Spiral pulse gas-water composite backflushing system

A backwashing and pulse technology, which is applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of backwashing water consumption, waste of clear water, and long time required, so as to reduce the backwashing time and reduce the amount of backwashing water , the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following describes in detail in conjunction with the embodiments and accompanying drawings.

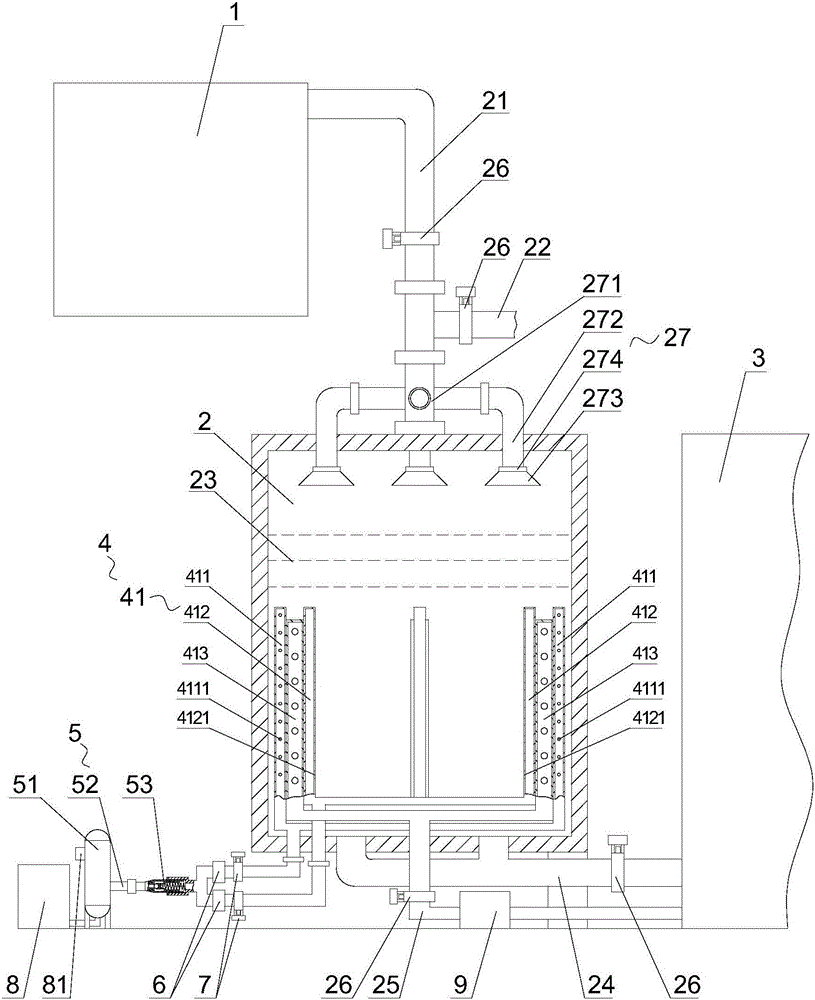

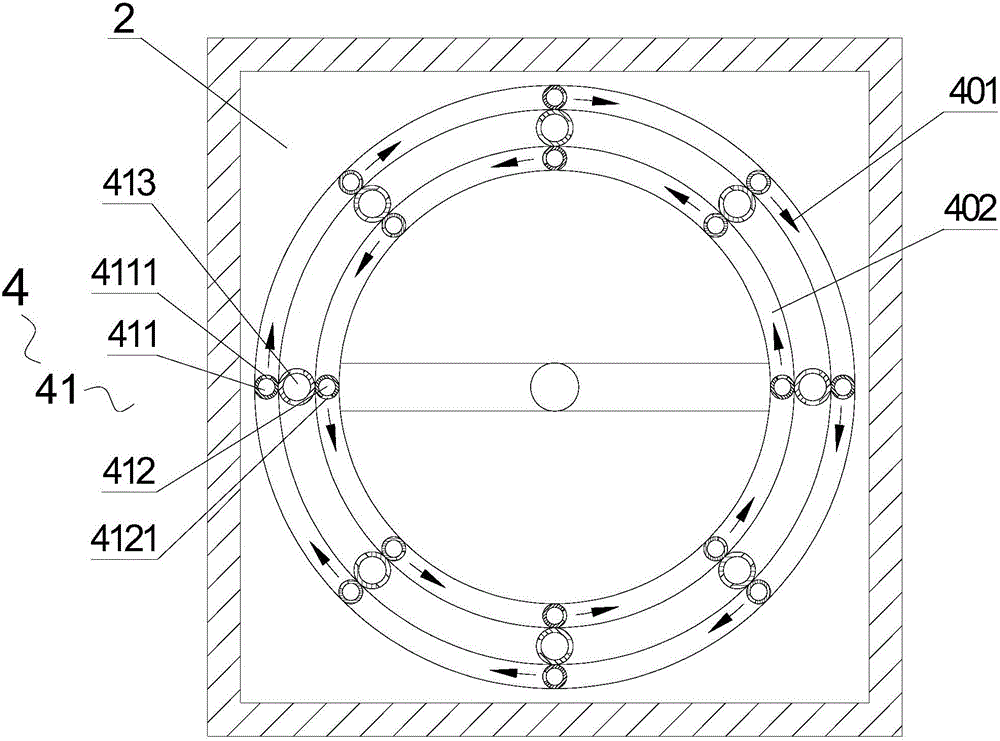

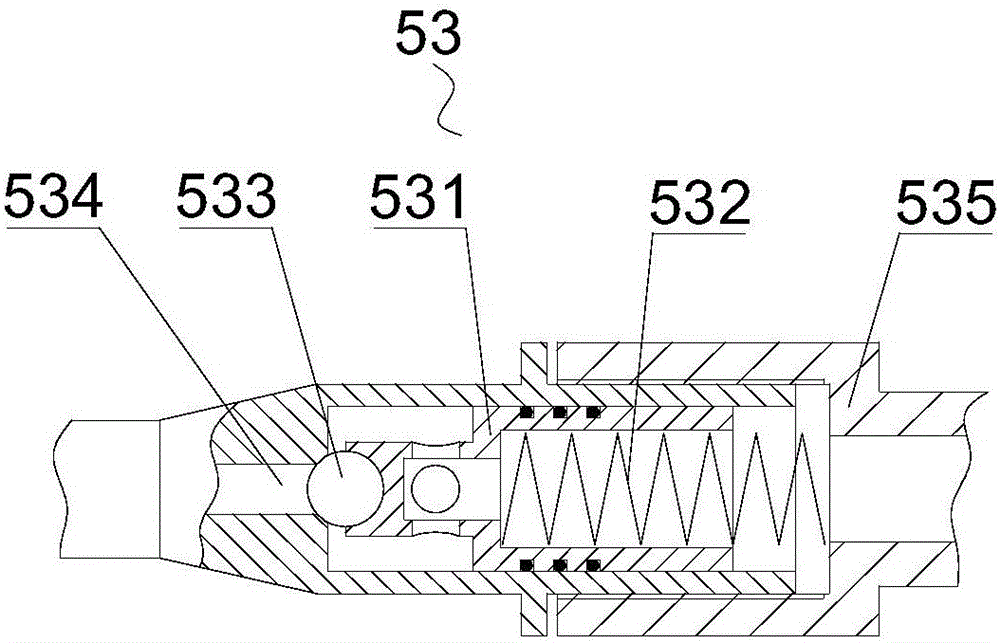

[0022] see Figure 1 to Figure 3 As shown, the spiral pulse air-water composite backwashing system of the present invention includes a filter tank 2 connected to the sedimentation tank 1, and the top of the filter tank 2 is provided with a water inlet pipe 21 connected to the high water outlet of the sedimentation tank 1. The filter The end of the water inlet pipe 21 at the top of the pool 2 is provided with a sewage pipe 22, the inside of the filter pool 2 is provided with a filter medium layer 23, and the bottom of the filter pool 2 is also provided with a clean water output pipeline 24 and a backwash pipeline connected to the clean water pool 3 25. The water inlet pipe 21, the sewage pipe 22, the clean water output pipe 24 and the backwash pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com