Patents

Literature

52results about How to "Short backwash time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage treatment method and device thereof

InactiveCN101544434AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment by sorptionActivated carbonFlocculation

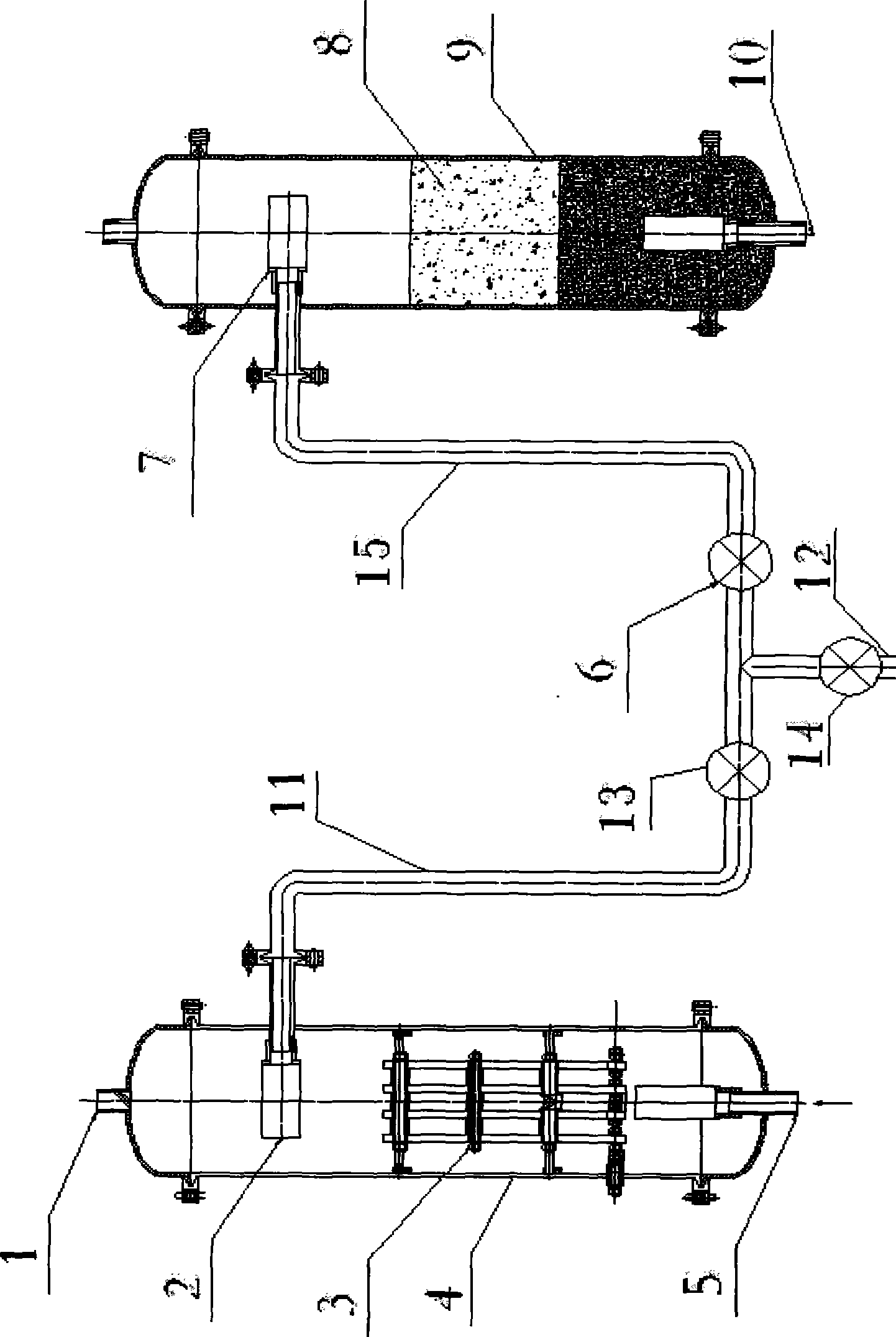

The invention relates to a sewage treatment method and a device thereof. The sewage treatment method is characterized in that the method comprises the following steps that: 1) the electric flocculation and the ozone catalytic oxidation are synchronously performed, and a flocculating agent produced by the electric flocculation and a small amount of activated carbon inside an electric flocculation vessel are a catalyst for ozone oxidation; and 2) water to be treated enters a treatment vessel body through an inlet of the treatment vessel body, is subjected to electric flocculation and ozone catalytic oxidation, is adsorbed by the activated carbon and then is drained from an outlet of the treatment vessel body. The sewage treatment device for realizing the method comprises the electric flocculation vessel body, an adsorption filtration vessel body, adsorption medium and an electrode plate, and is characterized in that the electric flocculation and the ozone catalytic oxidation are synchronously performed, COD in sewage is obviously reduced through the electric flocculation and the ozone catalytic oxidation after the sewage enters from a water inlet pipe, and then the sewage is adsorbed by the activated carbon further so as to realize high removal rate of the COD. The method and the device have good treatment effect and broad application range; and under same treatment conditions, the device is small and has less floor space.

Owner:杨高利

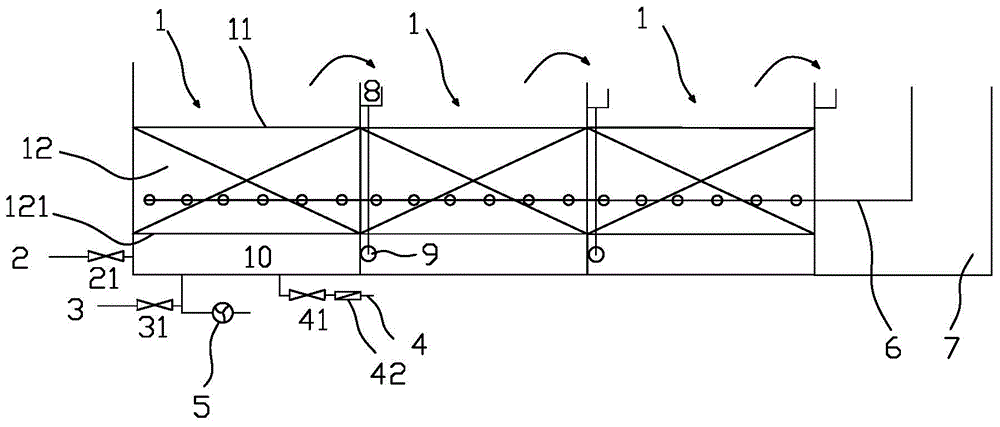

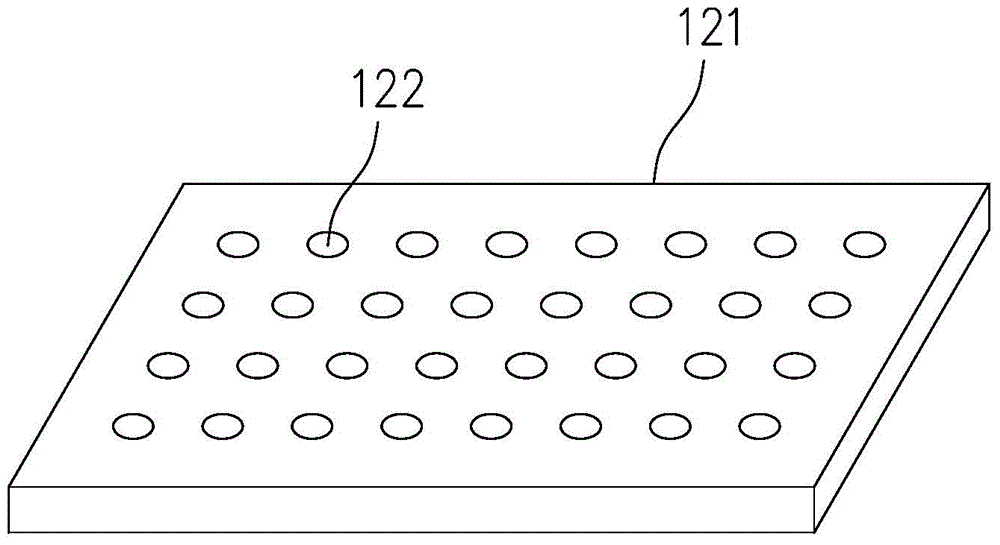

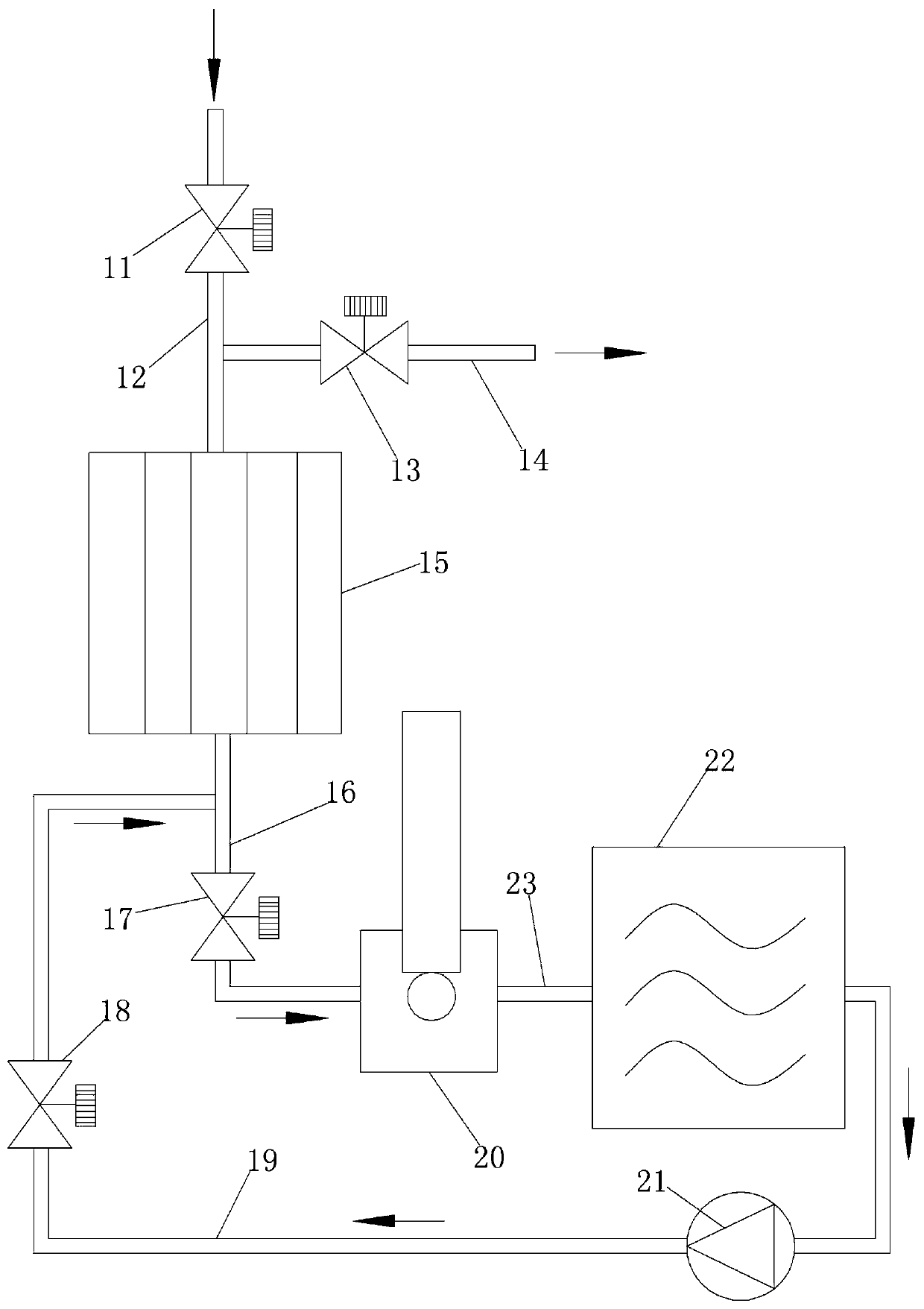

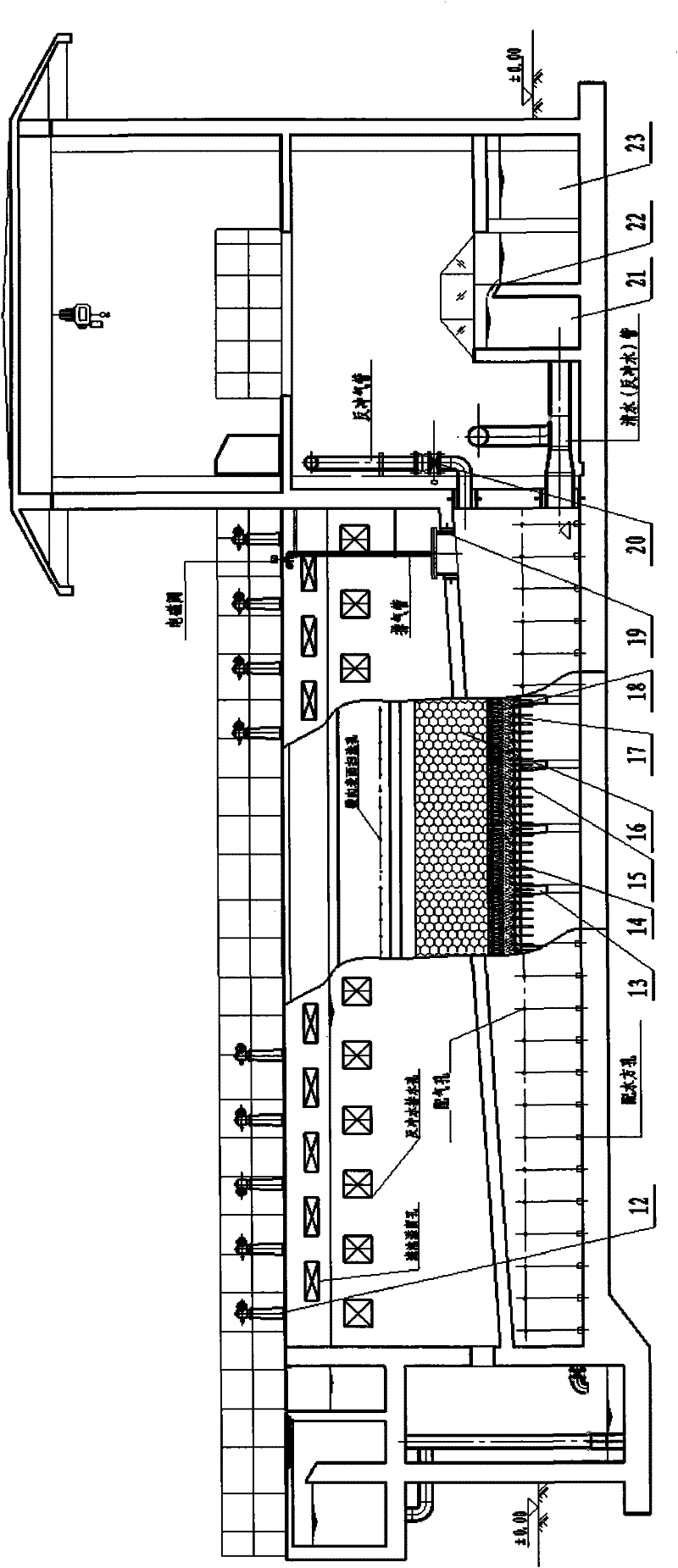

System and method for purifying sewage by powdered active carbon

ActiveCN103739104ALow running costLong continuous running timeWater treatment parameter controlSpecific water treatment objectivesActivated carbonSolenoid valve

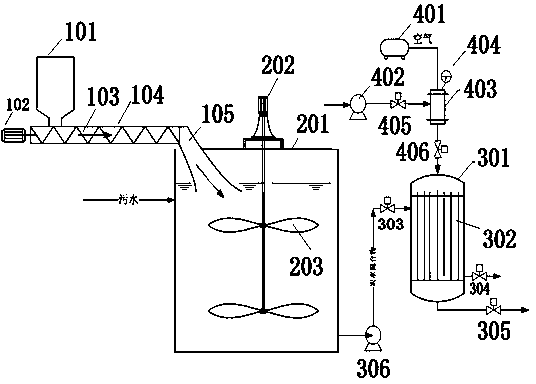

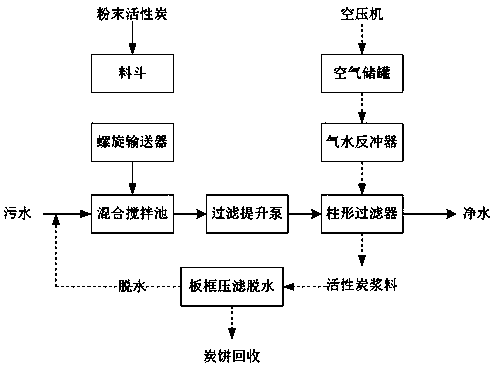

The invention discloses a system and a method for purifying sewage by powdered active carbon. The system comprises a carbon adding device, a mixing treatment device, a carbon-water separation device, a backwashing device, a control system and a power supply module. The method comprises the following steps: sufficiently mixing the powdered active carbon with the sewage and feeding a mixture into the carbon-water separation device by a feeding pump to be subjected to carbon-water separation; then detecting a water inlet and outlet pressure difference of the carbon-water separation device according to a pressure controller; automatically starting the backwashing device to carry out backwashing on a hollow micro-pore filtering pipe; and finally, closing the backwashing device and opening a coal slurry outlet solenoid valve; discharging the coal slurry; and activating after dehydrating and drying. The system and the method disclosed by the invention can be used for purifying the sewage by using the powdered active carbon; equipment is simple and easy to operate and low in operation cost; the separated powdered active carbon is intensively recycled; the continuous operation time of the equipment is long, the backwashing time is short and the efficiency is high.

Owner:HUBEI JUNJI WATER TREATMENT

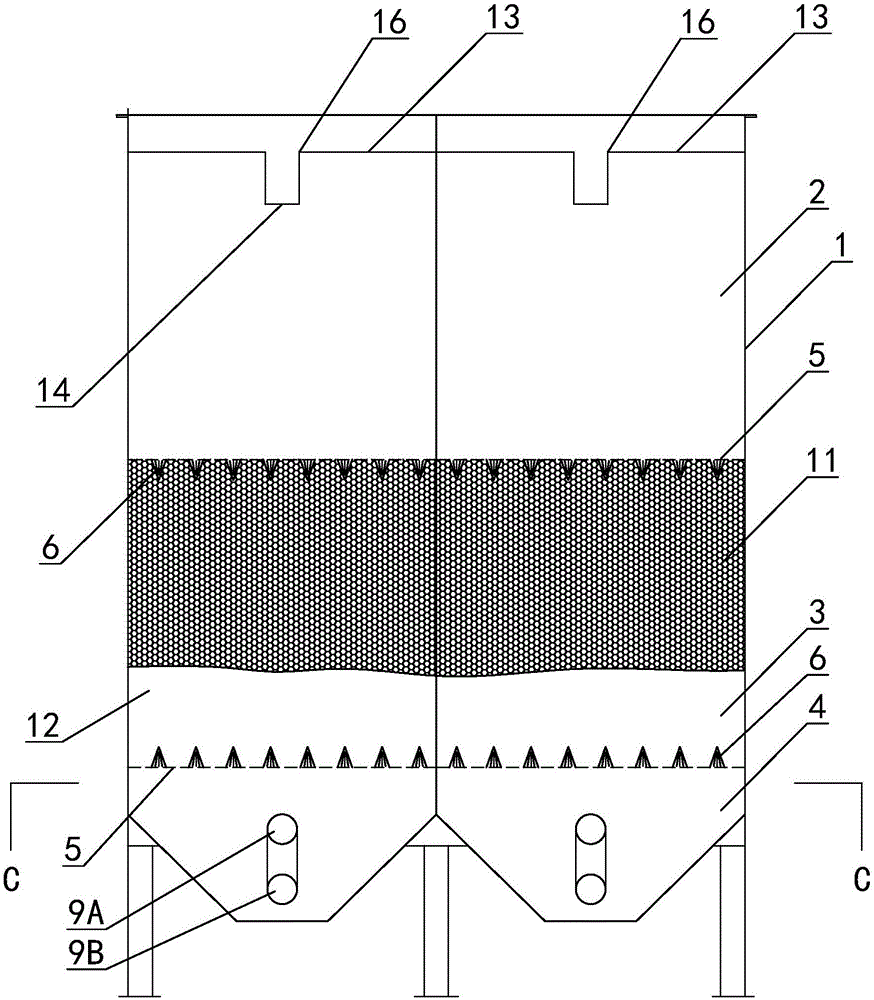

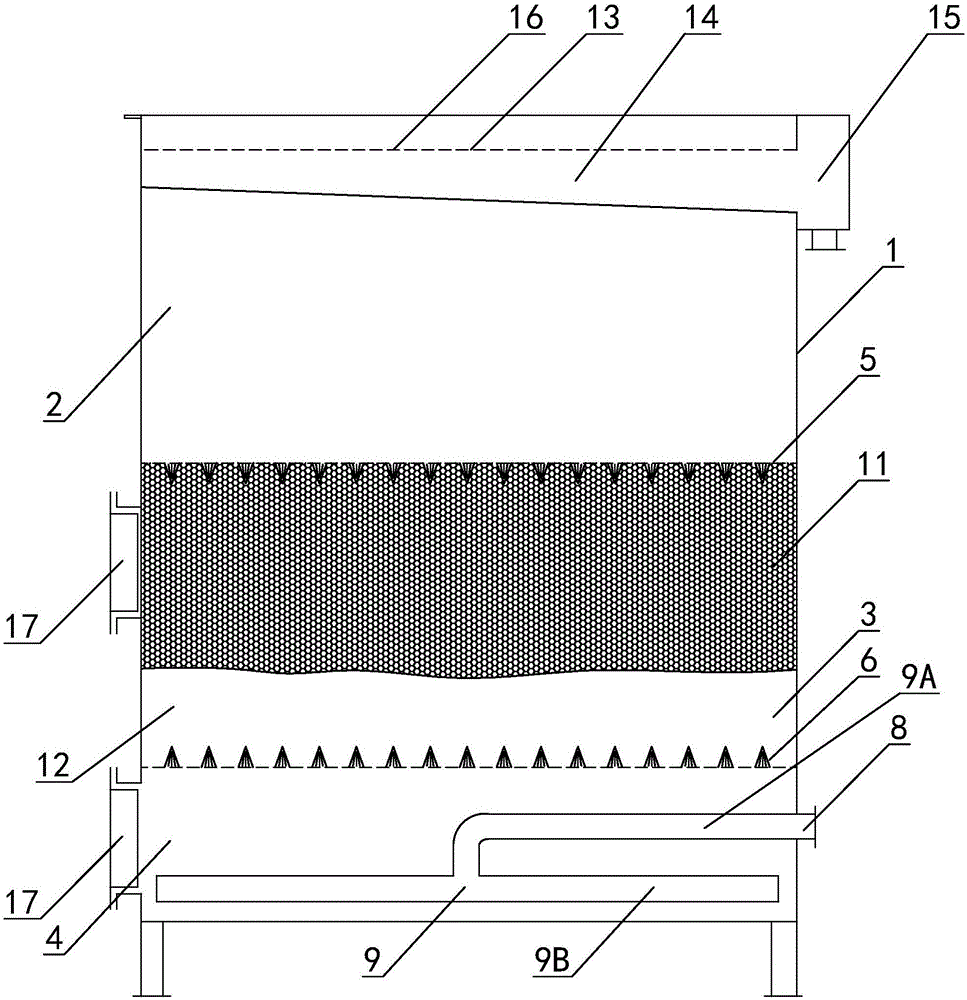

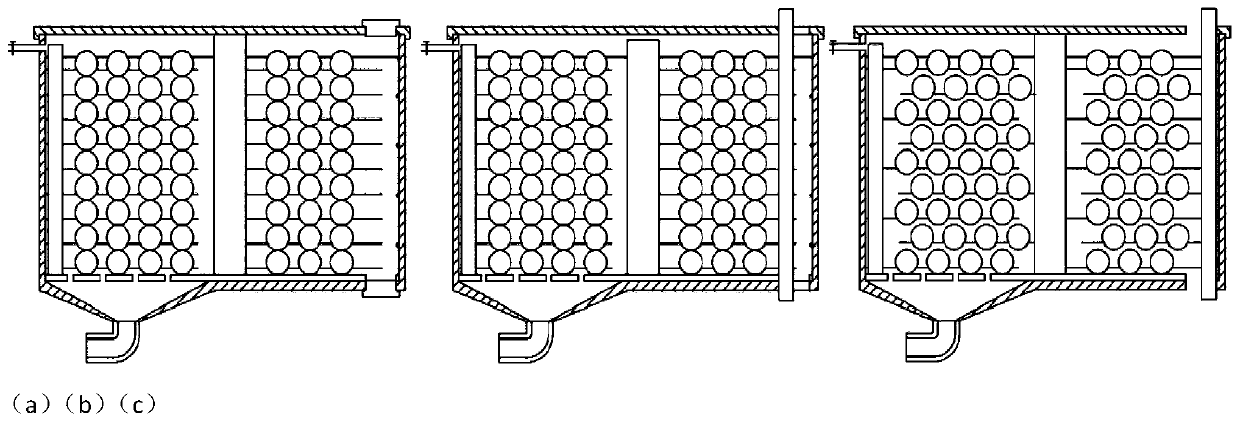

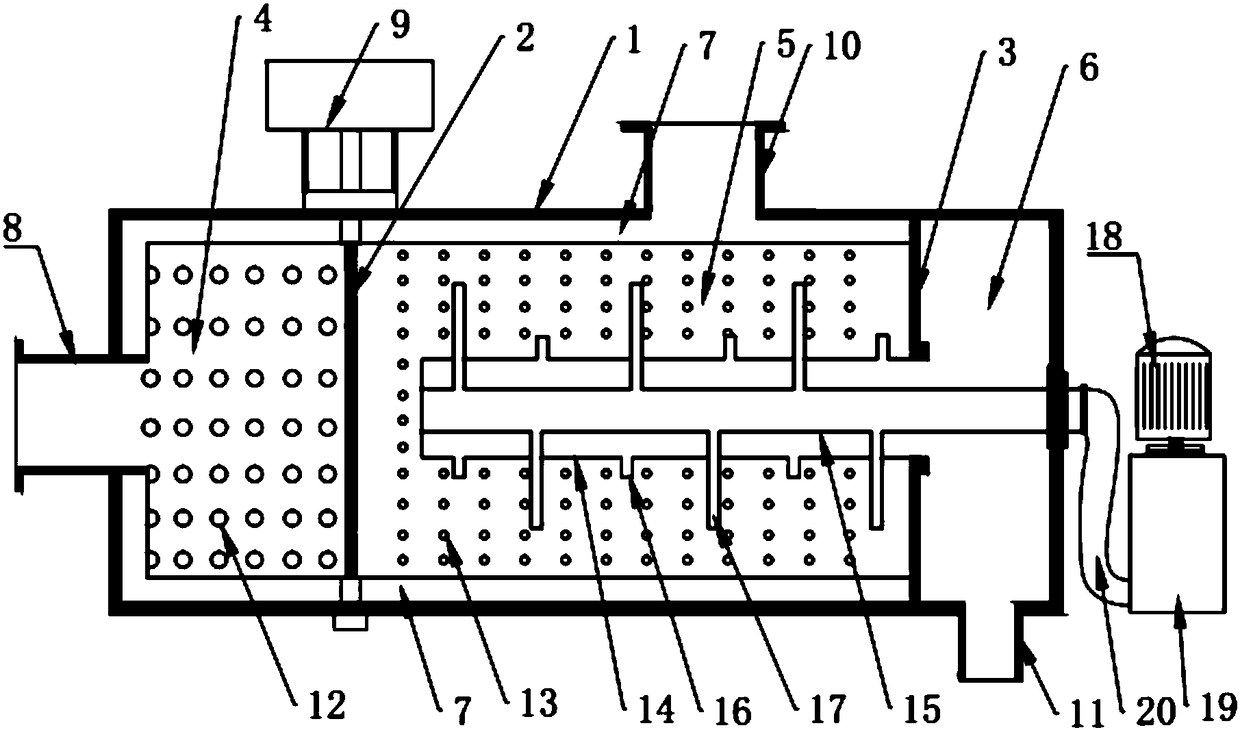

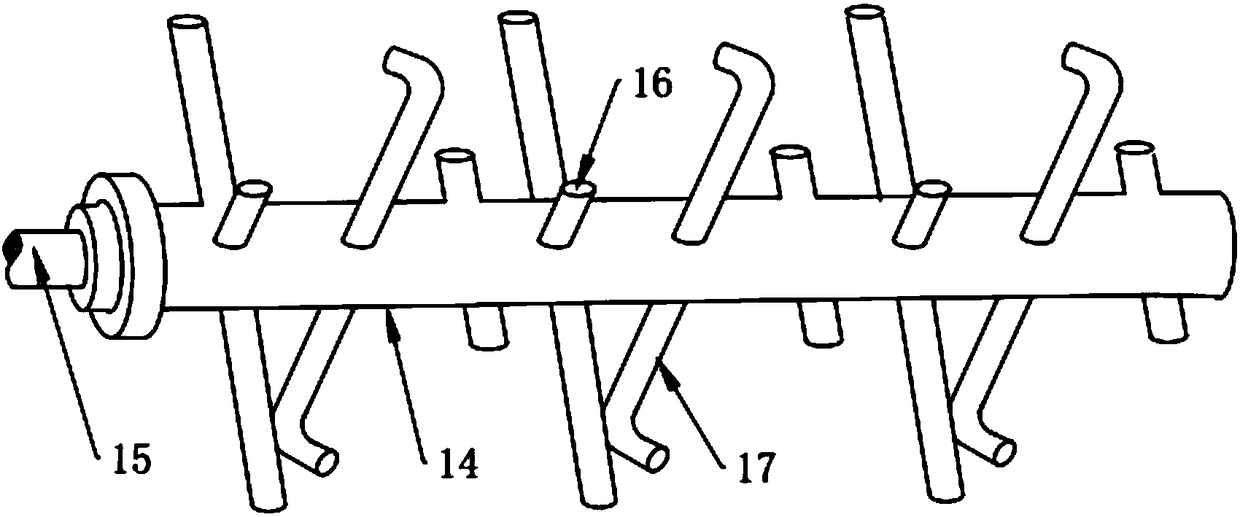

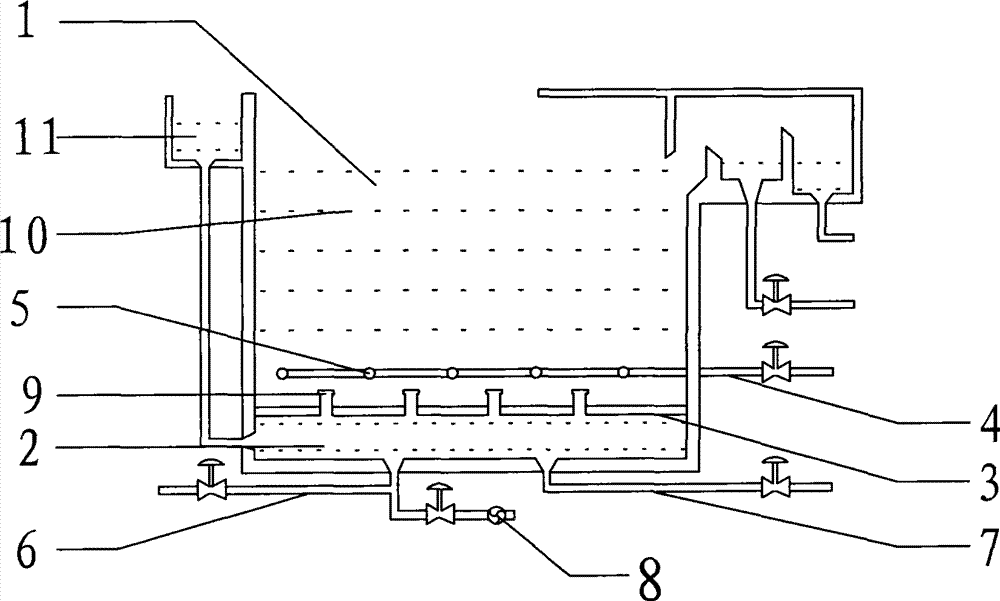

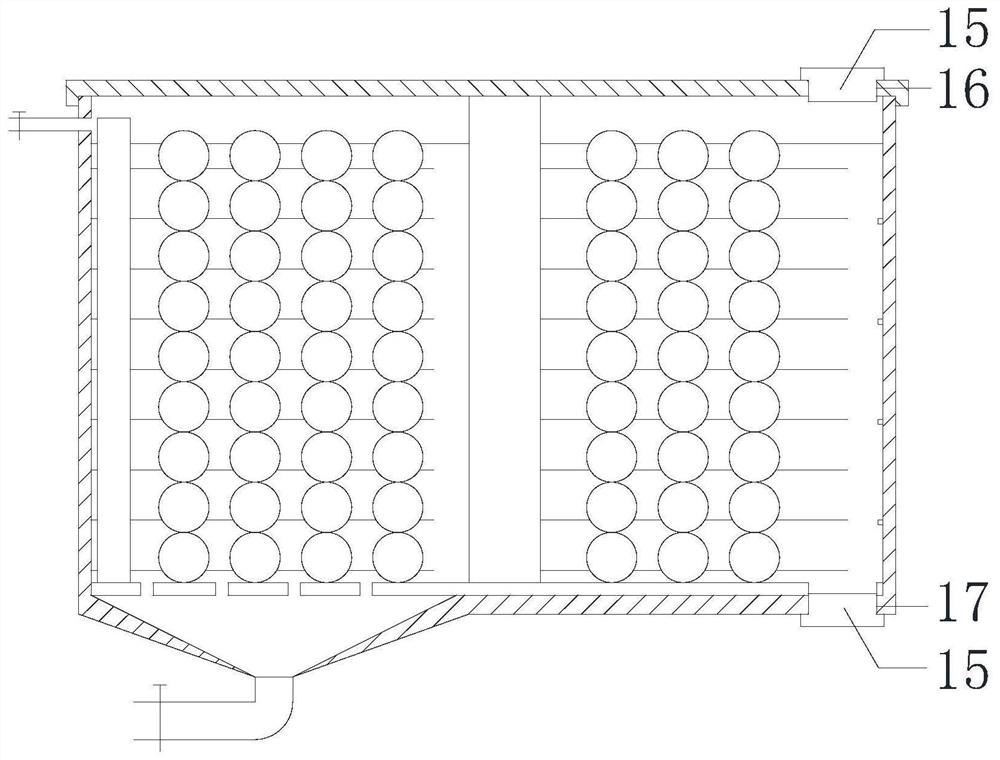

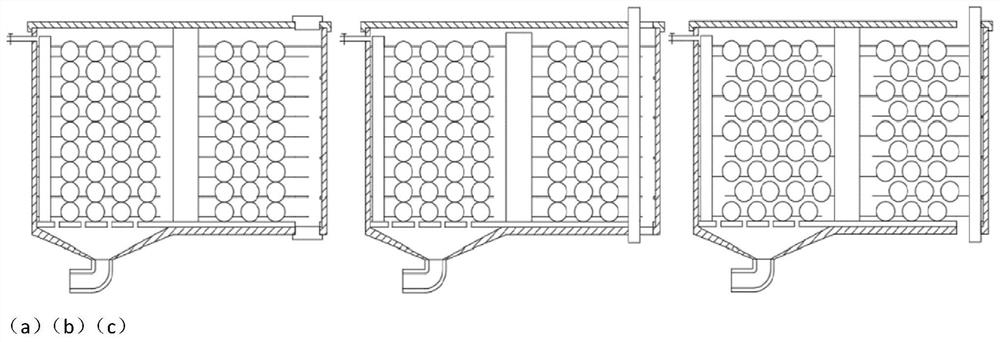

Integrated lightweight filter-material water treatment filter tank

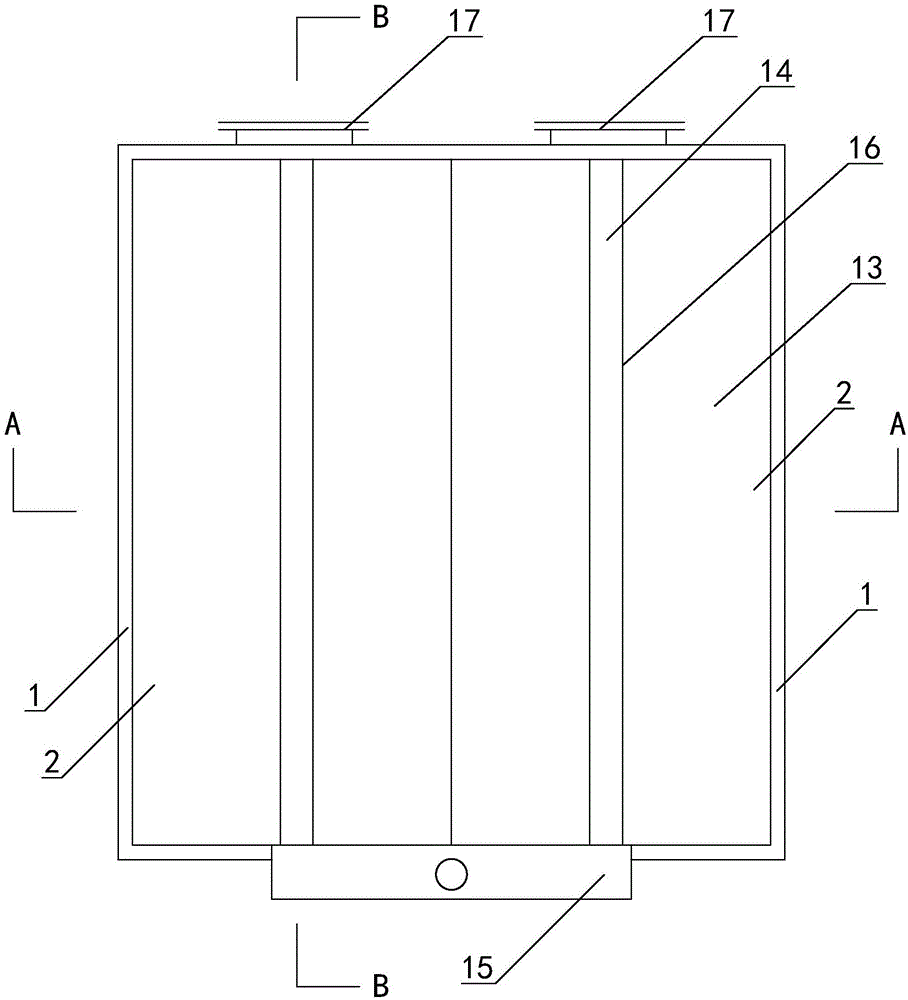

InactiveCN106466532AFilter evenlyEvenly distributedLoose filtering material filtersGravity filtersWater flowSewage

An integrated lightweight filter-material water treatment filter tank is characterized by comprising at least a water treatment unit. The water treatment unit comprises a tank. The tank is composed of a clear water area, a filtering area and a water inlet area which are communicated with each other through water-flow from the top to the bottom. Adjacent two areas of the above three areas are isolated through a filter board respectively. The filter board is provided with several water channels used for water flowing. The water inlet area has a water inlet used for receiving sewage to be filtrated. The filtering area holds several lightweight elastic filter material particles which have lower density than water. Particle size of the lightweight elastic filter material particles is greater than width of the water channels. After water-flowing, each lightweight elastic filter material particle forms a filter layer, and there is a gap between the filter layer and the lower filter board. The top of the clear water area is an overflow surface of clear water. The filter tank has advantages of good filtering effect, low backwashing requirement, high reliability, low cost, low operation cost, less land occupation and convenience in operation management.

Owner:谢绍舜

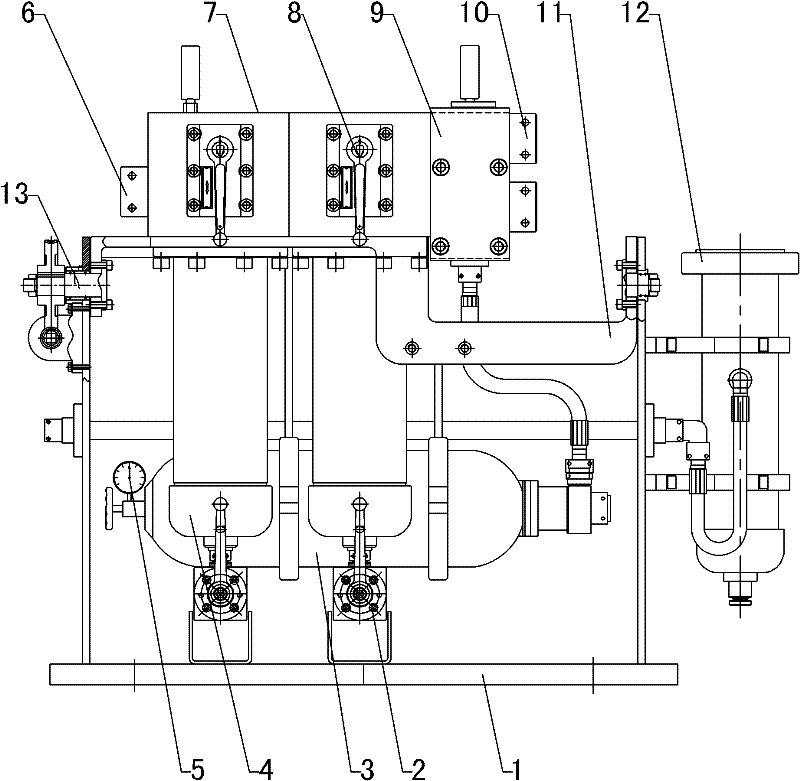

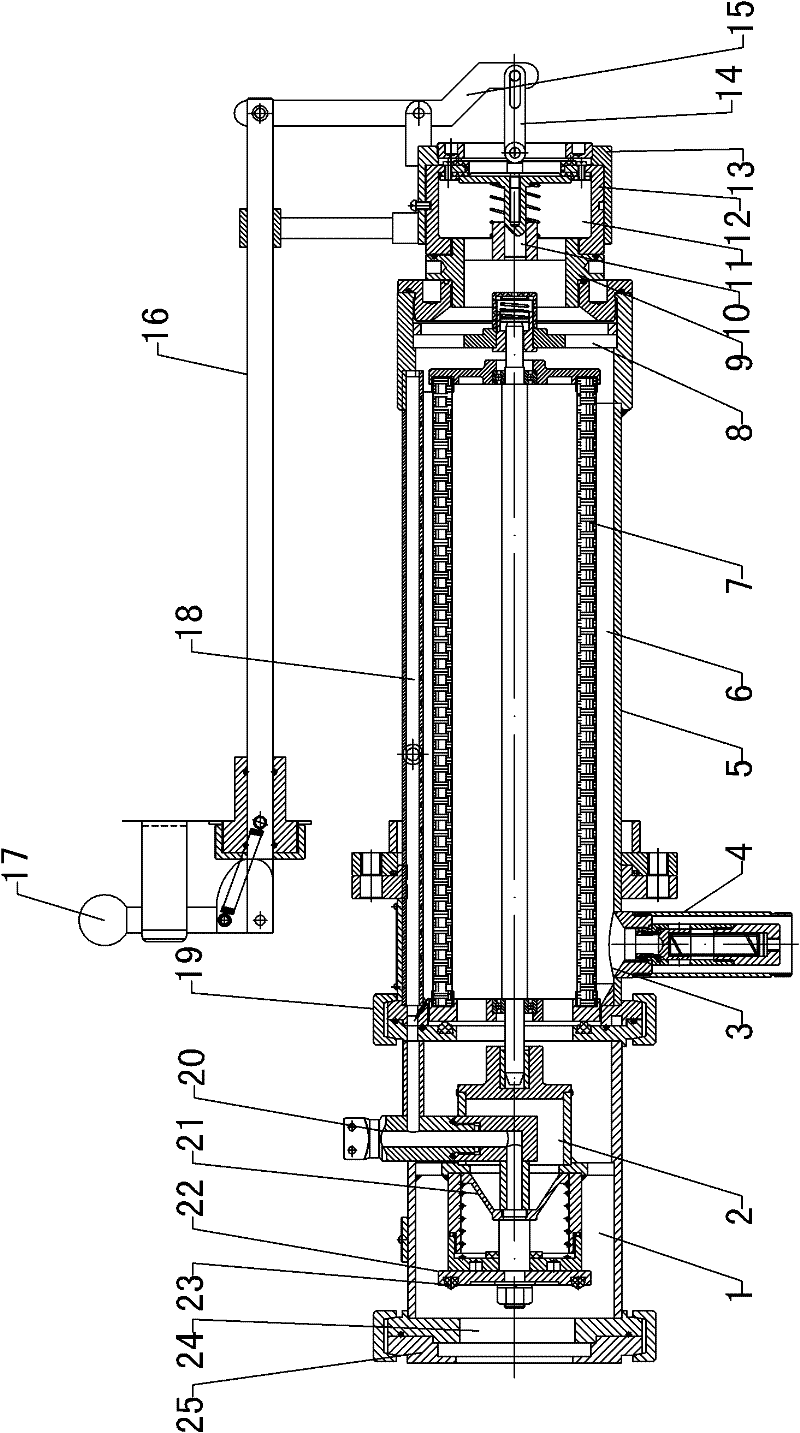

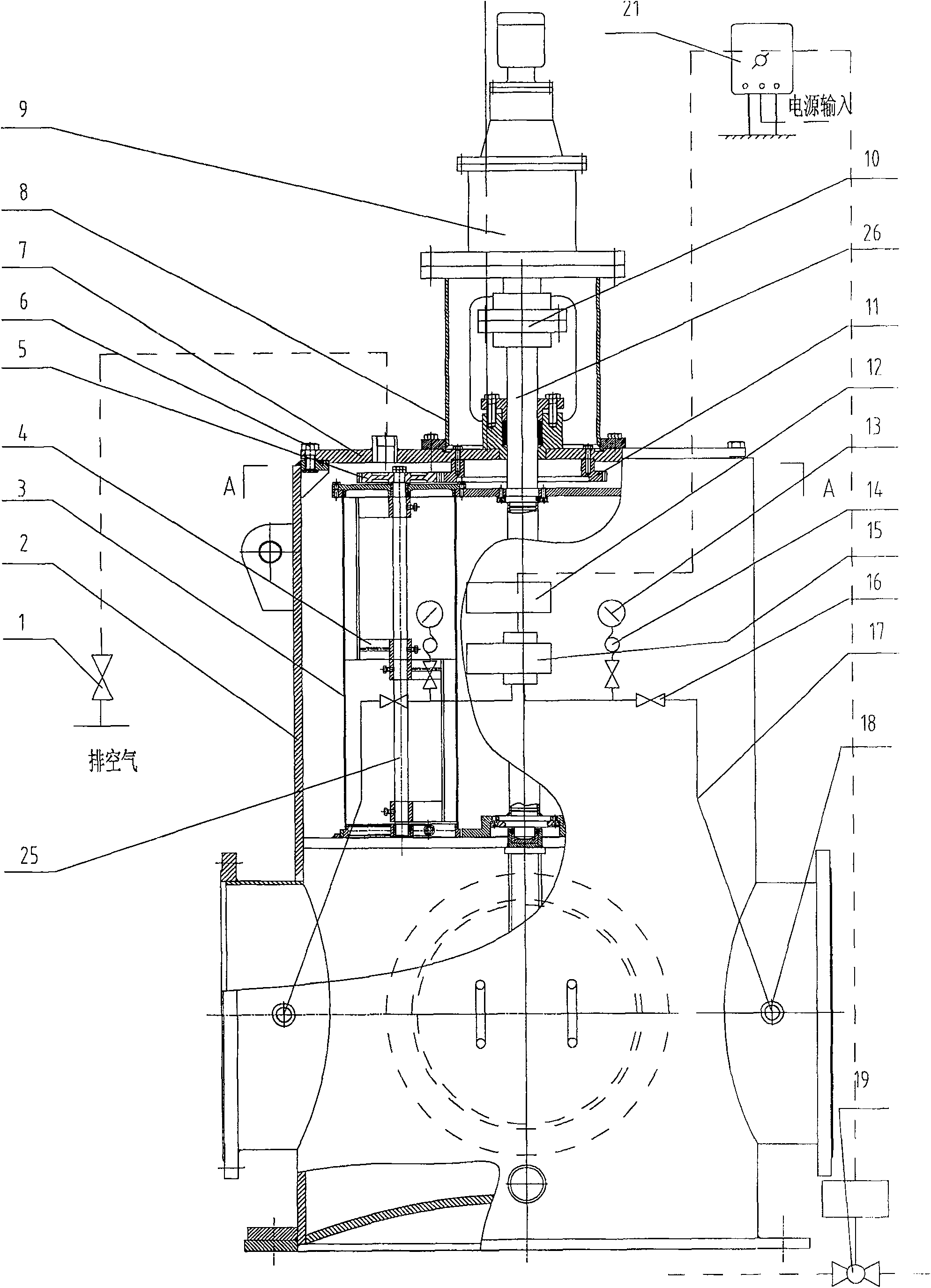

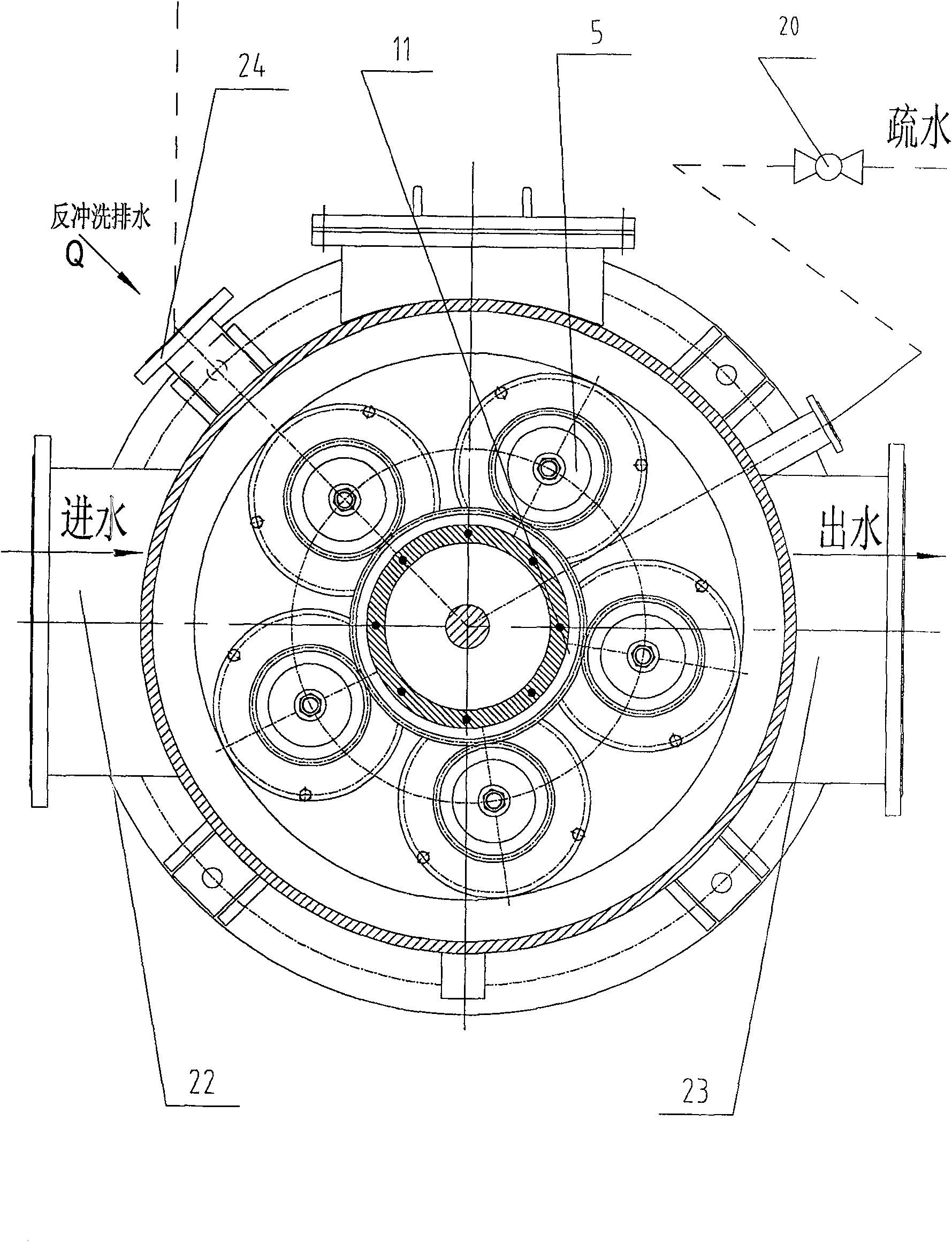

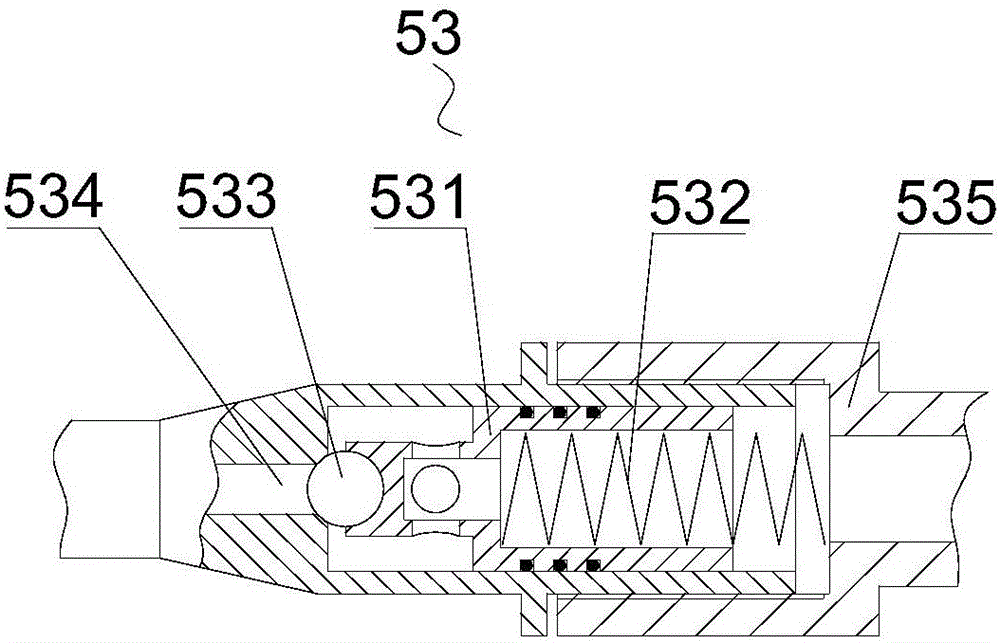

Backwash high pressure filter station

ActiveCN102258910ARealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsEngineeringHigh pressure

The invention discloses a backwashing high-pressure filter station, which belongs to the field of backwashing high-pressure filter devices for hydraulic systems of underground comprehensive mining hydraulic brackets. The backwashing high-pressure filter station comprises a machine seat (1) and a high-pressure filter (4), and is characterized in that: a rotating machine seat (11) is arranged on the upper part of the machine seat (1); an integrated valve seat device (7) is mounted through the rotating machine seat (11); the bottom of the integrated valve seat device (7) is connected with the high-pressure filter (4) and an energy storage device (3); the lower part of the high-pressure filter (4) is connected with a draining valve (2); and a waste liquid recovering device on the lower part of the draining valve (2) is connected with a recovery filter (12). The backwashing high-pressure filter station has the advantages of large flow, high precision, capability of on-line washing, obviouswashing effect, capability of recycling backwashing liquid and the like; and when the backwashing high-pressure filter station is used, the continuous production operation can be ensured, energy conservation and environment protection can be ensured and the cleanness of the working medium can be ensured effectively.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

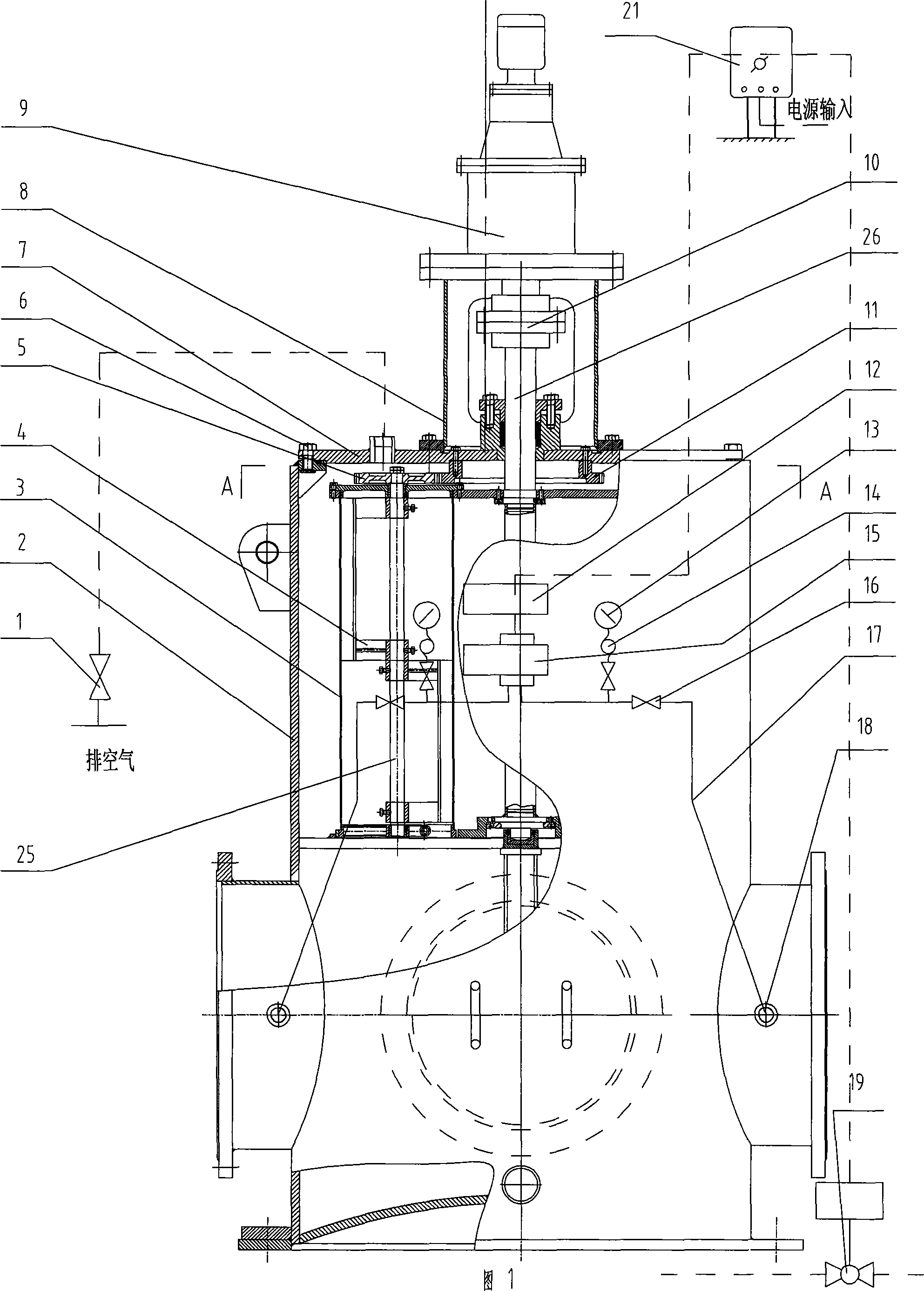

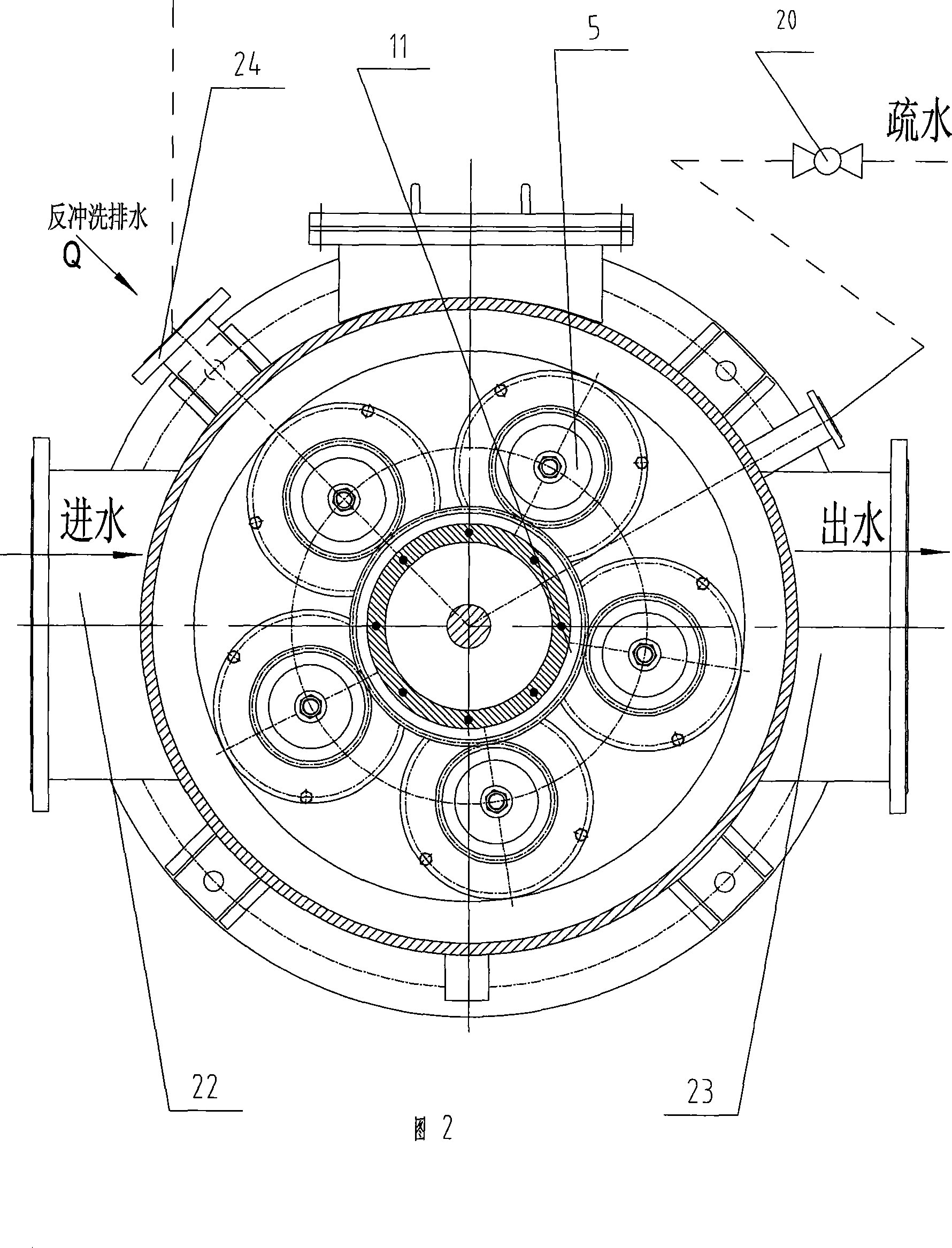

Full automatic suction type self-cleaning filter

InactiveCN1765464AReduce energy consumptionRealize intelligent controlStationary filtering element filtersExhaust valveControl system

The invention discloses a full-automatic suction self-cleaning filter comprising a casing, a filter screen, a mandrel, a soil pick-up pipe, a sucker, a driving device and a control system. Wherein, the casing is divided into a cleaning room and a soil exhaust room while the filter screen is mounted in the cleaning room, the mandrel is mounted in the casing to through the filter screen; the soil pick-up pipe is fixed on the mandrel; the sucker is mounted on the outer surface of soil pick-up pipe of cleaning room to be connected with the soil pick-up pipe; the casing has a water inlet and a water outlet; the filter screen has a water inlet connected to the one of casing; the floss hole of soil pick-up pipe is arranged in the soil exhaust room which has a soil exhaust hole through with outside; a soil exhaust valve is mounted on the floss hole or the soil exhaust hole; the driving device can rotate the mandrel when moves along the axis of mandrel; and the control system and the driving device are connected to the soil exhaust valve. The invention operates automatically without interrupted water supply to realize the intelligent control. And the invention has short reverse washing time, and lower water consumption for exhausting soil to save water and power resource.

Owner:北京禹宗水资源新技术有限公司

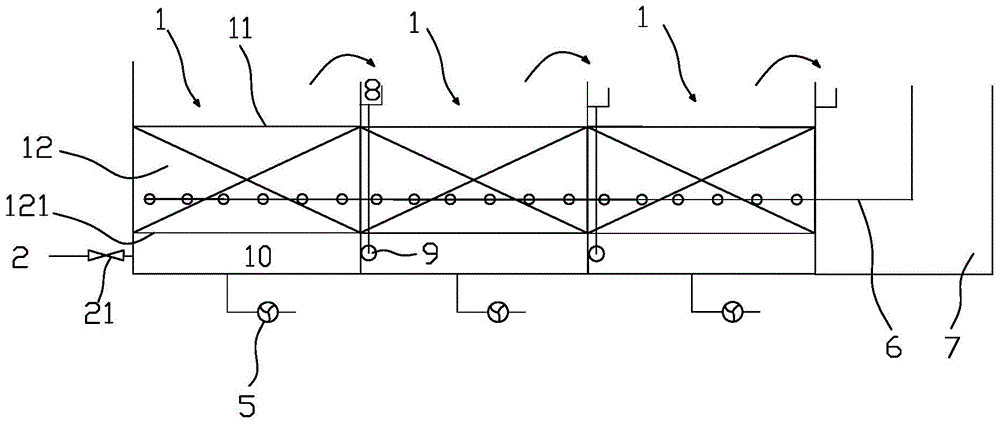

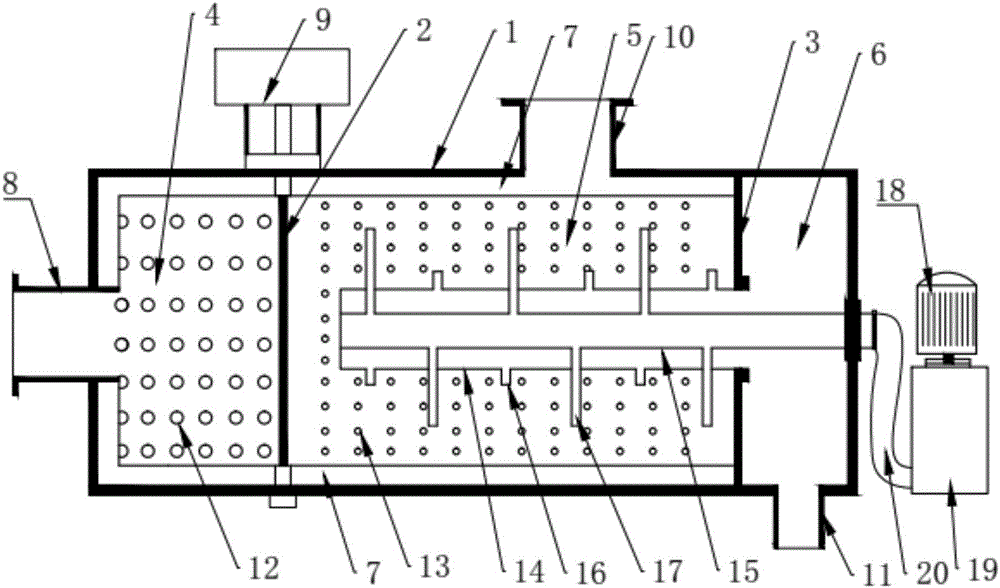

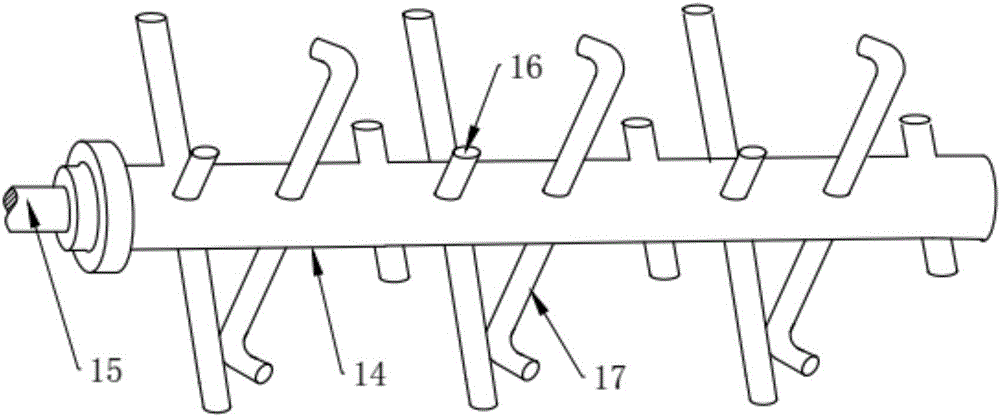

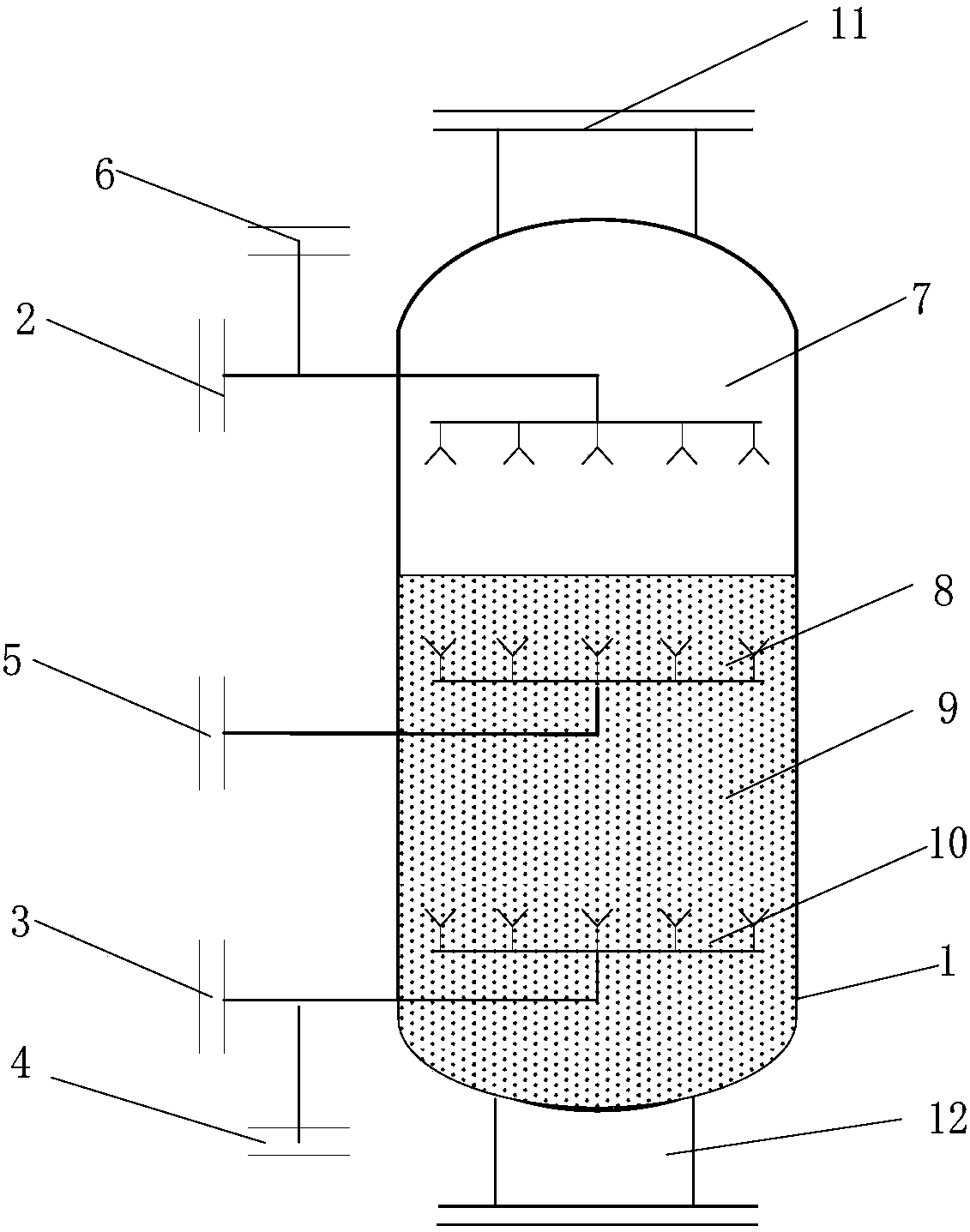

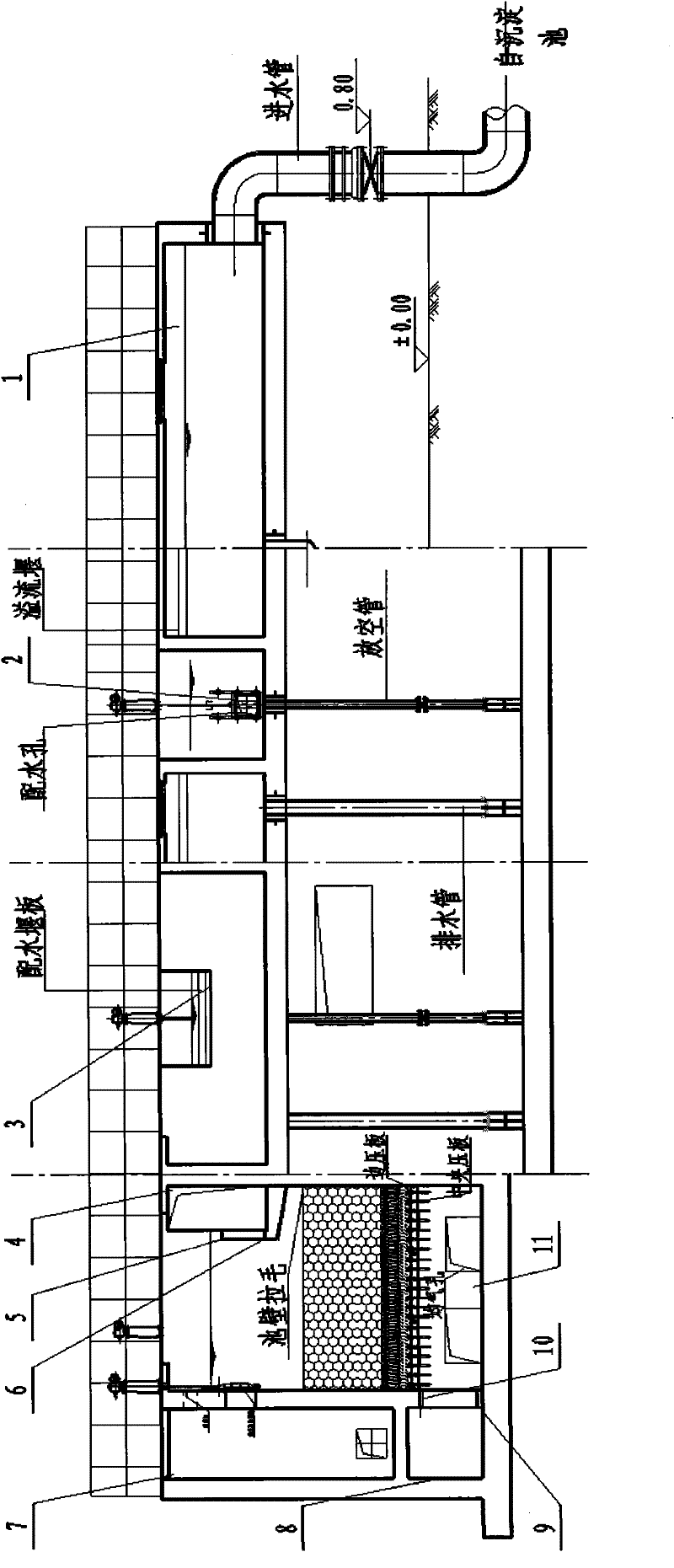

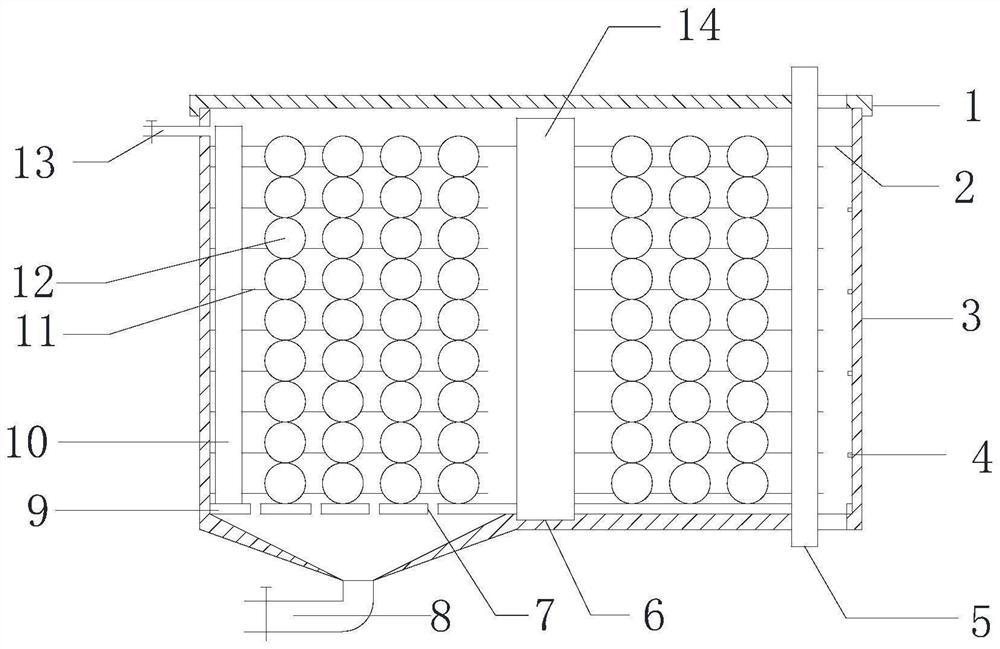

Upward flow type biological aerated filter

InactiveCN104528922AImprove dirt holding capacityExtended working hoursTreatment using aerobic processesWater contaminantsSewageFilter material

The invention relates to an upward flow type biological aerated filter. The biological aerated filter comprises a plurality of filter chambers which are connected in series sequentially, wherein a water inlet region is arranged in each filter chamber, sewage enters the water inlet region of the bottom of the first filter chamber by virtue of a pipeline, and each water inlet region is connected with a dredge pipe; a filter region is arranged in each filter chamber above the water inlet region, a ceramisite filter material covers each filter region, a supporting separator is arranged under each filter region, a filter head is fixedly arranged on each separator, and an aerator pipe is arranged under the filter material; except the first filter chamber, an overflow weir is arranged on the top of one side, close to the previous filter chamber, of an arbitrary filter chamber, and the water inlet region of an arbitrary filter chamber is connected with the overflow weir of the filter chamber by virtue of a water delivery pipe, so that the heights of the overflow weirs in the plurality of filter chambers are gradually reduced from the side of the water inlet end to the side of the water outlet end. The upward flow type biological aerated filter is easy to maintain, cannot be blocked easily, and can be used for effectively improving the sewage washing effect.

Owner:安徽南风环境工程技术有限公司

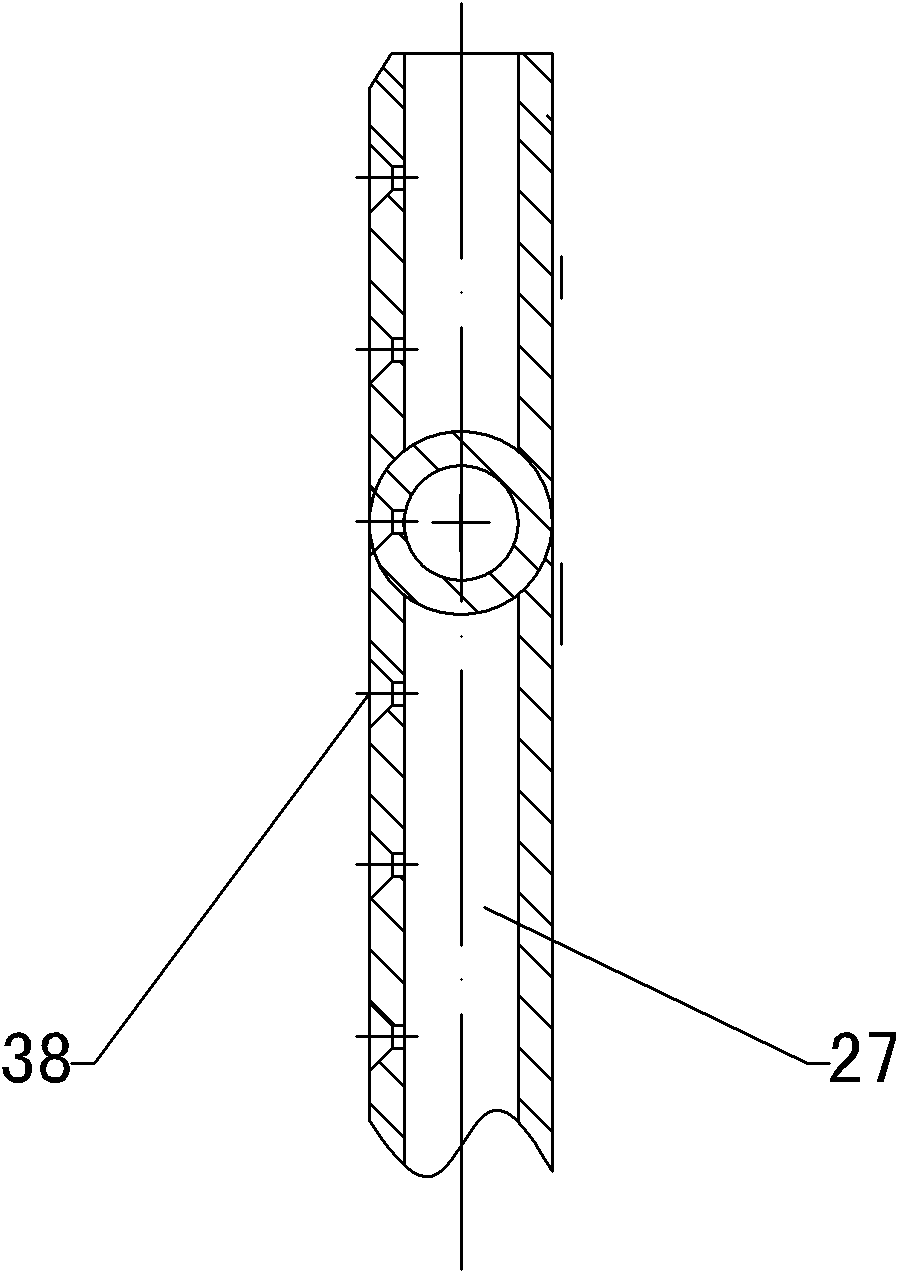

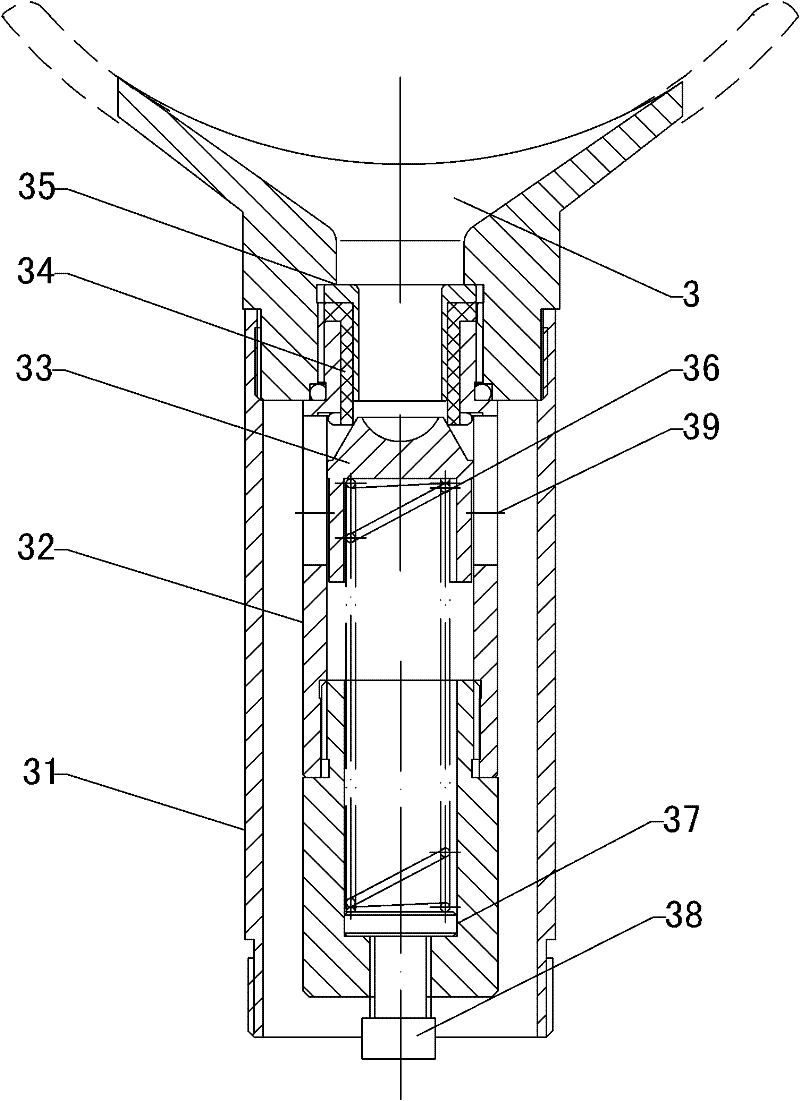

Automatic backwashing liquid-returning filter

ActiveCN102258898BImprove filtering effectEffective filteringStationary filtering element filtersEmulsionEngineering

The invention relates to an automatic backwashing liquid-returning filter, belonging to the field of automatic backwashing filtering devices of emulsion in a coal mine. A cylinder (10) is divided into an upper part and a lower part, the inside of the cylinder (10) is divided into a liquid inlet and outlet chamber (1) and a filter chamber (2), a liquid inlet (14) and a liquid outlet (22) are bisymmetrically arranged at the upper part of the liquid inlet and outlet chamber (1), two groups of backwashing devices are correspondingly installed inside the liquid inlet and outlet chamber (1), a filter element (9) is installed in the filter chamber (2) through a shaft (42) and a bearing (43), a big nut (6) and a stop member (5) are connected to the lower end of the filter chamber (2) in threads, the stop member (5) is connected with a drainage valve (4), a backwashing pipe (27) is arranged at one side inside the filter chamber (2), the backwashing devices are connected to the upper part of the backwashing pipe (27), and a plurality of backwashing holes (38) are uniformly distributed on pipe walls. The automatic backwashing liquid-returning filter has the advantages of long service life, large filter area, strong drainage capacity, timed or automatic online backwashing and the like.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

Back flush filter

InactiveCN106492528ASatisfy filterabilityFulfil requirementsStationary filtering element filtersFiltrationSewage

The invention provides a back flush filter, relating to the field of sewage purification treatment facilities. The back flush filter comprises a shell, an electrodynamic mechanism, a coarse screen, a fine screen, a sewage suction device and a gas supply unit, wherein the coarse screen and fine screen are arranged in the cavity of the shell; the coarse screen and fine screen are respectively cylindrical, and form a back flush chamber with the inner wall of the shell; one end of the shell is provided with a sewage inlet; the upper end of the shell is provided with the electrodynamic mechanism and a purified water outlet; the lower end of the shell is provided with a drainage port; the sewage suction device comprises a drainage pipe, a high-pressure gas pipe, a sewage suction pipe and an exhaust pipe; the high-pressure gas pipe is sheathed in the drainage pipe; the sewage suction pipe communicates with the inner cavity of the drainage pipe; the exhaust pipe penetrates through the wall of the drainage pipe and communicates with the inner cavity of the high-pressure gas pipe; the exhaust pipe comprises a straight-opening pipe and a bent-opening pipe; and the gas supply unit comprises a motor, a gas pump and a gas supply pipe. The back flush filter has the advantages of high cleaning efficiency and thorough cleaning, and can satisfy the quality requirements for sewage filtration and automatic drainage.

Owner:衡阳中重机械装备有限公司

High-efficiency desulfurization waste liquor salt extraction recycling device

ActiveCN104645830AIncreased Filtration ThroughputIncreased filtration surface areaDispersed particle separationFiltration circuitsLiquid wasteDevice form

The invention discloses a high-efficiency desulfurization waste liquor salt extraction recycling device. The device comprises a two-stage filtering device formed by connecting two micro-porous ceramic filtering devices with each other, wherein each micro-porous ceramic filtering device comprises a tank body (5) and a seal head (1); a liquid inlet (6) is formed in the lower part of the tank body; a liquid outlet (8) is formed in the upper part of the tank body; a backwash opening (9) is formed in the liquid outlet; a supporting disc (2) is arranged in the tank body; liquid outlet holes (19) are formed in the supporting disc at intervals; limiting sleeves (3) are fixedly arranged on the lower bottom surface of the supporting disc at intervals; the limiting sleeves are tightly connected with the outer diameters at the upper ends of micro-porous ceramic pipes in a matched mode; the micro-porous ceramic pipes are connected with a pressing plate (13); a riding fixing rack (18) is fixedly arranged on the supporting disc; and pull rods (15) through which the micro-porous ceramic pipes can be fixedly arranged on the supporting disc in a suspended mode at the intervals are arranged between the riding fixing rack and the pressing plate. According to the device disclosed by the invention, the occupied space can be reduced, the construction cost is saved, the filtering effect of desulfurization waste liquor can be improved, desulfurization liquor is conveniently filtered, and the backwash is conveniently performed.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

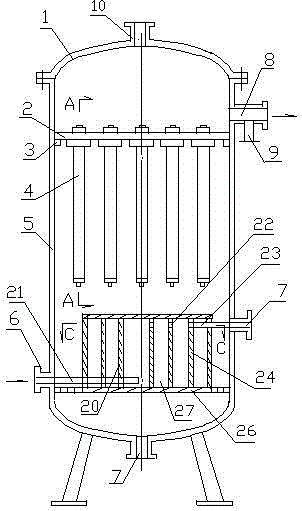

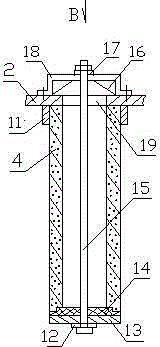

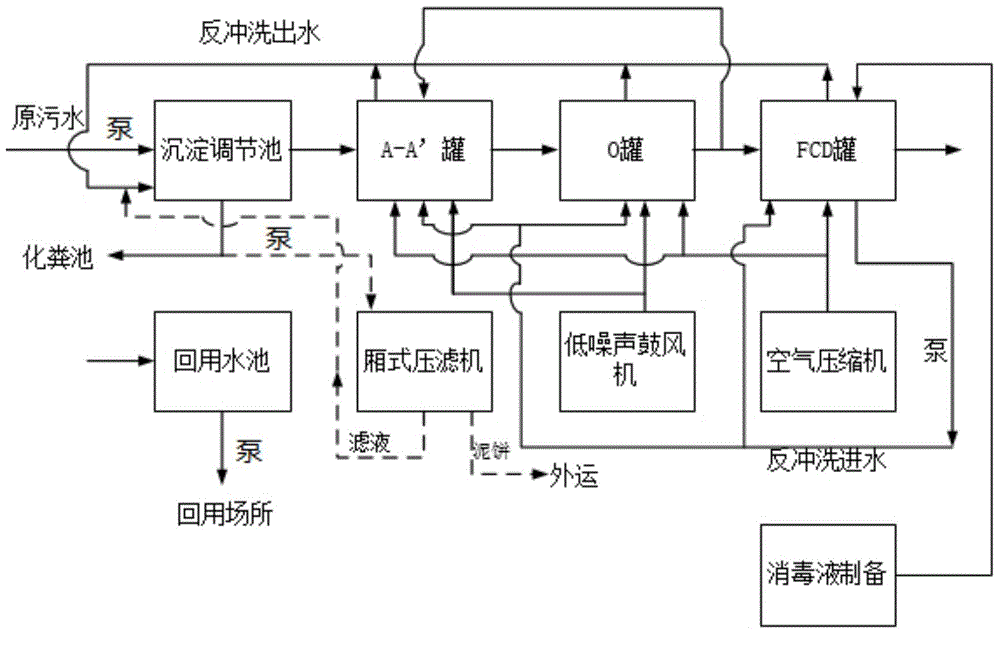

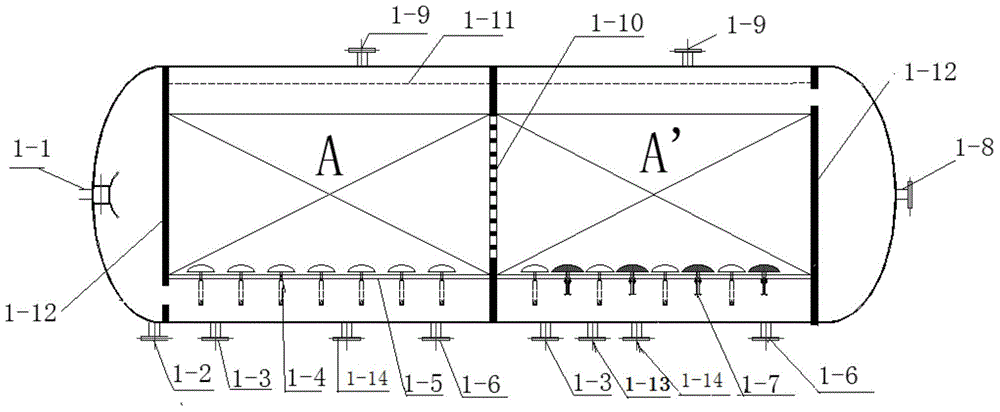

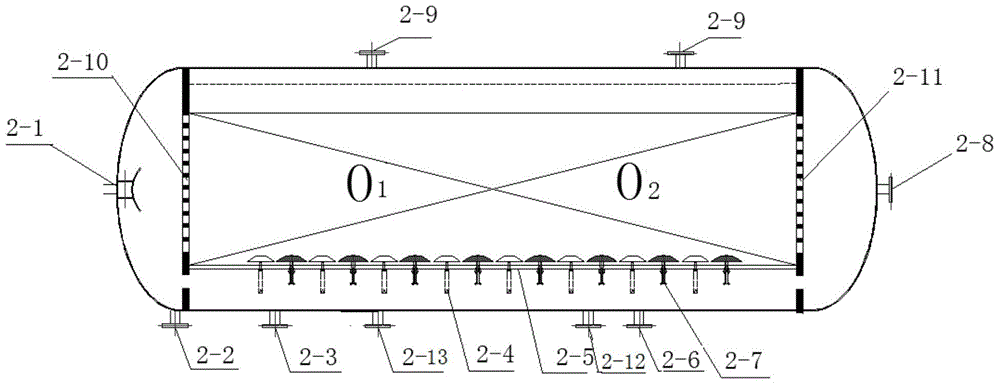

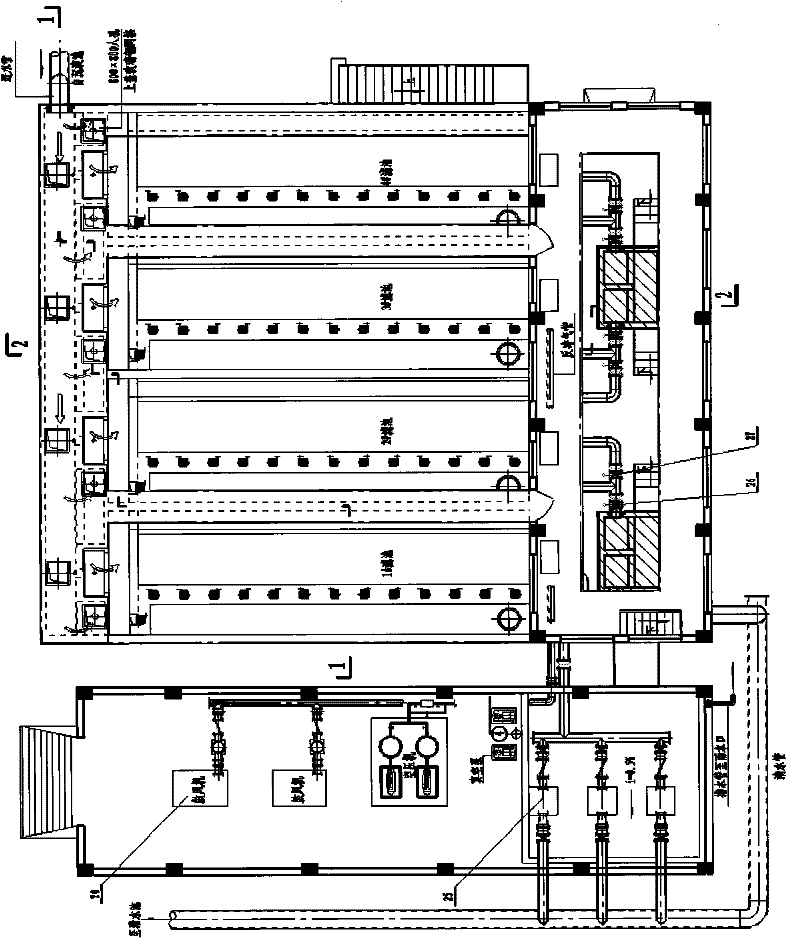

Integrated domestic sewage treatment device with novel structure

InactiveCN104016555AReduce pollution loadAchieve removalTreatment using aerobic processesTreatment with anaerobic digestion processesFlocculationSludge

The invention discloses an integrated domestic sewage treatment device with a novel structure. The sewage treatment device comprises an A-A' biological reaction tank, an O biological reaction tank, an FCD (Flocculation Control Device) reaction tank which are sequentially connected and arranged transversely, wherein the A-A' biological reaction tank and the O biological reaction tank constitute an anaerobic-anoxic-aerobic biological treatment system; since the A-A' biological reaction tank and O biological reaction tank both operate under the conditions that water and gas are supplied at a low pressure and the A-A' biological reaction tank and O biological reaction tank are sealed and equipped with particle fillers, the contents of oxygen dissolved in water and microbes are greatly increased. The FCD reaction tank is used for filtering water treated by the A-A'-O system and storing and disinfecting the cleaned water; a backwash water and gas inlet is arranged at the bottom of each of the FCD reactor tank, A-A' biological reaction tank and O biological reaction tank, and the top of the FCD reactor tank, the A-A' biological reaction tank and the O biological reaction tank are respectively connected with a backwash water outlet which is connected with the sludge inlet of the sedimentation-regulation tank; and a backwash mode of the treatment device is vertical backwash perpendicular to the water flowing direction.

Owner:山东华特达因健康股份有限公司

Automatic backwash suction filter

ActiveCN102258899AImprove filtering effectEffective filteringStationary filtering element filtersBlowoff valveAbsorption filter

The invention relates to an automatic back flush and liquid absorption filter, belonging to the field of an automatic back flush filter device for an emulsion in a coal mine. In the filter provided by the invention, a barrel body (5) is divided into two parts; the interior of the barrel body (5) is divided into a liquid absorption chamber (1) and a filtration chamber (6); a liquid outlet (24) is formed on one end surface of the liquid absorption chamber (1); a back flush device is installed in the liquid absorption chamber (1); a filter element (7) is installed in the filtration chamber (6) through a bearing (29) and a shaft (28); a check valve (11) is installed at the other end of the filtration chamber (6) through a limit piece (9); the check valve (11) is connected with a control mechanism (16); a blowoff valve (4) is installed in a drain outlet (3) at one side of the filtration chamber (6); a back flush pipe is installed at one side in the barrel body (5) and between the filter element (7) and the barrel body (5); one end of the back flush pipe is connected with the back flush device, and the other end is installed in the filtration chamber (6); and multiple back flush holes (40) are uniformly distributed on the wall of the pipe. The filter provided by the invention has the advantages of large filter area, strong drain capacity, long service life, can realize timing or automatic online cleaning and the like.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

Full automatic corrupt brushing backwash water filter

InactiveCN101185815AEasy to cleanGood removal effectStationary filtering element filtersInsertion stentGear wheel

The invention relates to a filter equipment, in particular to a full automatic sewage-brushing and backwashing water filter. According to the technical proposal provided by the invention, a filter screen is arranged in a shell body. The invention is characterized in that a reducer is arranged on the shell body; a plurality of cylinder-shaped filer screens is uniformly arranged on a stent; the stent is connected with a main shaft; the main shaft is connected with the output end of the reducer; every filter screen is internally provided with a rotating shaft which is provided with a brush; the end of the brush is touched with the inner wall of the filer screen; the end of the rotating shaft extends out of the filter screen. The end of the rotating shaft is also provided with a planetary gear while every planetary gear is respectively meshed with a gearwheel fixed in the shell body. A water inlet, a water outlet and a backwashing pipe are arranged at the lower part of the shell body 2. The water filter backwashes the filter screen automatically after being used for a period of time, which ensures the normal operation of the water filter and alleviates the labor intensity of workers.

Owner:陆昕 +1

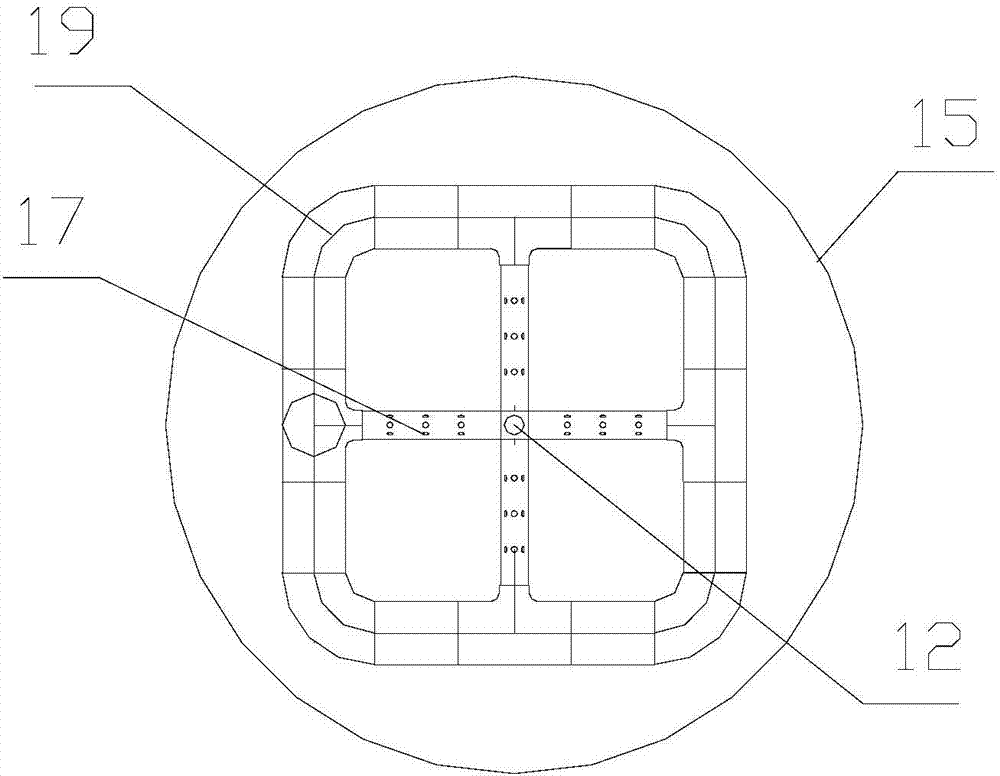

Front filter back flushing device and method

ActiveCN107961576ASolve the blockageHigh transparencySustainable biological treatmentStationary filtering element filtersControl theoryMechanical engineering

The invention discloses a front filter back flushing device and a front filter back flushing method. The front filter back flushing device comprises a cylinder body; the top part of the cylinder bodyis provided with a water inlet, the bottom part thereof is provided with a water outlet, and the middle part is provided with a back flushing water outlet; at least one group of filtering device is arranged in the cylinder body and located at the lower part of the back flushing water outlet; the filtering device comprises a first filter screen, a second filter screen, a third filter screen and a fourth filter screen which are arranged from top to bottom orderly; the filter screen parts of the first filter screen and the second filter screen are filter strips which are in parallel to each other, and the filter strips of the first filter screen and the second filter screen are staggered crossly and longitudinally under the filtering state and in parallel to each other under the back flushingstate; the filter screen parts of the third filter screen and the fourth filter screen are several concentric circles, and the concentric circles of the third filter screen and the fourth filter screen are staggered; the filter device further comprises an adjusting device for adjusting angle and height of corresponding filter screen under different states. The front filter back flushing device and method have the advantages of solving the problems of complex structure, long back flushing time, and others of the existing biochemical process back flushing filter.

Owner:ZHEJIANG YUTENG BAINUO ENVIRONMENTAL PROTECTION TECH CO LTD

Automatic backwashing system for water vapor sampling filter of thermal power plant

PendingCN110954365ADoes not affect accuracyClean in timeWithdrawing sample devicesTesting waterWater storage tankWater vapor

The invention relates to an automatic backwashing system for a water vapor sampling filter of a thermal power plant. The system comprises a filter, a measurement flow cell and a backwashing water storage tank, a water inlet of the filter is communicated with a water vapor inlet pipe; the water vapor inlet pipe is connected with a first electric control valve in series; the water vapor inlet pipe is communicated with a backwashing drain pipe; a second electric control valve is connected in series to the backwashing drainage pipe; a water outlet of the filter is communicated with a water vapor outlet pipe; the water vapor outlet pipe is connected with a third electric control valve in series; the water vapor outlet pipe is communicated with the measurement flow cell; the measurement flow cell is communicated with the backwashing water storage tank through a communicating pipe; a backwashing water storage tank is communicated with a backwashing pipe, the backwashing pipe is connected backto a water vapor outlet pipe, a backwashing water pump is connected in series to the backwashing pipe, a fourth electric control valve is connected in series to the backwashing pipe, and the filter can be automatically or manually backwashed after running for a certain period, so that the quality of water vapor in a system is guaranteed.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Electrostatic separator capable of changing packing stacking mode and cleaning method thereof

ActiveCN111349456AAchieve purificationEasy to fillRefining by electric/magnetic meansCleaning using liquidsElectrostatic separationStructural engineering

The invention provides an electrostatic separator capable of changing a packing stacking mode and a cleaning method thereof, the packing stacking mode can be conveniently changed in the electrostaticseparator without disassembly; the technical problem of backwashing of a packing is insufficient, the backwashing efficiency is low, and the packing is difficult to dry in the prior art are solved. The electrostatic separator comprises a cylinder body; a plurality of packing plates are arranged among an electrode column, an inner electrode and the cylinder body which are coaxial, each packing plate is provided with an assembly column insertion hole, a fixed column insertion hole, a movable column insertion hole, an electrode hole and a packing placement hole, packing is arranged on the packingplates, odd-numbered plates are fixed through fixed columns, and horizontal movement of even-numbered plates is controlled through movable columns to change the packing stacking mode.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

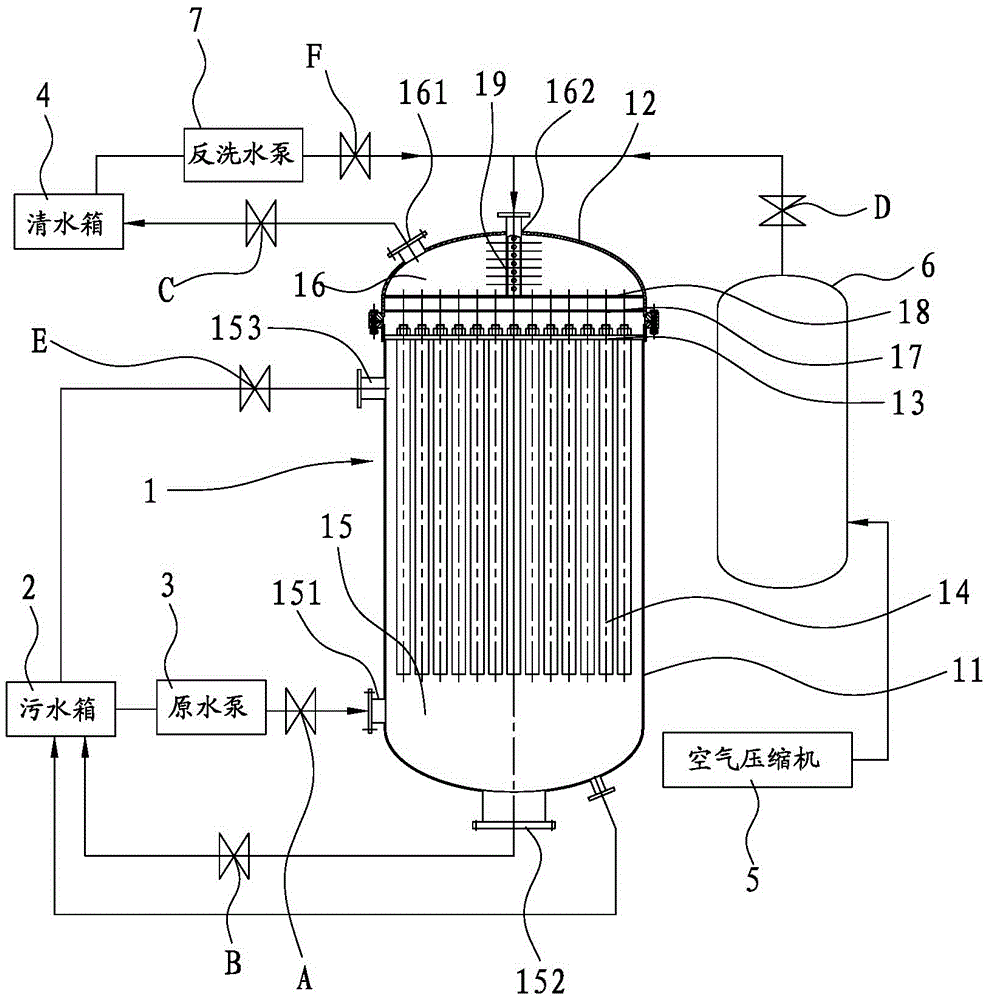

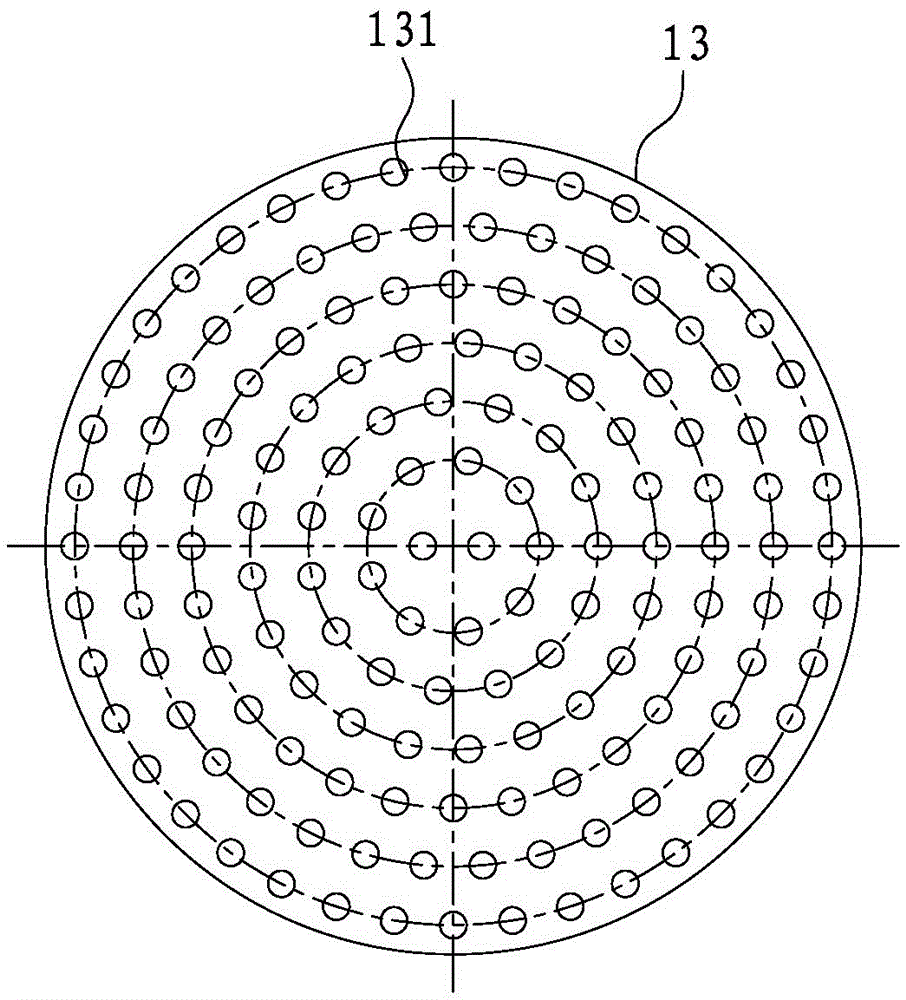

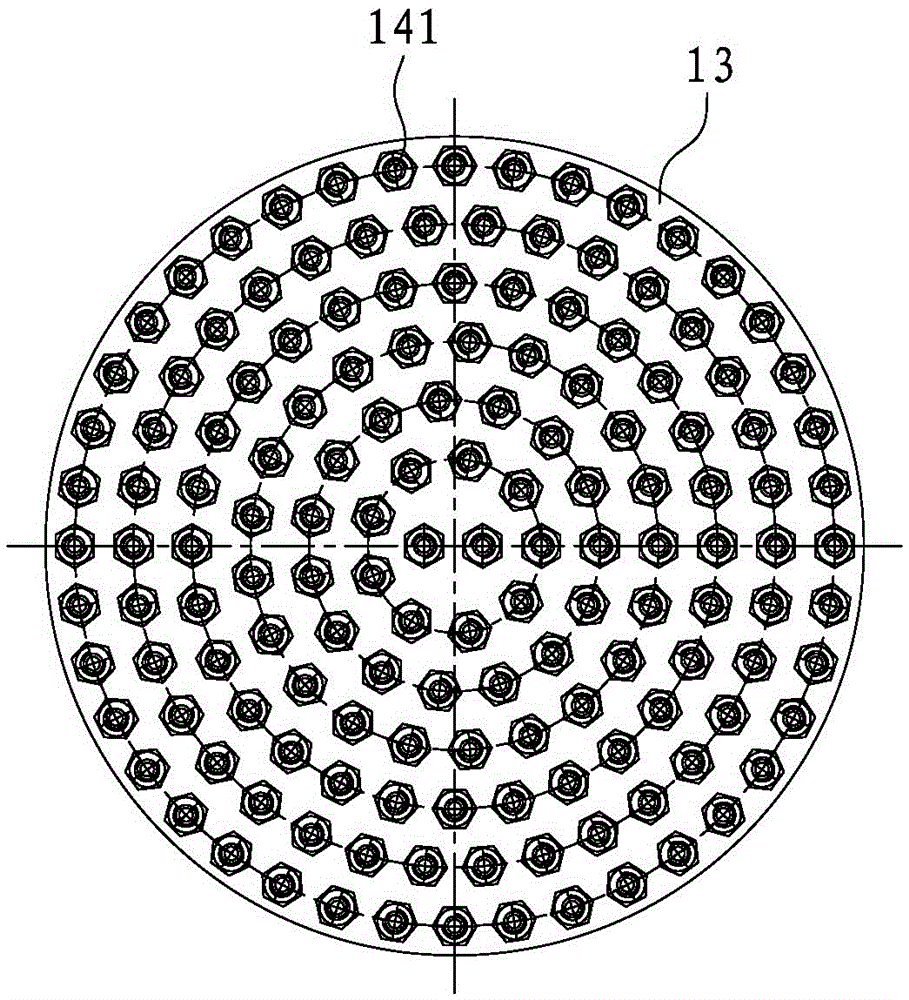

A gas-water back-flushing device for tubular sintered membrane filter

InactiveCN103566767BShorten speedReduce shockSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEngineeringWater pipe

Owner:XIAMEN UNIV OF TECH

Full automatic corrupt brushing backwash water filter

InactiveCN100588446CEasy to cleanGood removal effectStationary filtering element filtersGear wheelInsertion stent

The invention relates to a piece of filter equipment, in particular to a full automatic sewage-brushing and backwashing water filter. According to the technical proposal provided by the invention, a filter screen is arranged in a shell body. The invention is characterized in that a reducer is arranged on the shell body; a plurality of cylinder-shaped filer screens are uniformly arranged on a stent; the stent is connected with a main shaft; the main shaft is connected with the output end of the reducer; every filter screen is internally provided with a rotating shaft which is provided with a brush; the end of the brush is touched with the inner wall of the filer screen; the end of the rotating shaft extends out of the filter screen. The end of the rotating shaft is also provided with a planetary gear while every planetary gear is respectively meshed with a gearwheel fixed in the shell body. A water inlet, a water outlet and a backwashing pipe are arranged at the lower part of the shellbody 2. The water filter backwashes the filter screen automatically after being used for a period of time, which ensures the normal operation of the water filter and alleviates the labor intensity ofworkers.

Owner:陆昕 +1

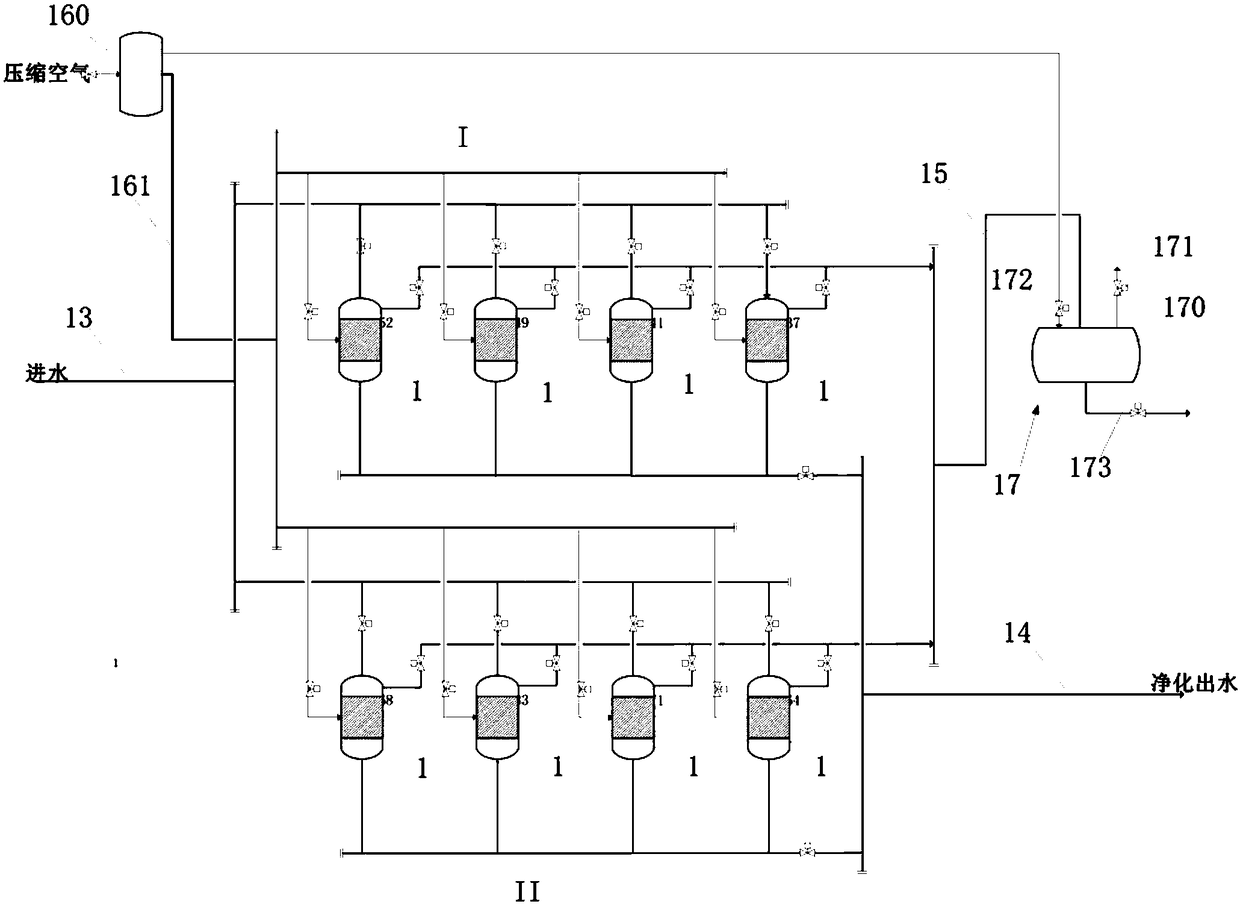

Static bed filtering and purifying system and fluid filtering and purifying method

PendingCN108499172AReduce lossEasy to separateLoose filtering material filtersGravity filtersSewageFilter material

The invention discloses a static bed filtering and purifying system and a fluid filtering and purifying method adopting the system. The static bed filtering and purifying system comprises multiple parallel-connection static bed filters, each static bed filter comprises a tank and a filtering bed, a guide-in pipe and a sewage drainage pipe which are used for introducing fluid into each tank are arranged at the upper portion of the tank, and a purified water outlet pipe is arranged at the lower portion of each tank; the static bed filters further comprise air purging units which introduce gas into the tanks to make a filter material fluidized, water inlet pipelines, sewage drainage pipelines, water outlet pipelines and gas supply units, the water inlet pipelines, the sewage drainage pipelines and the water outlet pipelines are communicated with the guide-in pipes, the sewage drainage pipes and the purified water outlet pipes of all the static bed filters respectively, and switch valves are arranged on all the guide-in pipes and the sewage drainage pipes. By means of the static bed filtering and purifying system, purified outlet water in the system serves as backwashing water, when asingle filter is backwashed, outlet water of the other filters serves as backwashing water, the backwashing flow is multiple times of the feeding flow, a backwashing pump is not needed, the cleaning efficiency is high, and the system is easy and reliable to operate.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

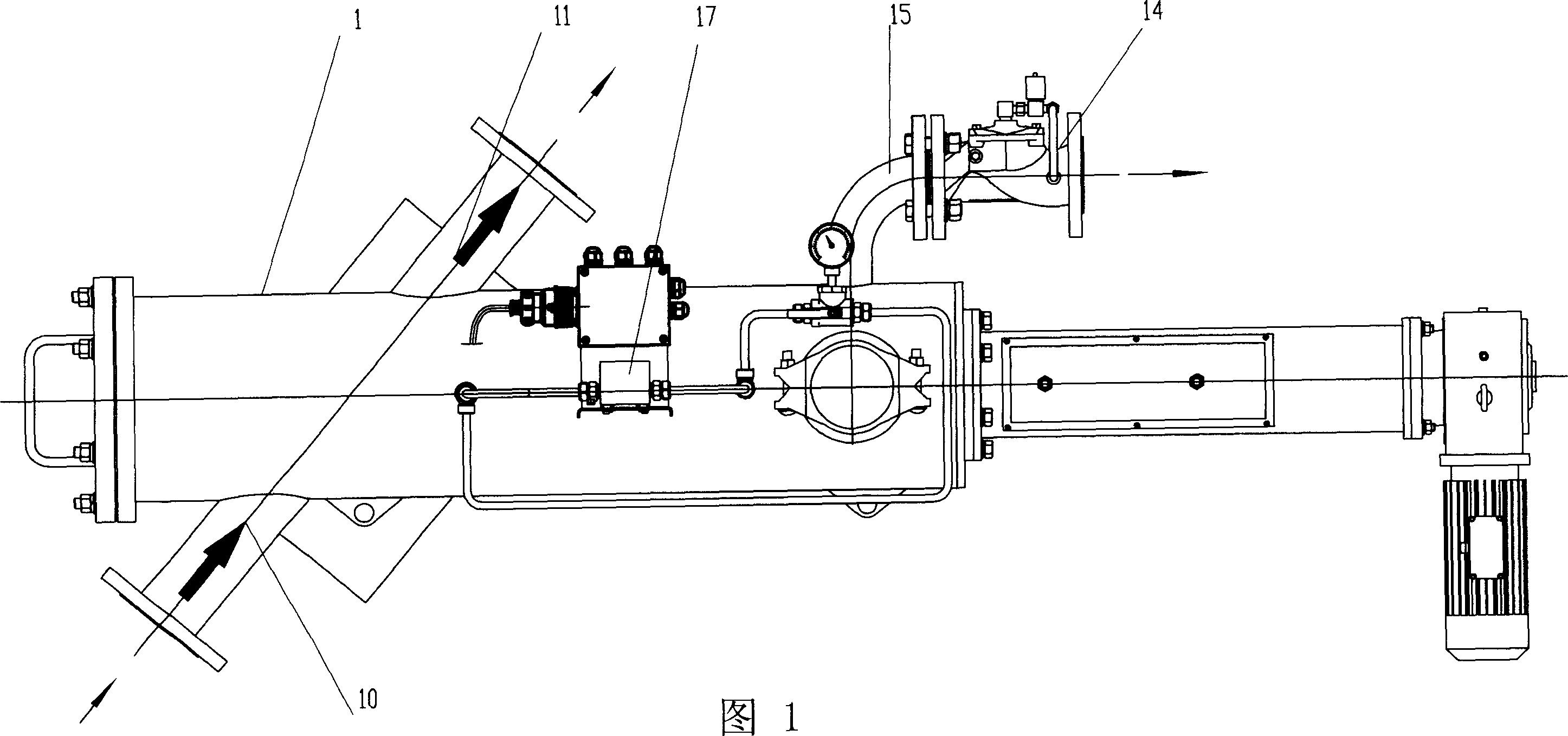

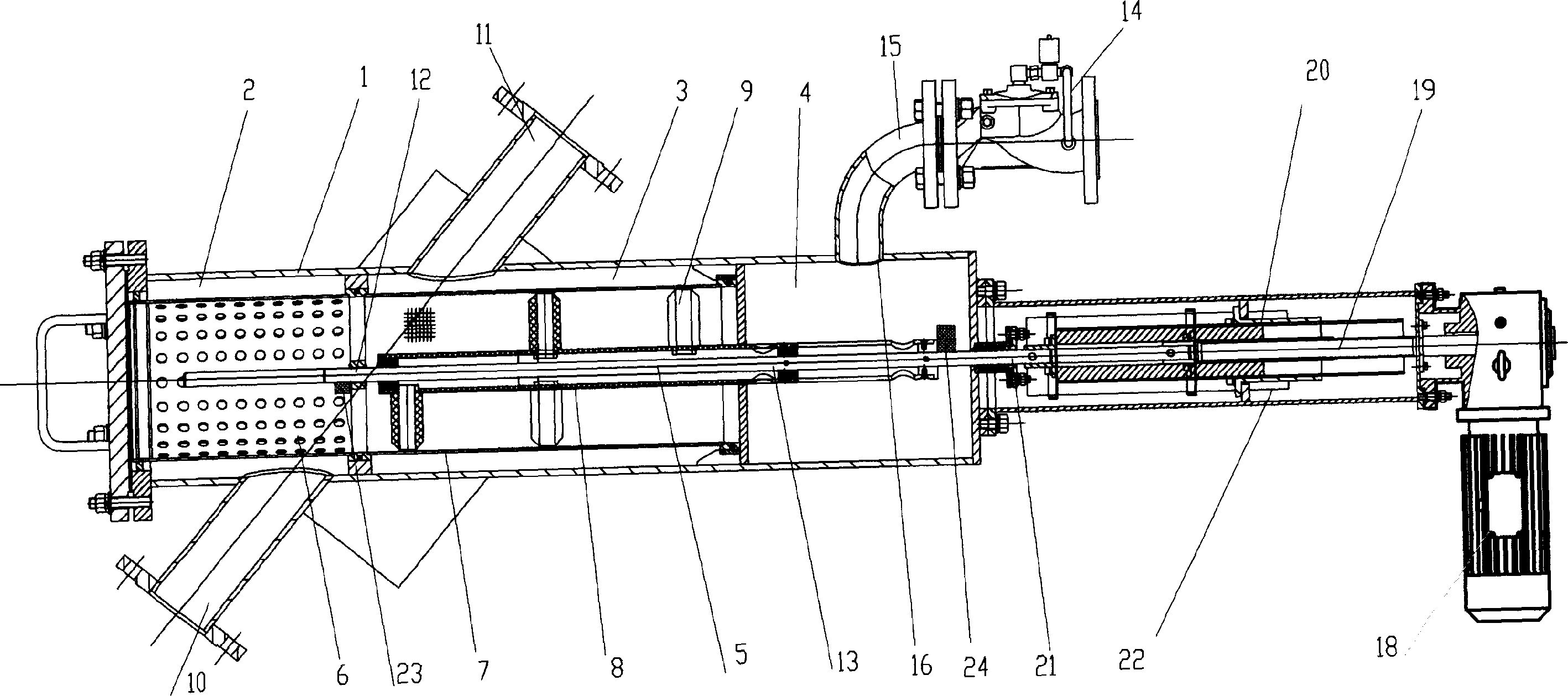

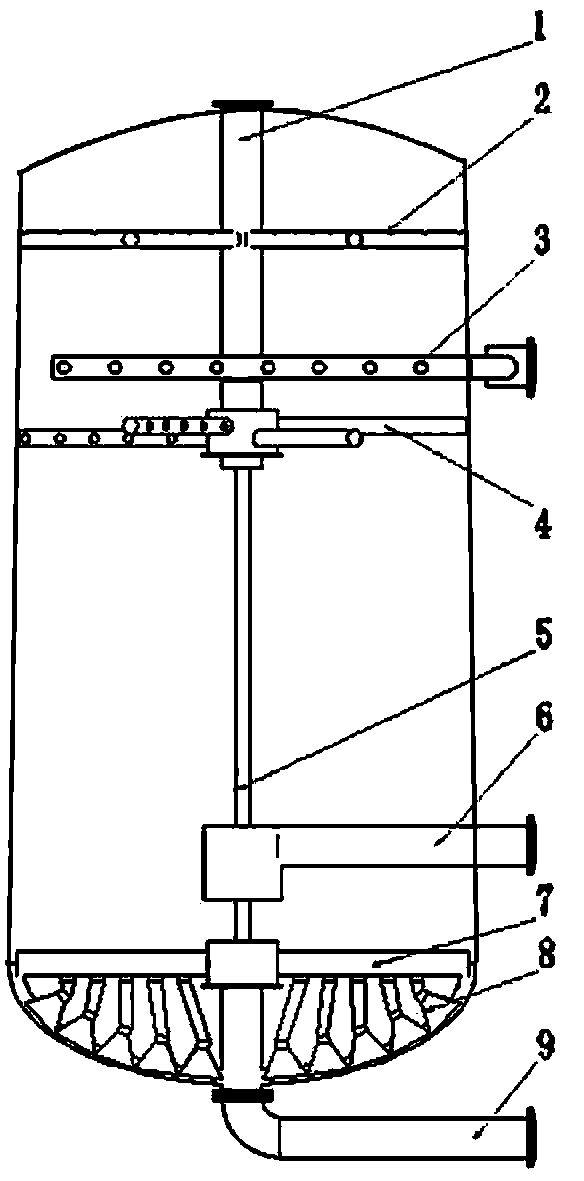

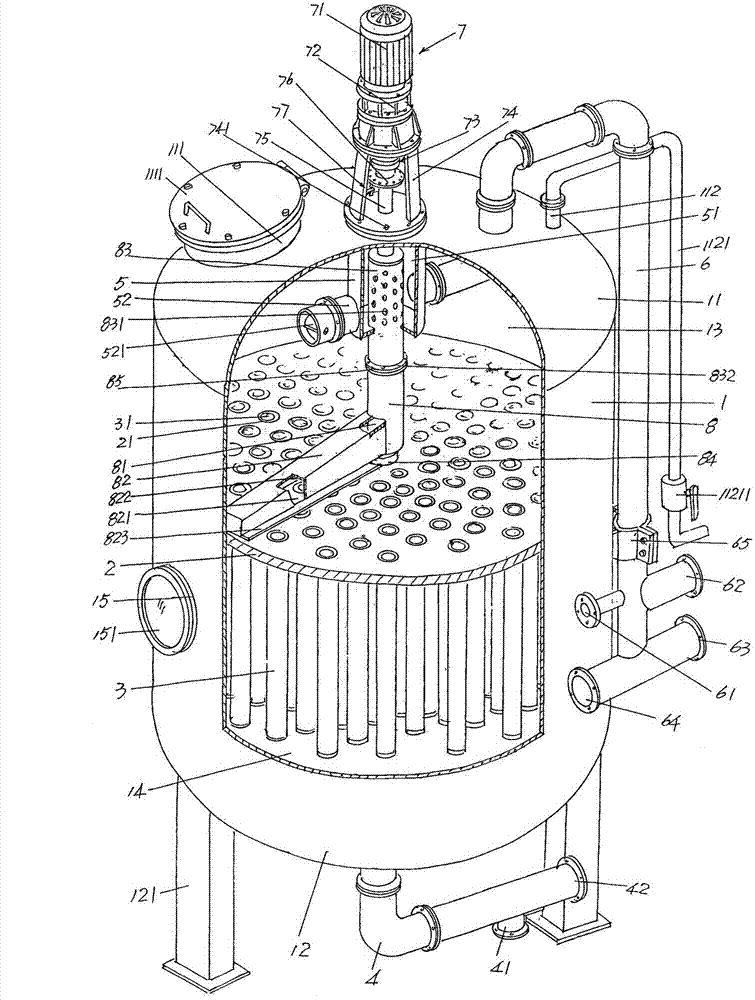

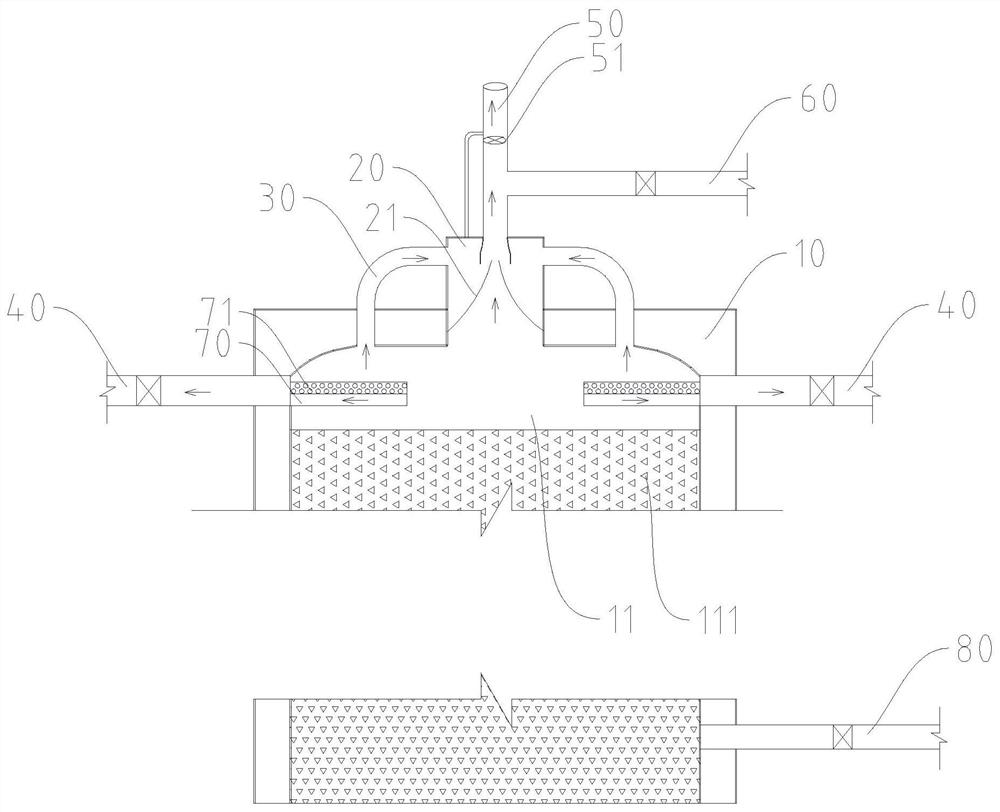

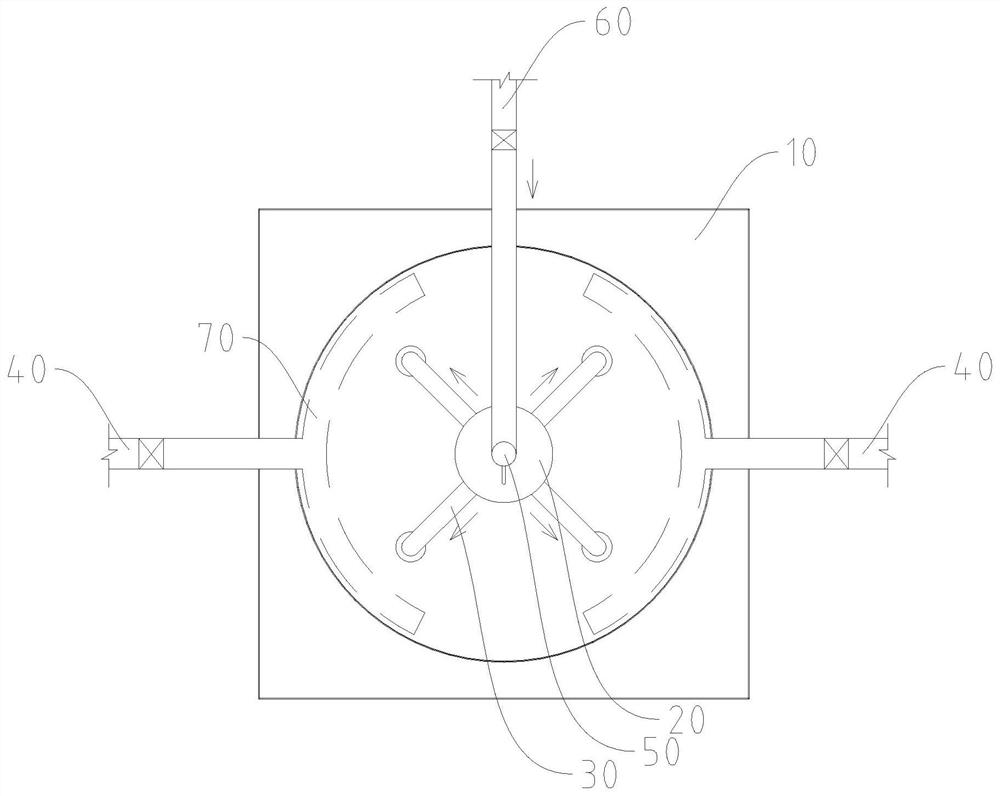

Novel rotating energy-saving water purifying device

ActiveCN103381305AShort backwash timeGood effectLoose filtering material filtersGravity filtersRaw waterWater purification filter

The invention discloses a novel rotating energy-saving water purifying device in the field of raw water purification. A water purifying container is cylindrical and tubular, oval sealing heads are adopted on the upper portion and the lower portion, and a sealing pressure bearing container is formed in a welding mode through metal. A scraper is a rotating type scraper. A scraper motor drives a lower scraping plate through a rotating shaft to move circularly around the central axis, the scraper motor is a hydraulic motor and utilizes self water pressure to spray water radially to generate counter acting force and moves circularly around the central axis under the drive of the counter acting force. High pressure raw water at a back washing dirt discharging water inlet / outlet is used for back washing a filtering material, the raw water enables a sand layer to be bulk by utilizing the self pressure from bottom to top during back washing, and intercepted impurities are brought out of the water purifying device through the high pressure water. The water purifying device has the advantages of being reasonable in process, low in energy consumption, short in back washing time, complete in sludge discharge and the like.

Owner:上海禹清环境技术有限公司

Automatic back flush and liquid absorption filter

ActiveCN102258899BImprove filtering effectEffective filteringStationary filtering element filtersBlowoff valveEmulsion

The invention relates to an automatic back flush and liquid absorption filter, belonging to the field of an automatic back flush filter device for an emulsion in a coal mine. In the filter provided by the invention, a barrel body (5) is divided into two parts; the interior of the barrel body (5) is divided into a liquid absorption chamber (1) and a filtration chamber (6); a liquid outlet (24) is formed on one end surface of the liquid absorption chamber (1); a back flush device is installed in the liquid absorption chamber (1); a filter element (7) is installed in the filtration chamber (6) through a bearing (29) and a shaft (28); a check valve (11) is installed at the other end of the filtration chamber (6) through a limit piece (9); the check valve (11) is connected with a control mechanism (16); a blowoff valve (4) is installed in a drain outlet (3) at one side of the filtration chamber (6); a back flush pipe is installed at one side in the barrel body (5) and between the filter element (7) and the barrel body (5); one end of the back flush pipe is connected with the back flush device, and the other end is installed in the filtration chamber (6); and multiple back flush holes (40) are uniformly distributed on the wall of the pipe. The filter provided by the invention has the advantages of large filter area, strong drain capacity, long service life, can realize timing or automatic online cleaning and the like.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

A backwash filter

InactiveCN106492528BImprove suction efficiencyWash thoroughlyStationary filtering element filtersFiltrationAir pump

The invention provides a back flush filter, relating to the field of sewage purification treatment facilities. The back flush filter comprises a shell, an electrodynamic mechanism, a coarse screen, a fine screen, a sewage suction device and a gas supply unit, wherein the coarse screen and fine screen are arranged in the cavity of the shell; the coarse screen and fine screen are respectively cylindrical, and form a back flush chamber with the inner wall of the shell; one end of the shell is provided with a sewage inlet; the upper end of the shell is provided with the electrodynamic mechanism and a purified water outlet; the lower end of the shell is provided with a drainage port; the sewage suction device comprises a drainage pipe, a high-pressure gas pipe, a sewage suction pipe and an exhaust pipe; the high-pressure gas pipe is sheathed in the drainage pipe; the sewage suction pipe communicates with the inner cavity of the drainage pipe; the exhaust pipe penetrates through the wall of the drainage pipe and communicates with the inner cavity of the high-pressure gas pipe; the exhaust pipe comprises a straight-opening pipe and a bent-opening pipe; and the gas supply unit comprises a motor, a gas pump and a gas supply pipe. The back flush filter has the advantages of high cleaning efficiency and thorough cleaning, and can satisfy the quality requirements for sewage filtration and automatic drainage.

Owner:衡阳中重机械装备有限公司

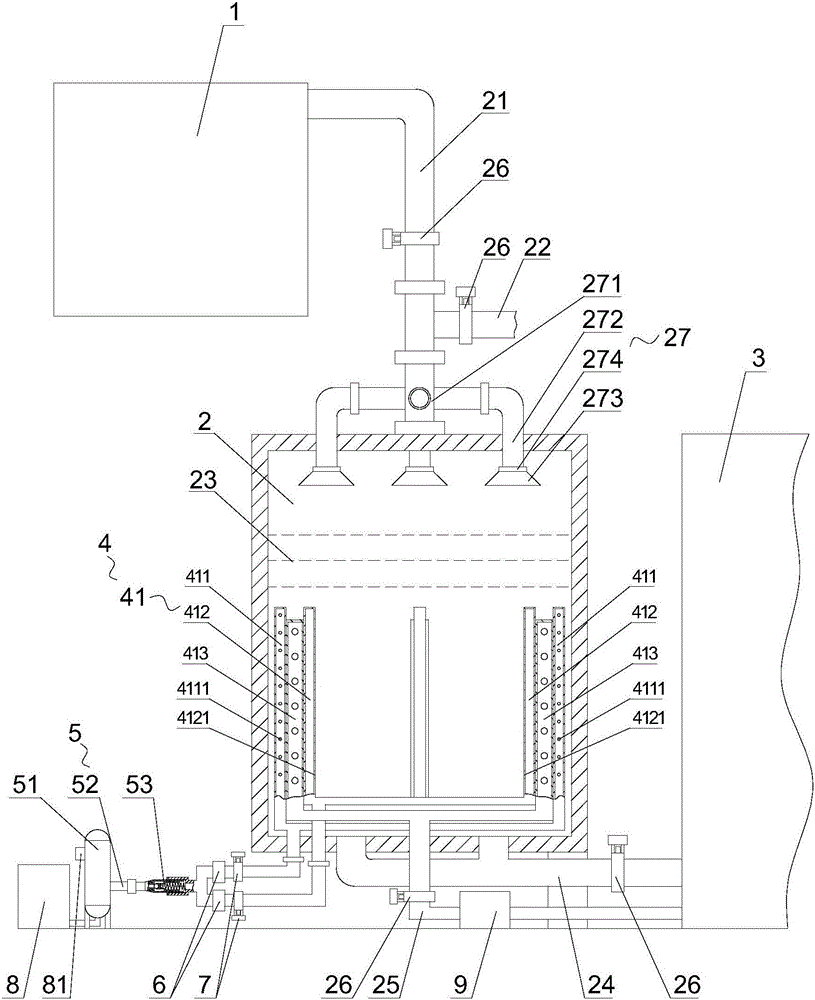

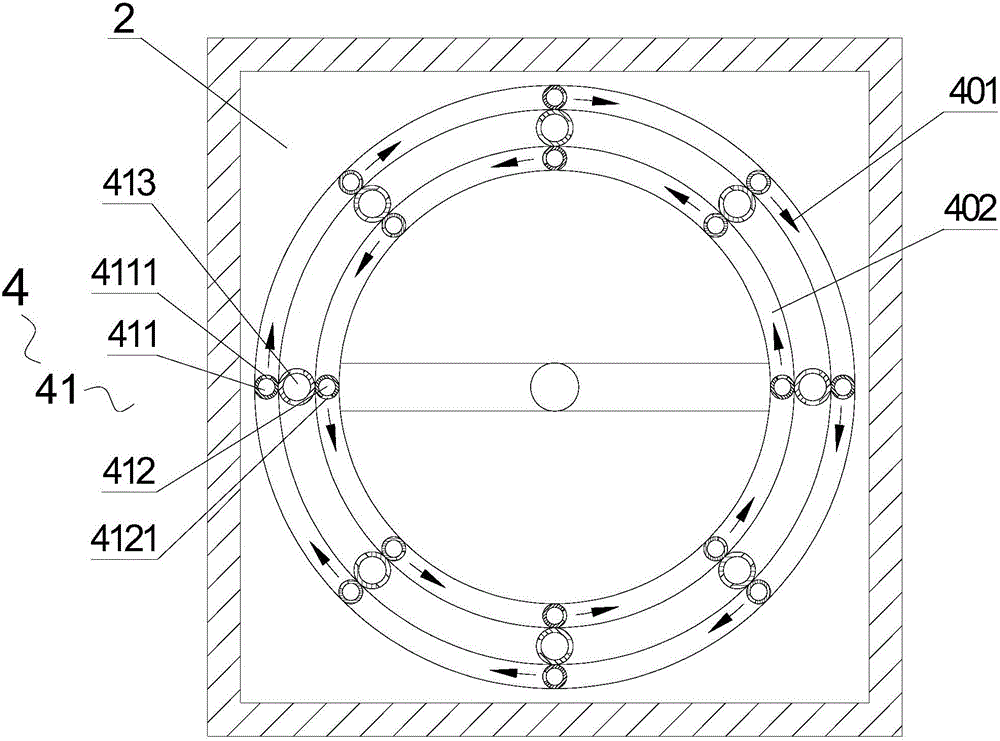

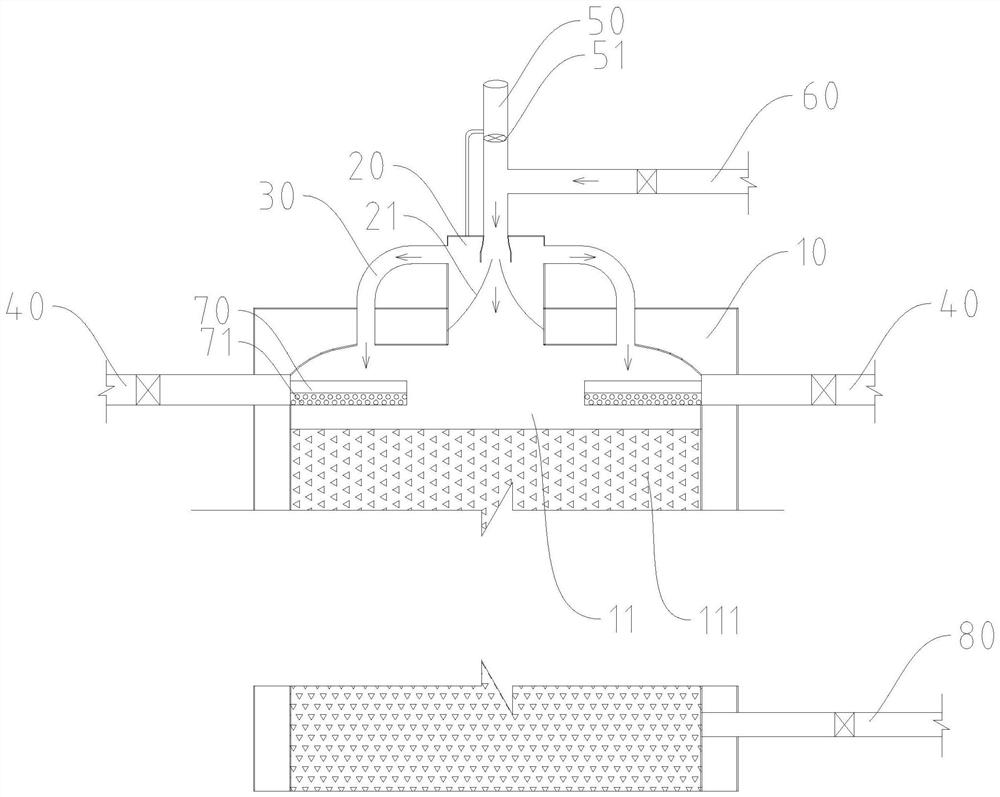

Spiral pulse gas-water composite backflushing system

PendingCN106310776AShort backwash timeSave backwash waterLoose filtering material filtersGravity filtersFilter mediaEngineering

The invention discloses a spiral pulse gas-water composite backflushing system which includes a filter tank, gas-water mixing jet pipes are in circumference array arrangement in the filter tank, independent first and second pulse gas jet branch pipes and a backflushing water jet pipe are arranged in each gas-water mixing jet pipe, the out-jet direction of jet ports of the first pulse gas jet branch pipes are in clockwise arrangement according to the circumference array to form a positive spiral pulse gas-water mixing jet system, the out-jet direction of gas-water jet ports of the second pulse gas jet branch pipes are in anticlockwise arrangement according to the circumference array to form a negative spiral pulse gas-water mixing jet system, and the first and second pulse gas jet branch pipes are connected with a pulse gas source input device. A filter media in the filter tank can be stirred at a high speed by spiral pulse compound gas and water, the filter media can intensely collide and move in the filter tank, discharge of impurities in the filter media into water is accelerated, and the filter media can be quickly restored to the level before filtration.

Owner:ZHONGKE JIELI FUZHOU ENVIRONMENTAL PROTECTION TECH

Filter for sea water desalination pretreatment

ActiveCN102344174AIncreased durabilityImprove backwashing effectSeawater treatmentWater/sewage treatmentWater desalinationMetallic materials

The invention relates to a filter for a pretreatment technology of sea water desalination. Sea water corrosion resistant antiseptic is added into filter concrete; a concrete interior surface contacting with sea water is coated with sea water resistant anticorrosive paint; steel bar in the concrete is provided with steel bar rust remover; metal pieces contacting with sea water in the filter are made of high alloy duplex stainless steel S32205 (ASTM); non-metallic materials comprise sea water corrosion resistant FRP glass fiber reinforced plastic, ABS engineering plastic and EPDM rubber, etc. Durability of the filter is enhanced; air water back washing and surface sweep washing are employed by the filter to realize a good back washing effect; technical breakthrough in filter material selection is realized by employing a double layer filter material, which has strong dirt containing ability, and quality of water outlet from the filter is improved substantially; during air water back washing, electric draining gate valve is closed, so as to realize high speed backwashing, short backwashing time, long backwashing period, small water consumption and avoid loss of filter material during backwashing. The filter has a high degree of automatic operation and is convenient for management; besides, a civil structure is simple in order to save capital construction investment and facilitate construction.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

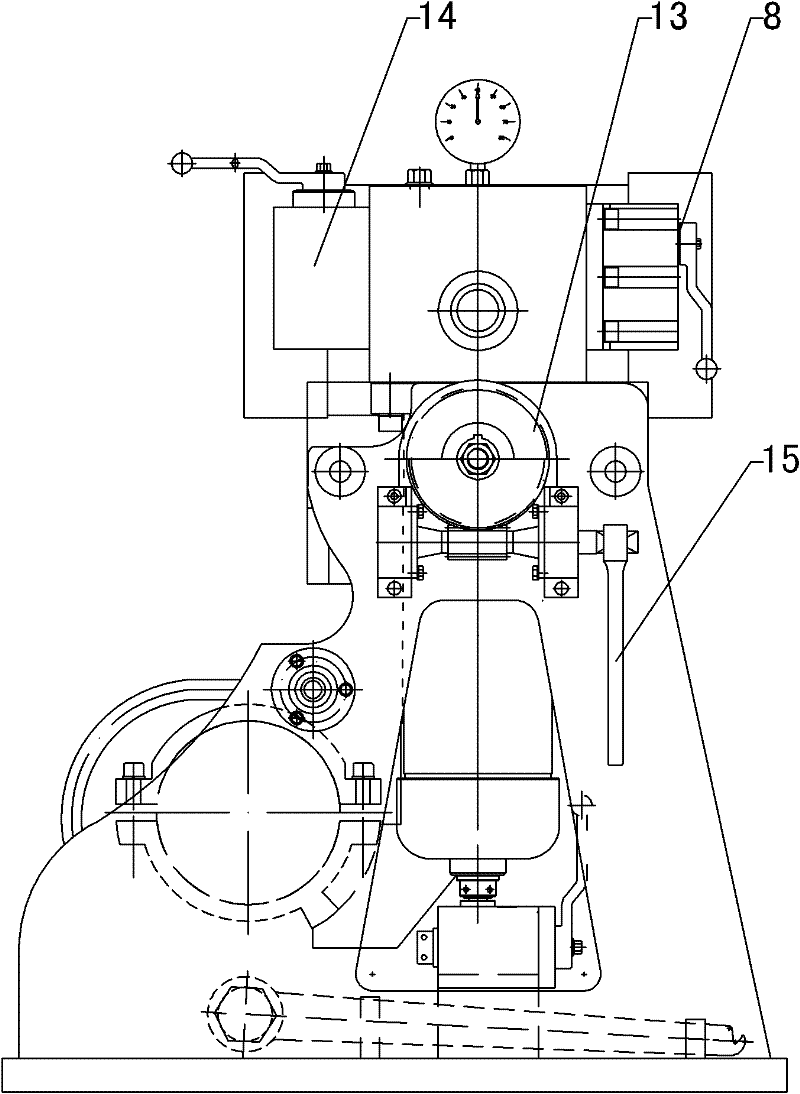

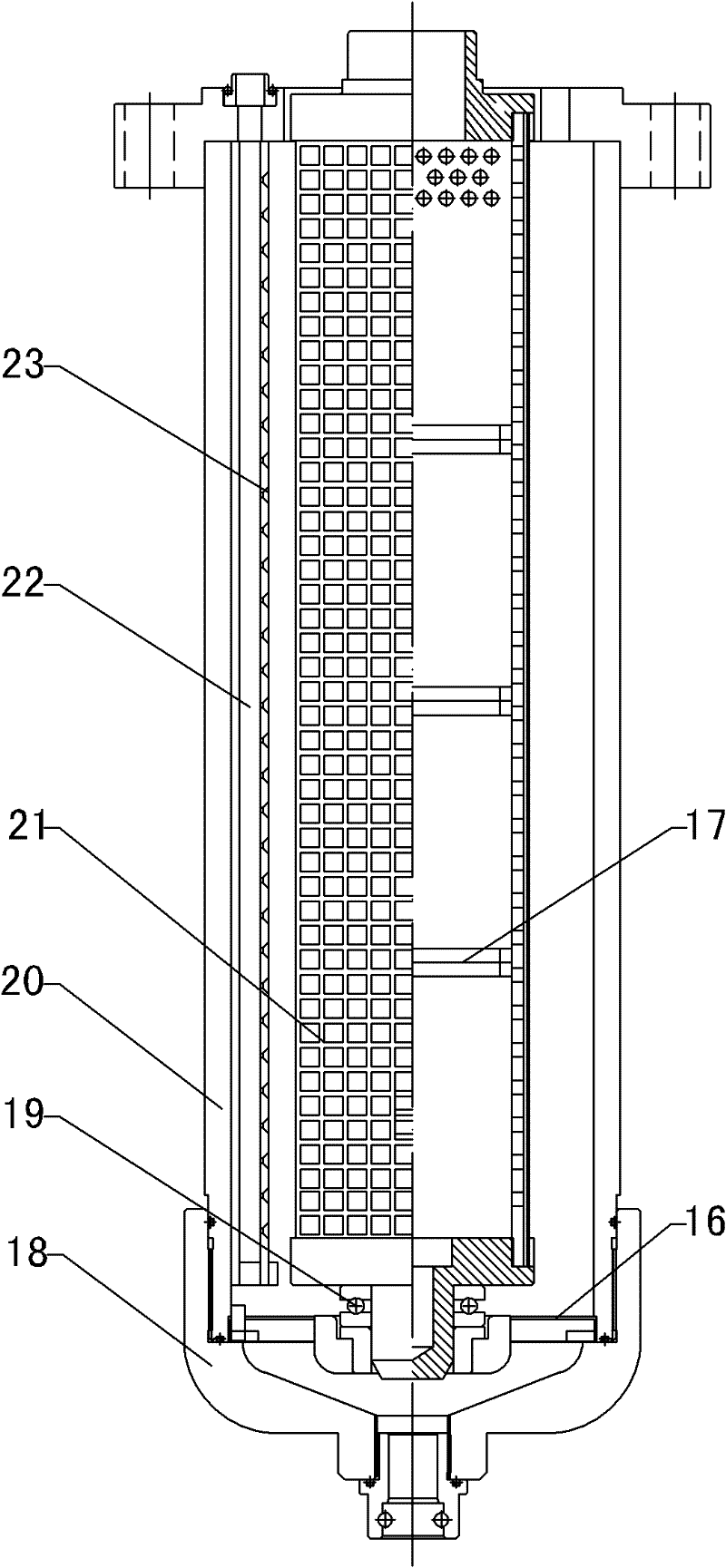

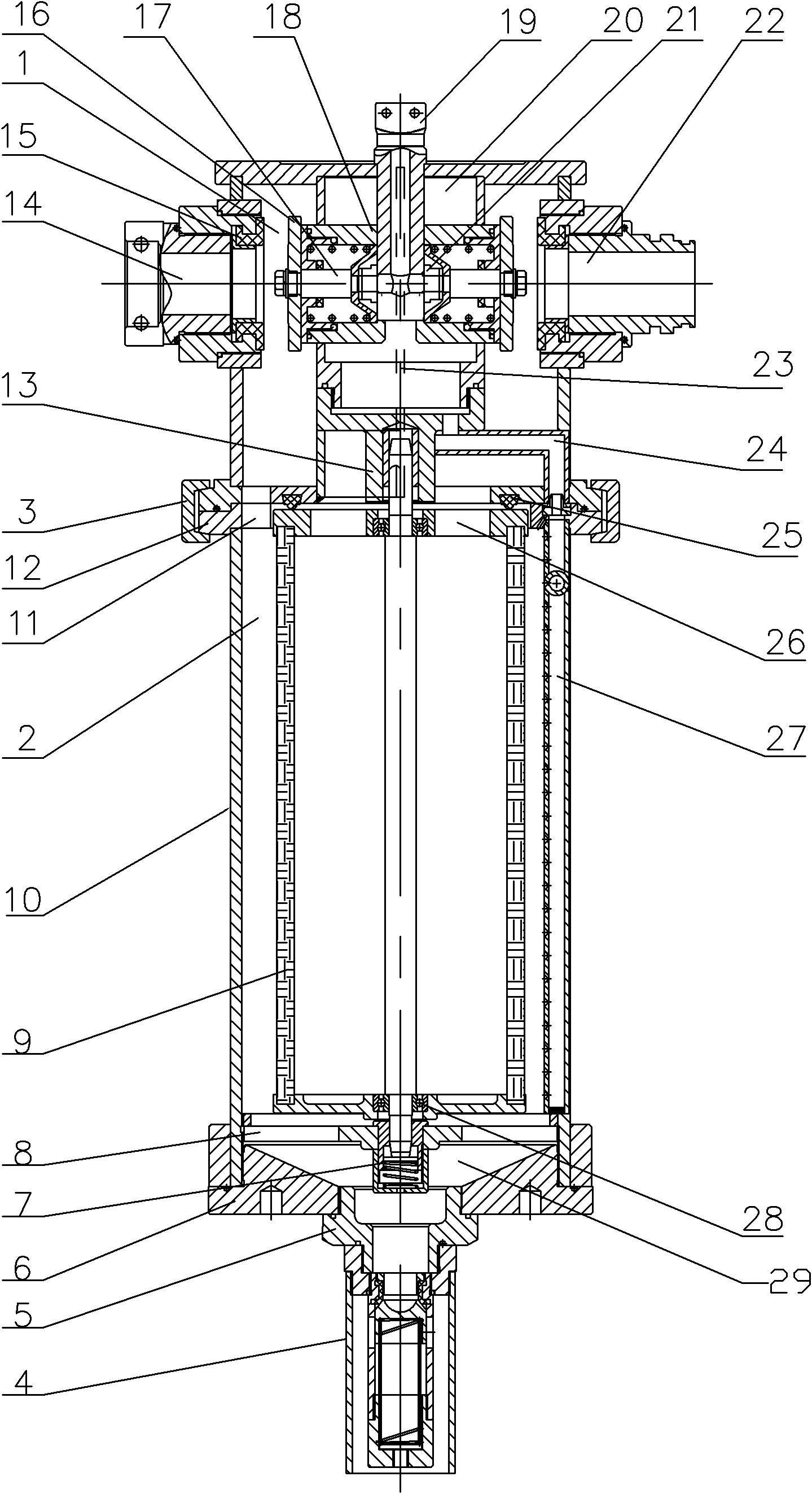

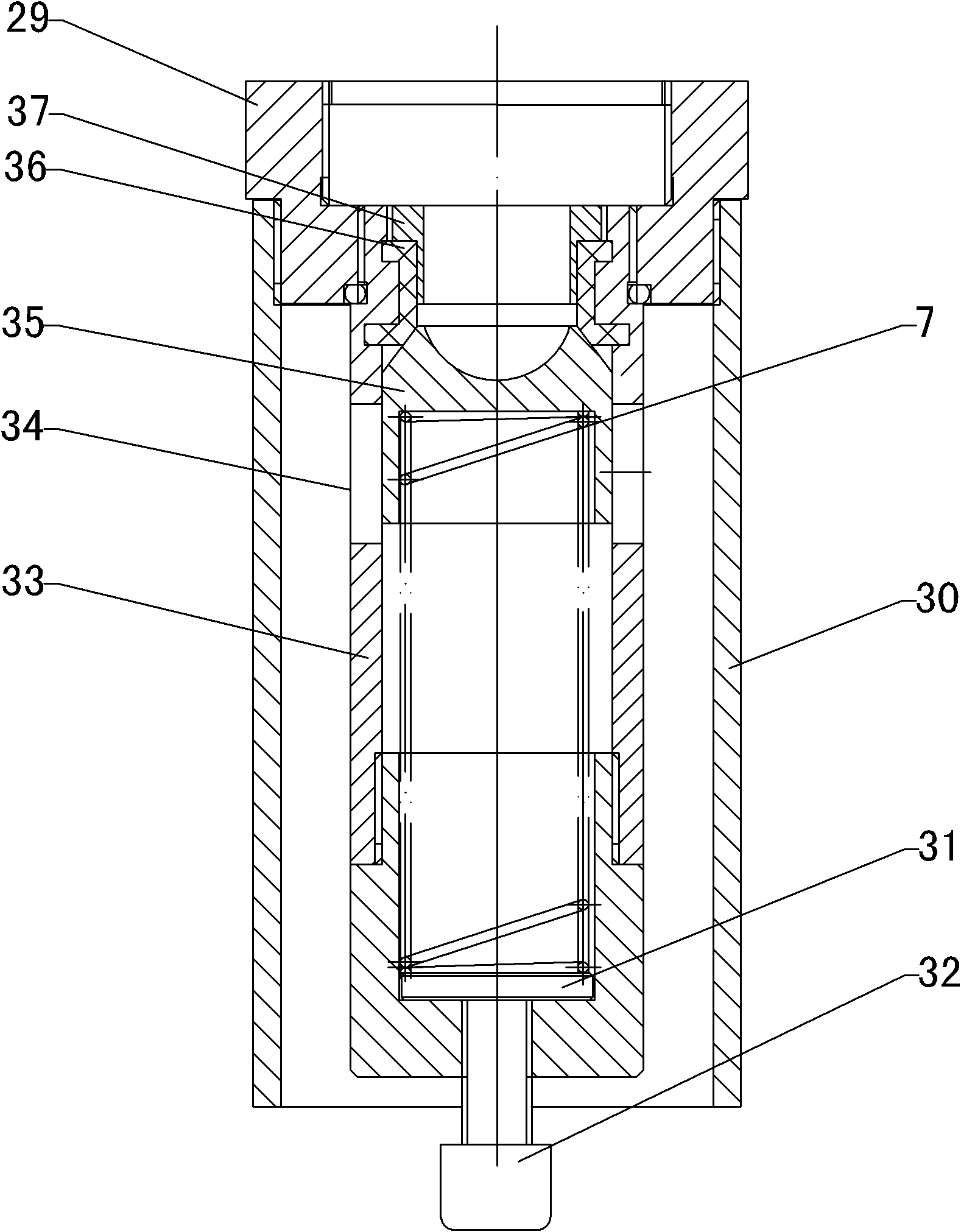

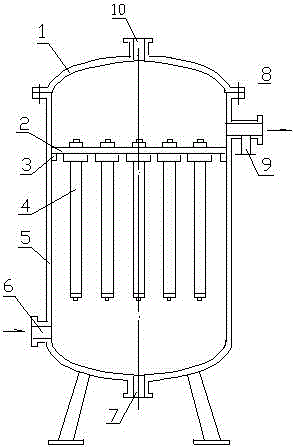

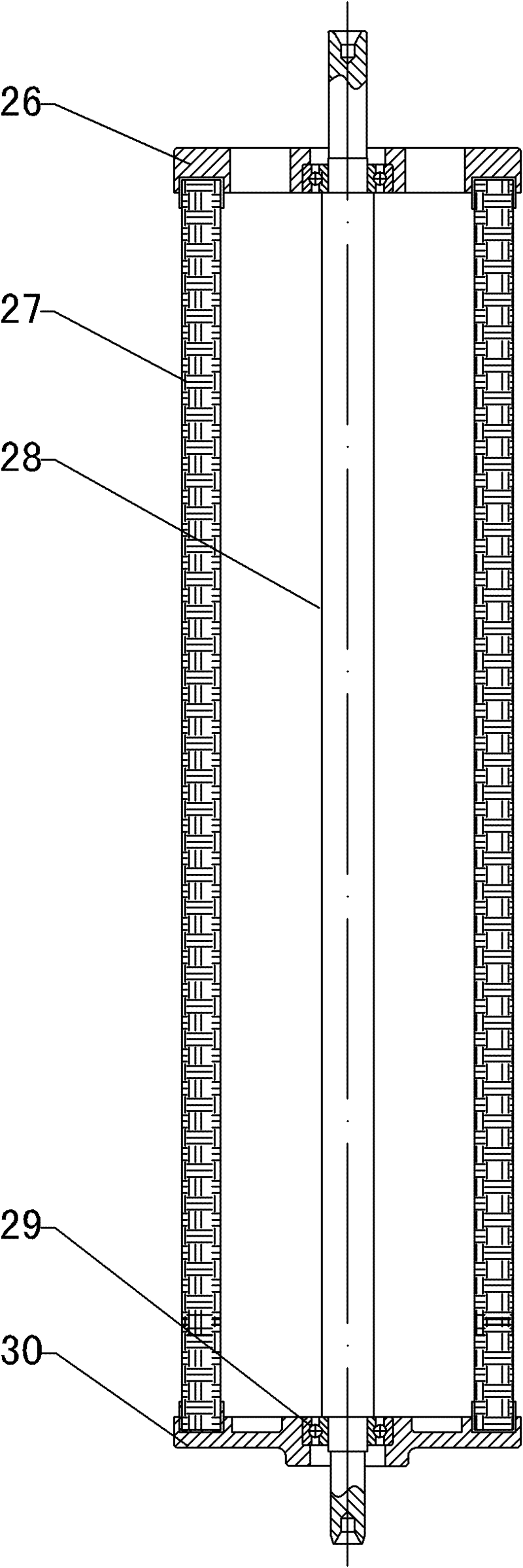

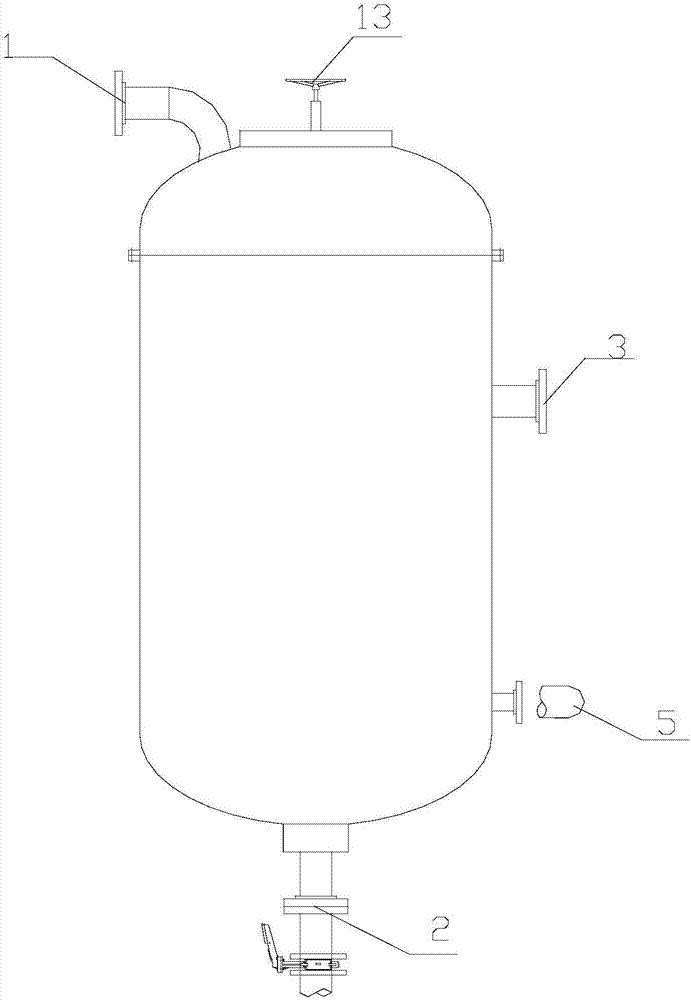

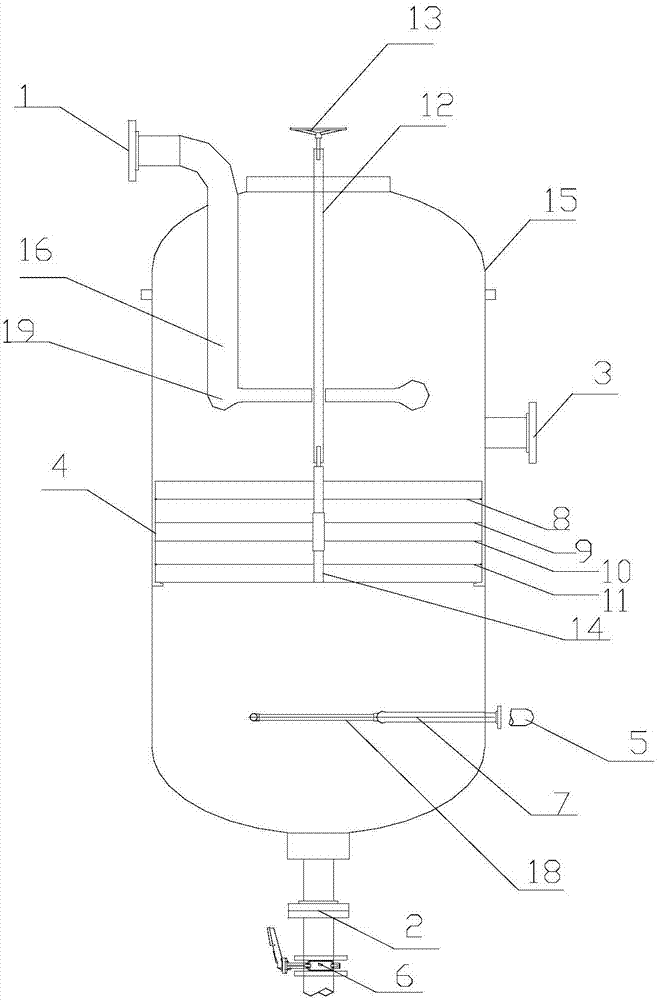

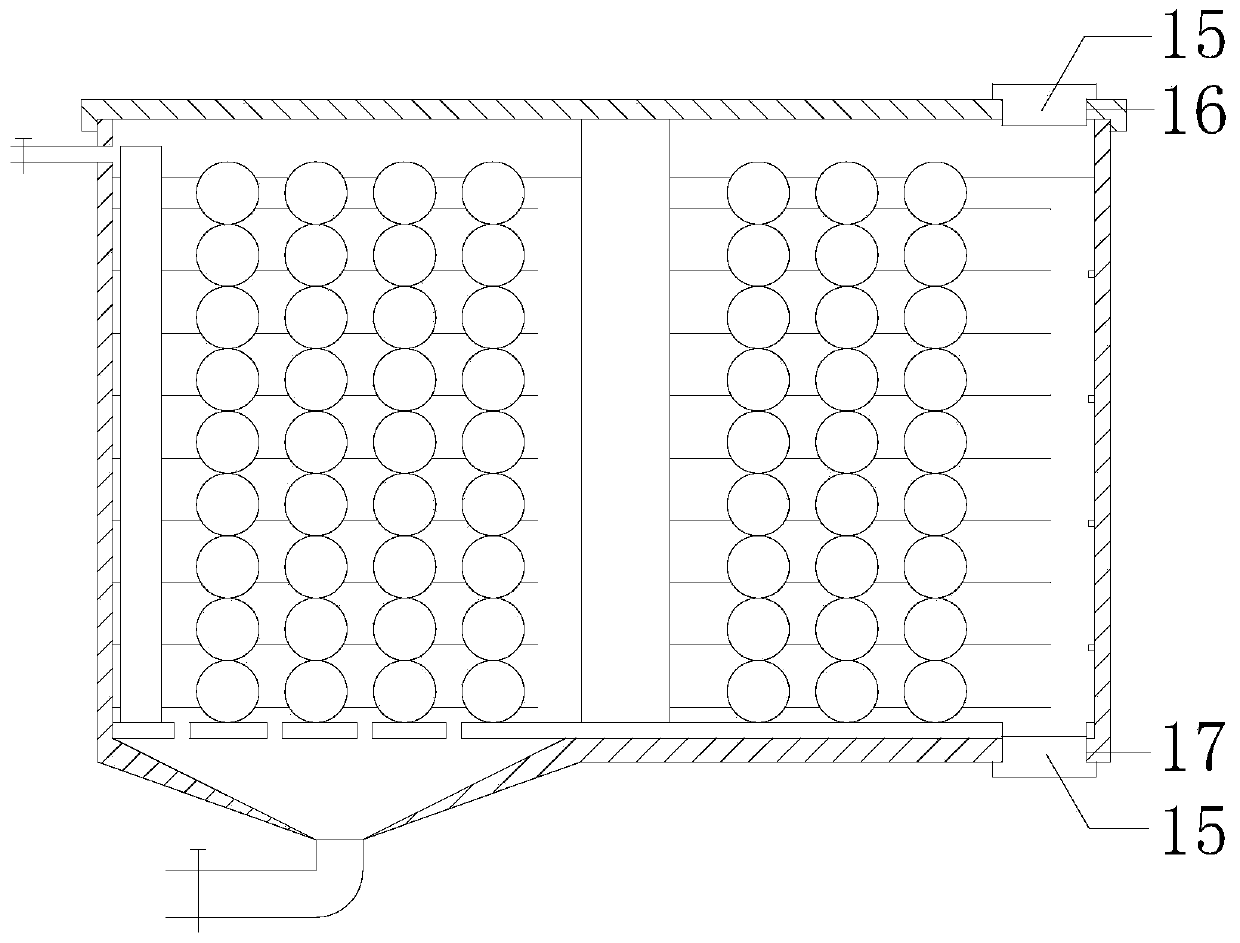

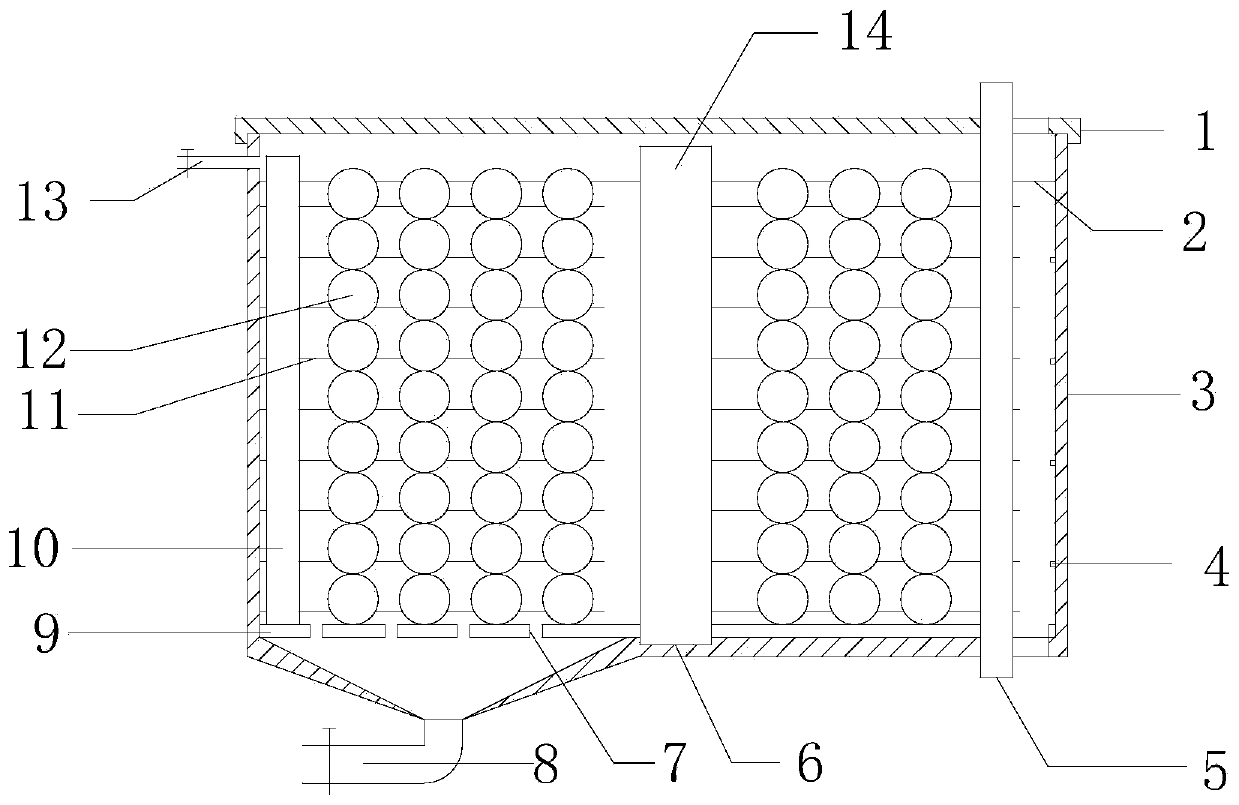

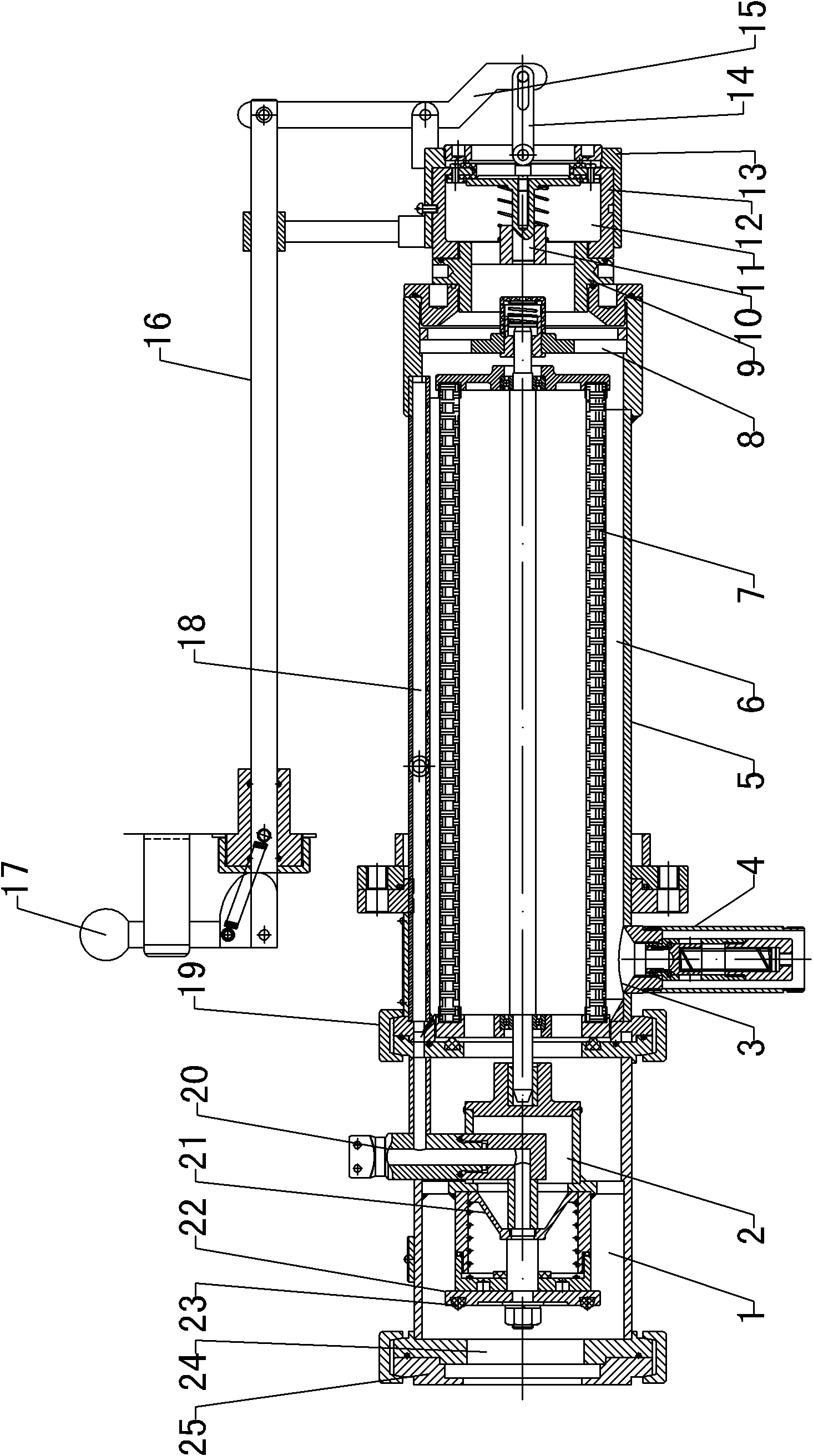

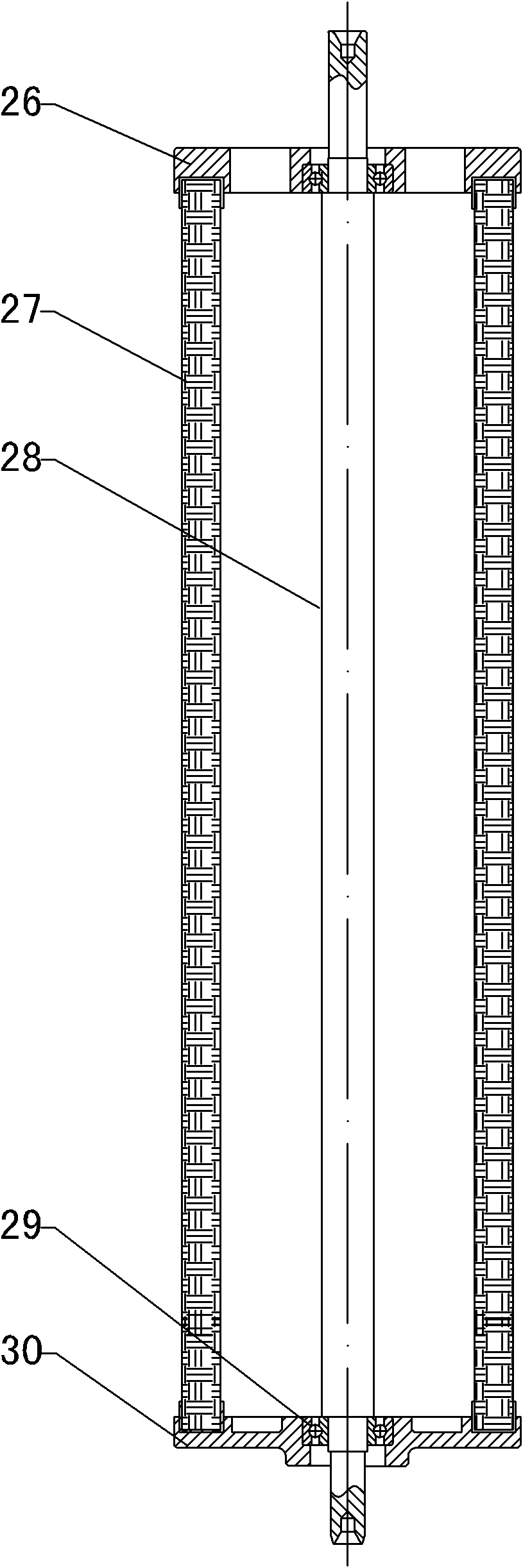

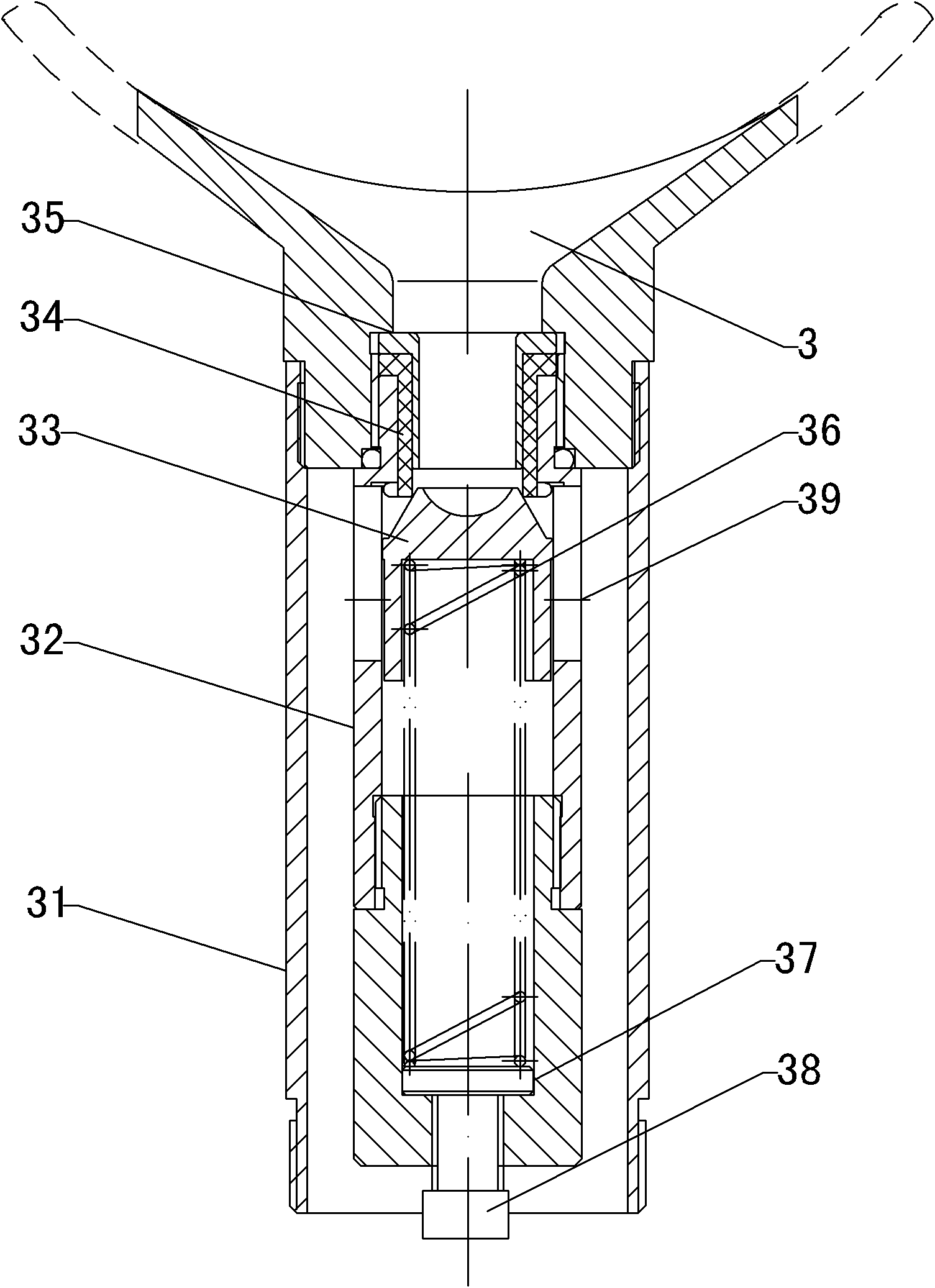

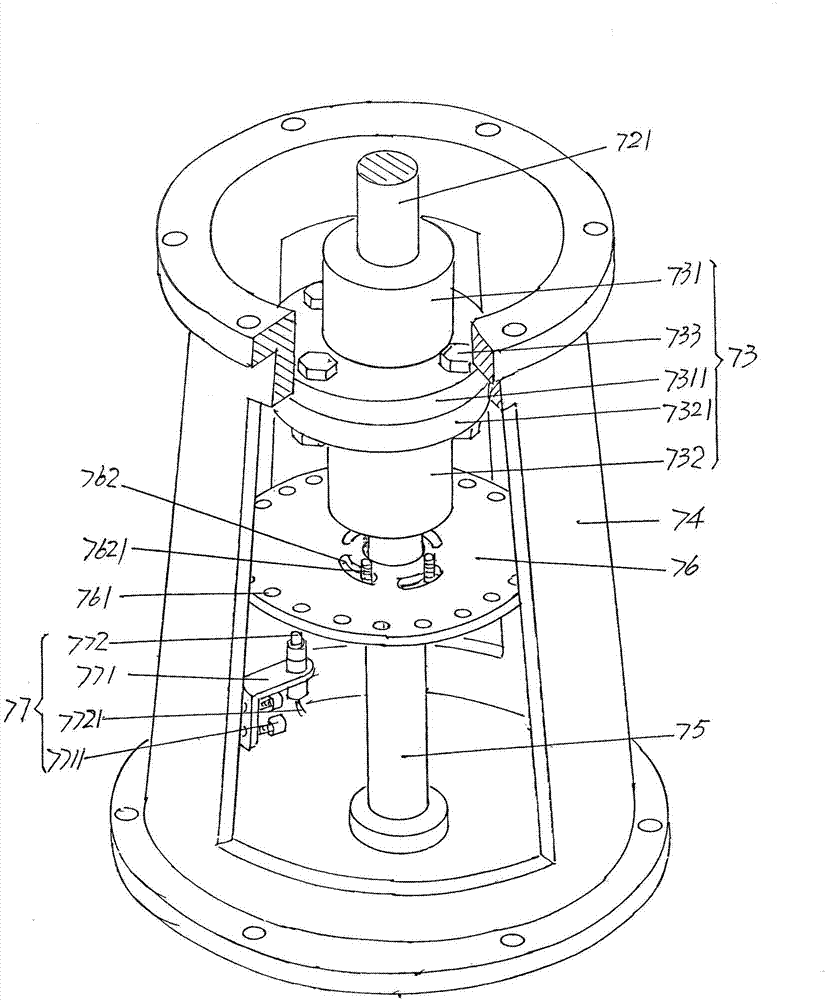

Precision treater for condensed water

ActiveCN103480193AGood backwash effectShort backwash timeStationary filtering element filtersEngineeringMechanical engineering

A precision treater for condensed water belongs to the technical field of water treatment equipment, and comprises a barrel, a barrel cavity partition plate, a group of lower cavity filter elements, a condensed water leading-in pipe, a spacer sleeve, a return water pipe, a back-wash pipe drive mechanism and a back-wash pipe, wherein the barrel is provided with an upper seal head and a lower seal head; the barrel cavity partition plate is arranged in a barrel cavity; a group of lower cavity filter element liquid outlet matching holes are formed in the barrel cavity partition plate; the lower cavity filter elements are arranged in the lower cavity of the barrel; the condensed water leading-in pipe is fixed with the bottom of the lower seal head; the spacer sleeve is fixed on one side of the upper seal head; a spacer sleeve water inlet connector extends from one side of the spacer sleeve; a one-way valve is arranged on the water inlet connector; one end of the return water pipe extends into the cavity of the spacer sleeve, and the other end thereof extends out of the barrel cavity; the back-wash pipe drive mechanism is arranged on the upper seal head; the upper end of the back-wash pipe extends into the cavity of the spacer sleeve, and the lower end thereof is supported in the center of the barrel cavity partition plate. The precision treater has the characteristics that a back-wash liquid spray arm is fixed at the lower end of the back-wash pipe, a spray arm opening is formed in the bottom of the back-wash liquid spray arm, the back-wash effect is ideal, the back-wash time is shortened, energy is saved, the outage time of the equipment is shortened, the structure is simplified, and the material is saved.

Owner:常熟市华能水处理设备有限责任公司

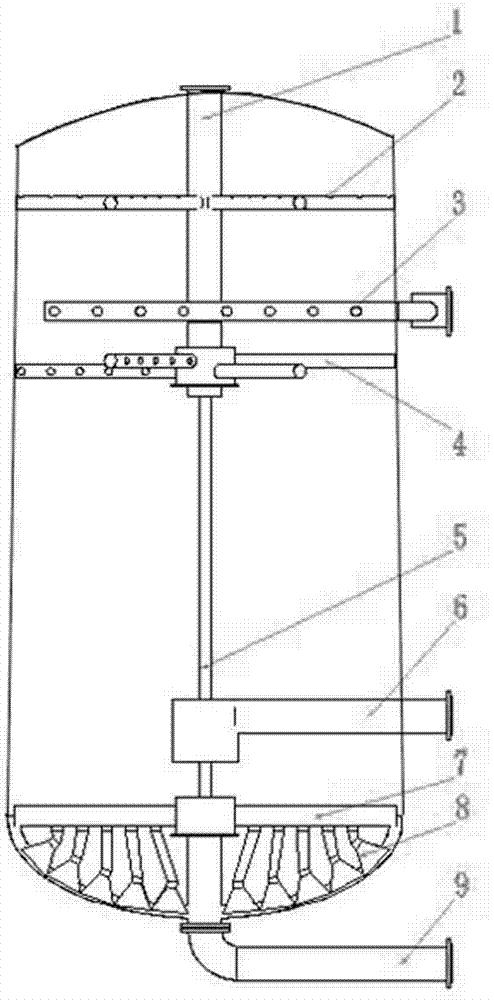

Biological aerated filter

InactiveCN102557244BShort backwash timeLarge amount of waterSustainable biological treatmentBiological water/sewage treatmentSludgeInjection air

Owner:陕西蓝清环境科技有限公司

Novel rotating energy-saving water purifying device

ActiveCN103381305BReasonable workmanshipReduce energy consumptionLoose filtering material filtersGravity filtersHydraulic motorMotor drive

The invention discloses a novel rotating energy-saving water purifying device in the field of raw water purification. A water purifying container is cylindrical and tubular, oval sealing heads are adopted on the upper portion and the lower portion, and a sealing pressure bearing container is formed in a welding mode through metal. A scraper is a rotating type scraper. A scraper motor drives a lower scraping plate through a rotating shaft to move circularly around the central axis, the scraper motor is a hydraulic motor and utilizes self water pressure to spray water radially to generate counter acting force and moves circularly around the central axis under the drive of the counter acting force. High pressure raw water at a back washing dirt discharging water inlet / outlet is used for back washing a filtering material, the raw water enables a sand layer to be bulk by utilizing the self pressure from bottom to top during back washing, and intercepted impurities are brought out of the water purifying device through the high pressure water. The water purifying device has the advantages of being reasonable in process, low in energy consumption, short in back washing time, complete in sludge discharge and the like.

Owner:上海禹清环境技术有限公司

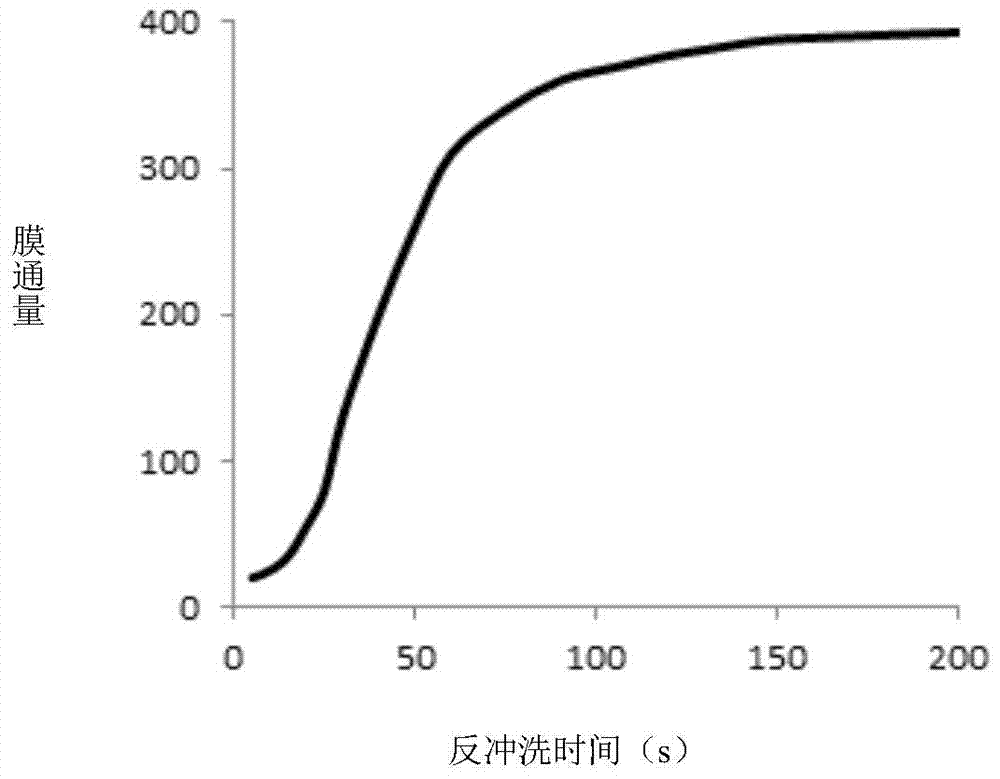

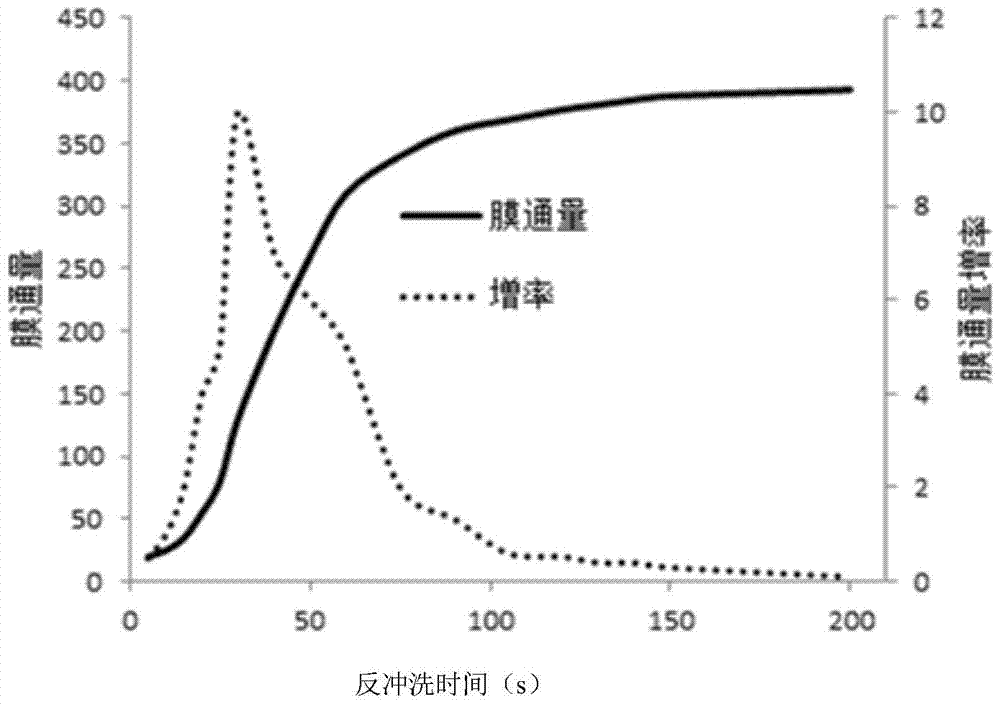

Method for Optimizing Backwashing Time of Membrane Bioreactor

ActiveCN105084528BImprove daily runtimeReduce energy consumptionSustainable biological treatmentBiological water/sewage treatmentMembrane bioreactorEnergy consumption

The invention discloses a method for optimizing the backwashing time of a membrane bioreactor. The method comprises the following steps: conducting backwashing on the membrane bioreactor, and establishing a relation curve of the backwashing time and the membrane flux of a membrane assembly; calculating the membrane flux increase rate mu of the membrane assembly, and establishing a relation curve of the membrane flux increase rate mu and the backwashing time; confirming the highest membrane flux increase rate mu1 and the corresponding backwashing time T1, and searching for the backwashing time T2 corresponding to a ratio of the highest membrane flux increase rate mu1 to a, wherein if T2 is longer than T1, T2 is the optimized backwashing time of the membrane bioreactor. According to the method, the efficiency of cleaning the membrane bioreactor is improved, the energy consumption is reduced, the damage of washing to the membrane bioreactor is weakened, and the service life of the membrane assembly in the membrane bioreactor is prolonged.

Owner:BEIJING JINKONG DATA TECH +1

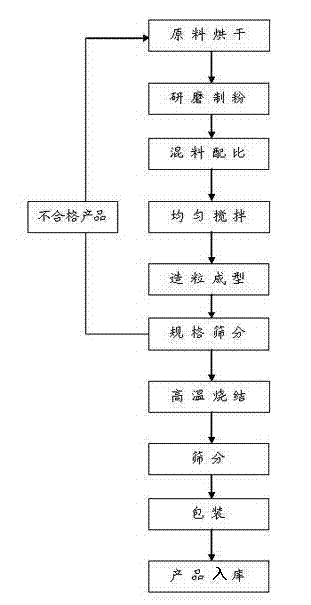

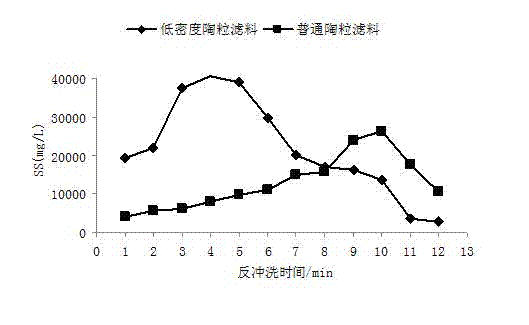

Low-density ceramsite filter material for biological aerated filter, and preparation method thereof

InactiveCN102258913BModerate densityLow densitySustainable biological treatmentFiltration separationVolumetric Mass DensityHigh surface

The invention relates to a low-density ceramsite filter material for a biological aerated filter, and a preparation method thereof. The invention provides the low-density ceramsite filter material for the biological aerated filter, and the low-density ceramsite filter material is mainly prepared from Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and a charcoal material. Theinvention also provides a preparation method for the low-density ceramsite filter material. The invention has the advantages that: the Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and charcoal powder are used as raw materials, so that the excellent physical properties such as a large specific surface area, and high surface roughness and mechanical strength and the like of the low-density conventional heavy ceramsite filter material are kept, the density of the low-density ceramsite filter material is reduced well so as to reduce energy consumption during backwashing, contribute to complete backwashing, and avoid the problem that the filter material is hardened during long-term running and the like, the production cost and the waste water treatment cost are greatly reduced, and the popularization and application of the biological aerated filter process can be facilitated.

Owner:谭海燕

An electrostatic separator and cleaning method that can change the packing method

ActiveCN111349456BAchieve purificationEasy to fillRefining by electric/magnetic meansCleaning using liquidsElectrostatic separationStructural engineering

The present invention proposes an electrostatic separator and a cleaning method capable of changing the packing accumulation mode, so that the packing accumulation mode can be conveniently changed without disassembly in the electrostatic separator, and solves the problem of insufficient backwashing of the packing material in the prior art. The technical problems of low efficiency and difficult packing drying include the cylinder body, the coaxial electrode column, a number of packing plates between the inner electrode and the cylinder body, and the packing plates are equipped with assembly column insertion holes, fixed column insertion holes, and moving column Jack holes, electrode holes and filler placement holes, the fillers are arranged on the filler plate, the position of the odd-numbered plates is fixed by the fixed column, and the horizontal movement of the even-numbered plates is controlled by the moving column to change the packing accumulation method.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Molecular sieve filter tank water distribution system capable of uniformly distributing water

PendingCN113648687AGuaranteed safe operationEasy dischargeSpecific water treatment objectivesTreatment involving filtrationMolecular sieveDistribution system

The invention discloses a molecular sieve filter tank water distribution system capable of uniformly distributing water. The system comprises a filter tank body, a main water distributor arranged at the top end of the filter tank body and communicated with the filter tank body, at least one water distributor with one end communicated with the main water distributor and the other end communicated with the filter tank body, at least one blow-off pipe arranged on the outer side wall of the filter tank body and communicated with the filter tank body, and an air outlet pipe arranged at the top end of the main water distributor and communicated with the main water distributor, the water inlet pipe is communicated with the air outlet pipe, the water outlet pipe is arranged on the outer side wall of the bottom end of the filter tank body and communicated with the filter tank body, a cut-off device is arranged in the air outlet pipe, the water inlet pipe is located below the cut-off device, and the blow-off pipe is communicated with a blow-off screen pipe which is located in the filter tank body and located below the water distributor. According to the invention, uniform water distribution is realized through the main water distributor and the water distributors, and meanwhile, the effects of quickly separating and discharging water vapor, gas and water in the backwashing process of the molecular sieve filter, shortening the backwashing time, reducing the backwashing water consumption and improving the backwashing efficiency are also achieved.

Owner:福建省水投勘测设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com