Assembly method and assembly fixture for pitching frame component

An assembly method and a technology for assembling tooling, which are applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems of difficult size, cumbersome adjustment, and heavy operation, and achieve the effects of easy operation, accurate size positioning, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated below by describing preferred specific embodiments in detail in conjunction with the accompanying drawings.

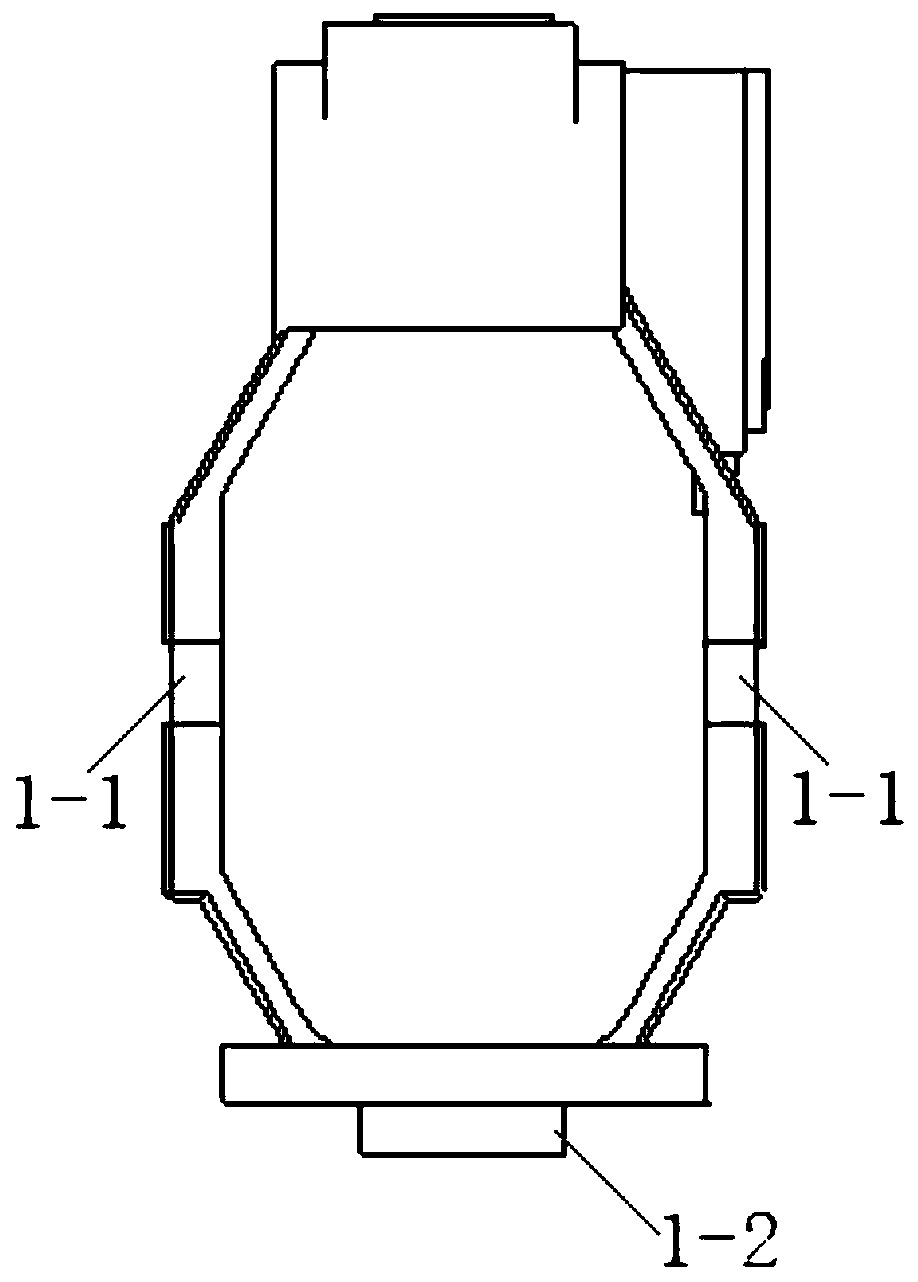

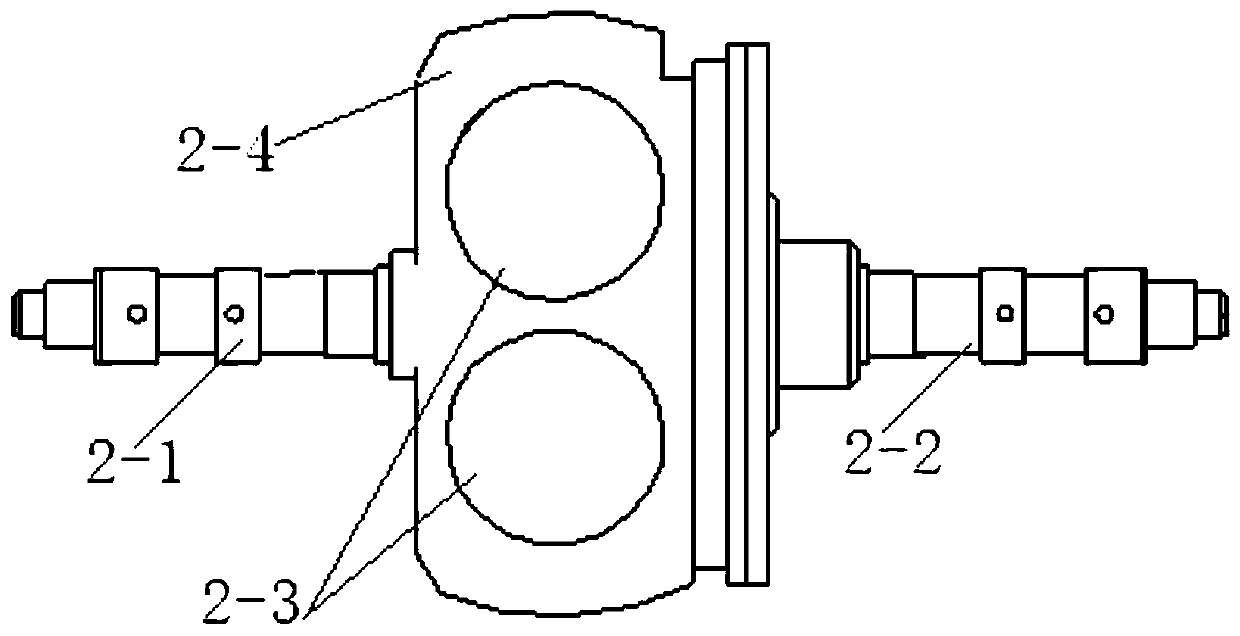

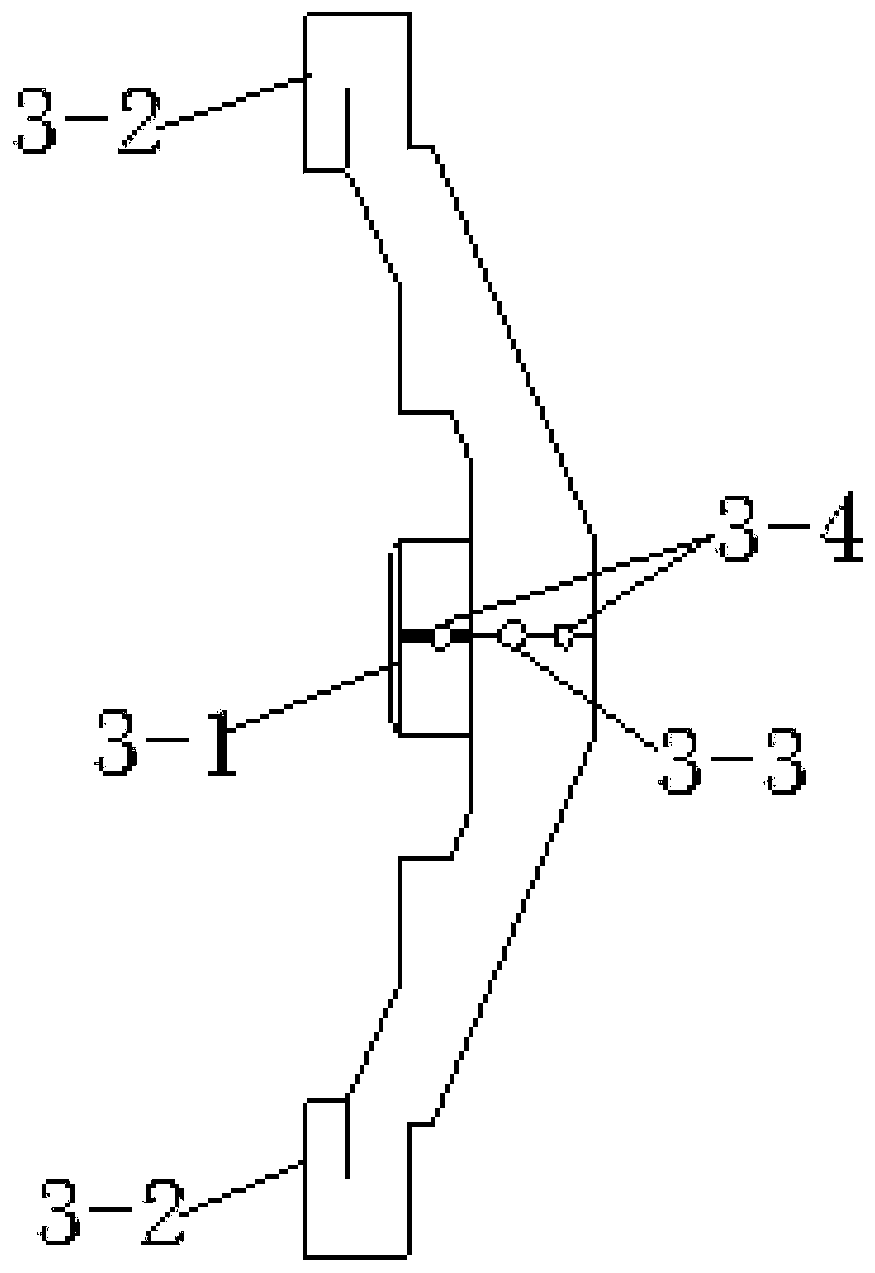

[0054] image 3 It is a schematic diagram of an assembled pitch frame assembly, which includes a pitch frame 1, a gyro platform 2, a first rocker arm 3, and a second rocker arm 4, Figure 1a is a schematic diagram of the pitch frame structure, Figure 1b Schematic diagram of the structure of the gyro platform, Figure 1c It is a structural schematic diagram of the rocker arm (including the first rocker arm and the second rocker arm).

[0055] Such as Figure 1a As shown, the frame of the pitch frame 1 is provided with a bearing hole 1-1 and an inner hole 1-2, and the pitch frame 1 carries the gyro platform 2 through the bearing hole 1-1, and the gyro platform assembled on the pitch frame 1 2 Based on the inner hole 1-2, adjust the position to meet the symmetry requirements of the gyro platform 2 on the pitch f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com