Digital textile printer nozzle trolley structure and digital textile printer with nozzle trolley

A technology of digital printing machine and nozzle trolley, which is applied in printing, typewriter, transfer material, etc., and can solve the problems of low assembly efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

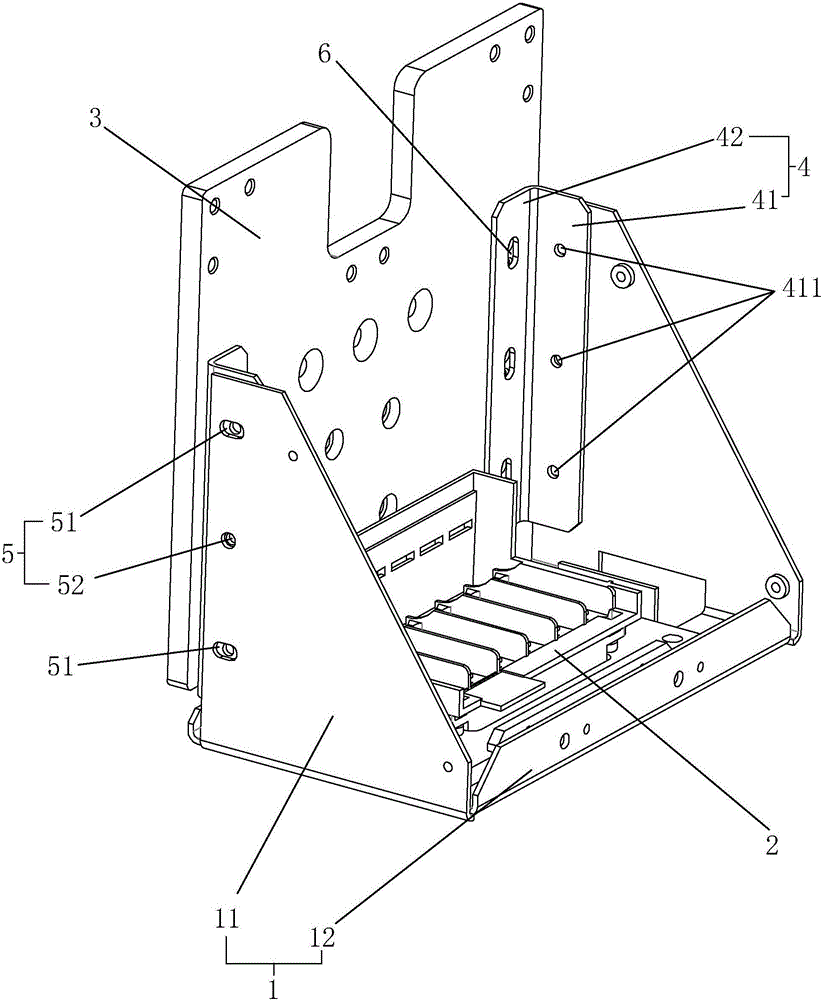

[0035] Embodiment one, such as figure 1 As shown, a nozzle trolley structure of a digital printing machine includes a back plate 3, a housing 1 and a nozzle 2, and the housing 1 further includes a bottom plate 12 and two side plates 11 integrally provided with the bottom plate 12. The casing 1 is made by bending a metal plate, and the spray head 2 is fixedly installed on the bottom plate 12 .

[0036] The side plate 11 is perpendicular to the back plate 3, an adjustment plate 4 is arranged between the side plate 11 and the back plate 3, and the adjustment plate 4 includes a first connecting plate 41 and a second connecting plate 41 arranged vertically to each other. The connecting plate 42 , the first connecting plate 41 is connected to the side plate 11 , and the second connecting plate 42 is connected to the back plate 3 .

[0037] The first connecting plate 41 is provided with at least two through holes 411 in the vertical direction. Here, two through holes 411 or three th...

Embodiment 2

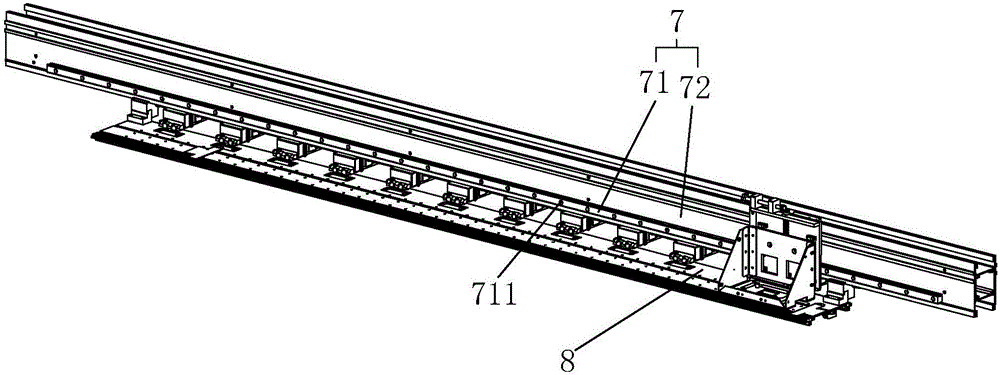

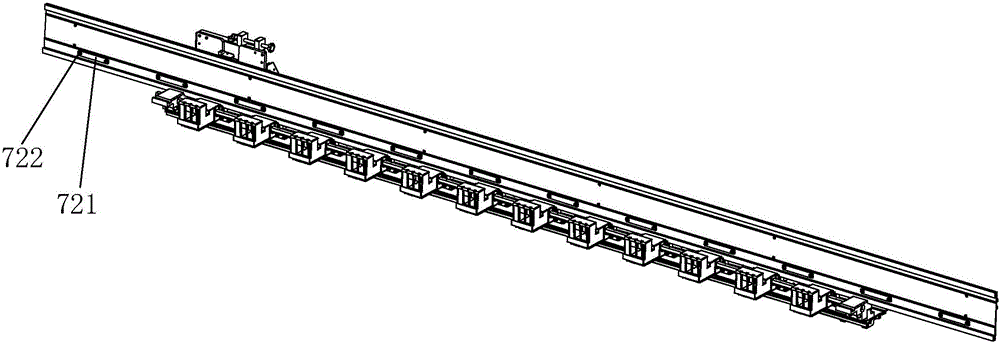

[0041] Embodiment two, such as Figure 2-Figure 3 As shown, a digital printing machine includes a printing platform 8 and a slide rail assembly 7. The slide rail assembly 7 includes a support beam 72 and a guide rail 71 connected to the support beam 72. The guide rail 71 is connected to the back Sliding connection is formed between the boards 3 through means such as sliders in the prior art.

[0042] The supporting beam 72 is provided with a plurality of first positioning holes arranged at intervals, and the first positioning holes are arranged along the transverse direction, and the third positioning hole 711 matched with the first positioning holes is arranged on the described guide rail 71, so that The support beam 72 is provided with a backing plate 721 on the other side end surface relative to the guide rail 71, the backing plate 721 is arranged in a long waist shape, and the backing plate 721 is provided with at least two second positioning holes, The scheme of two seco...

Embodiment 3

[0046] Embodiment three, such as Figure 4-Figure 5 As shown, the difference between the third embodiment and the first embodiment lies in the moving structure 6. In this embodiment, the moving structure 6 includes a lifting block 61 arranged between the back plate 3 and the second connecting plate 42, two adjusting plates 4 The second connecting plate 42 is fixed to the lifting block 61 by bolts, and the two positions of the lifting block 61 corresponding to the second connecting plate 42 are provided with a guide column 64, and the two ends of the guiding column 64 are connected to the back plate 3 are connected by setting a fixed seat 63, the fixed seat 63 is fixed on the back plate 3 by bolts, the guide column 64 is axially positioned between the two fixed seats 63, and the lifting block 61 A spring 62 is arranged between the two fixing seats 63 , and the spring 62 is sheathed in the guide column 64 .

[0047] The middle position of the lifting block 61 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com