Method for Optimizing Backwashing Time of Membrane Bioreactor

A membrane bioreactor, backwashing technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. problems such as normal operation, to achieve the effect of saving backwashing time, increasing the daily processing capacity of the process, and increasing the daily running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0048] In this embodiment, the degree of contamination of the membrane module is judged by the transmembrane pressure difference of the membrane module.

[0049] 1. Normal process operation of membrane bioreactor

[0050] Take a water plant with a daily treatment capacity of 9,000 tons as an example. The plant adopts the MBR biofilm reactor membrane process, and the water production cycle is operated in the way of water inflow for 7 minutes and stop for 1 minute.

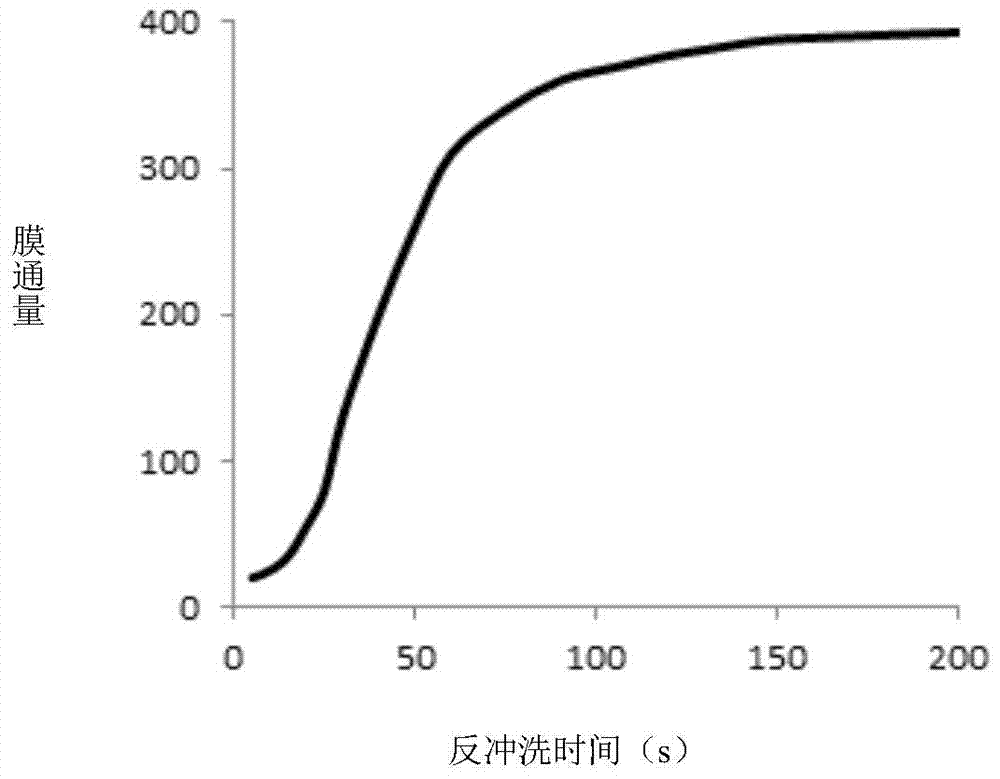

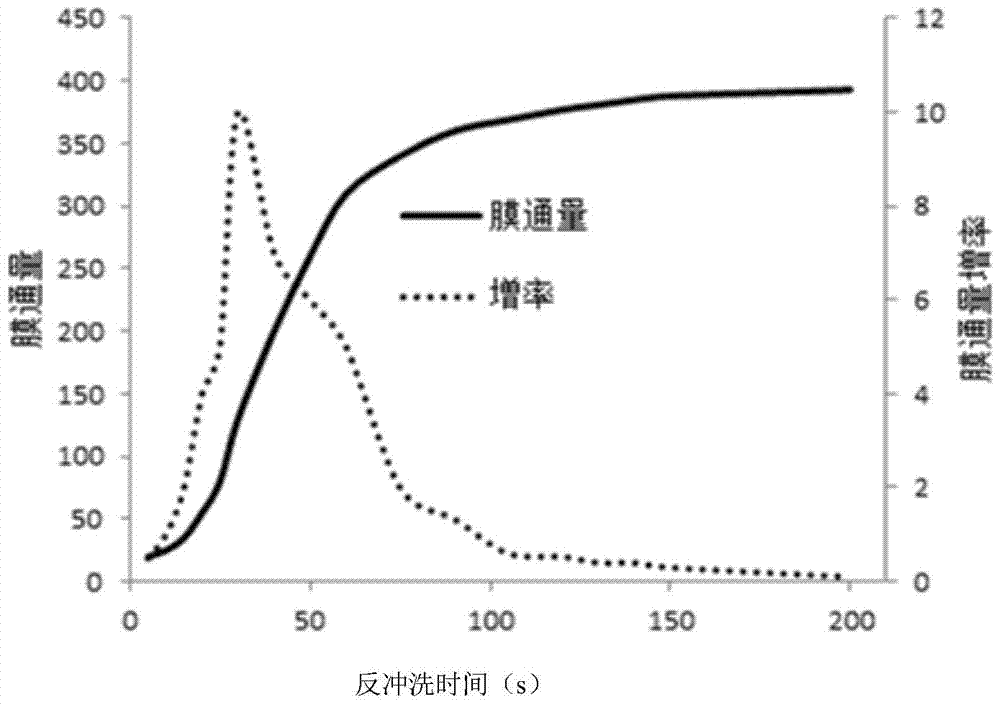

[0051] 2. Backwash time optimization

[0052] 2.1. Preset the transmembrane pressure difference of the membrane module of the membrane bioreactor, and operate the membrane bioreactor under the test process state. Whenever the transmembrane pressure difference of the membrane module reaches the preset transmembrane pressure difference, the membrane The components are backwashed at different backwashing times, and the flow value of the membrane module is recorded when different backwashing times T have elapsed. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com