Folding roof bolter capable of carrying out circumferential rotation for multi-hole construction

A bolter rig and folding part technology, which is applied in the direction of installation of anchor rods, drill pipes, drill pipes, etc., can solve the problems that the anchor holes cannot be on the same straight line and cannot be satisfied, so as to improve the transition efficiency, improve the passability, The effect of improving the quality of anchor holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

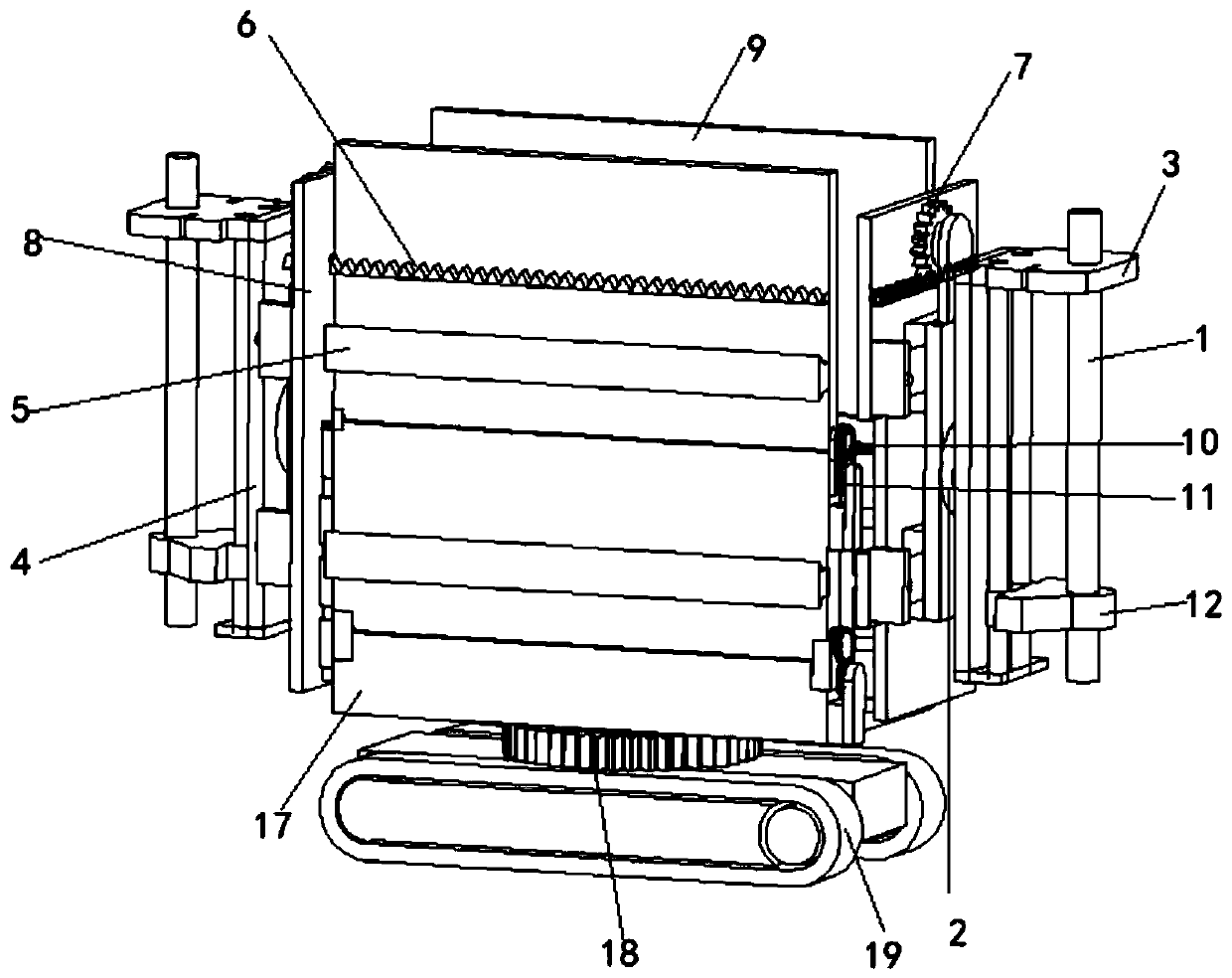

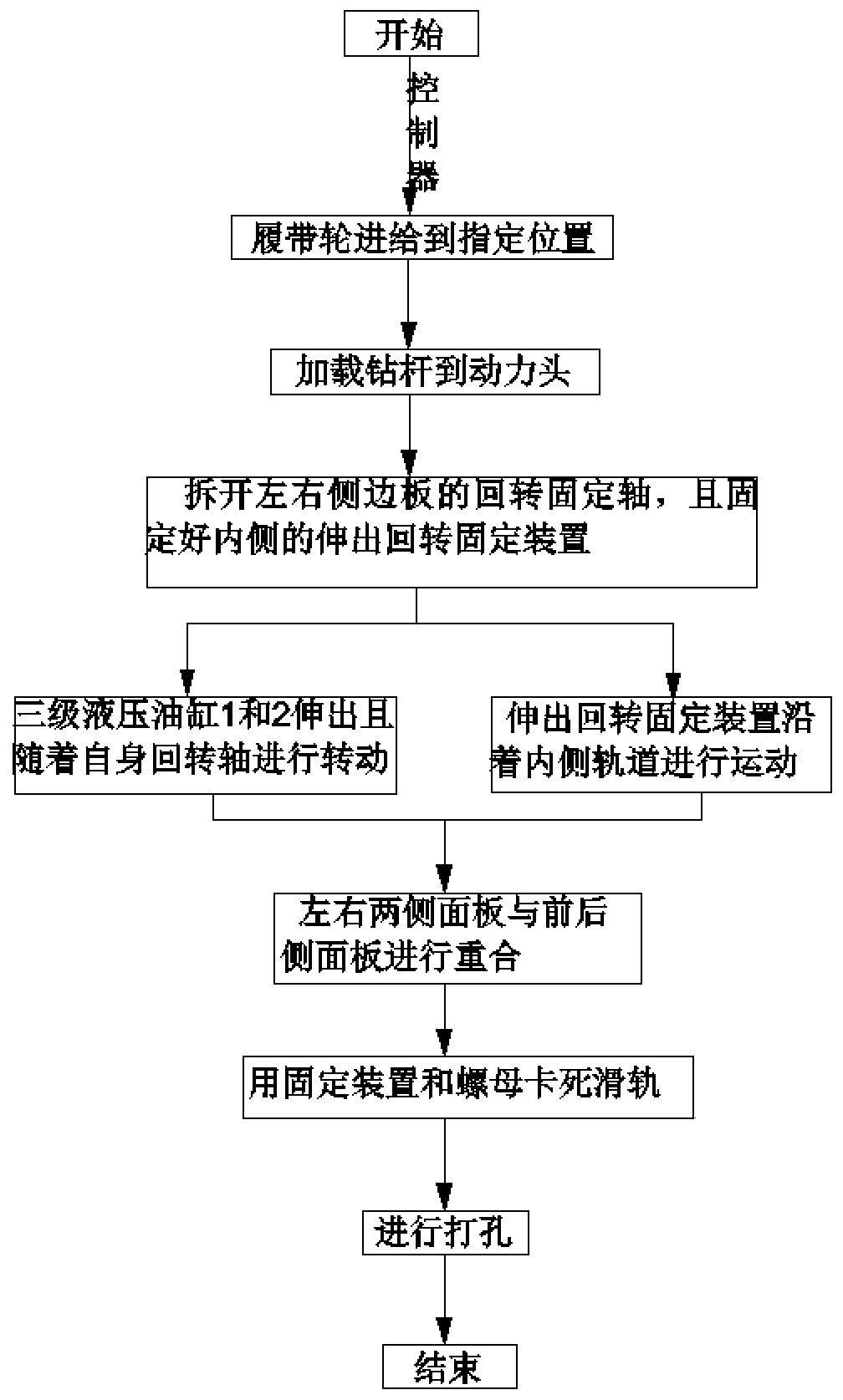

[0061] This embodiment provides a foldable rock bolt drill capable of circumferentially rotating multi-hole construction, which includes a base part, a circumferential hole-forming part and a two-stage folding part, all of which are carried on the base part, and the circumferential hole-forming part includes a second A circumferential hole-forming portion and a second circumferential hole-forming portion are located on two sides of the base portion; the two-stage folded portion includes a first two-stage folded portion and a second two-stage folded portion located on the other two sides of the base portion; The first circumferential hole-forming portion and the second circumferential hole-forming portion have the same structure and are arranged at intervals; the first two-stage folded portion and the second two-stage folded portion have the same structure and are arranged at intervals;

[0062] The first or second circumferential hole-forming portion is provided with a hole-for...

Embodiment 2

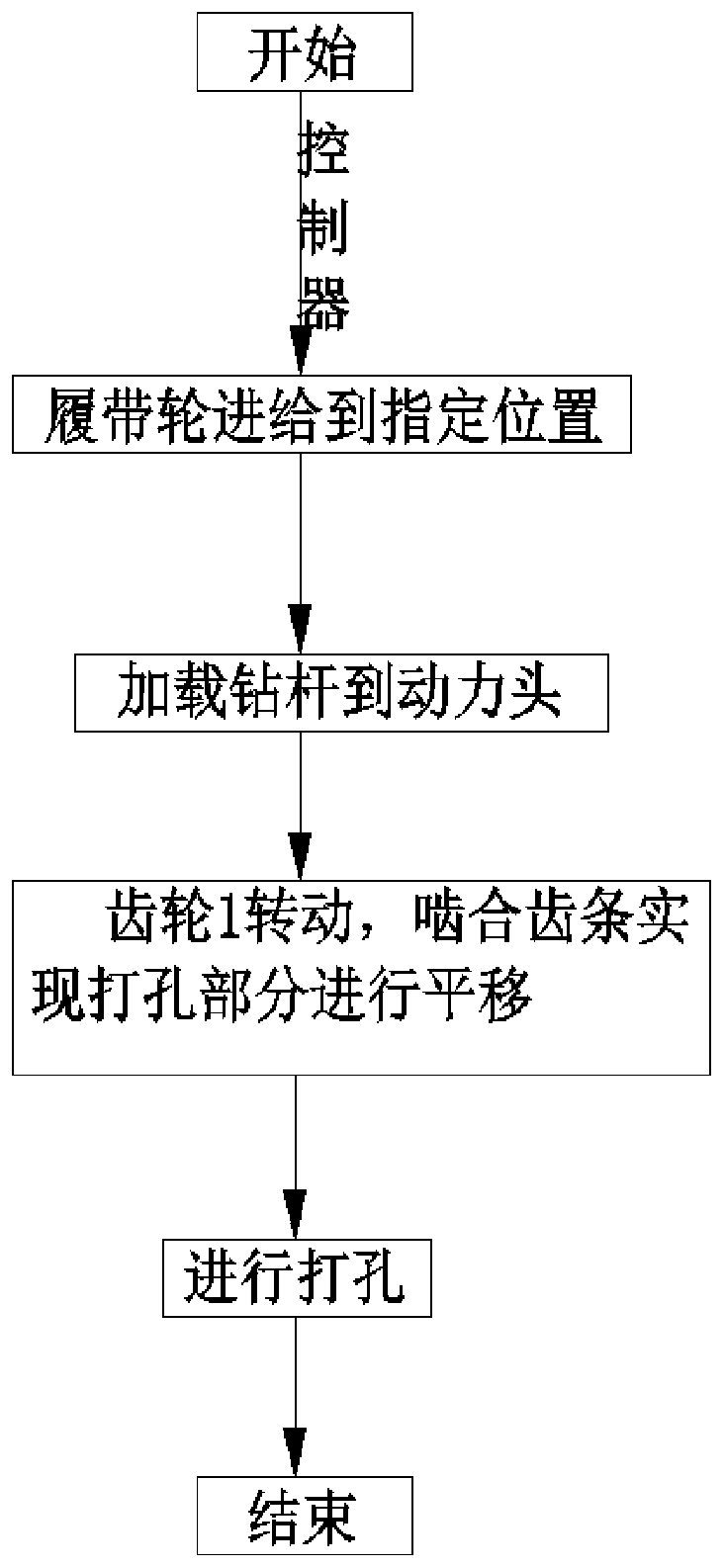

[0076] This embodiment presents a folding rock bolt rig capable of circumferentially rotating multi-hole construction, which mainly uses different types of oil cylinders, rack and pinion mechanisms, gear meshing parts, fixed pins, rotary support mechanisms, grading platforms, slide rails, etc. The structure realizes two-stage folding function and translational feeding function. This device mainly includes the following parts:

[0077] The first part is the base part. Consists of crawler wheels 19, chassis, base 17, bottom slewing support platform 18, driving gear. The crawler wheels 19 and the chassis are connected by axles and bolts; the slewing support platform 18 at the bottom is fixed on the base 17 and the chassis by bolts and nuts; The crawler wheel 19 is responsible for the translational feeding operation of the rock bolter; the slewing support platform 18 can realize the overall rotation of the upper part of the rock bolter, which is suitable for the hole forming ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com