Adjustment method for lifting mechanism with four lead screws to lift with high straightness in whole stroke

A lifting mechanism and a technology for assembling and adjusting methods, which are applied in the directions of mechanical roughness/irregularity measurement, mechanical equipment, measuring devices, etc., can solve problems such as verification of lifting straightness, safety risks, etc., so as to improve work efficiency and reduce assembly. Cost, the effect of smooth and not stuck lifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

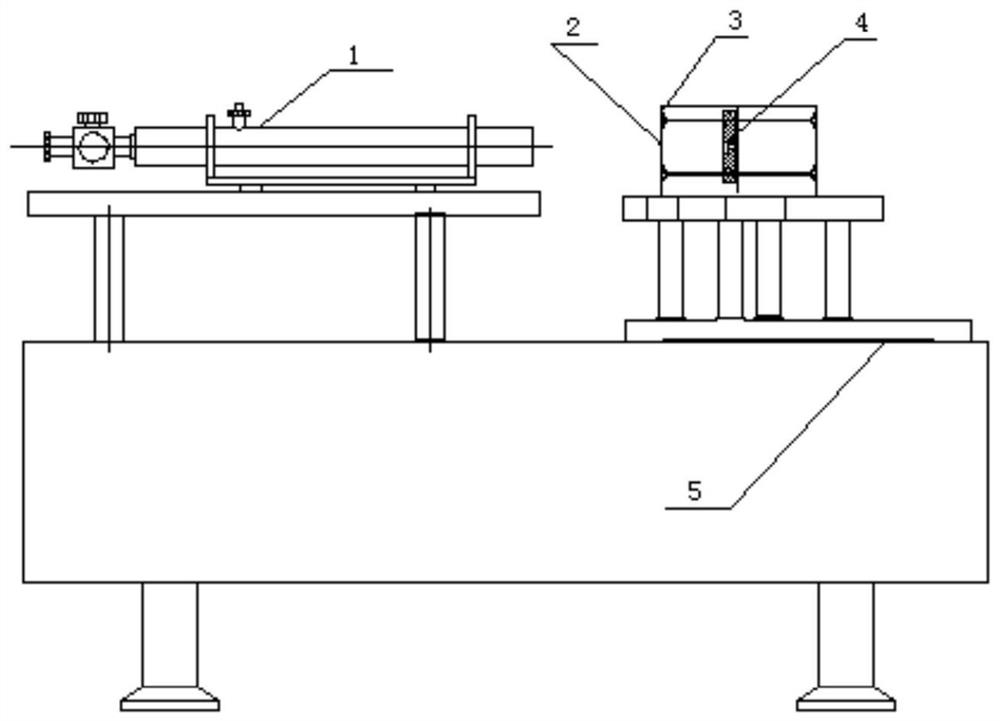

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

[0046] A method for assembling and adjusting a lifting mechanism with four lead screws in a high straightness within a full stroke, comprising the following steps:

[0047] 1) Preparation before installation

[0048] A. Lead screw preparation

[0049] a1) Check the four lead screws of the lifting mechanism to be installed to ensure that the height difference between the four lead screws is ≤0.03mm, and there are no obvious discontinuities and distortions in the tooth profile of each lead screw;

[0050] Use an altimeter to measure the height between one end face of the lead screw and the other end face. If there is a large height difference between the four lead screws, grind the two end faces of the lead screw to ensure that the height difference of the four lead screws is ≤0.03 mm.

[0051] a2) Use the detection method of the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com