A special frame for adjusting the position of the hanging beam screw to the guide rail

A beam-hanging screw, a special-purpose technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as difficult to master, labor and time-consuming, complicated operation, etc., to achieve easy mastery, reduce installation time, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment

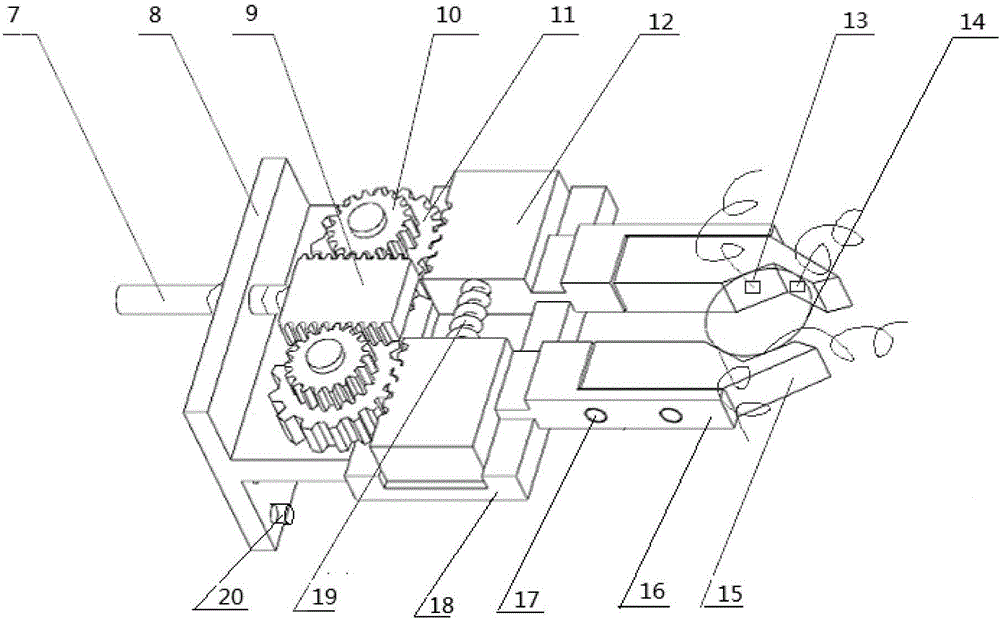

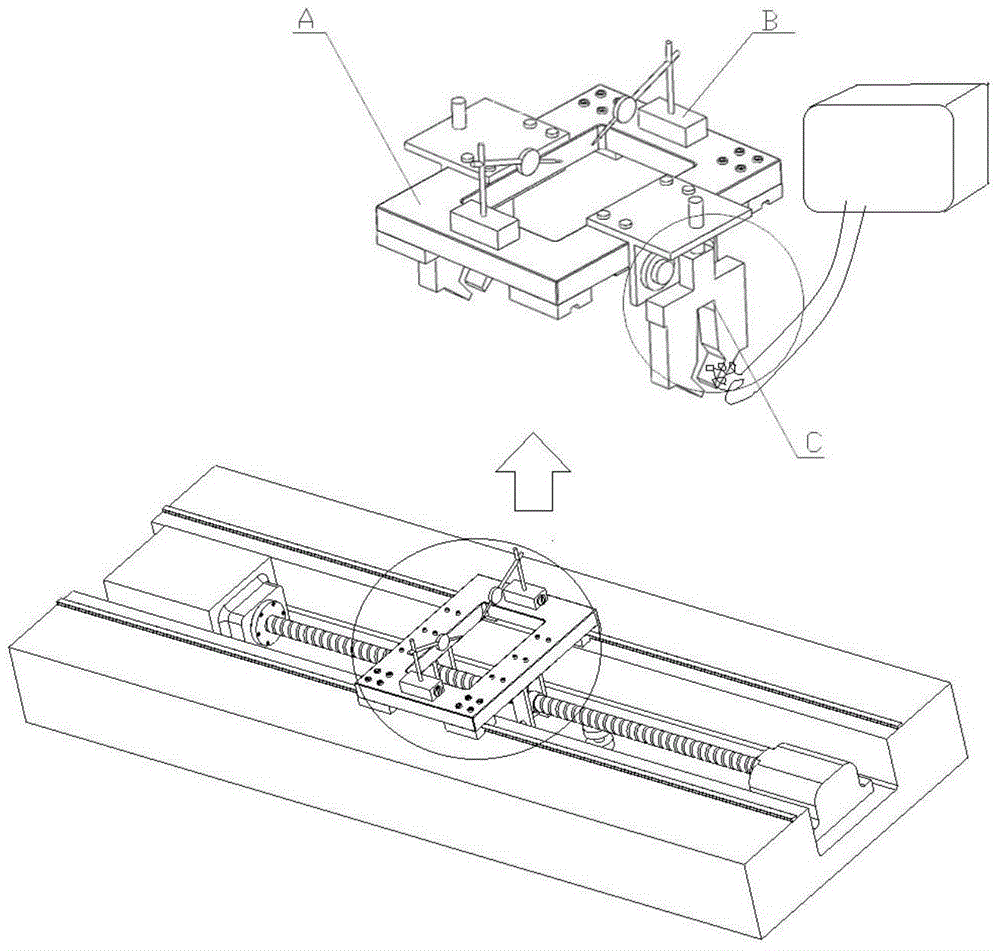

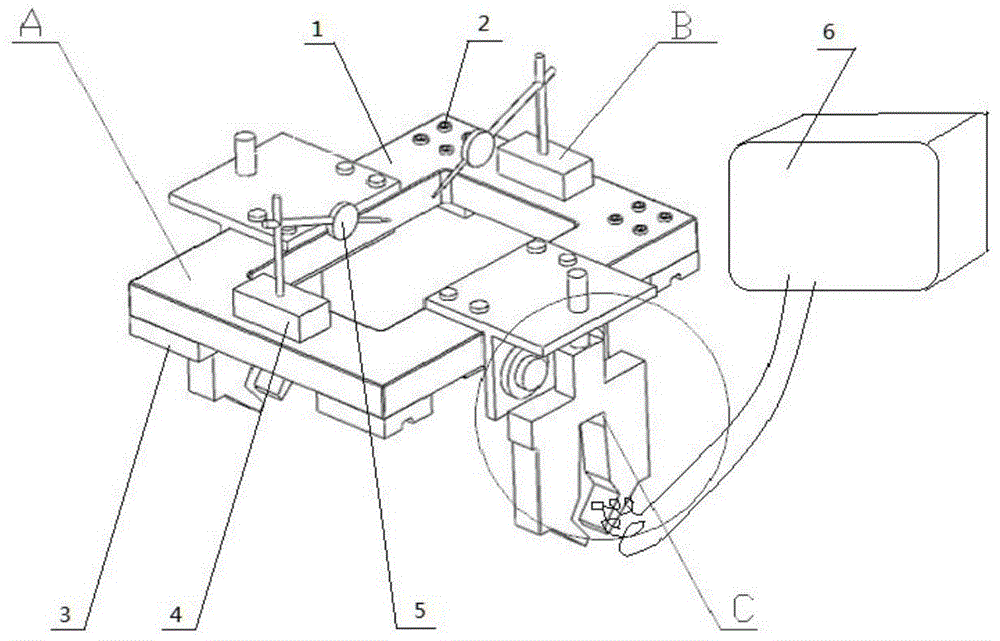

[0016] Such as Figure 1-3 As shown, the present invention provides a special frame for adjusting the position of the hanging beam screw to the guide rail. The special frame includes a frame A, a detection device B and a clamping device C. The frame A includes a return-shaped plate 1 and a guide rail slider 3 , one end of the return-form plate 1 is connected with the guide rail slide block 3 through a screw 2 , and the other end is in natural contact with the guide rail slide block 3 .

[0017] The detection device B includes two sets of micrometers 5, which are respectively located on both sides of the frame A. The both sides of back-shaped plate 1 being in guide rail position are adsorbed and equipped with magnetic gauge base 4 respectively, and micrometer 5 is fixed on the frame A by magnetic gauge base 4, and dial gauge 5 measuring positions, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com