A circular linkage error measuring device with rotation angle feedback function

A technology for measuring the angle of rotation and error. It is used in measuring devices, optical devices, instruments, etc. It can solve problems such as large comprehensive errors and affect processing accuracy, and achieves improved motion error compensation efficiency, strong practicability, and high-precision processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

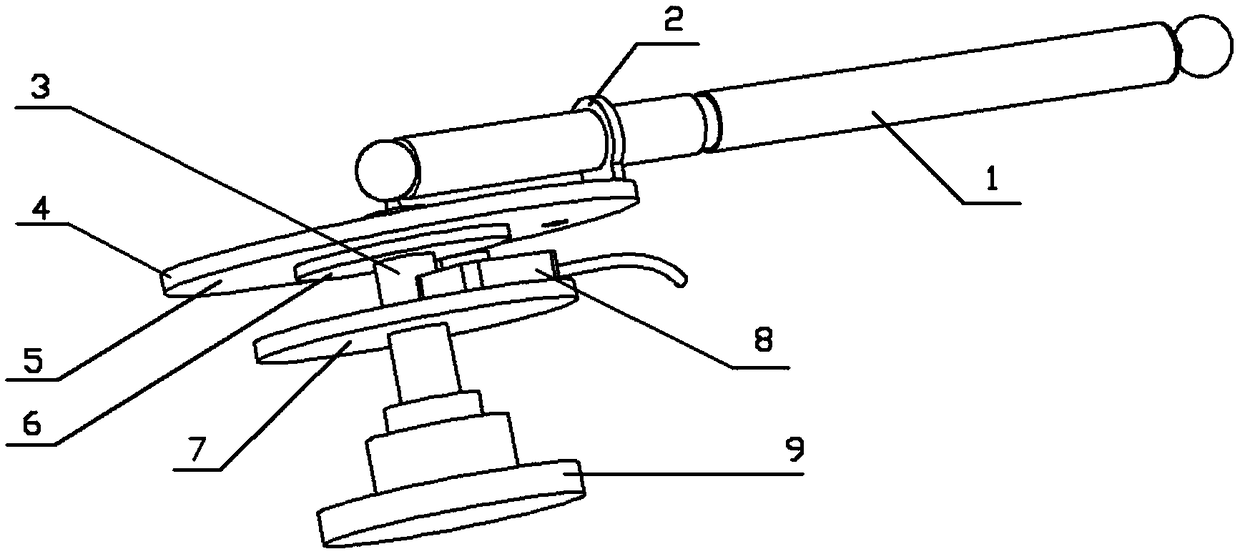

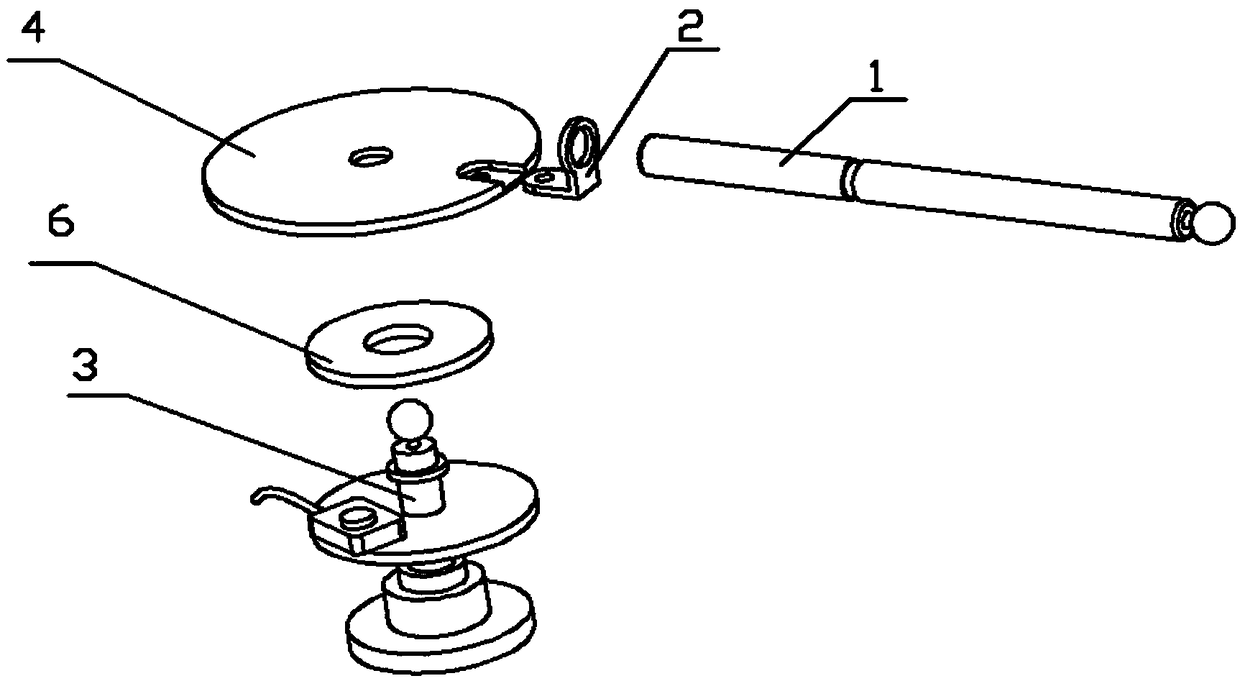

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] see figure 1 and 2 , the embodiment of the present invention is provided with base 9, fixed end ball shaft 3 and telescopic measuring rod 1; On the shoulder of fixed end ball shaft 3, a reading head support 7 is arranged, and reading head 8 is installed on the reading head support 7. One end on the shaft shoulder of the end ball shaft 3 is provided with a grating support disk 4, and the grating support disk 4 can rotate around the fixed end ball shaft 3; Disk 6; the telescopic measuring rod 1 is provided with a shaft sleeve 2, and when the moving end of the telescopic measuring rod 1 makes an arc movement, the shaft sleeve 2 can drive the disc 4 of the grating support to rotate synchronously, so that the disc 4 attached to the grating support The circular grating glass code disc 6 rotates, and a reading head 8 which is stationary relative to the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com