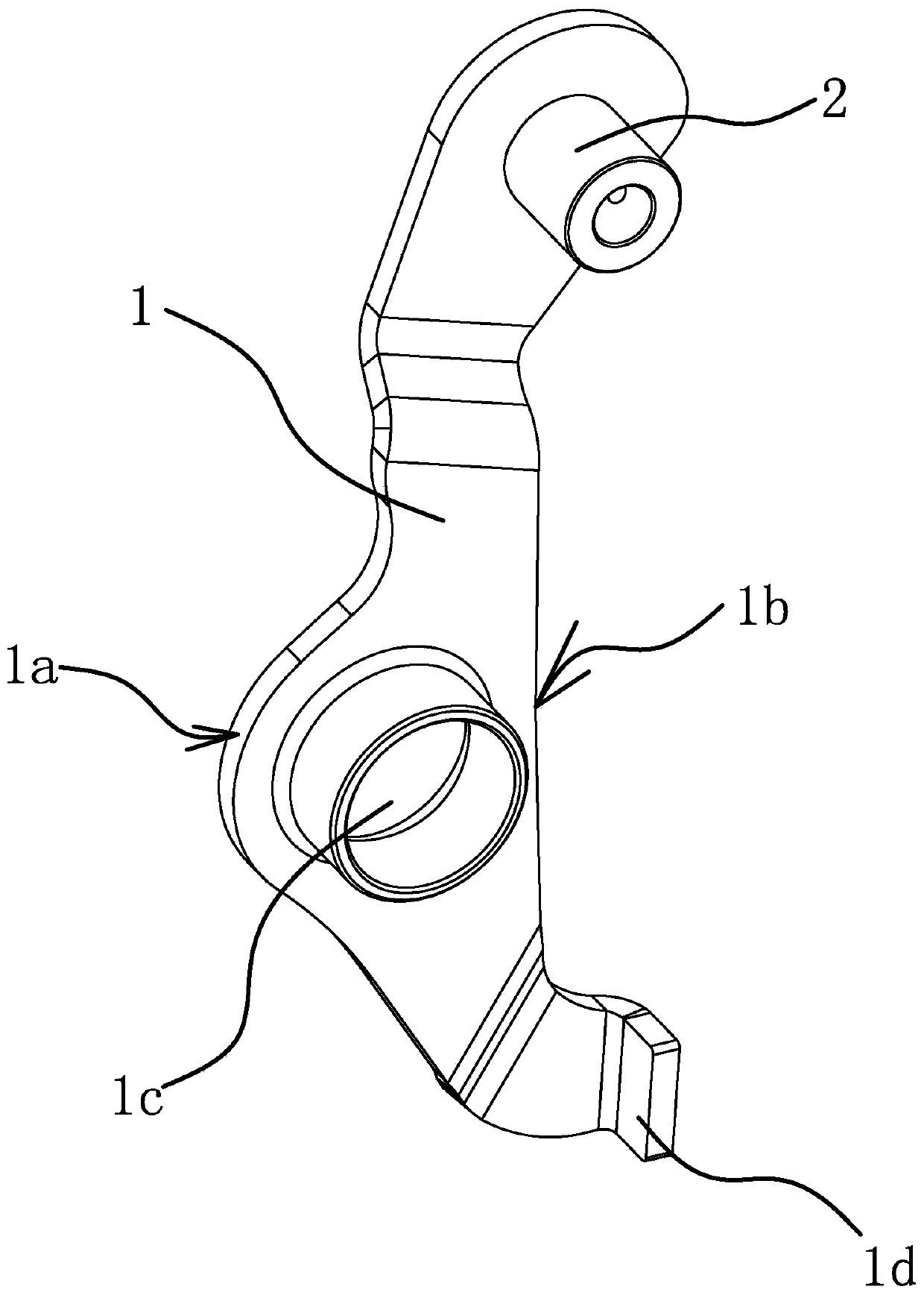

Chuck for tightening arm machining

A chuck and disk body technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inconvenient installation of high-precision machining shaft holes, and achieve the purpose of ensuring accuracy, ensuring machining accuracy, and improving machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

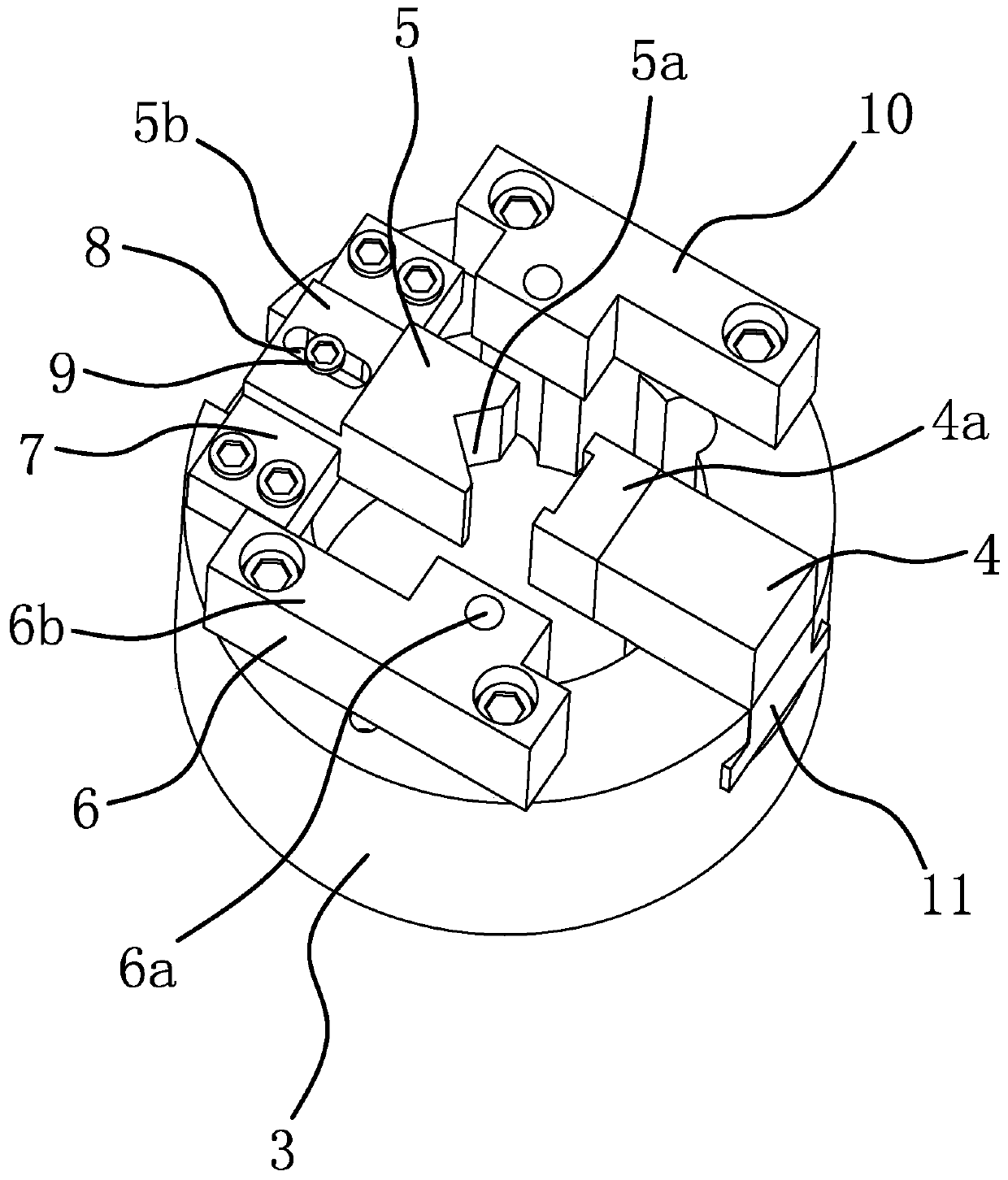

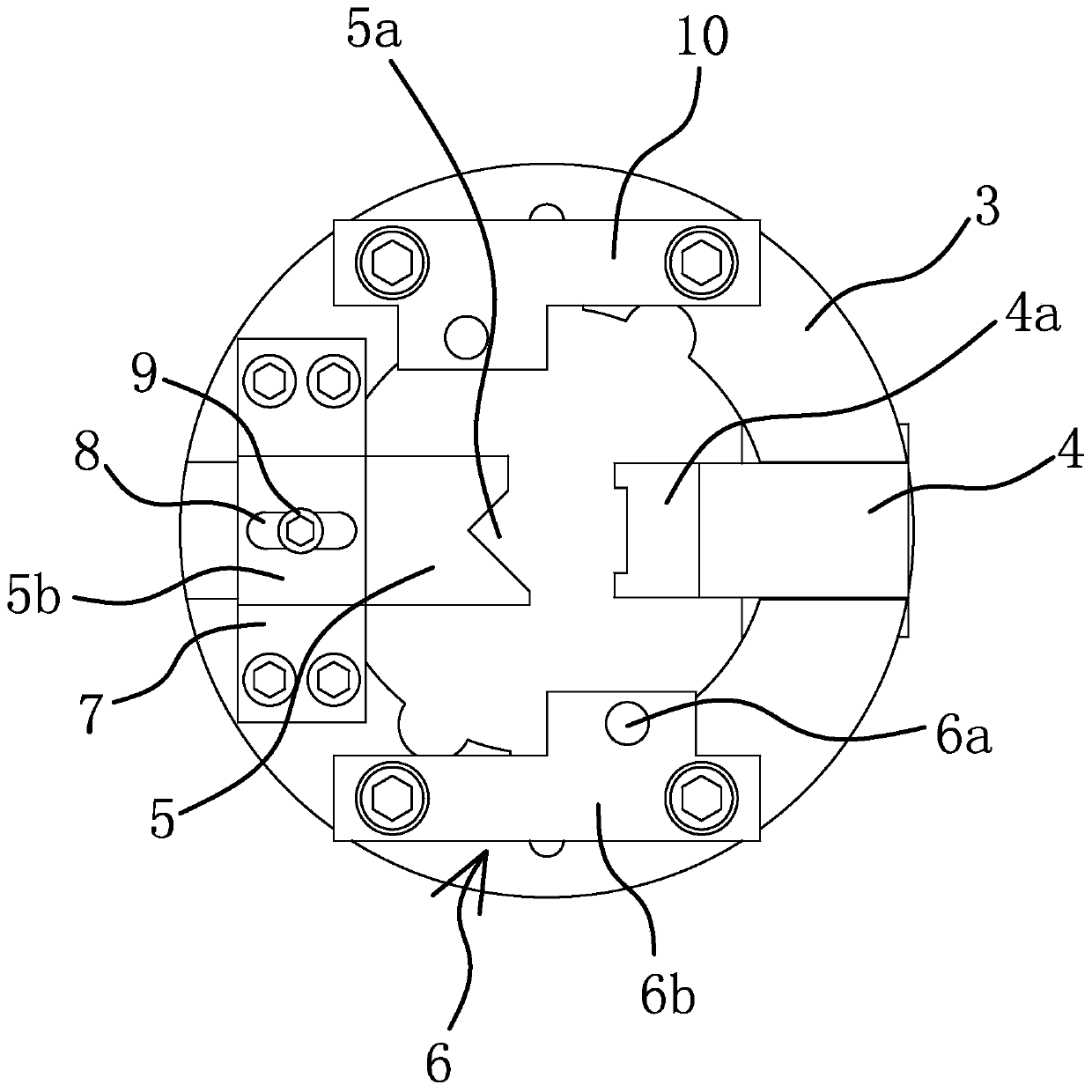

[0035] like figure 2 and image 3 As shown, a chuck for tensioning arm processing includes a disc body 3 and a clamping block 4 slidably connected to one end of the disc body 3 in the radial direction. The end of the disc body 3 is also fixed with a positioning block 5, and the positioning block 5 is located on the sliding path of the clamping block 4. Specifically, the disc body 3 is radially provided with a sliding groove, and a sliding block 11 is slidably disposed in the sliding groove, and the clamping block 4 is fixed on the sliding block 11 by fasteners to realize sliding.

[0036] like figure 2 and image 3 As shown, the end of the disc body 3 where the positioning block 5 is located is also fixed with a mounting block 6 , and the positioning block 5 and the clamping block 4 are located on the same side of the mounting block 6 . One side of the positioning block 5 facing the clamping block 4 is provided with a V-shaped groove 5a, and one side of the V-shaped groo...

Embodiment 2

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the installation block 6 is provided with a mounting column, the axis of the mounting column is perpendicular to the disc body 3, and the V-shaped groove 5a The groove walls on both sides are parallel to the axis of the mounting column. The counterweight 10 has the same shape and size as the installation block 6 , and the counterweight 10 is provided with the same protrusion as the installation post, and the counterweight 10 and the installation block 6 are centrally symmetrical.

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the clamping block 4 is made of flexible material, and the clamping part 4a is the part of the clamping block 4 facing the positioning block 5 . The flexible material can be nylon, rubber or plastic, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com