Supporting structure and riveting machine

A technology of support structure and riveting machine, applied in the field of processing, can solve problems such as increasing project cost and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a support structure and a riveting machine. The support structure is used to support the three-axis manipulator of the riveting machine, which meets the parallelism requirements of the three-axis manipulator, improves machining accuracy, and reduces production costs.

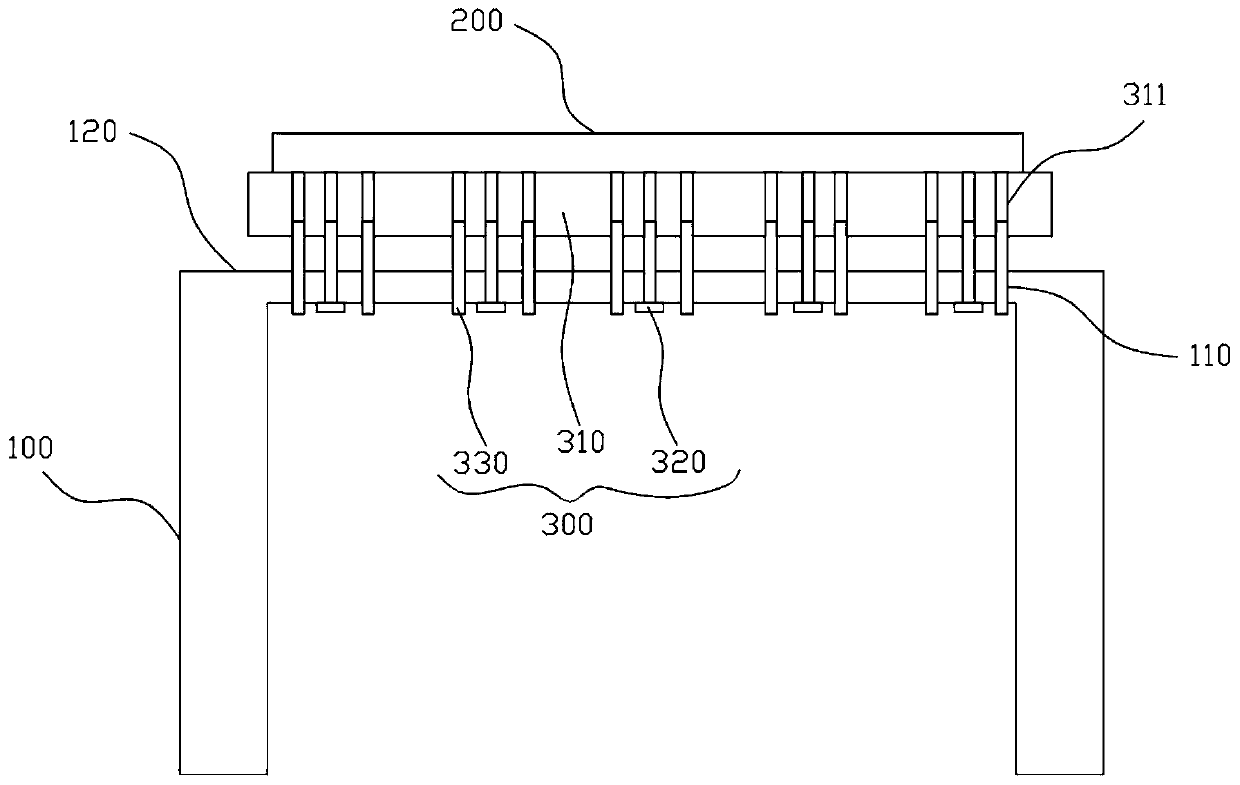

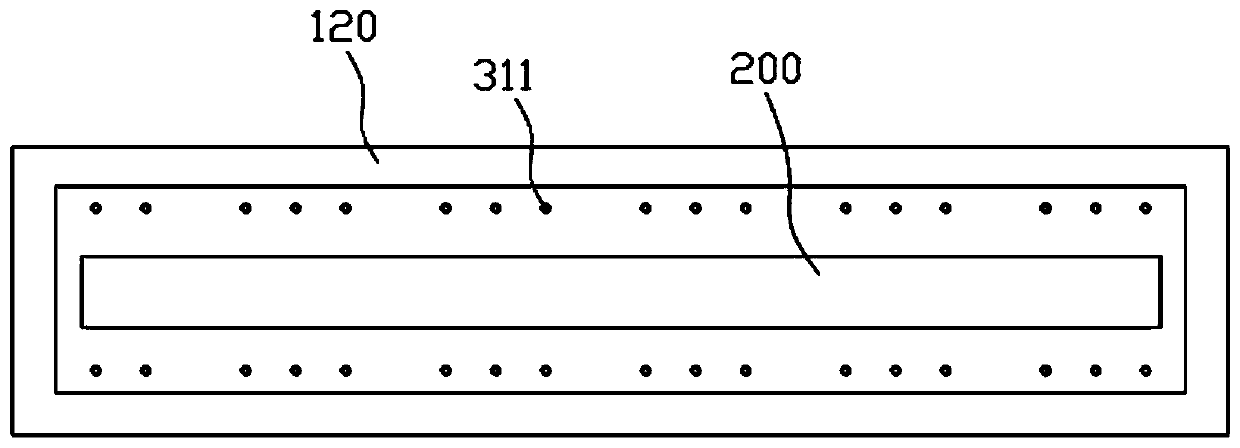

[0029] refer to figure 1 As shown in -2, the support structure includes a frame body 100, a support member 200 and an adjustment mechanism 300. The top of the frame body 100 is provided with a mounting part 120 for mounting the support part 200, and the mounting part 120 is provided with a connection hole 110; the adjustment mechanism 300 includes The base plate 310 and the first adjustment member 320 and the second adjustment member 330 installed on the base plate 310, the support member 200 is fixedly installed on the base plate 310, and the first adjustment member 320 and the second adjustment member 330 are respectively connected to the connection holes 110 of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com