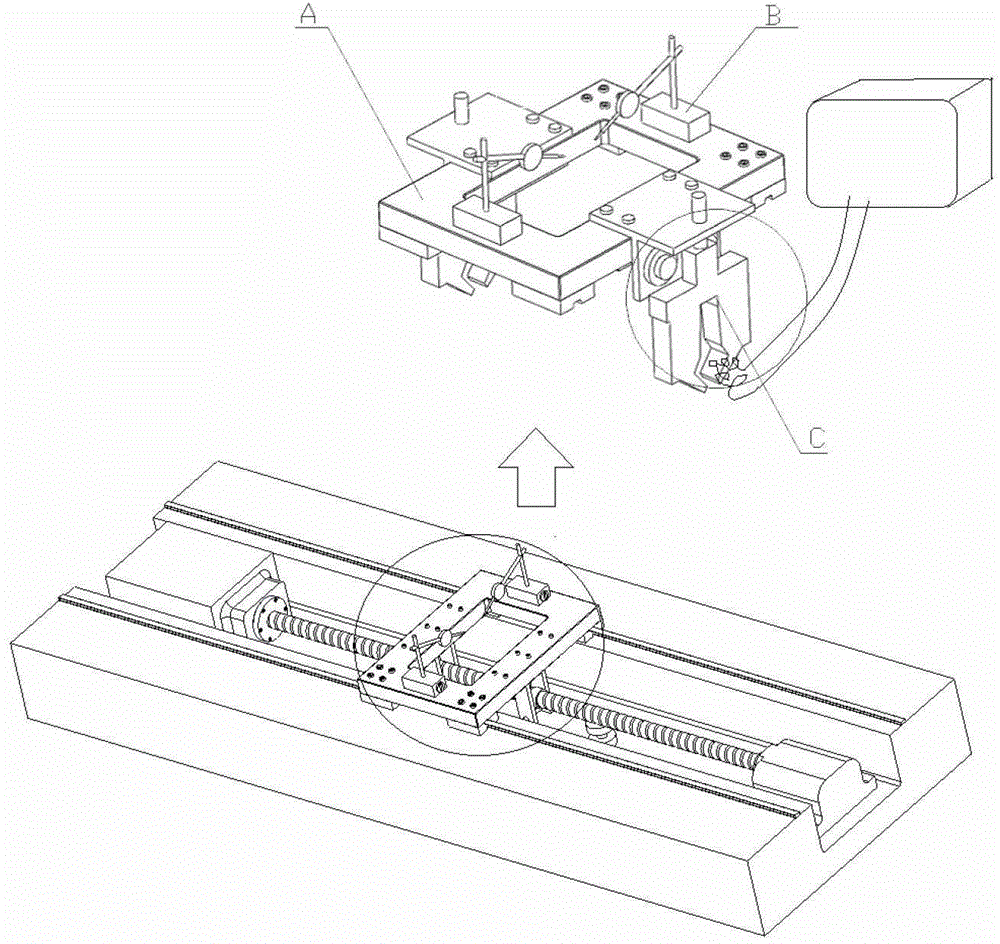

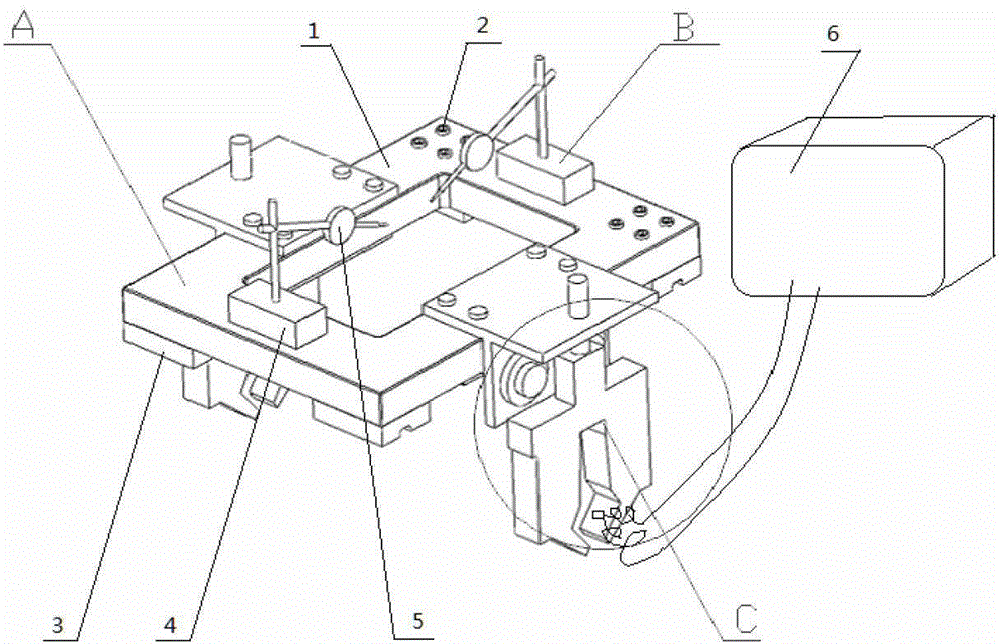

Method and special rack capable of adjusting position of suspended beam screw rod to guide rail

InactiveCN103084818ARealize automated detectionLowering techniqueMetal working apparatusMechanical measuring arrangementsData acquisitionPressure sensor

The invention provides a method capable of adjusting the position of a suspended beam screw rod to a guide rail. The method includes the steps of aligning a special rack on the guide rail screw rod with the known accuracy, reading data on a data acquisition unit and zero clearing, arranging the adjustment rack on the parallel guide rail to be detected, clamping screw rod nut through a clamping device, contacting the screw rod nut with a pressure sensor, and displaying a pressure value of a contact point of a clamping device mechanical arm and the screw rod in real time by being connected with the data acquisition unit. The special rack is capable of slowly moving on the guide rail through rotation of the screw rod to achieve automatic detection. A dial indicator which is arranged on the special rack is capable of being used for detecting, when the screw rod is arranged or positional accuracy of the screw rod is periodically detected. The method capable of adjusting the position of the suspended beam screw rod to the guide rail has the advantages of being simple in structure, reasonable in design, high in installation accuracy, capable of automatically detecting, integral in installation and detection, easy to operate and convenient to handle. The invention further provides the special rack capable of adjusting the position of the suspended beam screw rod to the guide rail.

Owner:SUZHOU LEAD LASER TECH +2

Double-camera system, double-camera adjusting method and terminal

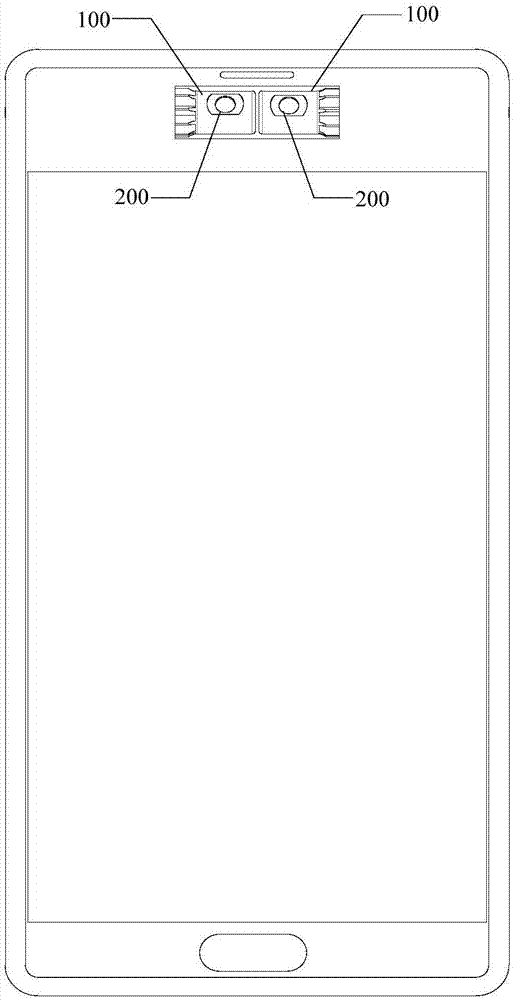

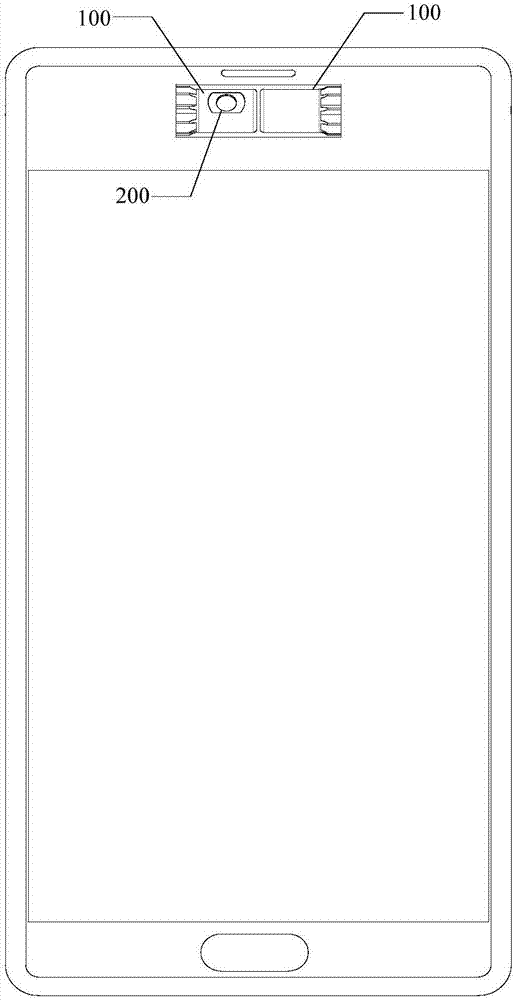

InactiveCN107087096AImprove clarityLow costTelevision system detailsColor television detailsLaser rangingOptical axis

The embodiment of the invention discloses a double-camera system, a double-camera adjusting method and a terminal. The double-camera system is applied to the terminal, and a shell of the terminal is provided with a cavity area. The double-camera system comprises two turnover components, two cameras, a laser ranging part, a processor and a motor, wherein the processor generates a driving instruction, the motor receiving the driving instruction drives the turnover components to rotate, and the two cameras rotate along with the turnover components, so that by rotating the turnover components, the two front-mounted cameras or the two rear-mounted cameras or one front-mounted camera and one rear-mounted camera are obtained; the laser ranging part transmits the distance value between a laser transmitting point and a laser receiving point to the processor, the processor judges whether or not the two cameras meet the requirement of the parallelism degree of the optical axis according to the distance value, if not, the processor generates the driving instruction, and the motor receiving the driving instruction drives the turnover components, so that the two cameras meet the requirement of the parallelism degree of the optical axis, and the definition of shot images is improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Digital textile printer nozzle trolley structure and digital textile printer with nozzle trolley

InactiveCN106113950AAchieve parallelismMeet the requirements of parallelismTypewritersPower drive mechanismsBackplaneEngineering

The invention discloses a nozzle trolley structure of a digital printing machine, which includes a back plate, a casing and a nozzle. The casing includes two side plates and a bottom plate. The nozzle is fixed on the bottom plate. The adjusting plate, the adjusting plate includes a first connecting plate and a second connecting plate arranged at right angles, the first connecting plate and the side plate are hingedly connected and the casing can rotate around the hinge point, and the casing is provided with a The casing is fixed on the limit piece on the adjusting plate, and a moving structure is arranged between the second connecting plate and the back plate to drive the adjusting plate to move in the vertical direction, and at the same time discloses a digital printing machine with the nozzle trolley structure The purpose of the present invention is to provide a digital printing machine nozzle carriage structure and a high-precision digital printer that can improve installation efficiency while ensuring installation efficiency.

Owner:杭州彩悦图邦科技有限公司

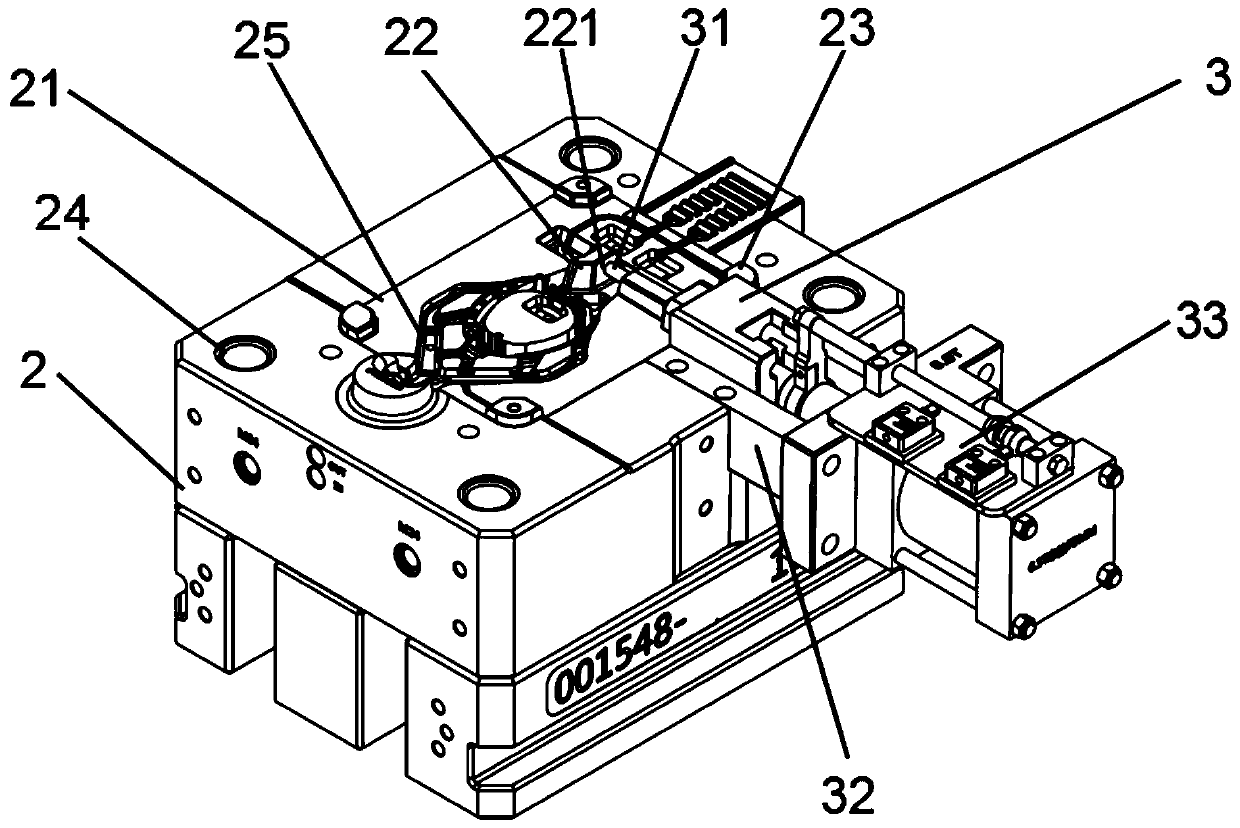

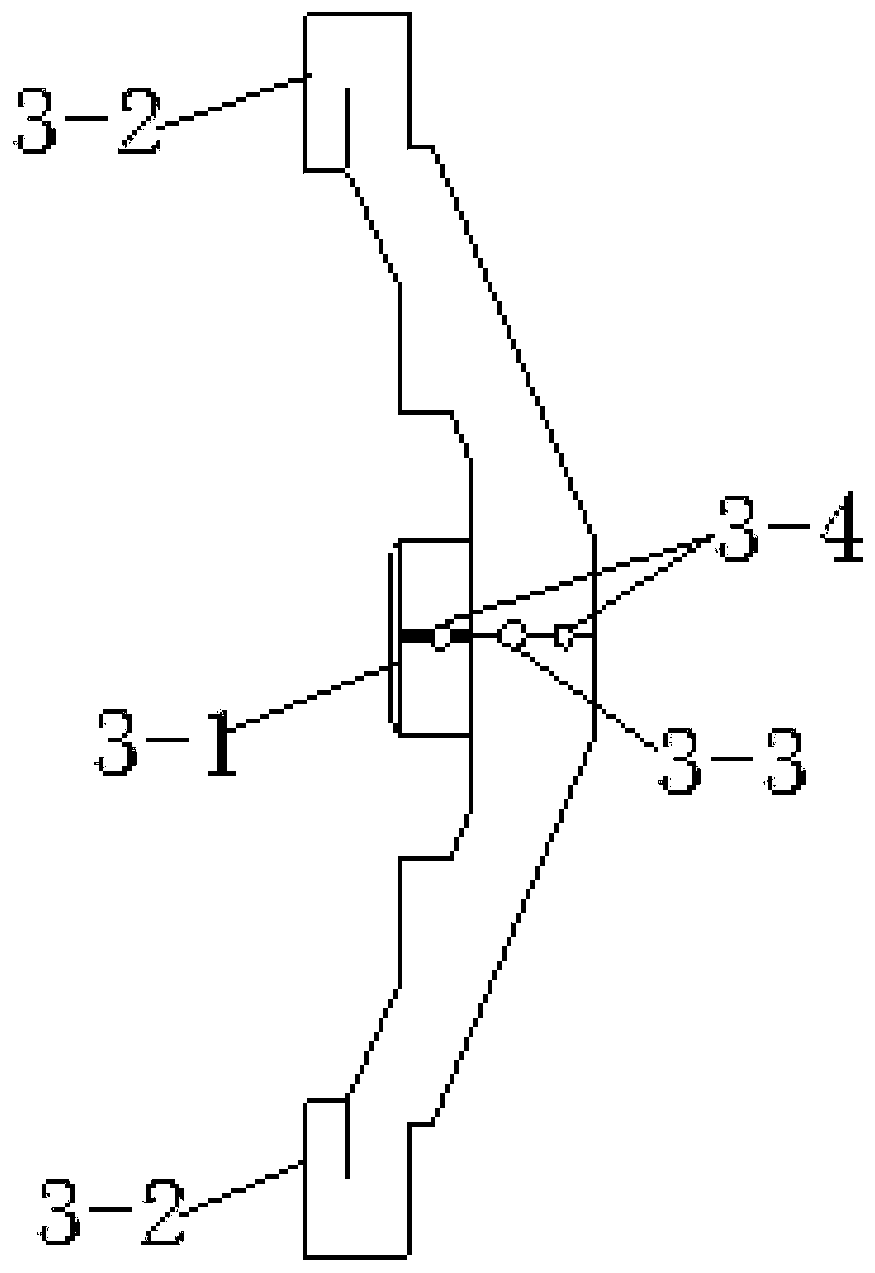

Spray head frame positioning device of continuous ink-jet printing production line, and control method thereof

ActiveCN105584226AHigh positioning accuracyMeet the requirements of parallelismTypewritersPower drive mechanismsProduction lineCoupling

The invention relates to a spray head frame positioning device of a continuous ink-jet printing production line, and a control method thereof. The device comprises a left crossbeam lifting plate, a fixed plate, a right crossbeam lifting plate and a transmission mechanism. The device is characterized in that the left crossbeam lifting plate is provided with a fixed block A and a fixed block B, and the fixed block A and the fixed block B are respectively provided with a steel ball A and a steel ball B; the right crossbeam lifting plate is provided with a fixed block C, and the fixed block C is provided with a steel ball C; and the transmission mechanism comprises a nut, a leading screw, a worm and gear, a shaft coupling and a servo motor. The invention provides technical means of integral position adjustment of a large-span spray head frame; the parallelism requirement between a spray head and a fabric surface is effectively met, and the printing precision is ensured; in addition, manual adjustment is avoided, and the production efficiency is improved.

Owner:HANGZHOU HONGHUA DIGITAL TECH +1

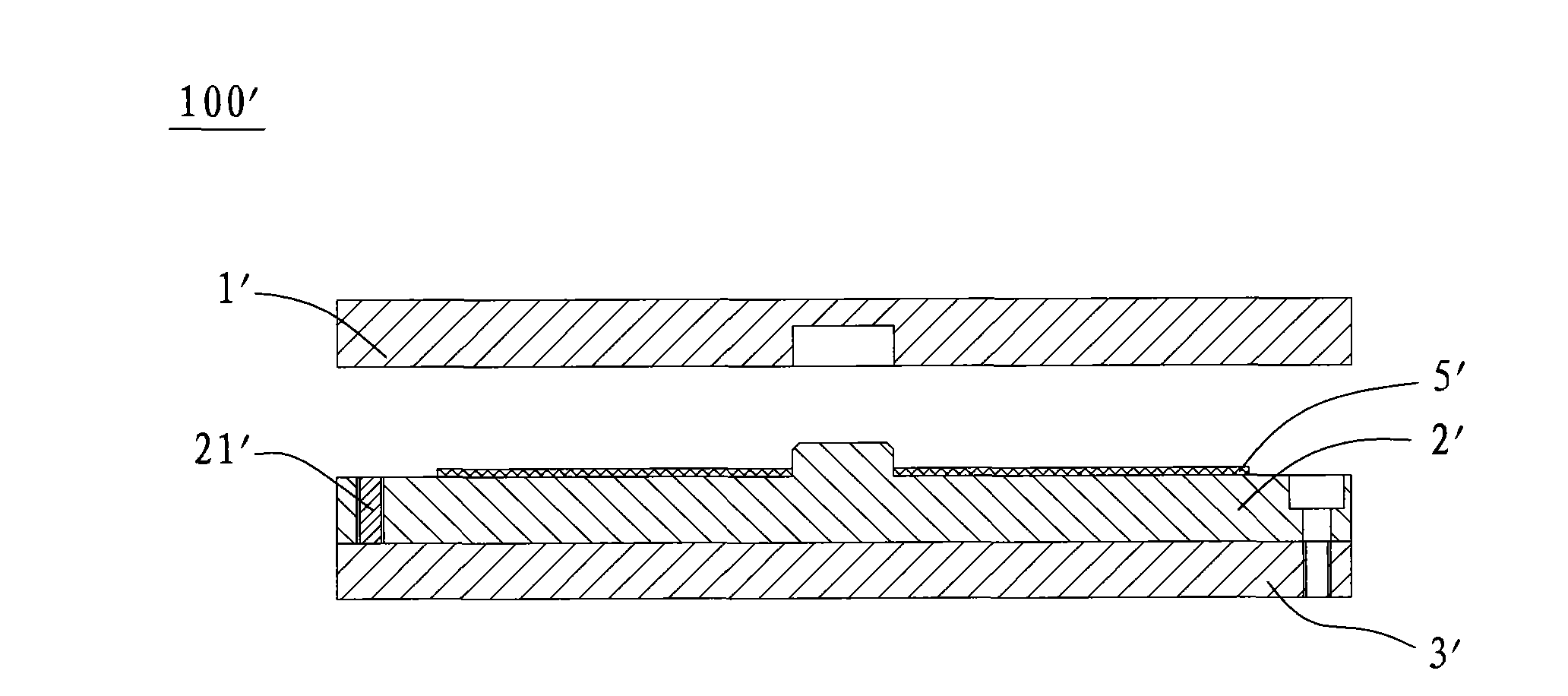

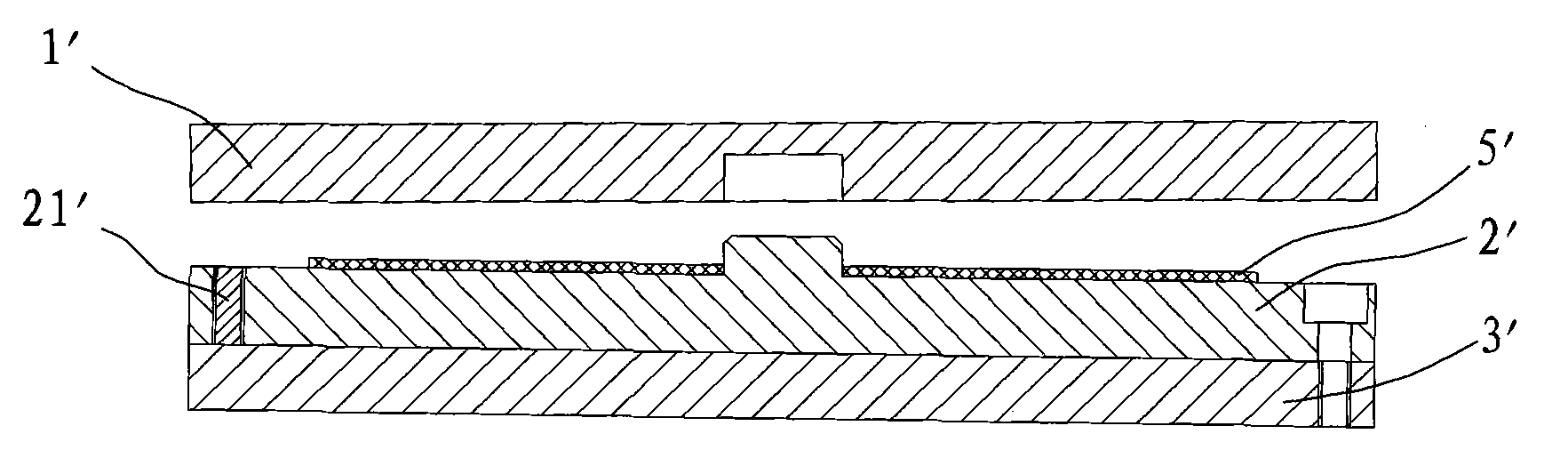

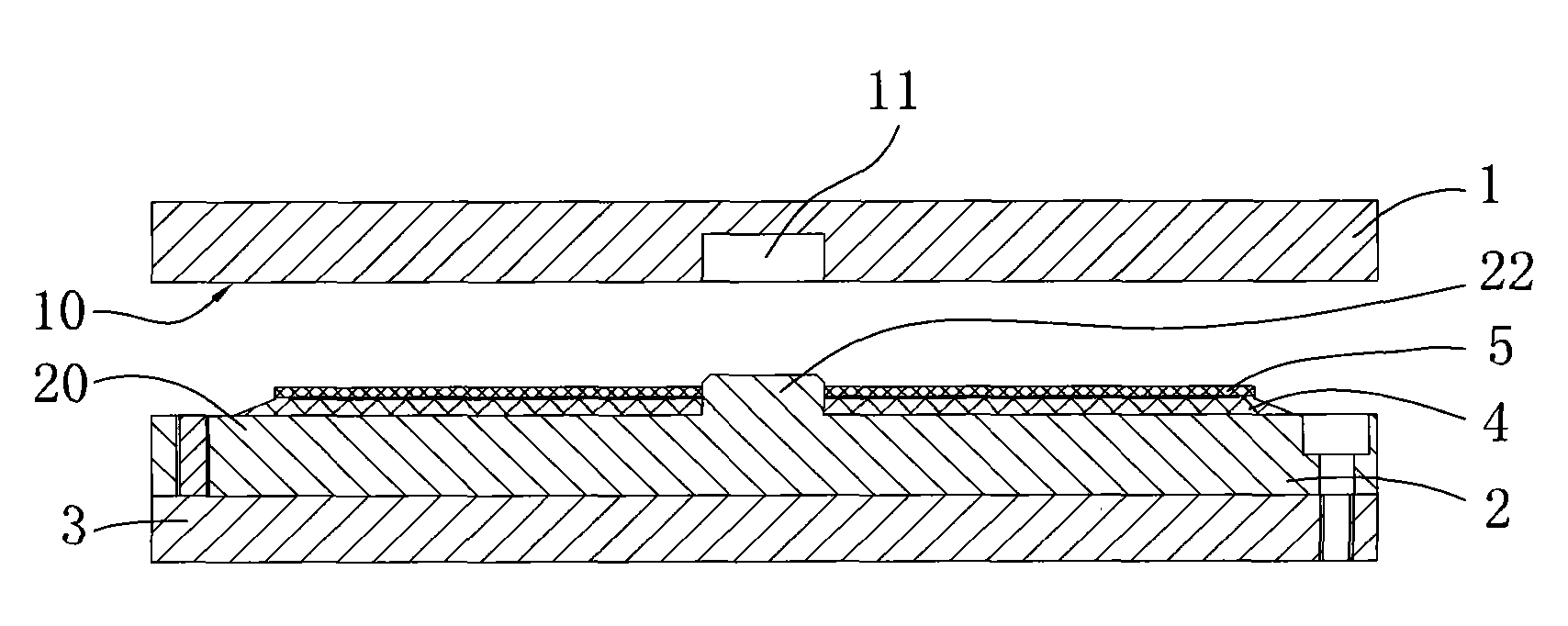

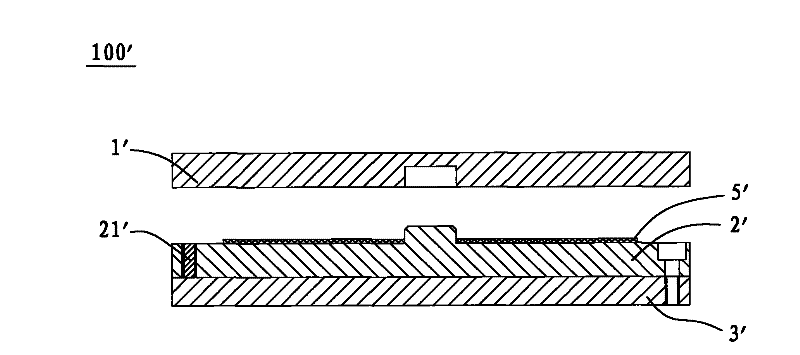

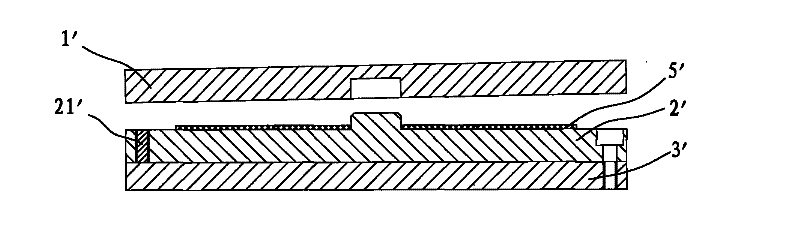

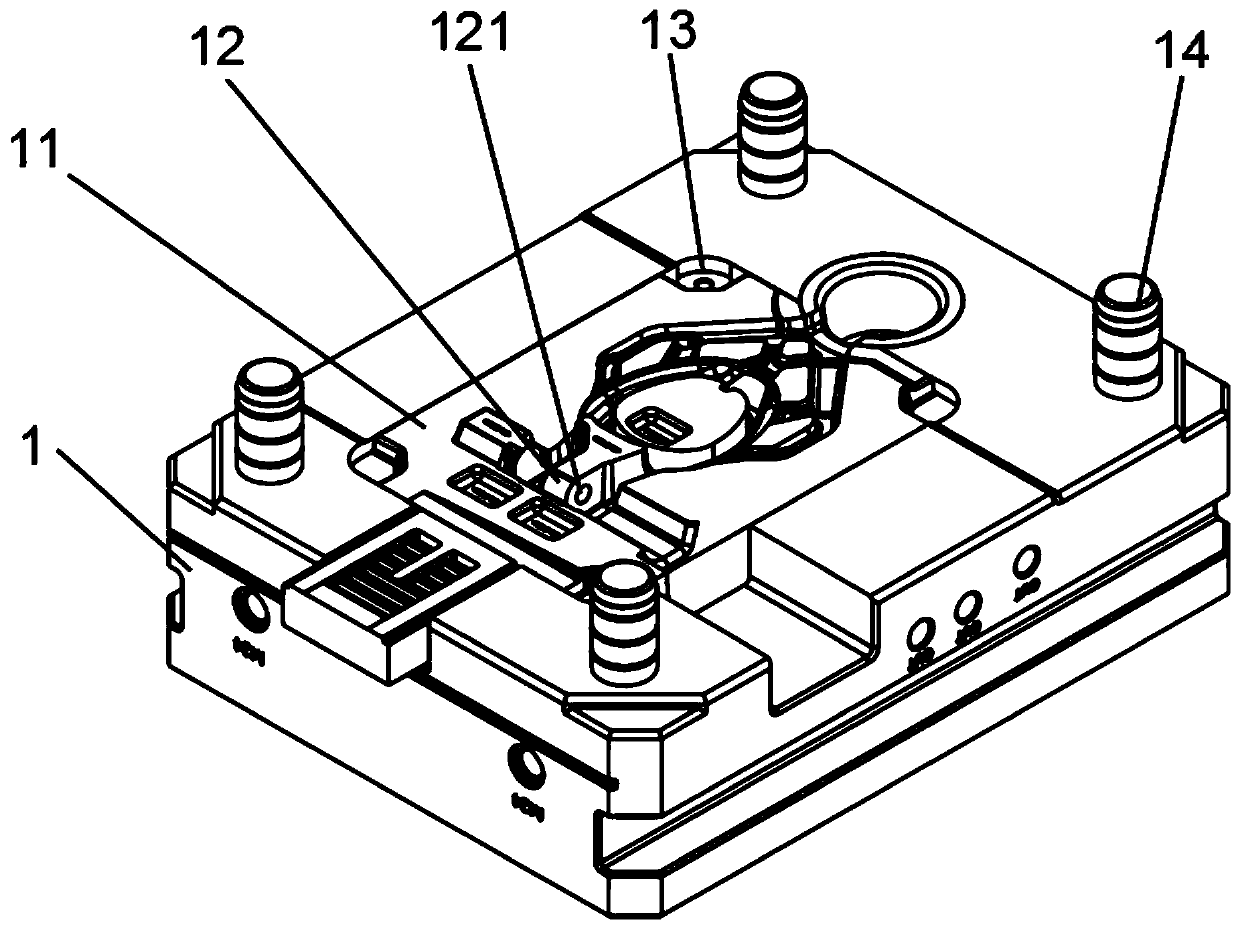

Blue-ray disc die assembly

InactiveCN101777361AMeet the requirements of parallelismMake up for shrinkage deformationRecord information storageRecording/reproducing/erasing using optical interference patternsEngineeringBlue light

The invention discloses a blue-ray disc die assembly, which comprises a mounting base, a lower mold plate and an upper mold plate. The mounting base is provided with a level mounting surface; the lower mold plate is arranged on the mounting surface; the lower mold plate is provided with a level lower laminating surface; the upper mold plate is provided with a level upper laminating surface opposite to the lower laminating surface; the center of the lower laminating surface protrudes a positioning column; and the upper laminating surface facing the positioning column dents inwards to form a positioning hole. The blue-ray disc die assembly also comprises an elastic circular gasket, wherein the center of the gasket is provided with a mounting hole; the positioning column passes through the mounting hole of the gasket to make the gasket borne on the lower laminating surface; and an outer ring of the gasket is provided with a protruding ring protruding the faced upper laminating surface. The blue-ray disc die assembly can automatically adjust an upper mold and a lower mold to reach micron-sized parallelism in the process of pressing dies.

Owner:HENAN KAIRUI DIGITAL

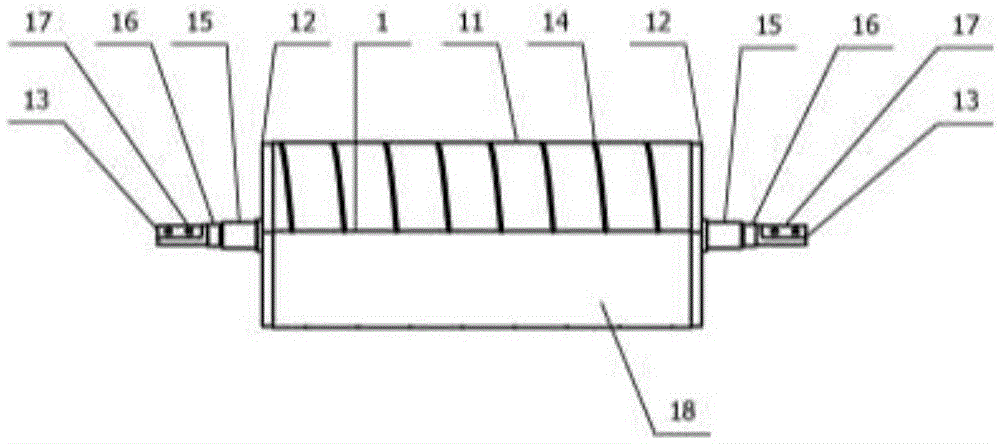

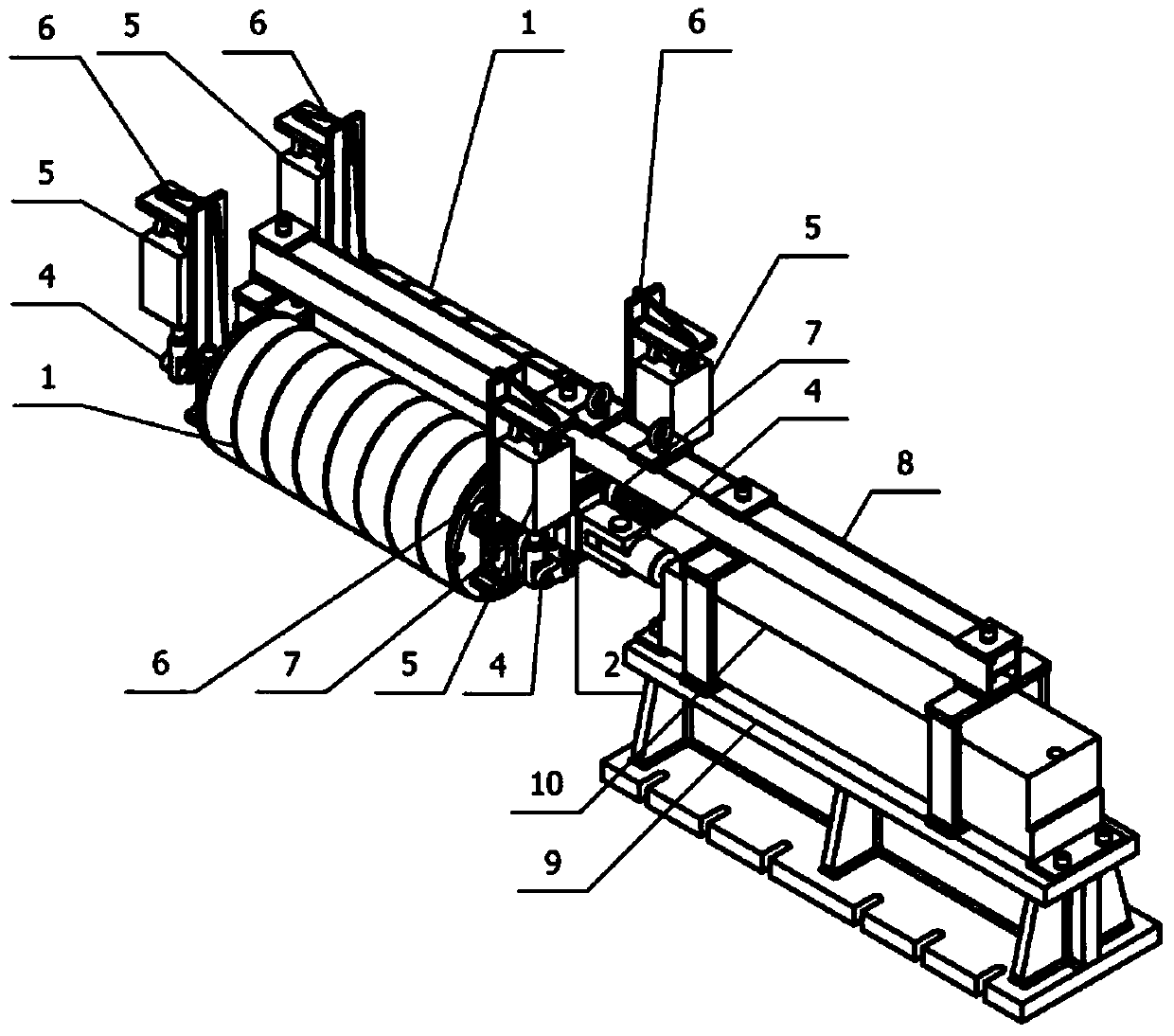

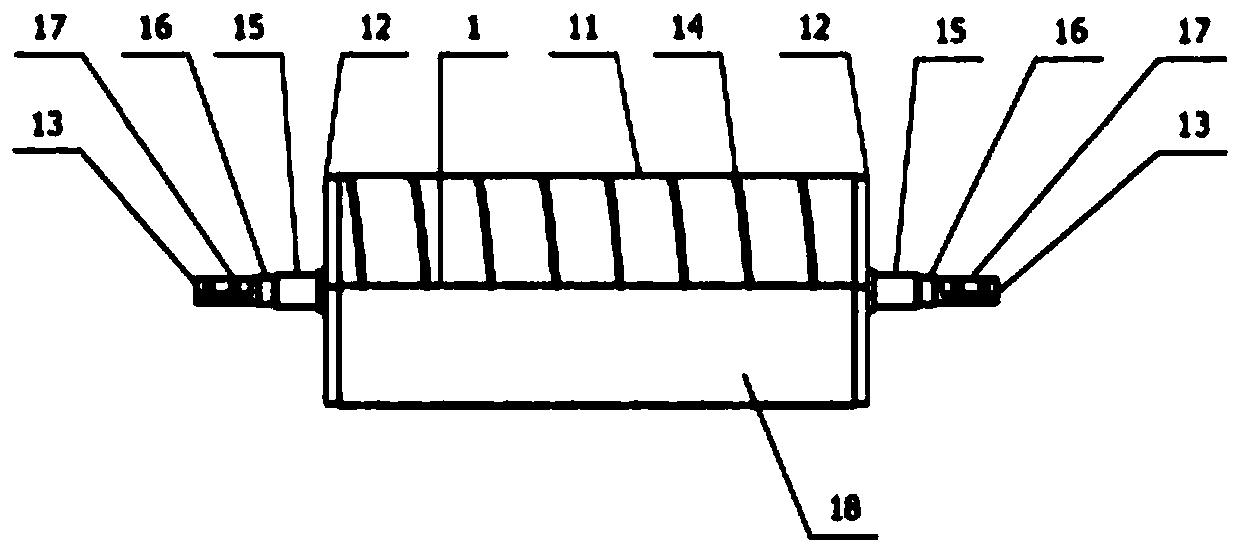

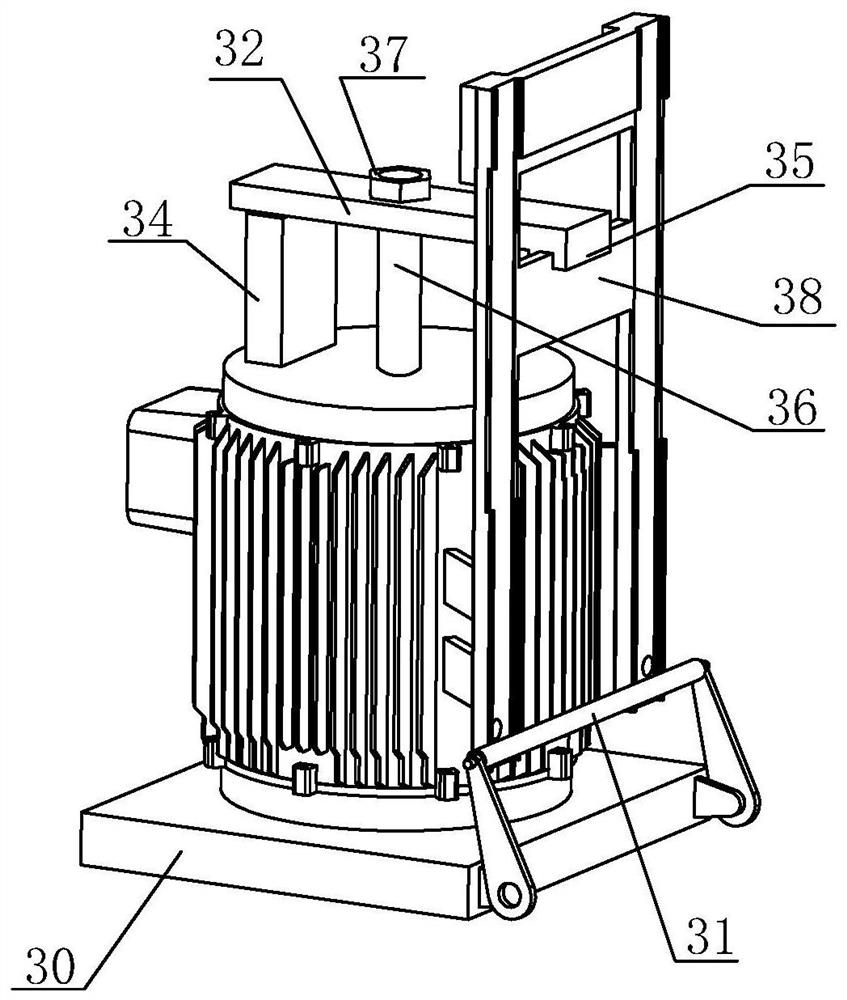

Automatic grinding device

ActiveCN105643377AAutomatic grindingMeet the requirements of parallelismRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to an automatic grinding device. The automatic grinding device comprises two mutually-parallel grinding tool bodies, a rotary grinding cylinder, a linear grinding cylinder and a frame, wherein the rotary grinding cylinder is used for controlli8ng the grinding tool bodies to rotate; the linear grinding cylinder is used for controlling the grinding tool bodies to perform rectilinear motion; the frame is connected with the grinding tool bodies, the rotary grinding cylinder and the linear grinding cylinder; the automatic grinding device also comprises a bearing seat and a hoisting device, wherein the bearing seat is used for supporting the grinding tool bodies, and the hoisting device is used for hoisting; two frames are respectively mounted at the two ends of the two parallel grinding tool bodies; the other side of one frame is connected with the linear grinding cylinder. The grinding tool is capable of realizing automatic grinding on 20 frame holes of a rolling machine by rotation motion and rectilinear motion of the grinding tool bodies and is also capable of guaranteeing the requirements on toughness and parallelism degree of the frame holes.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Blue-ray disc die assembly

InactiveCN101777361BMeet the requirements of parallelismMake up for shrinkage deformationRecord information storageRecording/reproducing/erasing using optical interference patternsEngineeringBlue light

The invention discloses a blue-ray disc die assembly, which comprises a mounting base, a lower mold plate and an upper mold plate. The mounting base is provided with a level mounting surface; the lower mold plate is arranged on the mounting surface; the lower mold plate is provided with a level lower laminating surface; the upper mold plate is provided with a level upper laminating surface opposite to the lower laminating surface; the center of the lower laminating surface protrudes a positioning column; and the upper laminating surface facing the positioning column dents inwards to form a positioning hole. The blue-ray disc die assembly also comprises an elastic circular gasket, wherein the center of the gasket is provided with a mounting hole; the positioning column passes through the mounting hole of the gasket to make the gasket borne on the lower laminating surface; and an outer ring of the gasket is provided with a protruding ring protruding the faced upper laminating surface. The blue-ray disc die assembly can automatically adjust an upper mold and a lower mold to reach micron-sized parallelism in the process of pressing dies.

Owner:HENAN KAIRUI DIGITAL

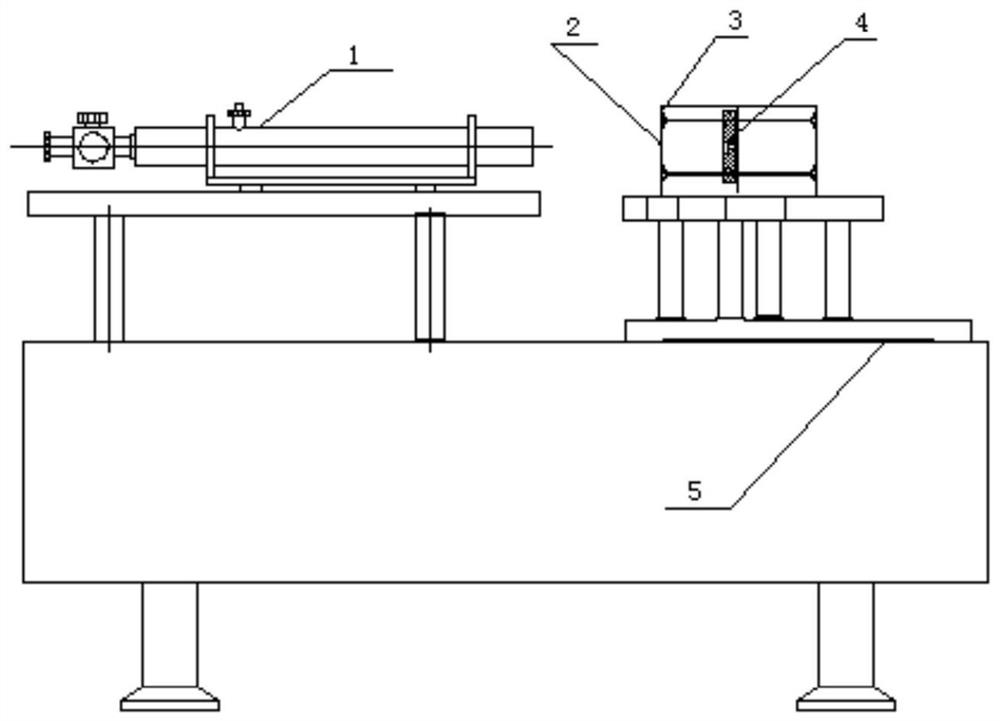

Manufacturing method for simulation test bed altitude chamber

ActiveCN106514142AMeet the requirements of parallelismAssembly precisionEngine testingEngineeringTest platform

The invention relates to a manufacturing method for a simulation test bed altitude chamber. The method comprises the following steps of assembly installing of a chamber body and a rear sealing head, strengthening ring assembly, assembling and welding of a door frame, test platform fixing, pre-installing adjusting of a hinge assembly, trepanning, welding of a door frame assembly and the chamber body and test platform chamber entry. According to the manufacturing method, accurate trepanning is achieved, and accurate assembling with the door frame is achieved. It is guaranteed that the test platform meets the requirement for the depth of parallelism. The method can be popularized to manufacturing of similar products.

Owner:SHENYANG AEROSPACE XINGUANG PRESSURE VESSEL

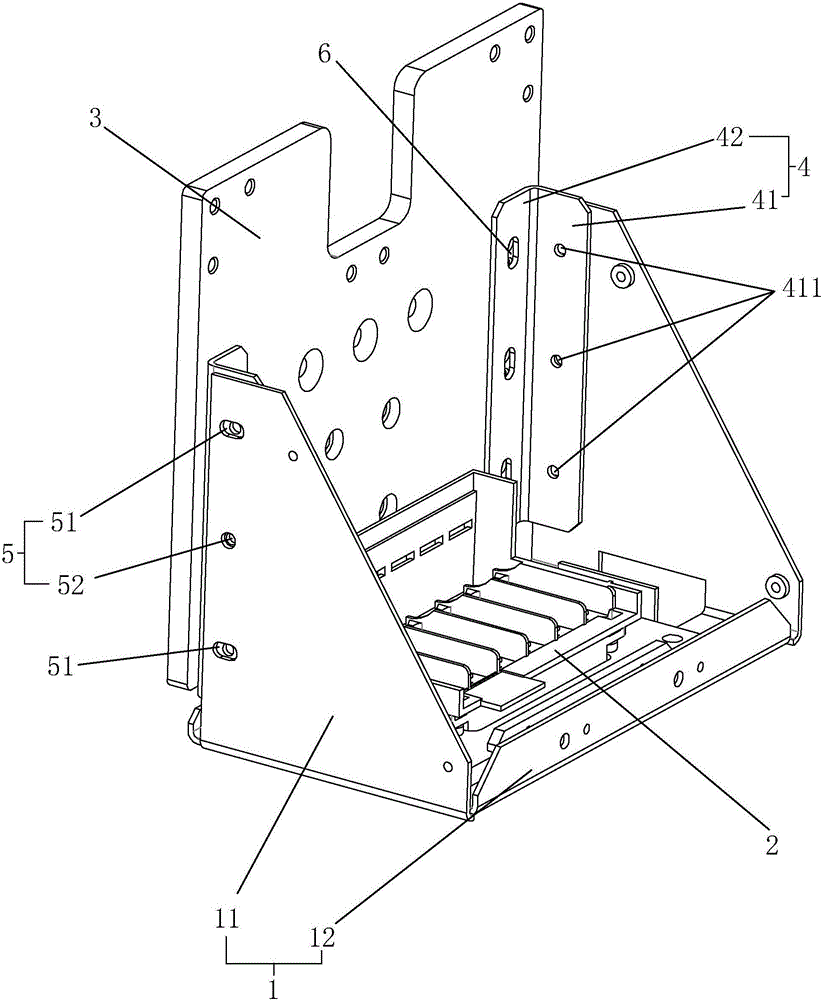

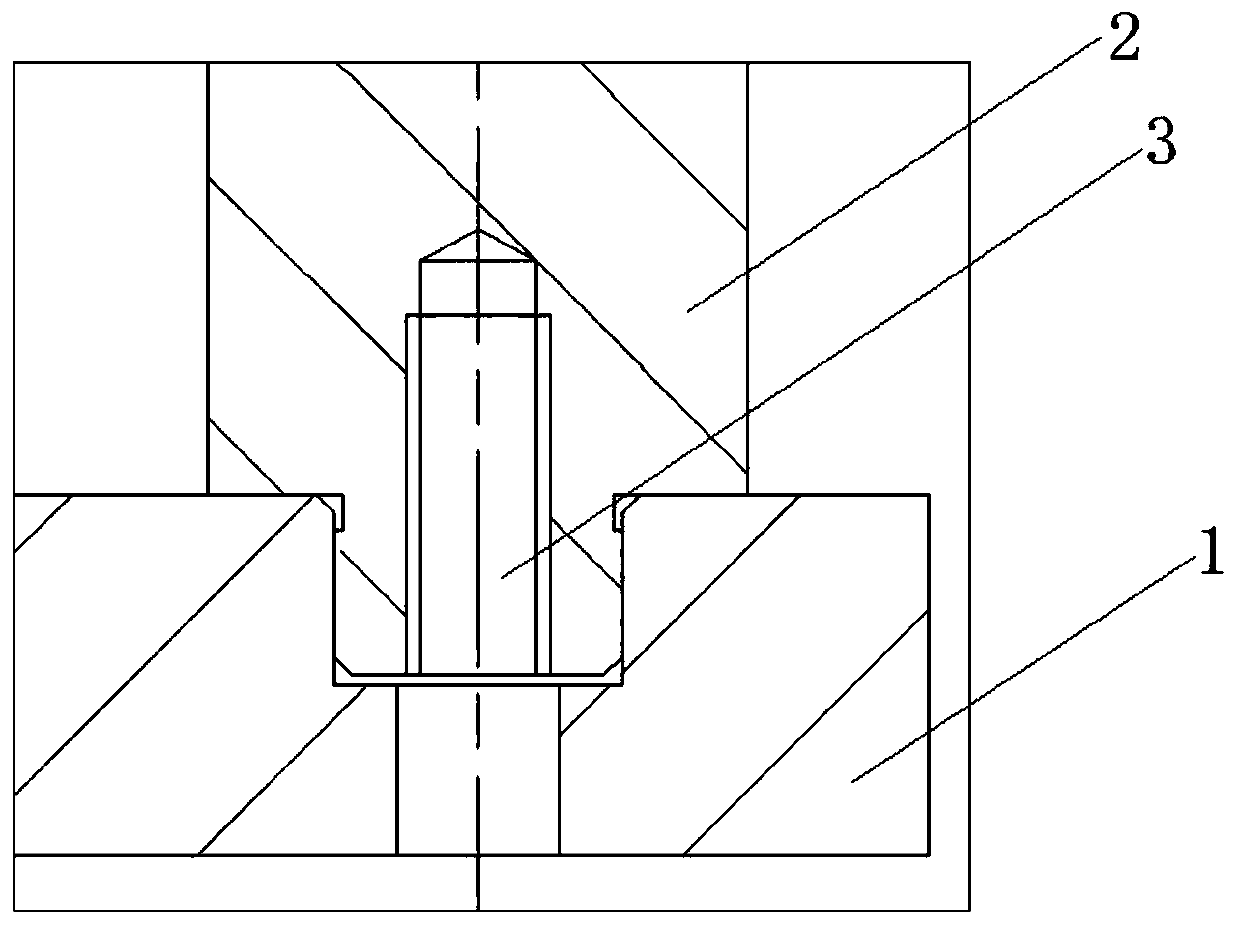

Device for adjusting installing parallelism and perpendicularity of components on wire cutting machine

ActiveCN103331498AReduce labor intensityMeet the requirements of parallelismElectrical-based auxillary apparatusWire cuttingStructural engineering

The invention discloses a device for adjusting installing parallelism and perpendicularity of components on a wire cutting machine. The device is used for installing first components to be installed and second components to be installed on the wire cutting machine. Adjusting screw seats with first spherical surfaces are arranged on the first components, adjusting screws with second spherical surfaces which are matched with the first spherical surfaces are arranged on the second components, then adjusting washer sets with spherical matching surfaces are arranged, the adjusting washer sets, the adjusting screws and the adjusting screw seats are compressed through compression screws, and the matching state of the first spherical surfaces and the second spherical surfaces is adjusted in the installing process, so that the positions of the first components and the positions of the second components are correspondingly adjusted to meet the requirements for the installing parallelism and the perpendicularity. The device is simple in structure. The installing surfaces of the components to be installed do not need to be secondarily or repeatedly machined in the installing process, the installing accuracy and the installing efficiency of the components to be installed on the wire cutting machine are improved, and labor intensity of relevant operators is also reduced.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

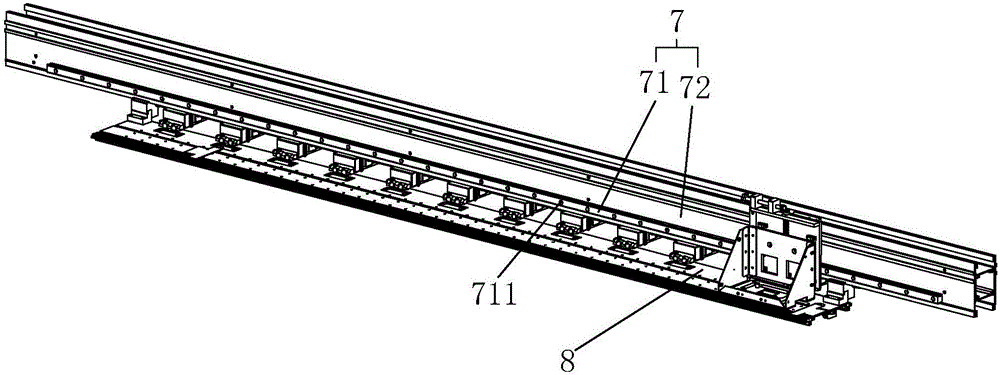

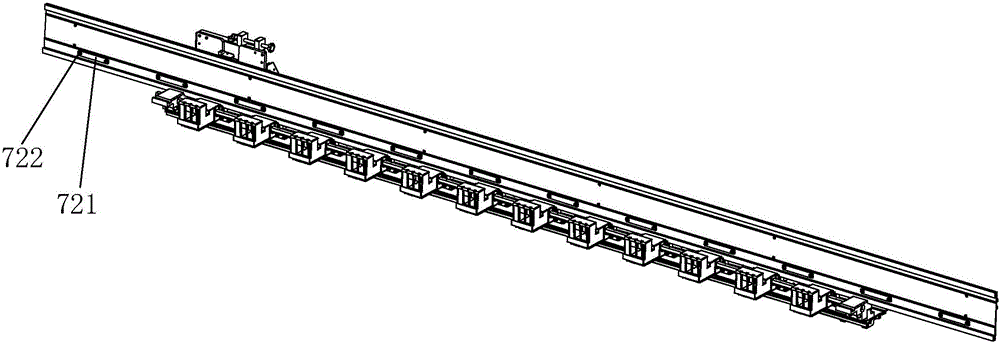

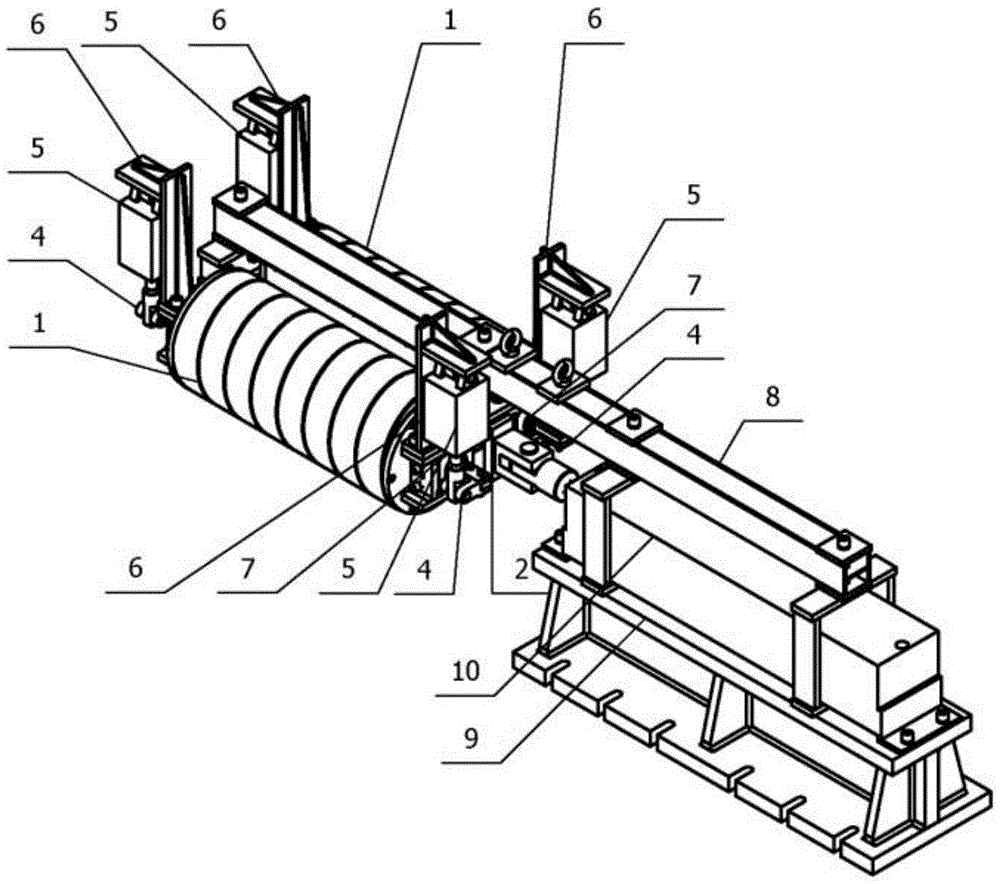

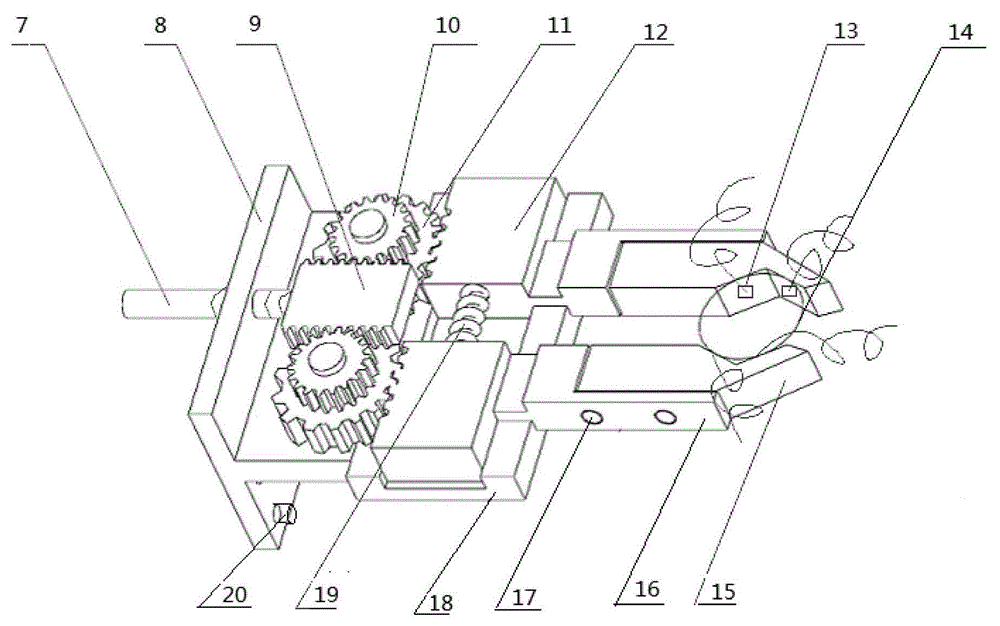

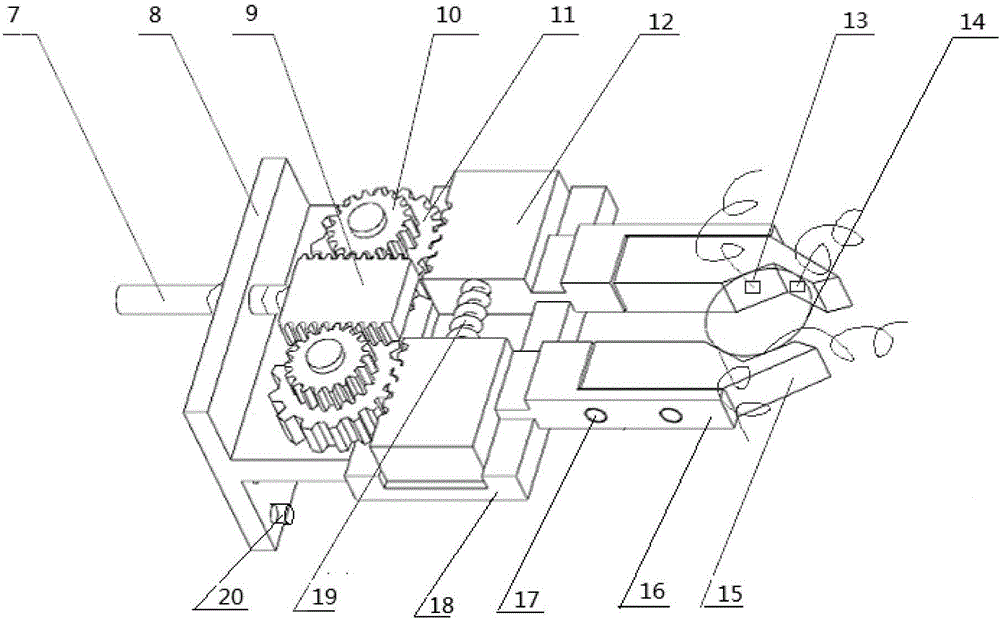

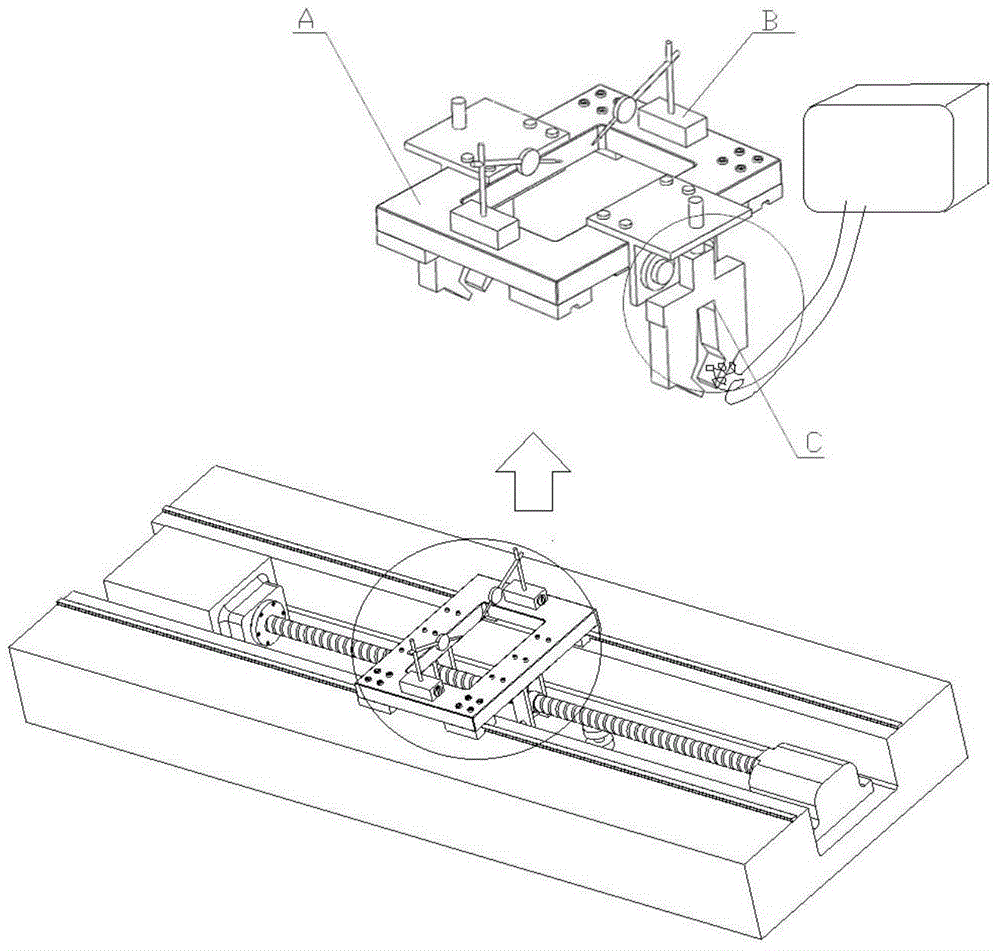

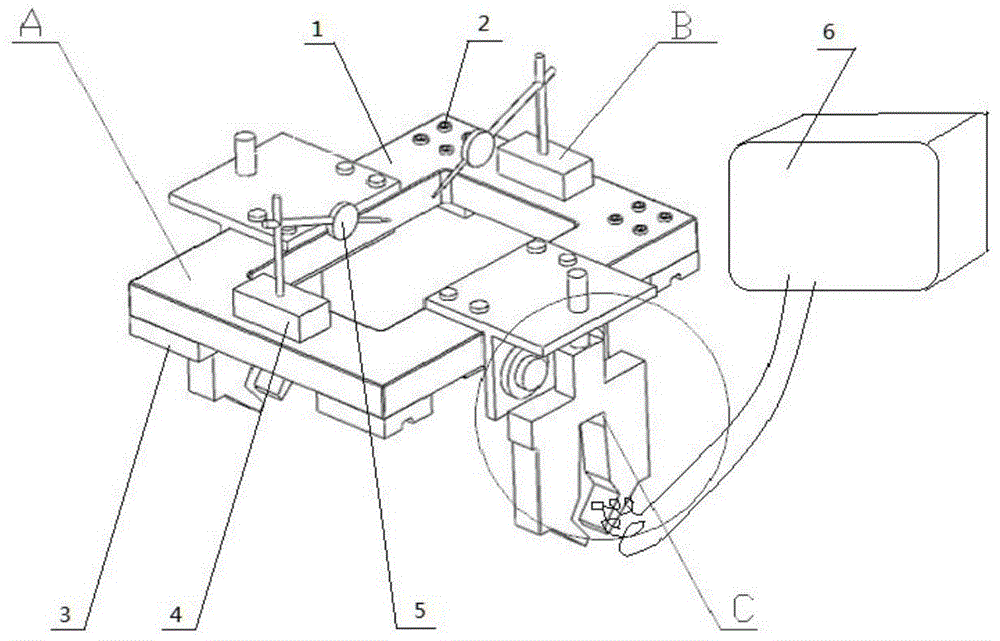

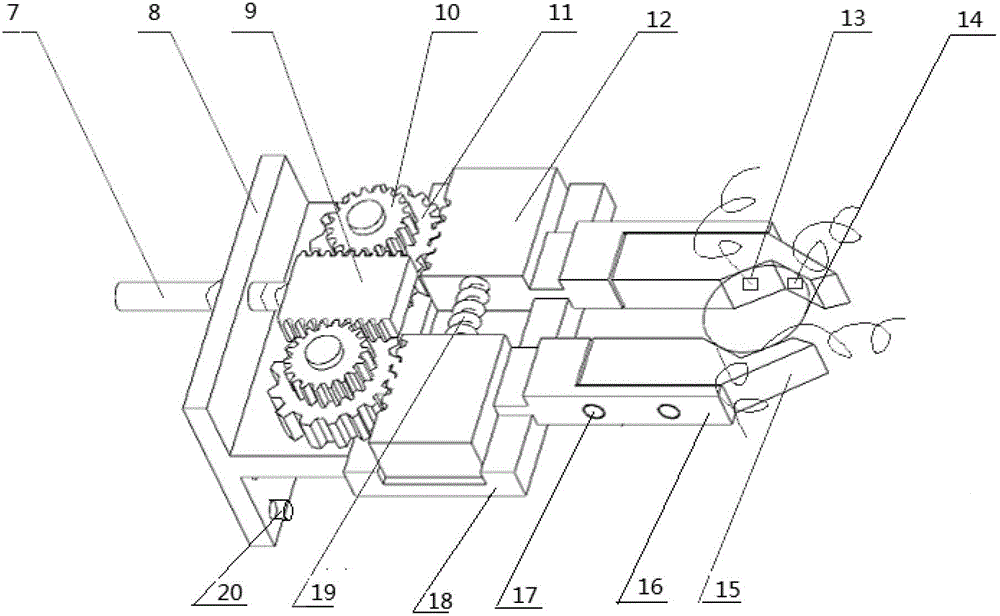

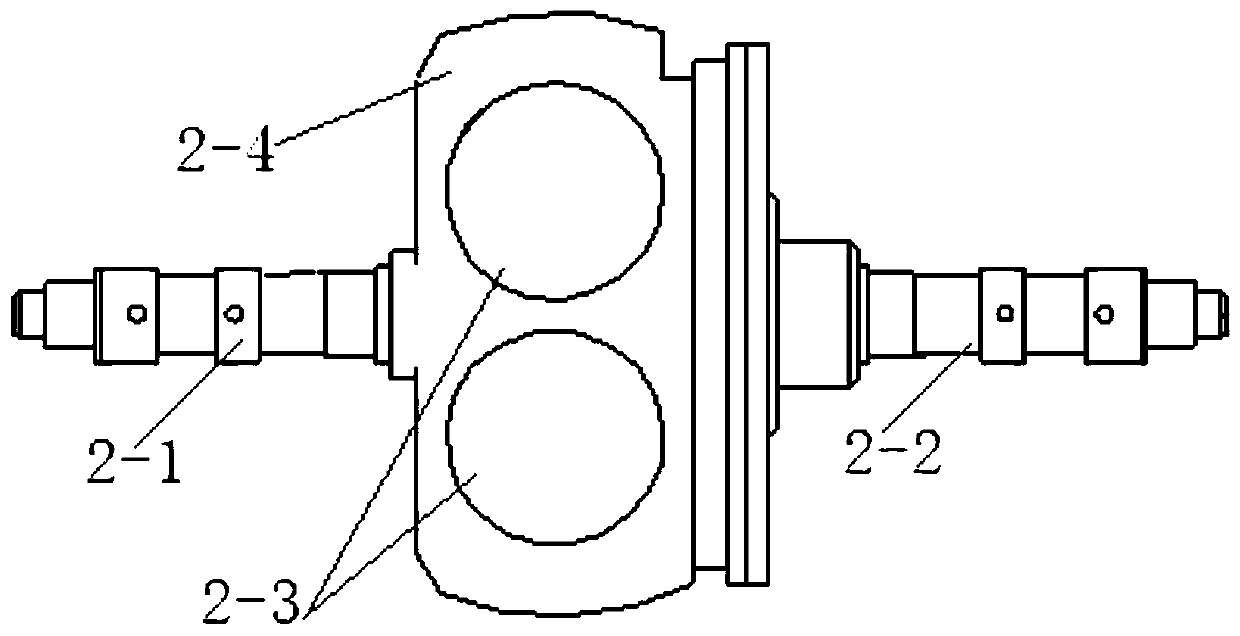

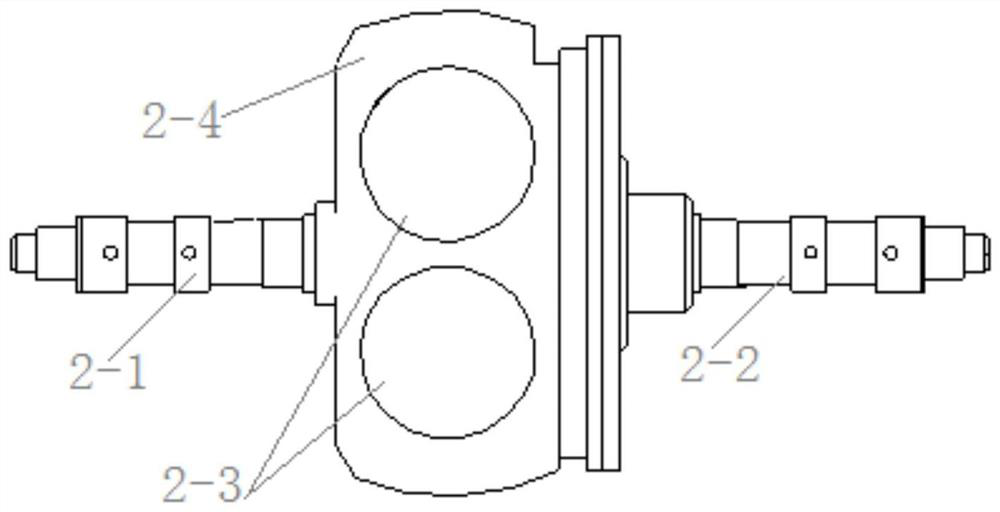

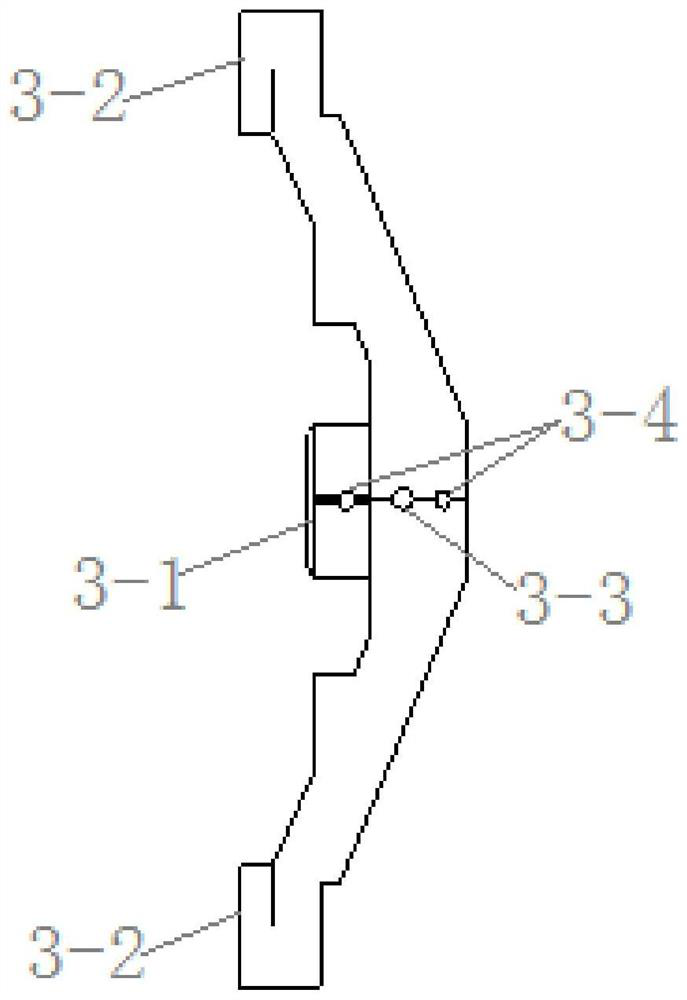

Special fixture for adjusting suspended beam lead screw position relative to guide rail

ActiveCN104596384ARealize automated detectionLowering techniqueMetal working apparatusMechanical measuring arrangementsScrew positionData acquisition

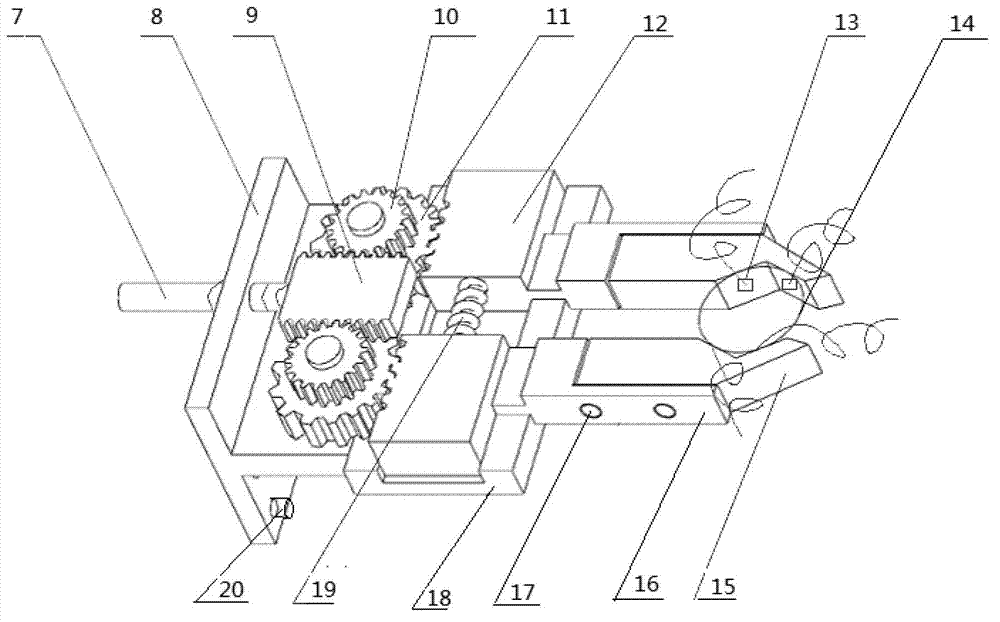

The invention provides a special fixture for adjusting the suspended beam lead screw position relative to a guide rail. The special fixture comprises a frame, two detection devices and two clamping devices, wherein the two detection devices and the two clamping devices are arranged on the frame; each clamping device comprises a screw, an assembling frame, a double-sided rack, two small gears, two large gears, two sliding racks, a replaceable claw clamp, a fixed claw clamp, a U-shaped groove, pressure sensors and a data collector; each double-sided rack is fixedly connected with the lower end of the corresponding screw; each two small gears are meshed with two sides of the corresponding double-sided rack respectively; each two large gears and the corresponding two small gears are coaxial and each two large gears are meshed with the corresponding sliding racks which are arranged below the large gears; each two sliding racks can slide freely in the corresponding U-shaped groove; a compression spring is arranged between each two sliding racks; each fixed claw clamp is rigidly connected below the corresponding sliding racks; each replaceable claw clamp is connected with the corresponding fixed claw clamp; each four pressure sensors are arranged on four sides of the corresponding replaceable claw clamp respectively. According to the special fixture for adjusting the suspended beam lead screw position relative to the guide rail, the structure is simple, the design is reasonable, the installation accuracy is high, the automatic detection can be achieved, the installation and the detection are integrated into a whole, the operation is simple, and the grasp is convenient.

Owner:WENZHOU UNIVERSITY

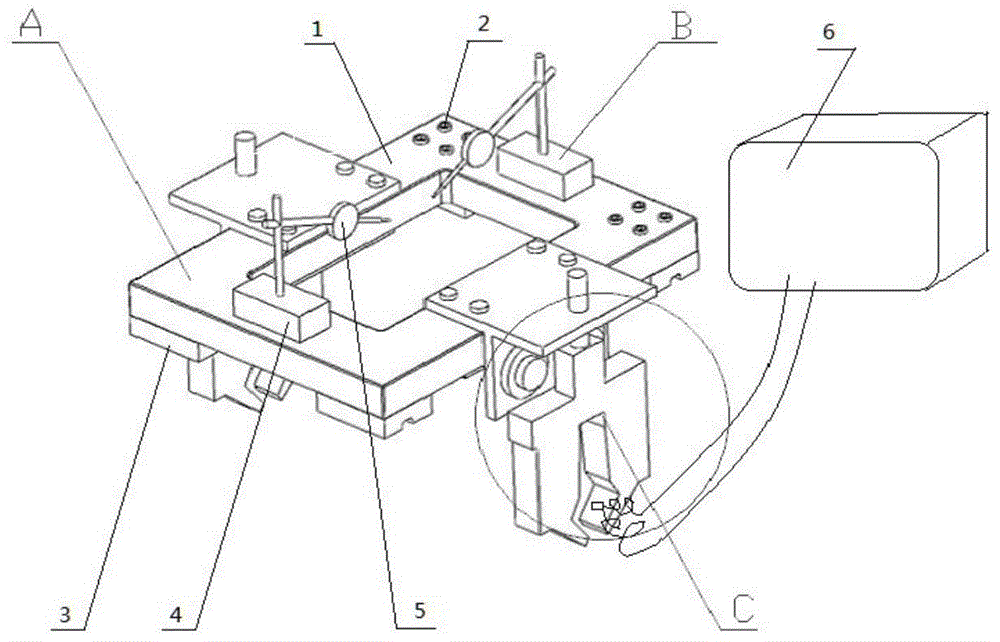

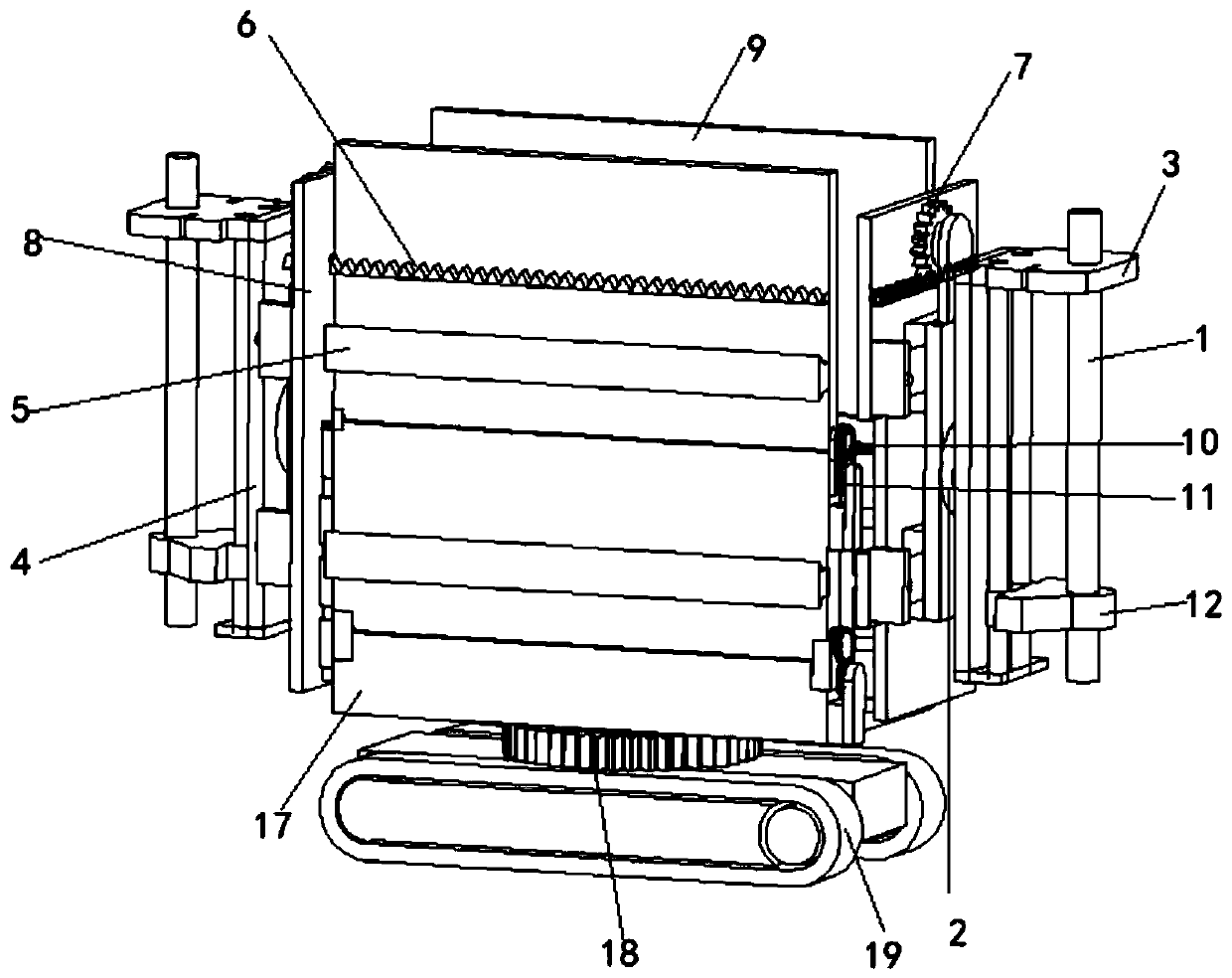

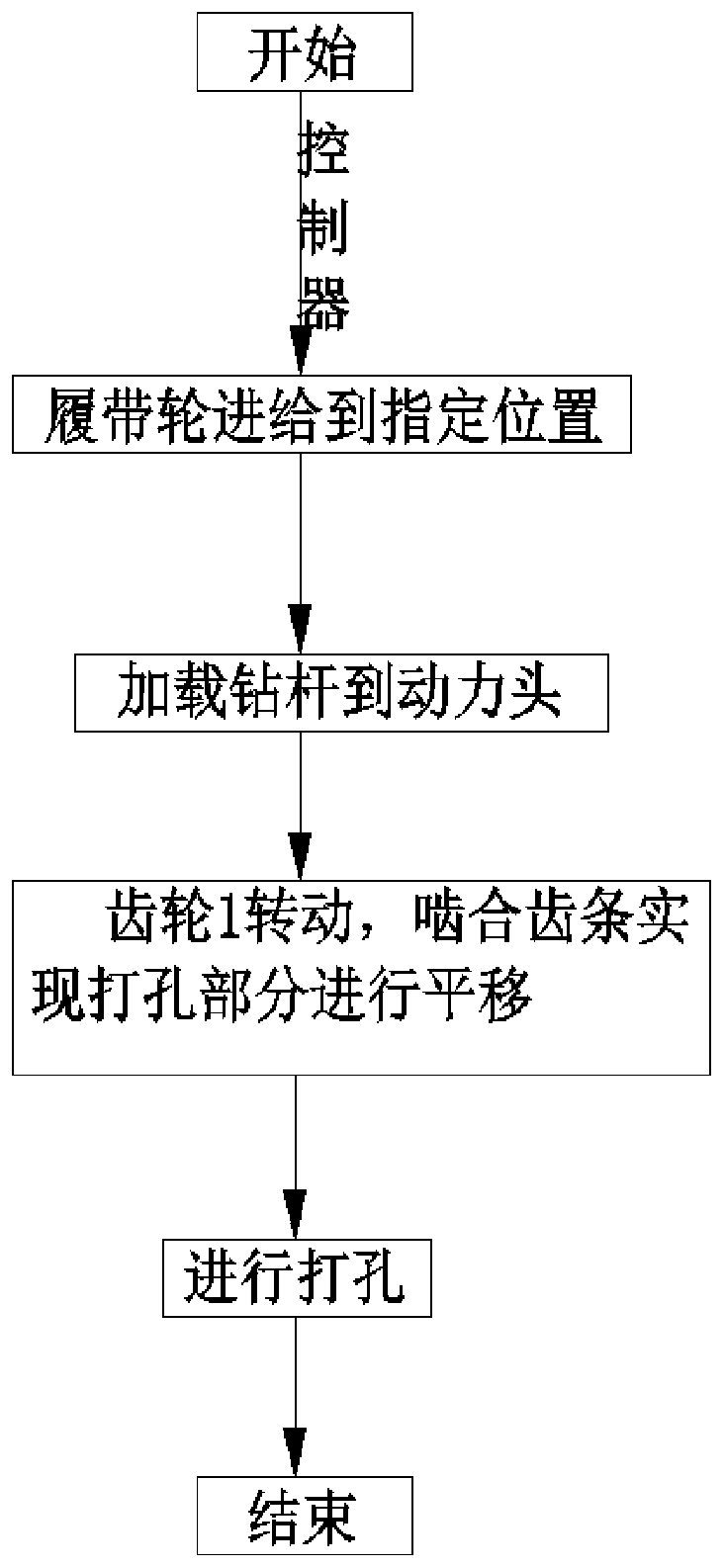

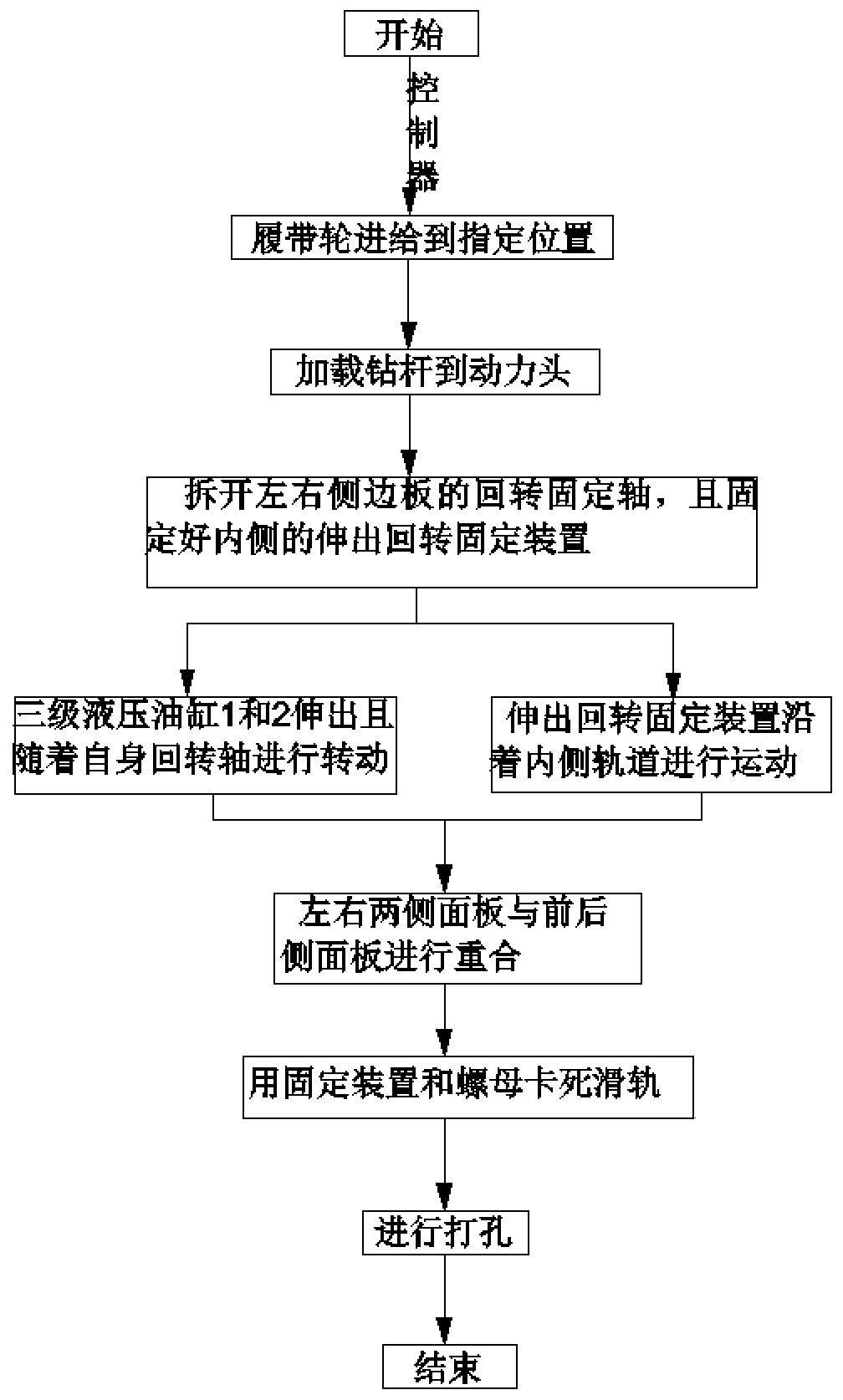

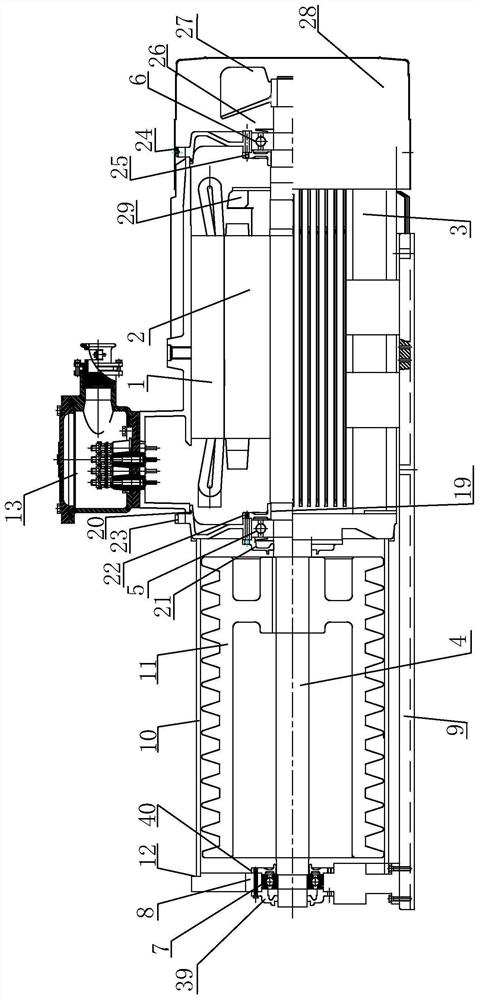

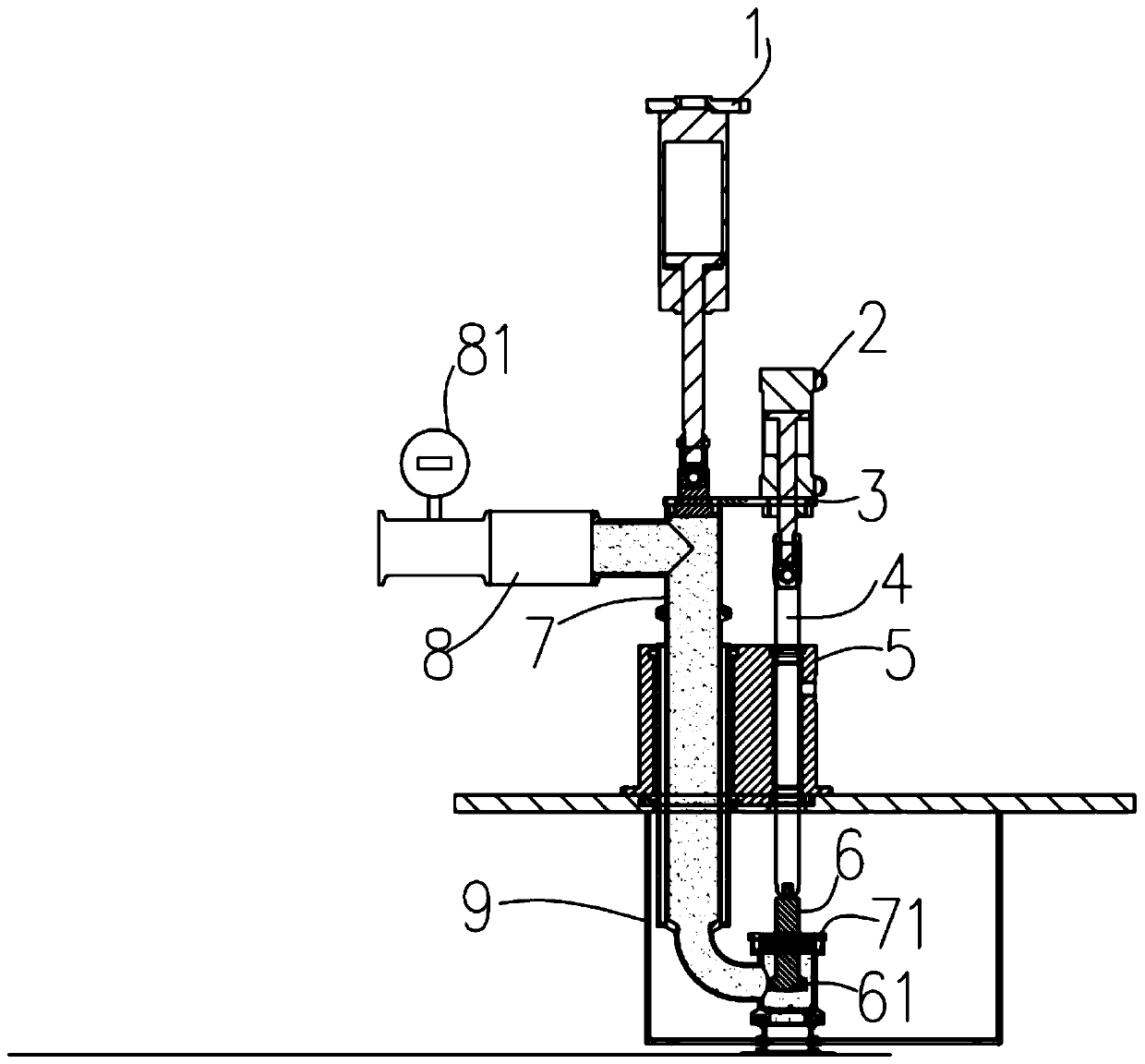

Folding roof bolter capable of carrying out circumferential rotation for multi-hole construction

PendingCN110905405AAchieving moment balanceImprove positioning accuracyDrilling rodsDerricks/mastsDrill holeRock bolt

The invention provides a folding roof bolter capable of carrying out circumferential rotation for multi-hole construction. The folding roof bolter comprises a base part, circumferential holing parts and two-stage folding parts. The circumferential holing parts are located on two sides of the base part. The two-stage folding parts are located on the other two sides of the base part. Each circumferential holing part is provided with a holing part and an axial rotation mechanism, wherein the axial rotation mechanism is used for making the circumferential holing part to axially rotate to be at thesame horizontal plane as the two-stage folding parts, and the holing part is used for smooth feeding drilling in the horizontal plane or a horizontal plane where the circumferential holing part is located on before or after axial rotation. The two-stage folding part is used for implementing inclined drilling. With the folding roof bolter capable of carrying out circumferential rotation for multi-hole construction, it is solved that a drilling equipment in the prior art cannot make anchor holes be in the same straight line, and cannot meet the requirements of construction for large, medium, small and narrow roadways either.

Owner:CHANGAN UNIV

A continuous inkjet printing production line nozzle frame positioning device and its control method

ActiveCN105584226BHigh positioning accuracyMeet the requirements of parallelismTypewritersPower drive mechanismsProduction lineCoupling

The invention relates to a spray head frame positioning device of a continuous ink-jet printing production line, and a control method thereof. The device comprises a left crossbeam lifting plate, a fixed plate, a right crossbeam lifting plate and a transmission mechanism. The device is characterized in that the left crossbeam lifting plate is provided with a fixed block A and a fixed block B, and the fixed block A and the fixed block B are respectively provided with a steel ball A and a steel ball B; the right crossbeam lifting plate is provided with a fixed block C, and the fixed block C is provided with a steel ball C; and the transmission mechanism comprises a nut, a leading screw, a worm and gear, a shaft coupling and a servo motor. The invention provides technical means of integral position adjustment of a large-span spray head frame; the parallelism requirement between a spray head and a fabric surface is effectively met, and the printing precision is ensured; in addition, manual adjustment is avoided, and the production efficiency is improved.

Owner:HANGZHOU HONGHUA DIGITAL TECH +1

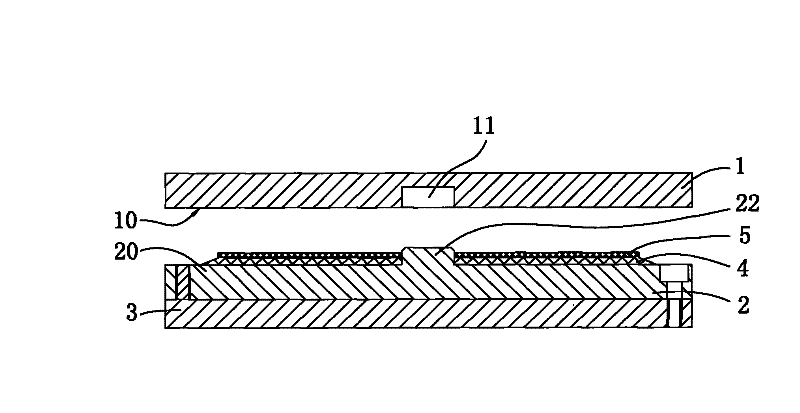

Broadband temperature tuning filter with air gap etalon structure

InactiveCN111474618AReasonable designMeet the requirements of parallelismOptical elementsThermal dilatationBi-isotropic material

The invention discloses a broadband temperature tuning filter with an air gap etalon structure. The broadband temperature tuning filter comprises an air gap etalon. The air gap etalon is formed by combining H-K9 and a quartz crystal, and the quartz crystal is used as a spacer block material of the H-K9. The broadband temperature tuning filter has the advantages that the anisotropism characteristicof thermal expansion of the quartz crystal is used as a spacer block to achieve temperature tuning of the cavity thickness, two isotropic materials are selected as the second material combination, the thermal expansion coefficient difference of the two isotropic materials is within 5E-6, and the temperature tuning air gap etalon is manufactured in cooperation with a special bonding film.

Owner:FUZHOU OPTOWIDE TECH CO LTD

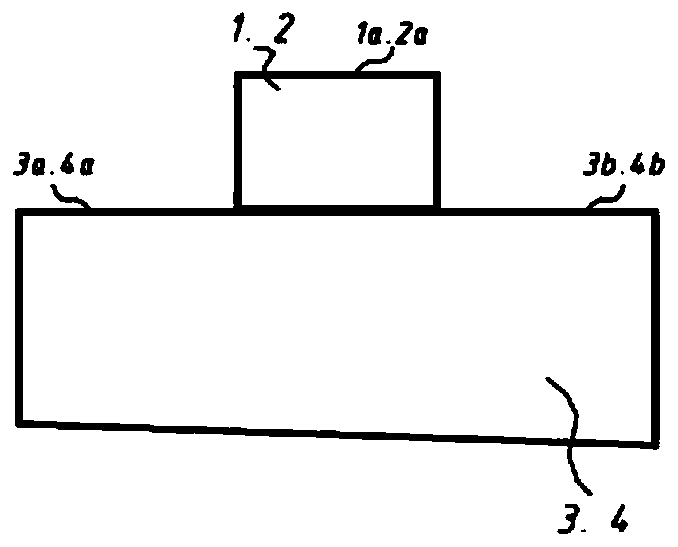

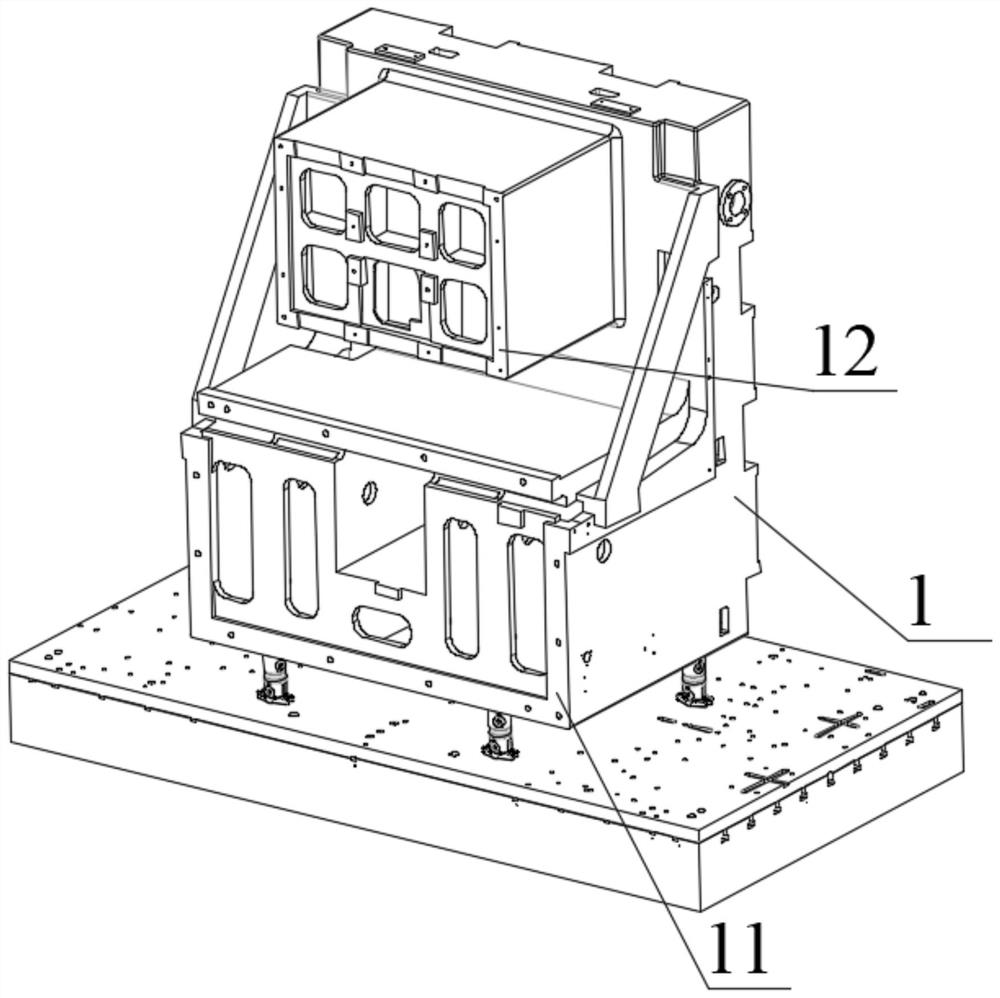

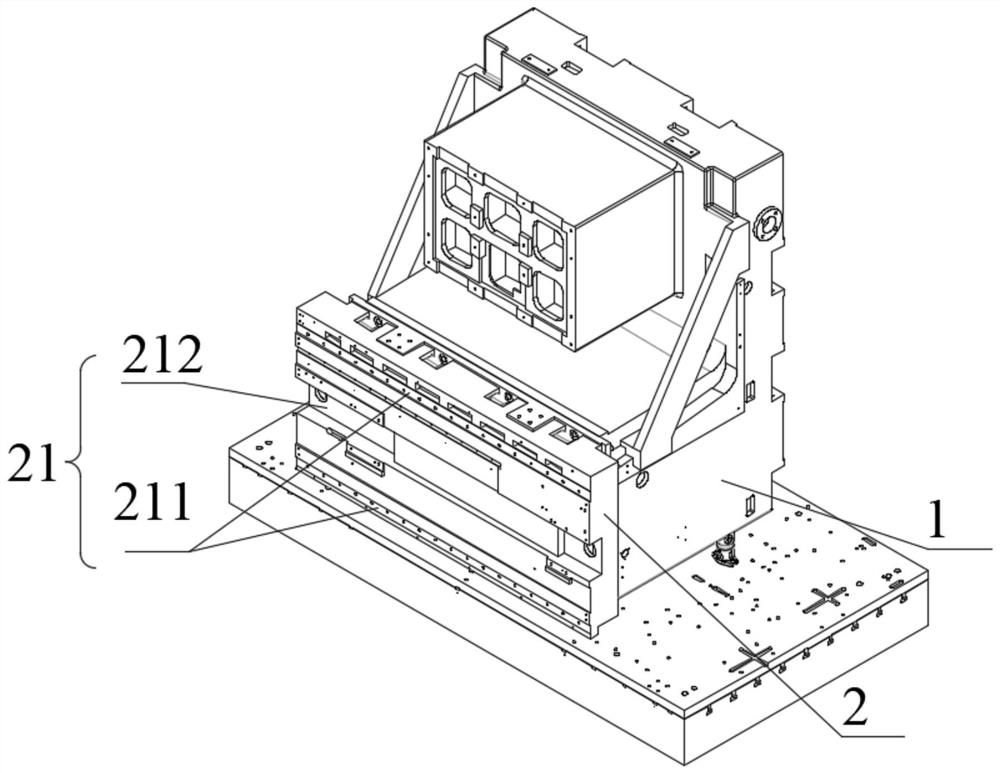

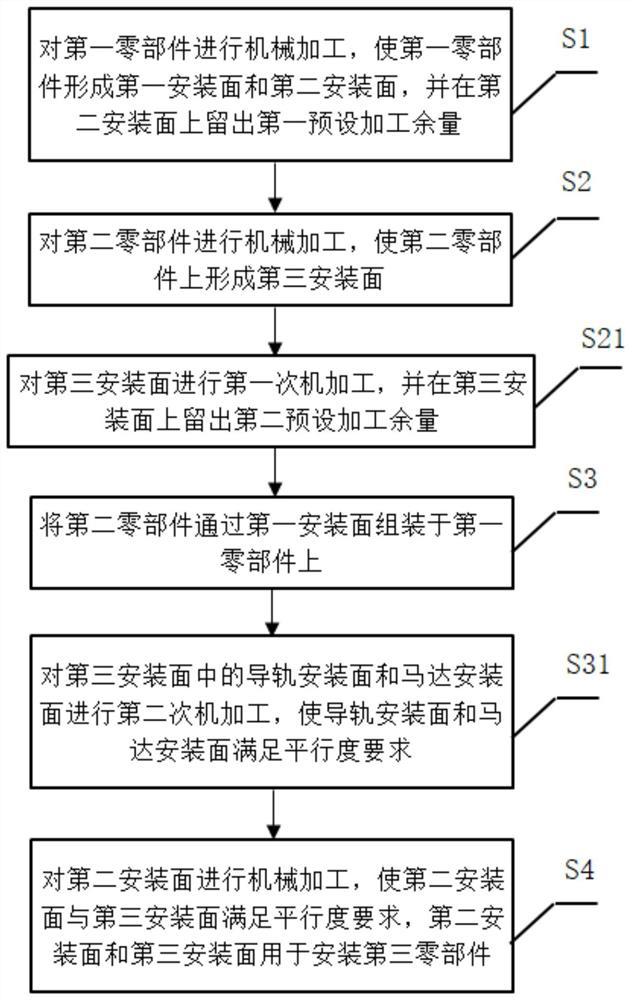

Assembly machining method

PendingCN113732633AMeet the requirements of parallelismReduce parallelism requirementsOther manufacturing equipments/toolsPositioning apparatusManufacturing engineeringIndustrial engineering

The invention relates to the technical field of machining, and discloses an assembly machining method. The assembly machining method comprises the steps that S1, a first part is machined, so that a first mounting surface and a second mounting surface are formed on the first part, and a first preset machining allowance is reserved on the second mounting surface; S2, a second part is machined, and a third mounting surface is formed on the second part; S3, the second part is assembled on the first part through the first mounting surface; and S4, the second mounting surface is machined, so that the second mounting surface and the third mounting surface meet the parallelism requirement, and the second mounting surface and the third mounting surface are used for mounting a third part. By means of the structure, the assembly machining method can meet the requirement for the parallelism of the installation surfaces so as to achieve the installation precision, and the machining cost can be reduced.

Owner:MAKINO MACHINE TOOL CHINA CO LTD

Preparation device of indoor single-cracked rock specimen

InactiveCN102435475BAvoid swingingMeet the requirements of parallelismPreparing sample for investigationRock coreButt joint

The invention relates to a preparation device of a rock cracked specimen, in particular to a preparation device of a single-cracked rock specimen filled with a binding material with a certain thickness. The preparation device comprises a base, an upper movable seat, a lower rock core fixing lantern ring, an upper rock core fixing lantern ring, a threaded spindle, an adjusting screw cap and a fastening screw cap; the concentricity of an upper rock core and a lower rock core arranged in the upper rock core fixing lantern ring and the lower rock core fixing lantern ring can be ensured through adjusting the position of the spindle relative to a through groove of the base and the position of the upper rock core fixing lantern ring relative to a horizontal through groove; the distance between the upper rock core and the lower rock core is controlled through the adjusting screw cap and the fastening screw cap; and meanwhile, the thickness of a binding layer between the upper rock core and the lower rock core is ensured so that the upper rock core and the lower rock core are coupled and butt-jointed to form a standard single-cracked rock specimen. The preparation device of the single-cracked rock specimen in the invention is easy to manufacture, simple in operation, strong in practicability and capable of being widely used for preparing single-cracked rock specimens.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

An automatic grinding device

ActiveCN105643377BAutomatic grindingMeet the requirements of parallelismRevolution surface grinding machinesGrinding drivesMechanical engineeringToughness

The invention relates to an automatic grinding device. The automatic grinding device comprises two mutually-parallel grinding tool bodies, a rotary grinding cylinder, a linear grinding cylinder and a frame, wherein the rotary grinding cylinder is used for controlli8ng the grinding tool bodies to rotate; the linear grinding cylinder is used for controlling the grinding tool bodies to perform rectilinear motion; the frame is connected with the grinding tool bodies, the rotary grinding cylinder and the linear grinding cylinder; the automatic grinding device also comprises a bearing seat and a hoisting device, wherein the bearing seat is used for supporting the grinding tool bodies, and the hoisting device is used for hoisting; two frames are respectively mounted at the two ends of the two parallel grinding tool bodies; the other side of one frame is connected with the linear grinding cylinder. The grinding tool is capable of realizing automatic grinding on 20 frame holes of a rolling machine by rotation motion and rectilinear motion of the grinding tool bodies and is also capable of guaranteeing the requirements on toughness and parallelism degree of the frame holes.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

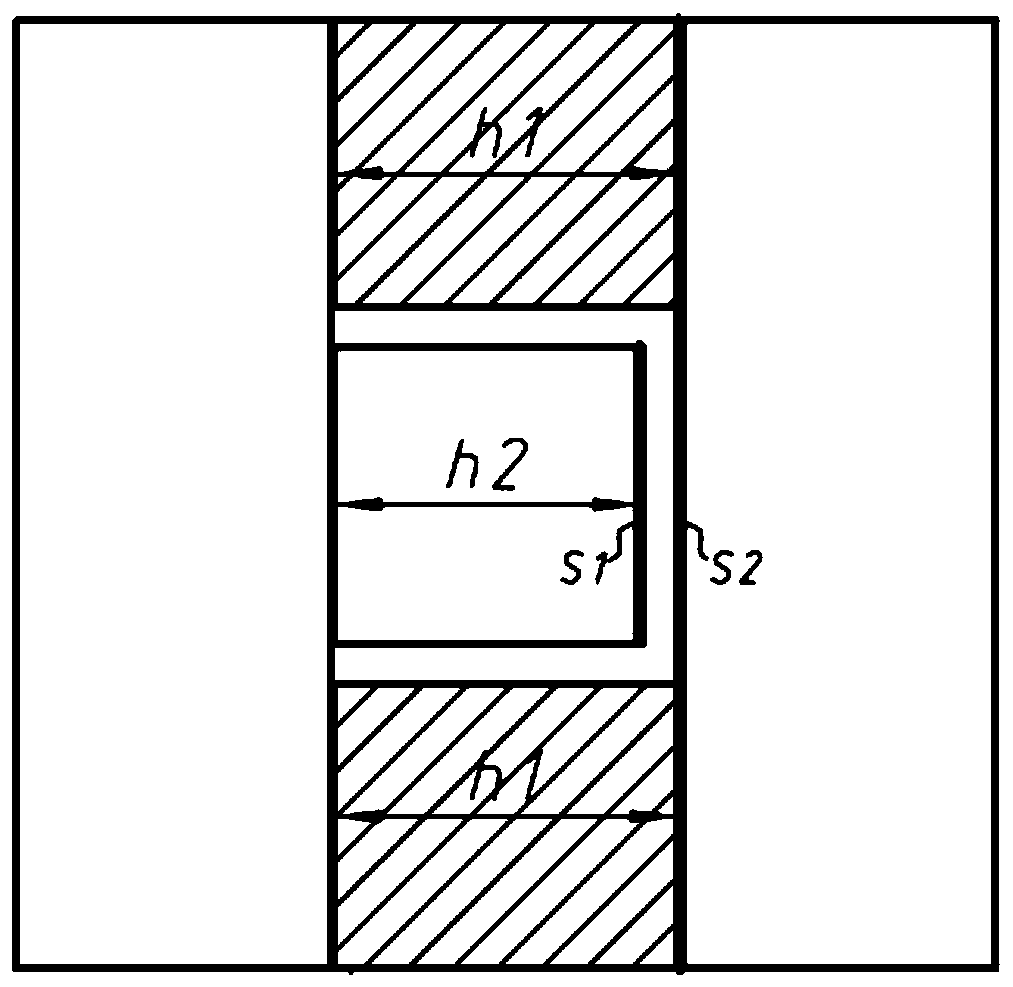

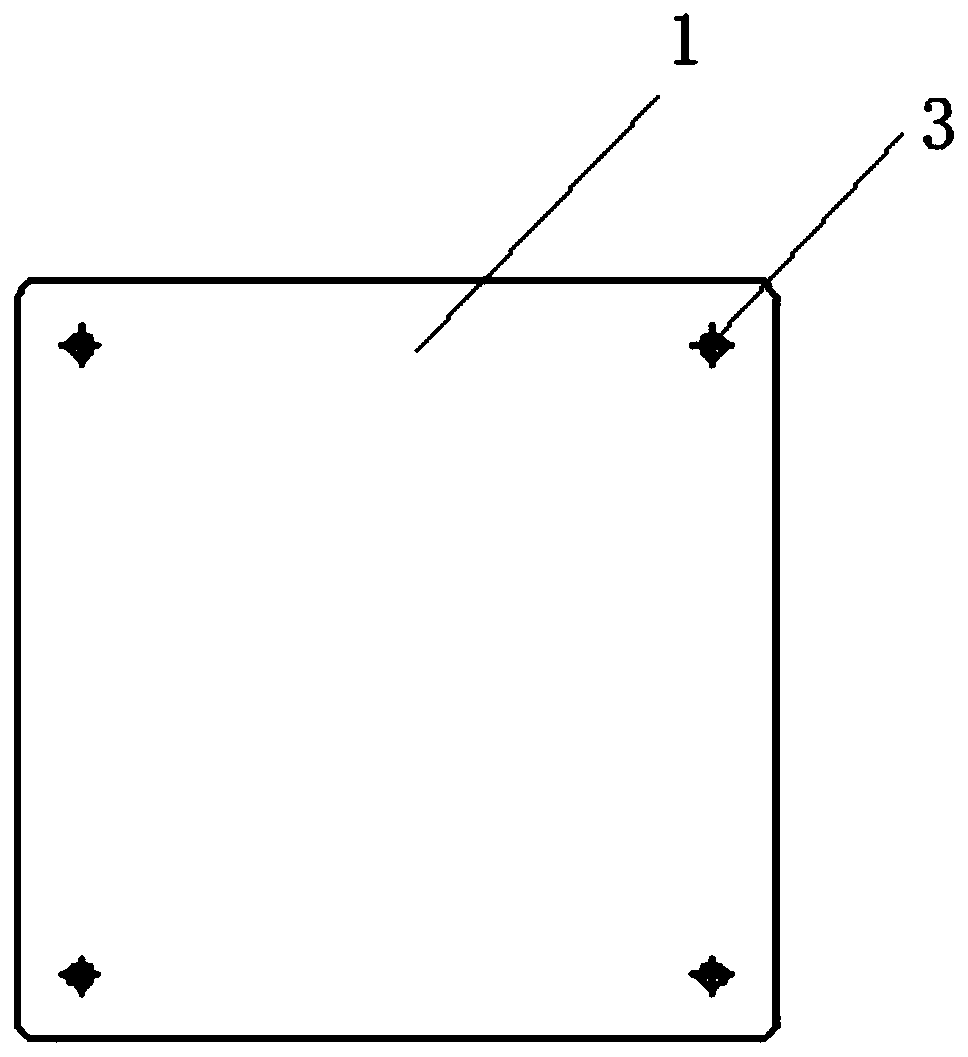

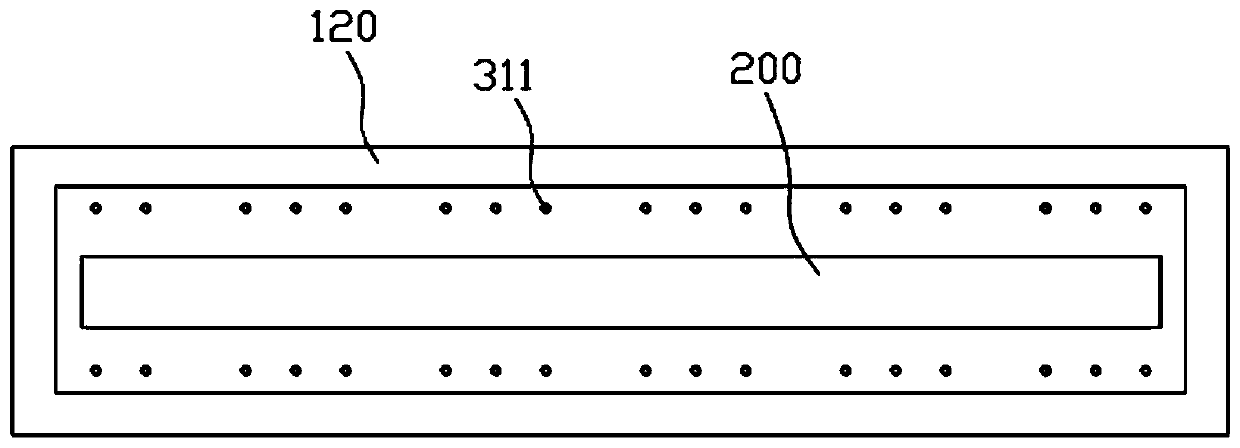

Structure for improving parallelism of parts after assembly

PendingCN110749344AMeet the requirements of parallelismGuaranteed contourMeasurement apparatus componentsComputer architectureStructural engineering

The invention discloses a structure for improving the parallelism of parts after assembly, comprising two reference plates parallel to each other, wherein the two reference plates are connected by support posts, two ends of the support posts are respectively connected with the two reference plates through sleeves, one ends of the sleeves are connected to the support posts, the other ends of the sleeves are connected to the reference plates, screws are disposed in the sleeves, and the screws are used to fix the support posts and the reference plates. Post pin structures for connecting two endsof the supports to reference surfaces are removed, and a middle insert is used, so that four support posts can be machined on the same grinder, equal height of the four posts is ensured, and the requirement for the parallelism of two surfaces in the use of equipment is met.

Owner:天永锂电自动化设备(太仓)有限公司

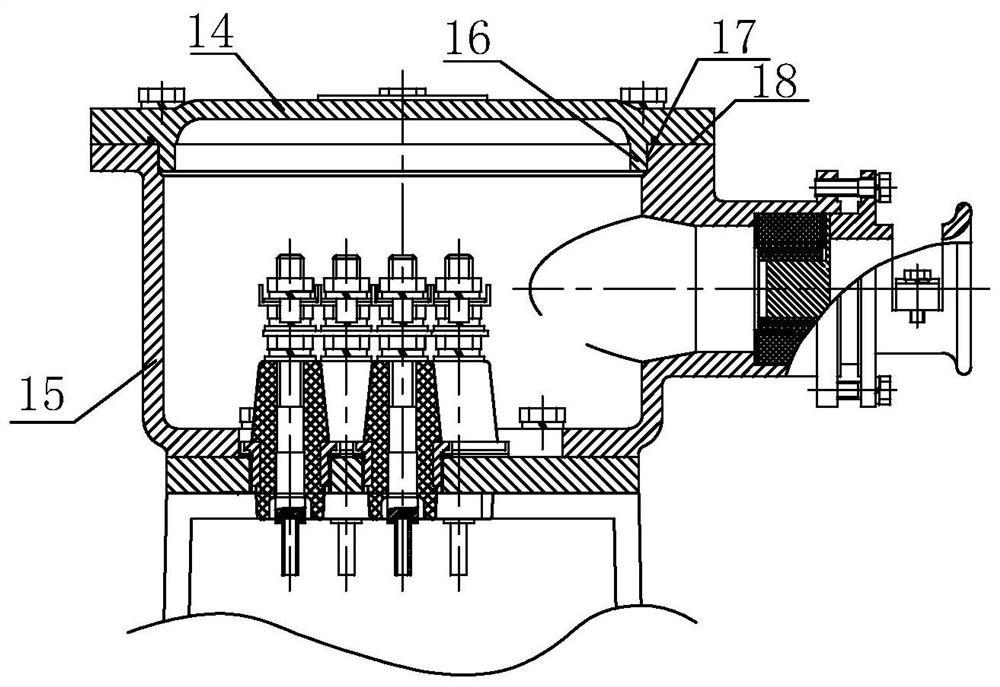

Special explosion-proof motor for plunger pump and process

ActiveCN111953119AReasonable forceImprove overload capacityManufacturing dynamo-electric machinesMechanical energy handlingCantilevered beamElectric machine

The invention discloses a special explosion-proof motor for a plunger pump and a process. The explosion-proof motor comprises a motor stator, a motor rotor and a base, the motor stator is arranged inthe base, and the motor rotor is arranged at the inner side of the motor stator. The explosion-proof motor also comprises a front shaft supporting structure and a machine base bottom foot plate. A motor shaft is arranged in the motor rotor and is sleeved with a belt wheel, and the front end of the motor shaft penetrates out of the front end of the belt wheel and then is connected with the front shaft supporting structure. According to the machining process of the explosion-proof motor, the base bottom foot plate of the explosion-proof motor is machined through a vertical milling machine. According to the explosion-proof motor, the unique front shaft supporting structure is newly added, so that the stress form of the motor shaft is changed into a simply supported beam from an existing cantilever beam, the stress of the motor shaft is reasonable, the overload capacity is enhanced, and the quality is guaranteed. Under the auxiliary effect of an auxiliary machining device, the upper end face and the lower end face of the machine base bottom foot plate are machined through the vertical milling machine so as to meet the requirement for parallelism of the upper end face and the lower endface of the machine base bottom foot plate.

Owner:山东众泰防爆电机股份有限公司

A special frame for adjusting the position of the hanging beam screw to the guide rail

ActiveCN104596384BRealize automated detectionLowering techniqueMetal working apparatusMechanical measuring arrangementsScrew positionData acquisition

The invention provides a special fixture for adjusting the suspended beam lead screw position relative to a guide rail. The special fixture comprises a frame, two detection devices and two clamping devices, wherein the two detection devices and the two clamping devices are arranged on the frame; each clamping device comprises a screw, an assembling frame, a double-sided rack, two small gears, two large gears, two sliding racks, a replaceable claw clamp, a fixed claw clamp, a U-shaped groove, pressure sensors and a data collector; each double-sided rack is fixedly connected with the lower end of the corresponding screw; each two small gears are meshed with two sides of the corresponding double-sided rack respectively; each two large gears and the corresponding two small gears are coaxial and each two large gears are meshed with the corresponding sliding racks which are arranged below the large gears; each two sliding racks can slide freely in the corresponding U-shaped groove; a compression spring is arranged between each two sliding racks; each fixed claw clamp is rigidly connected below the corresponding sliding racks; each replaceable claw clamp is connected with the corresponding fixed claw clamp; each four pressure sensors are arranged on four sides of the corresponding replaceable claw clamp respectively. According to the special fixture for adjusting the suspended beam lead screw position relative to the guide rail, the structure is simple, the design is reasonable, the installation accuracy is high, the automatic detection can be achieved, the installation and the detection are integrated into a whole, the operation is simple, and the grasp is convenient.

Owner:WENZHOU UNIVERSITY

Method and special rack capable of adjusting position of suspended beam screw rod to guide rail

InactiveCN103084818BLowering techniqueLower requirementMetal working apparatusMechanical measuring arrangementsData acquisitionEngineering

Owner:SUZHOU LEAD LASER TECH +2

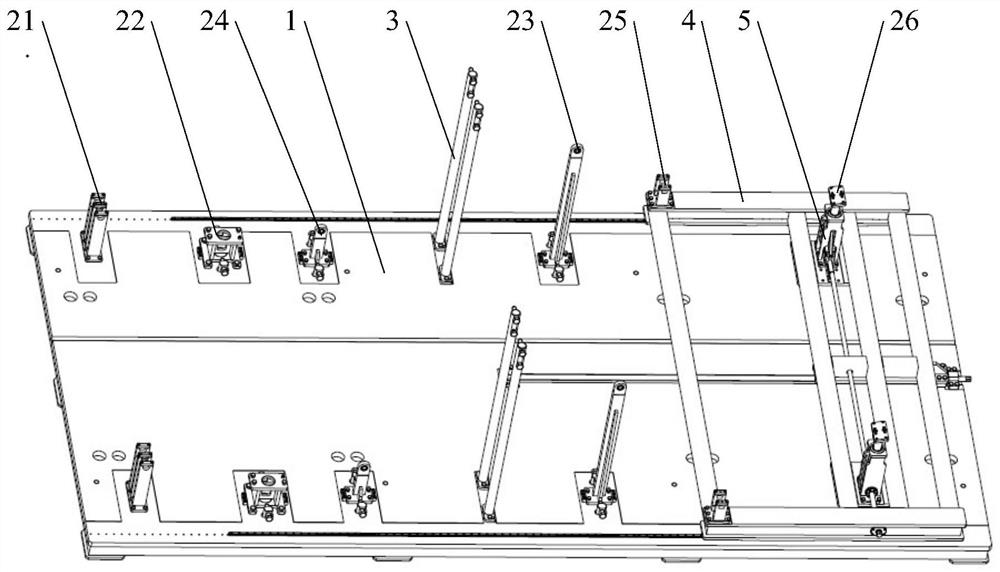

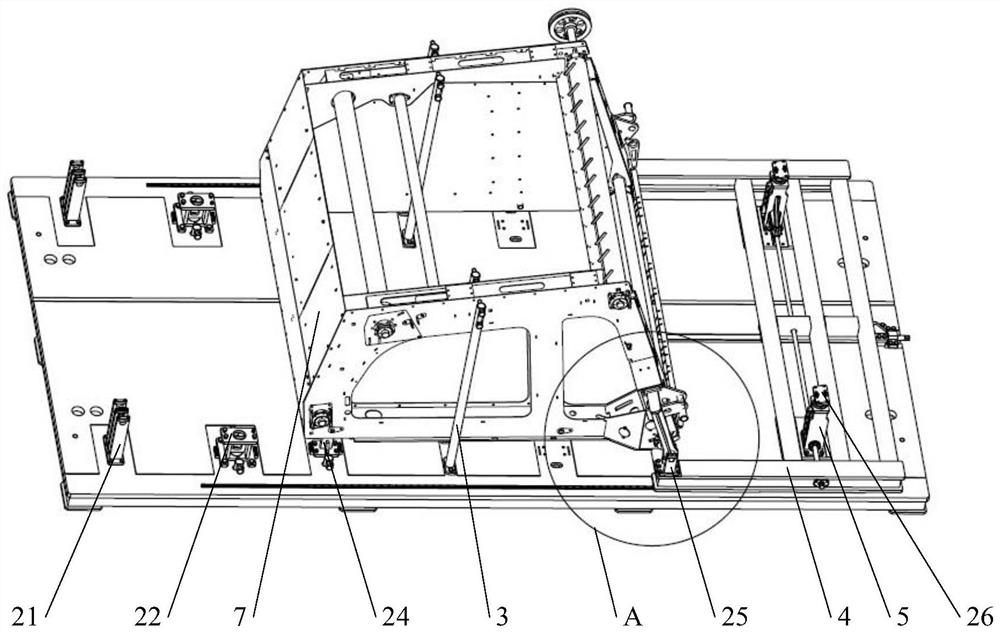

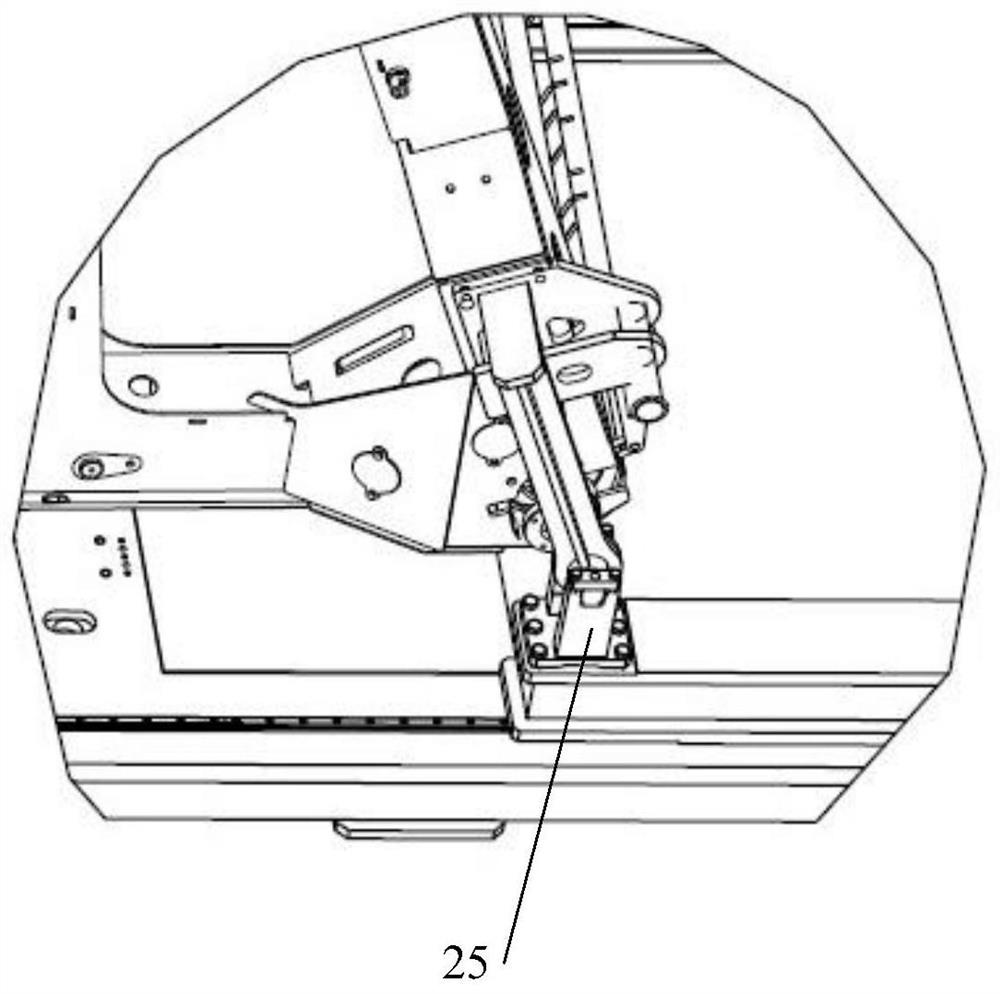

Cotton picking baler packaging system assembly tooling and method of use thereof

ActiveCN112975397BStable positionAccurate and efficient folding operationAssembly machinesStructural engineeringMechanical engineering

The invention discloses a packaging system assembly tool for a cotton picking baler and a method for using the same. It is used to limit the welding assembly on both sides when the front box and the rear box are assembled respectively; the moving component is used to drive at least one of the assembled and turned over front box assembly and the rear box assembly. or move, so that the front box assembly and the rear box assembly are docked; the position adjustment component is used to adjust the position of at least one of the front box assembly and the rear box assembly, so that the front box assembly and rear box assembly in the desired assembly location. The hoisting operation is simplified. During the assembly process, the front box and the rear box itself do not need to adjust the posture by driving; the position adjustment process in the assembly process of the front box assembly and the rear box assembly is reduced, saving time and effort , While ensuring the assembly quality, the assembly efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND +1

Manufacturing method of high-altitude cabin of simulation test bench

InactiveCN106514142BMeet the requirements of parallelismAssembly precisionEngine testingEngineeringTest platform

Owner:SHENYANG AEROSPACE XINGUANG PRESSURE VESSEL

Die-casting mold structure and die-casting method capable of achieving high parallelism

PendingCN111250674ARealize die casting productionMeet the requirements of parallelismCasting moldMachining

The invention discloses a die-casting mold structure and die-casting method capable of achieving high parallelism. The die-casting mold structure comprises a fixed mold, a movable mold and a core inserting structure; a mold cavity is formed between the fixed mold and the movable mold, the mold cavity comprises a fixed mold mold cavity formed in the fixed mold and a movable mold mold cavity formedin the movable mold, the fixed mold mold cavity is internally provided with a fixed mold protruding block, and the fixed mold protruding block is provided with a plurality of fixed mold fixing holes;the movable mold mold cavity is internally provided with a movable mold protruding block, and a plurality of movable mold fixing holes matched with the plurality of fixed mold fixing holes are formedin the movable mold protruding block; a core pulling mechanism is arranged on the side surface of the fixed mold and the movable mold, the core pulling mechanism comprises a plurality of sliding blockmold cores, the sliding block mold cores, the fixed mold fixing holes and the movable mold fixing holes are in one-to-one correspondence, and the plurality of sliding block mold cores are inserted into the corresponding fixed mold fixing holes and the corresponding movable mold fixing holes correspondingly. According to the die-casting mold structure and the die-casting method capable of achieving the high parallelism, the movable mold protruding block and the fixed mold protruding block are combined and the sliding block mold cores are taken to be combined in a penetrating, locking and matching manner, so that the product parallelism requirement which originally needs to be guaranteed through machining is reached.

Owner:上海海帕压铸件有限公司

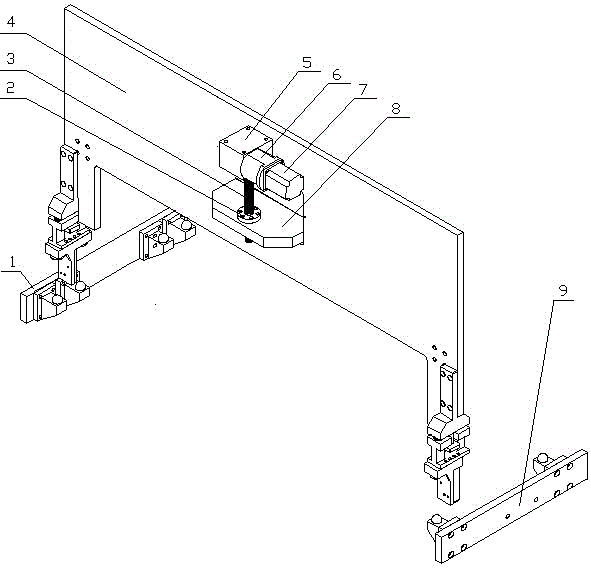

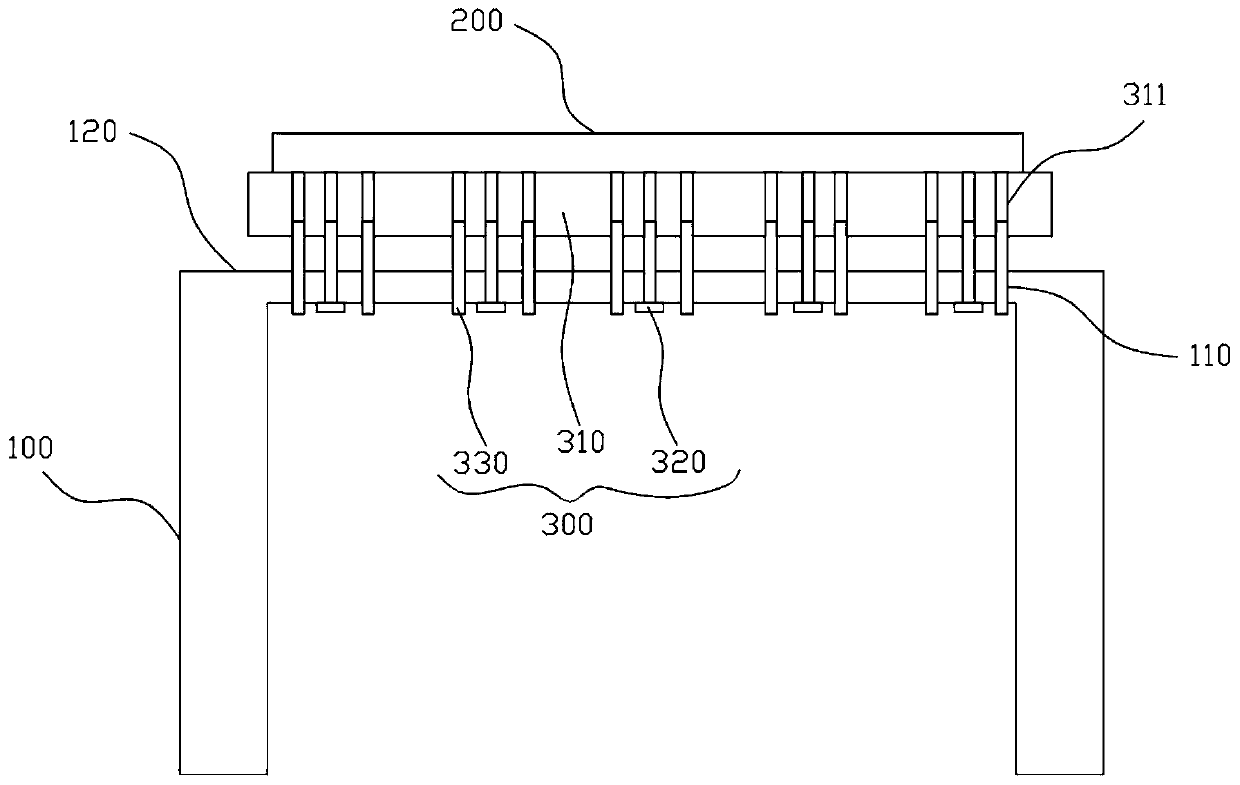

Supporting structure and riveting machine

The invention relates to the technical field of machining, in particular to a supporting structure and a riveting machine. The supporting structure is used for supporting a manipulator of the rivetingmachine, and comprises a frame body, a supporting piece and an adjusting mechanism, wherein the adjusting mechanism is arranged between the frame body and the supporting piece; the adjusting mechanism comprises a base plate connected with the supporting piece, a first adjusting piece and a second adjusting piece, wherein the first adjusting piece and the second adjusting piece are installed on the base plate and connected with the frame body correspondingly; and the first adjusting piece is used for adjusting the base plate to move towards the frame body, and the first adjusting piece is usedfor adjusting the base plate to move backwards the frame body. According to the scheme, the base plate is kept horizontal through adjusting the first adjusting piece and the second adjusting piece, so that the supporting piece is horizontal, parallelism requirements of the manipulator is met; and meanwhile, the first adjusting piece and the second adjusting piece apply force in opposite directions to the base plate, so that stability of the base plate is guaranteed.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Assembly method and assembly fixture for pitching frame component

ActiveCN111546283AAchieving Symmetry RequirementsMeet the requirements of parallelismMetal-working hand toolsRocker armIndustrial engineering

The invention discloses an assembly method and assembly fixture for a pitching frame component. The pitching frame component comprises a pitching frame, a gyroplatform, a first rocker arm and a secondrocker arm. The assembly method comprises the following steps of: firstly arranging the first rocker arm and the second rocker arm on the gyroplatform by virtue of the assembly fixture; then arranging the gyroplatform on the assembly fixture; adjusting the relative position of the rocker arms and the gyroplatform in the assembly fixture, and threshing a taper pin for positioning; disassembling the first rocker arm, the second rocker arm and the gyroplatform for cleaning; and finally loading the gyroplatform in the pitching frame, and loading the first rocker arm and the second rocker arm in the gyroplatform according to threshing holes, thereby completing assembly. Compared with a conventional assembly method, the assembly method for the pitching frame component has the advantages that bychanging the assembly reference and adjusting the assembly sequence, the assembly operation is simplified, the assembly difficulty is reduced, and the assembly accuracy and the assembly efficiency are improved.

Owner:SHANGHAI RADIO EQUIP RES INST

A kind of pitching frame component assembly method and its assembly tooling

ActiveCN111546283BAchieving Symmetry RequirementsMeet the requirements of parallelismMetal-working hand toolsEngineeringRocker arm

The invention discloses an assembly method of a pitch frame assembly and an assembly tool thereof. The pitch frame assembly includes a pitch frame, a gyro platform, a first rocker arm, and a second rocker arm. The method for assembling the pitch frame assembly provided by the present invention utilizes the assembly tool, firstly assembling the first rocker arm and the second rocker arm on the gyro platform, then loading the gyro platform into the assembly tool, and adjusting the rocker arm and the gyro platform in the assembly tool The relative position of the rocker arm and the taper pin are used for positioning, then the first rocker arm, the second rocker arm and the gyro platform are disassembled for cleaning, and finally the gyro platform is installed into the pitch frame, and the first rocker arm, the second rocker arm Load the gyro platform to complete the assembly. Compared with conventional assembly methods, the pitch frame assembly assembly method provided by the present invention simplifies assembly operations, reduces assembly difficulty, and improves assembly accuracy and assembly efficiency by changing the assembly reference and adjusting the assembly sequence.

Owner:SHANGHAI RADIO EQUIP RES INST

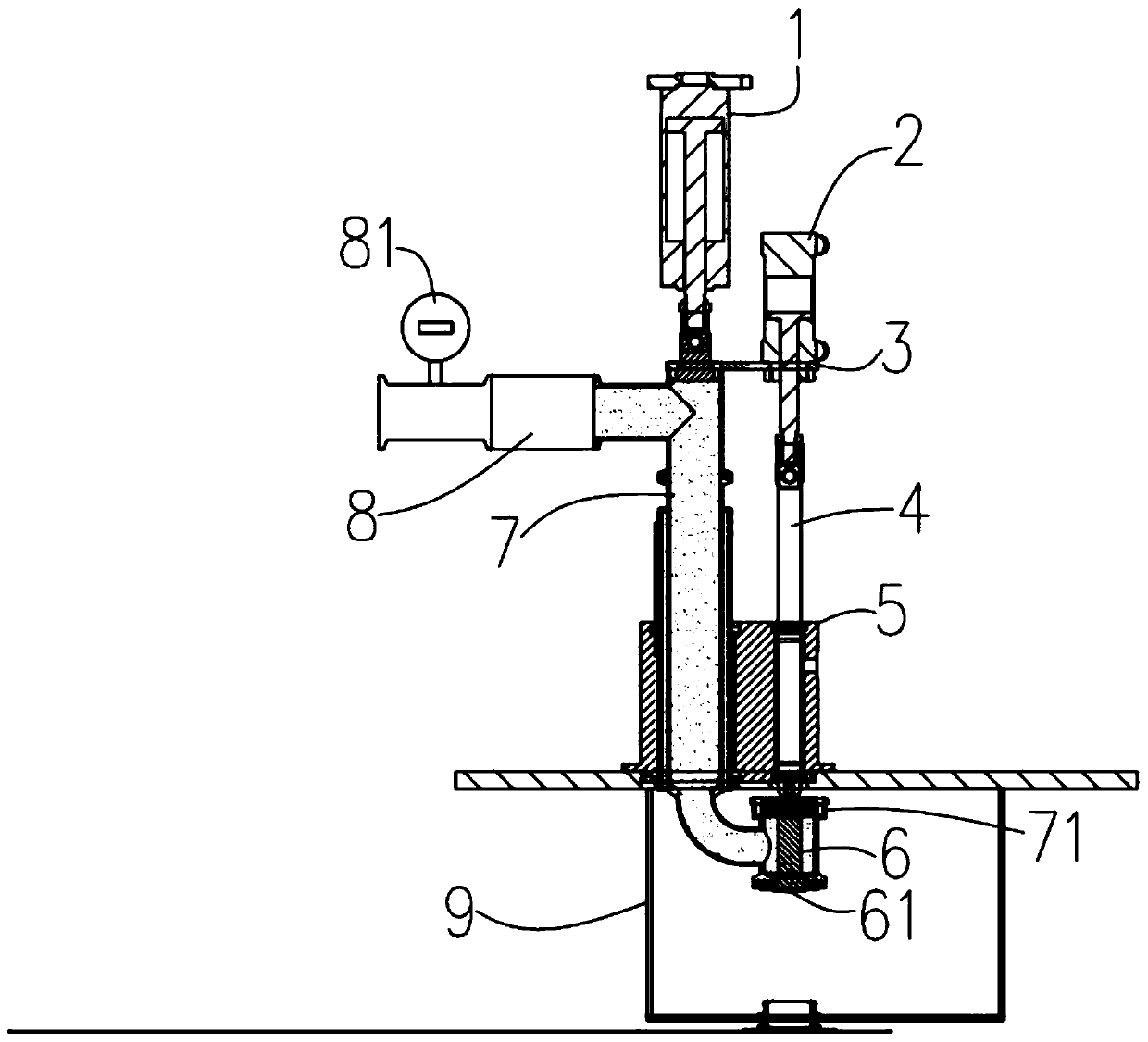

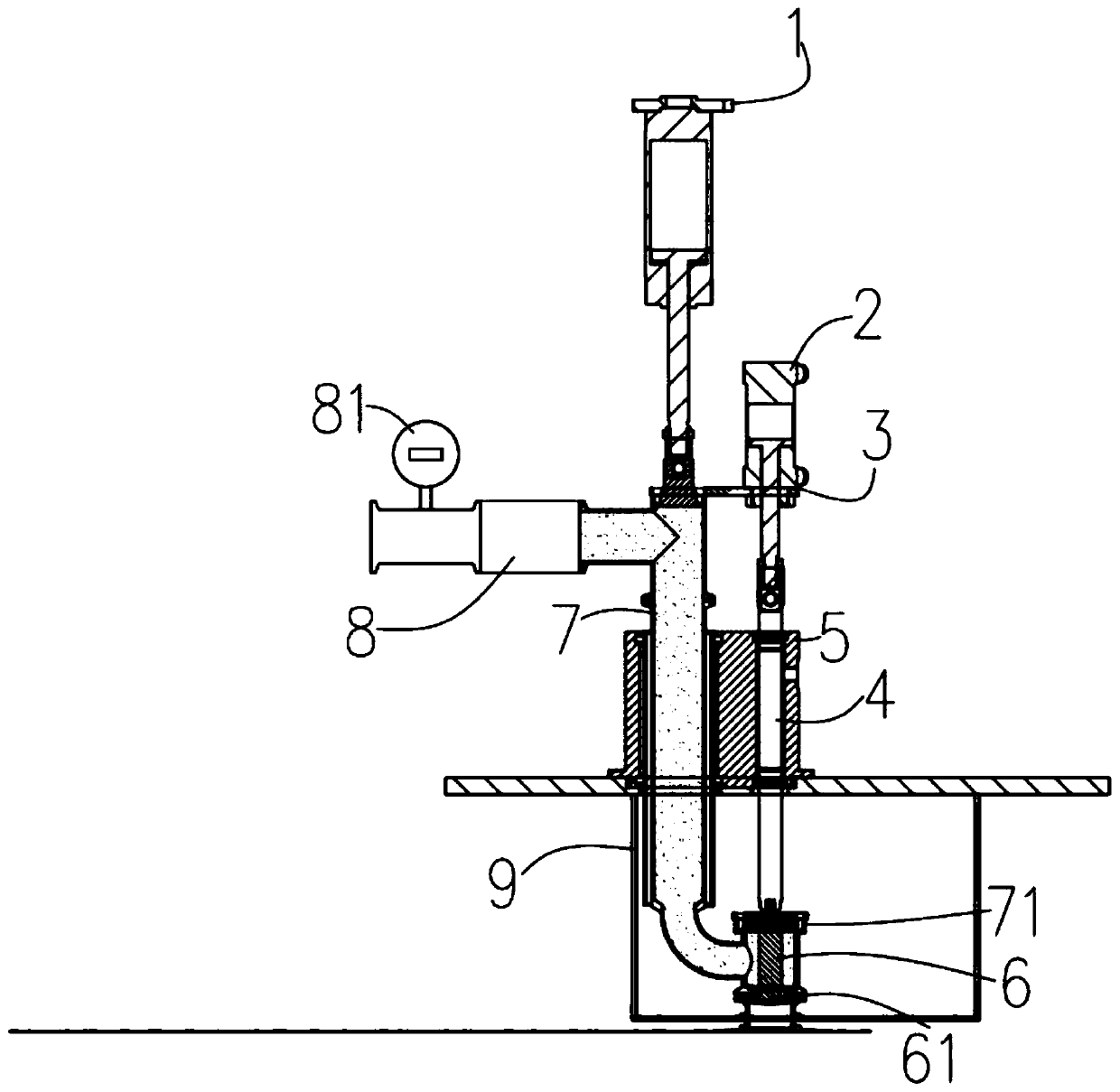

Sterile filling device

InactiveCN111348252APrecise closureLow machining accuracy requirementsPackaging machinesMachining processIndustrial engineering

The invention relates to a sterile filling device. The sterile filling device comprises a filling valve and a stop valve, wherein the filling valve is connected with a first power mechanism, the stopvalve is connected with a second power mechanism, and the filling valve is connected with a shell of the second power mechanism; the filling valve is provided with a feeding port; the filling valve communicates with a filling head matched with a bag mouth; and the stop valve comprises a first valve rod used for opening and closing the filling head, wherein the first valve rod is movably connectedwith the filling head, the first valve rod is connected with a second valve rod, and the second valve rod is matched with the second power mechanism in arrangement. Through adopting the technical scheme, machining precision requirements of the stop valve during production is lowered, so that the filling valve and the stop valve are easy to machine, and the corresponding production cost is reduced;the defect that a traditional filling valve is high in requirement for straightness in the stop valve machining process is overcome, and convenient installation is realized; and meanwhile, an effectof reducing the production cost is achieved, thereby achieving sterile filling.

Owner:广州市铭慧机械股份有限公司

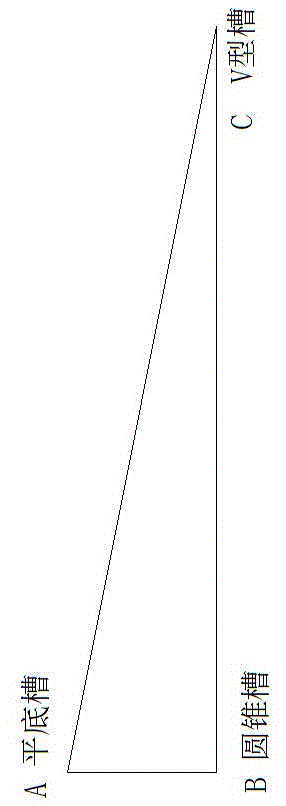

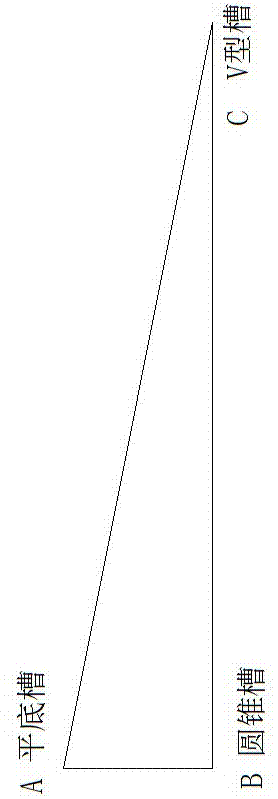

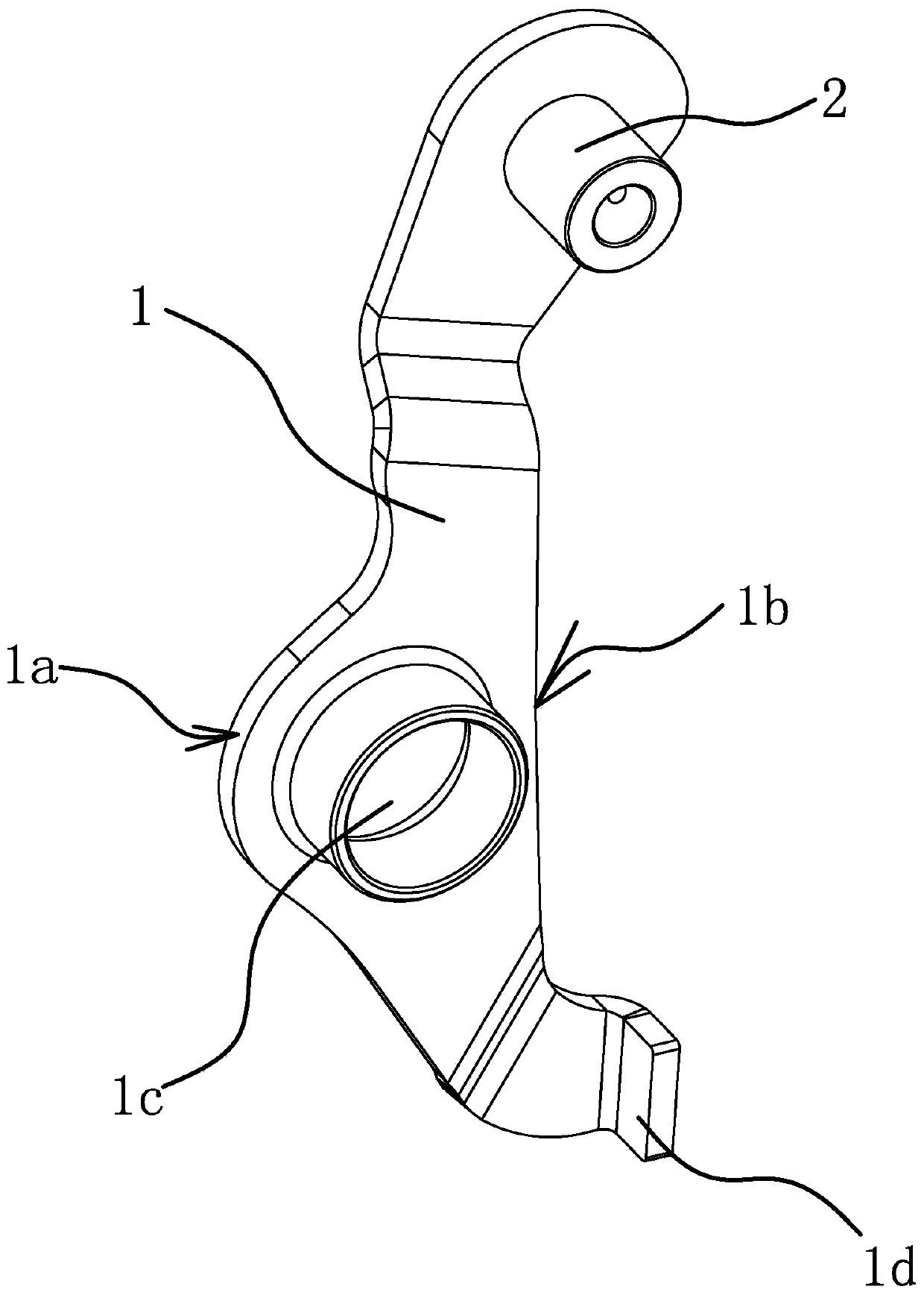

Chuck for tightening arm machining

PendingCN110814828AGuaranteed high precision processingMeet the requirements of parallelismPositioning apparatusMetal-working holdersEngineeringMachining

The invention provides a chuck for tightening arm machining, and belongs to the technical field of machinery. The problem of inconvenient mounting when shaft holes are machined with high precision issolved. The chuck includes a disc body and a clamping block slidably connected to one end of the disc body in the radial direction, a positioning block and a mounting block are further fixed to one end of the disc body, the positioning block is located on a sliding path of the clamping block, a V-shaped groove is formed in the side, facing the clamping block, of the positioning block, and the positioning block and the clamping block are arranged on the same side of the mounting block, a mounting hole is formed in the mounting block, the center line of the mounting hole is perpendicular to thedisc body, and the grooves walls on the two sides of the V-shaped groove are parallel to the center line of the mounting hole respectively. The chuck has the advantages of being high in machining accuracy, convenient to mount, simple in structure, and convenient to produce.

Owner:YUHUAN ZHONGBEN MACHINERY

Adjustment method for lifting mechanism with four lead screws to lift with high straightness in whole stroke

ActiveCN114264218AGuaranteed accuracyImprove work efficiencyGearingGear lubrication/coolingUncrewed vehicleStructural engineering

The invention provides an assembling and adjusting method for high-linearity lifting of a mechanism comprising four lead screws in the whole stroke, and solves the technical problem that safety risks exist due to the fact that an existing mechanism comprising the four lead screws does not have a quantitative means for verifying the lifting linearity in the whole stroke. According to the invention, an internal focusing telescope, a framed reticle tool and a half-load product simulation tool are utilized to assist debugging, and high-linearity lifting adjustment of a lifting mechanism containing four lead screws in a whole stroke is completed. High-straightness lifting of the lead screw is a common working mode of photoelectric products of the unmanned aerial vehicle, and on the premise that the product precision is guaranteed, the working efficiency is improved, the assembly cost is reduced, and wide application prospects are achieved.

Owner:中航洛阳光电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com