Patents

Literature

38results about How to "Does not affect production progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

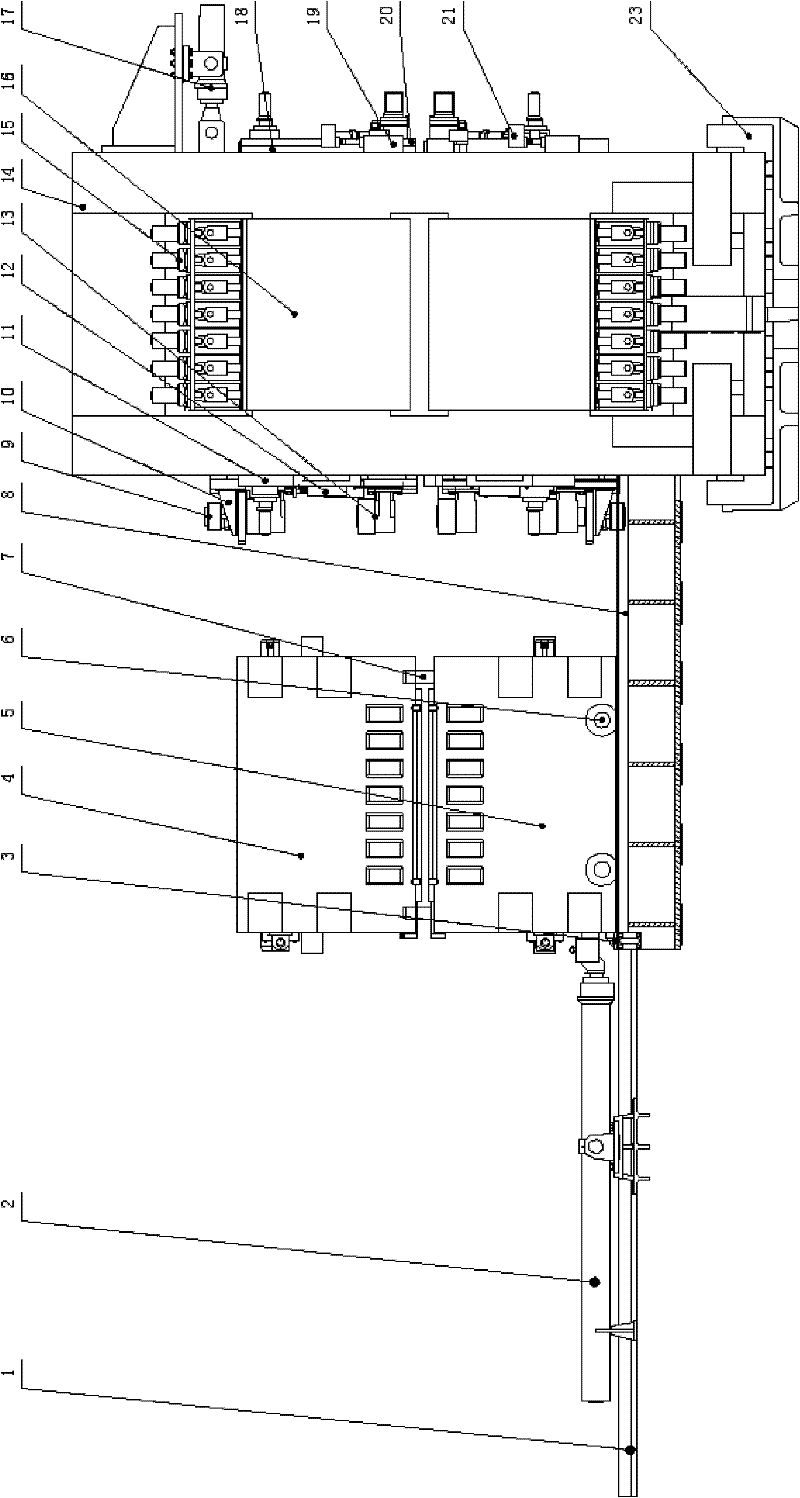

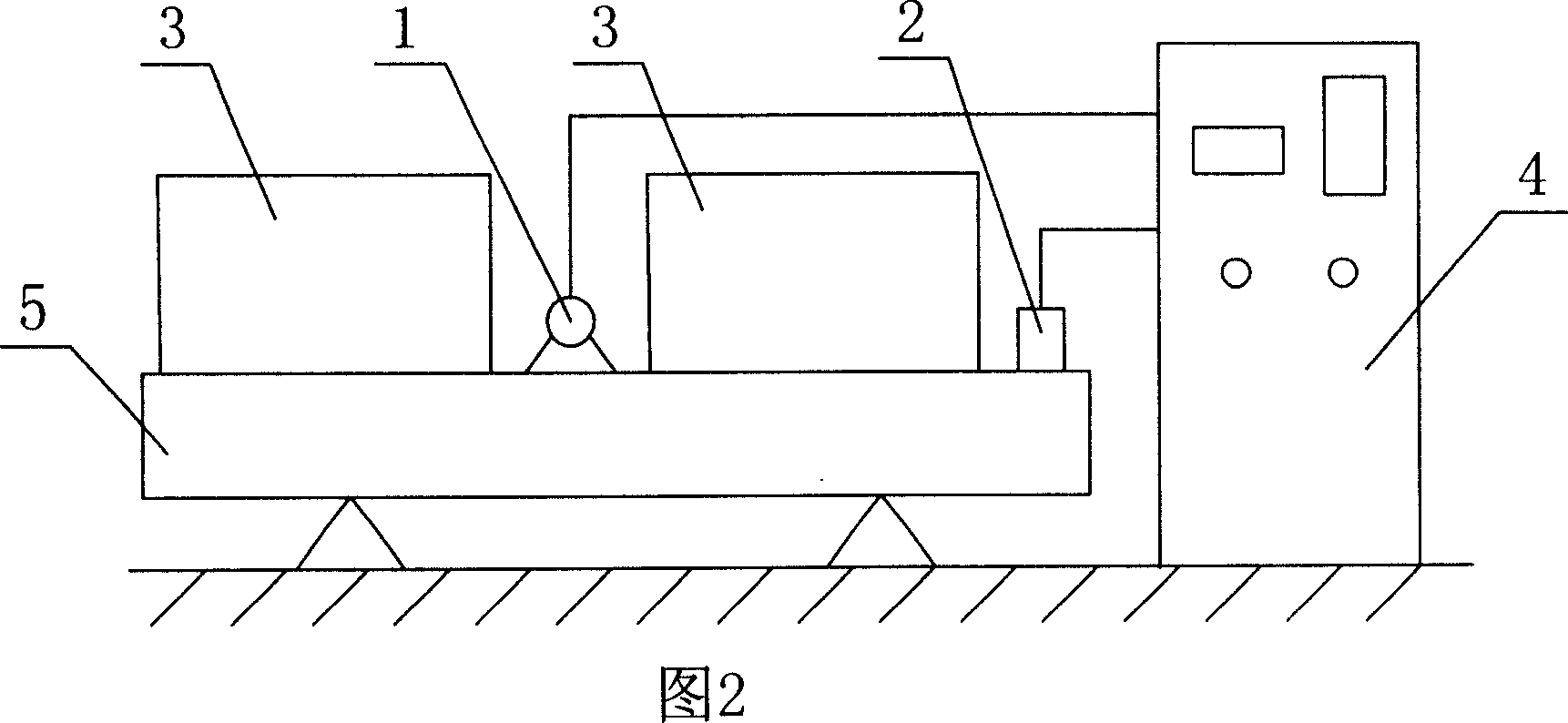

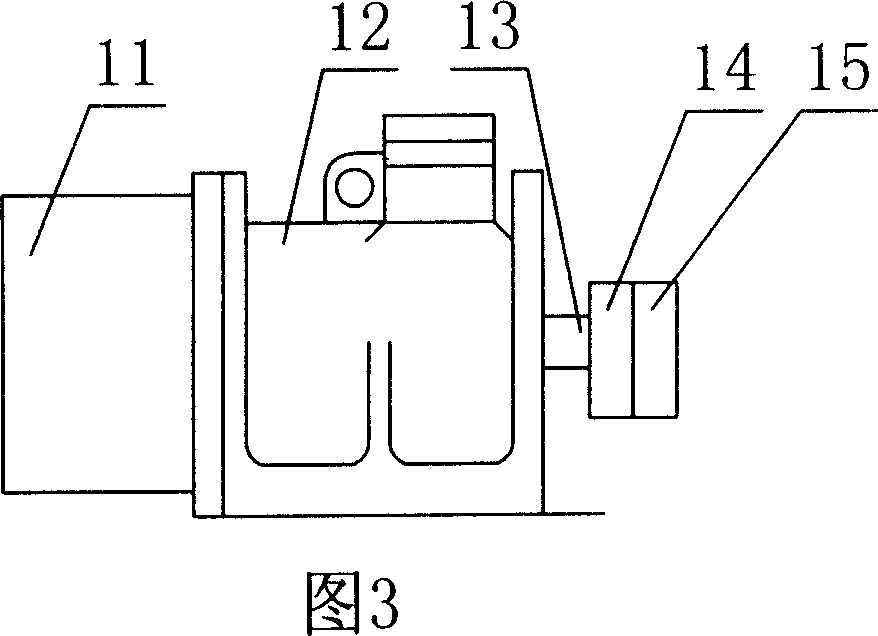

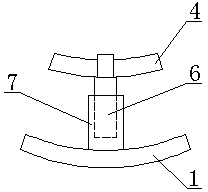

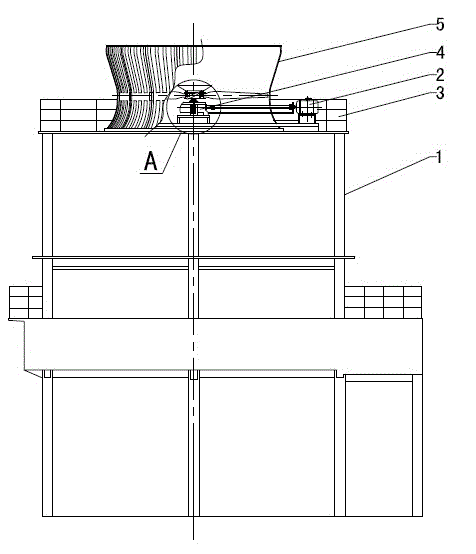

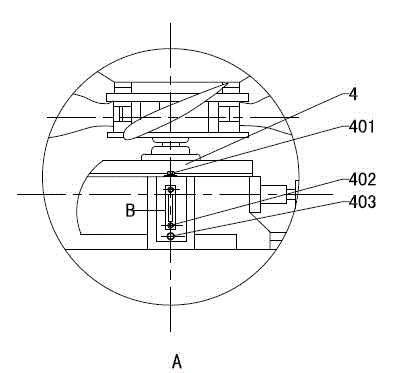

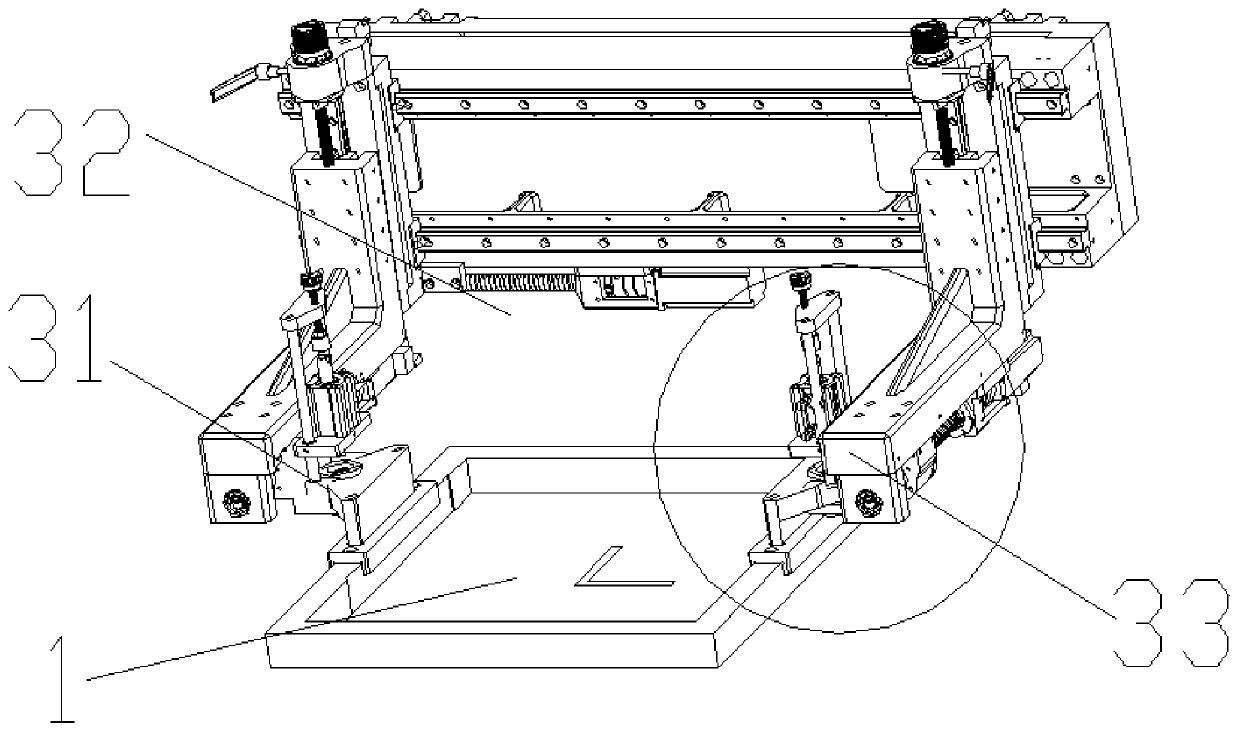

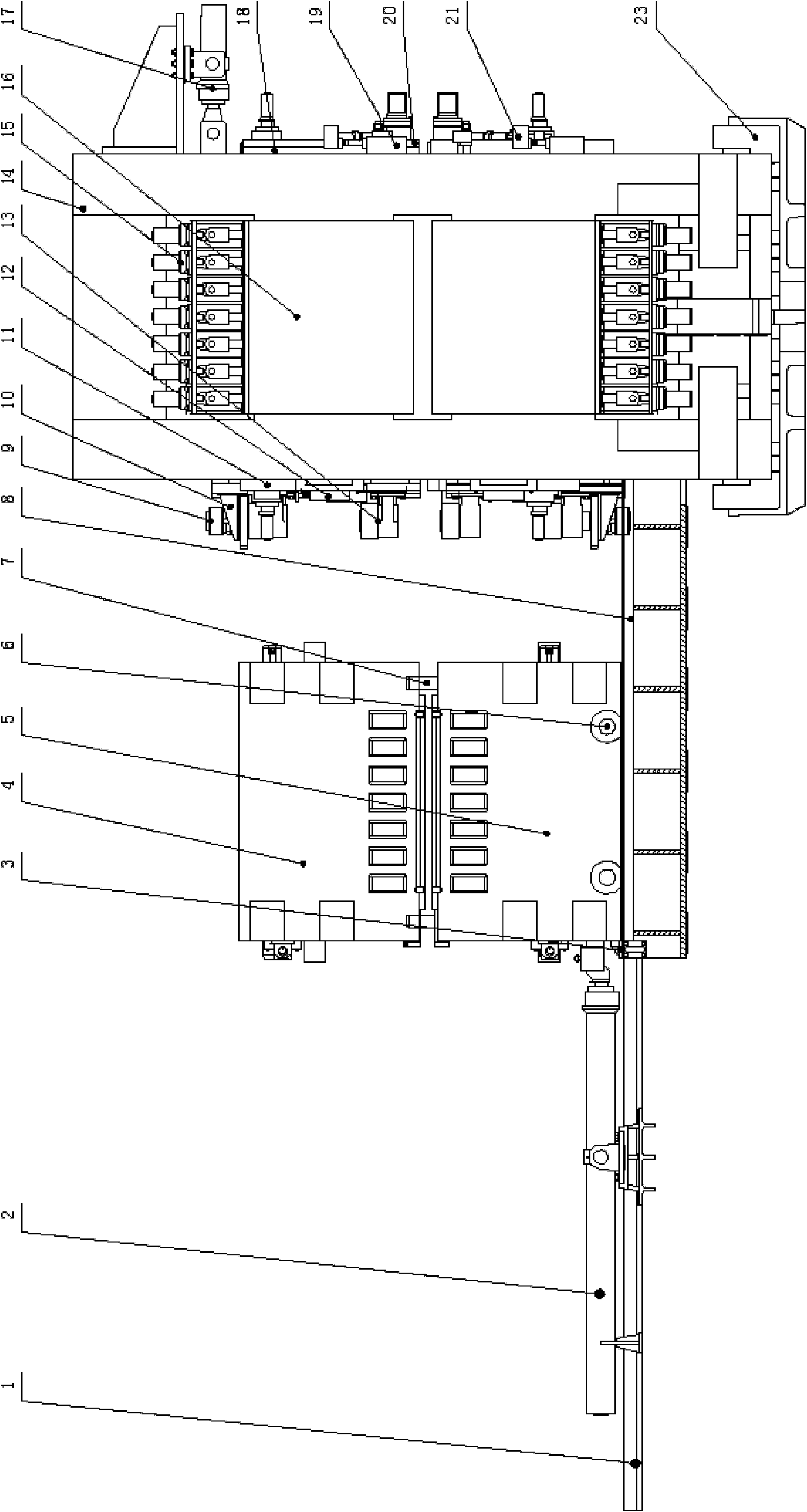

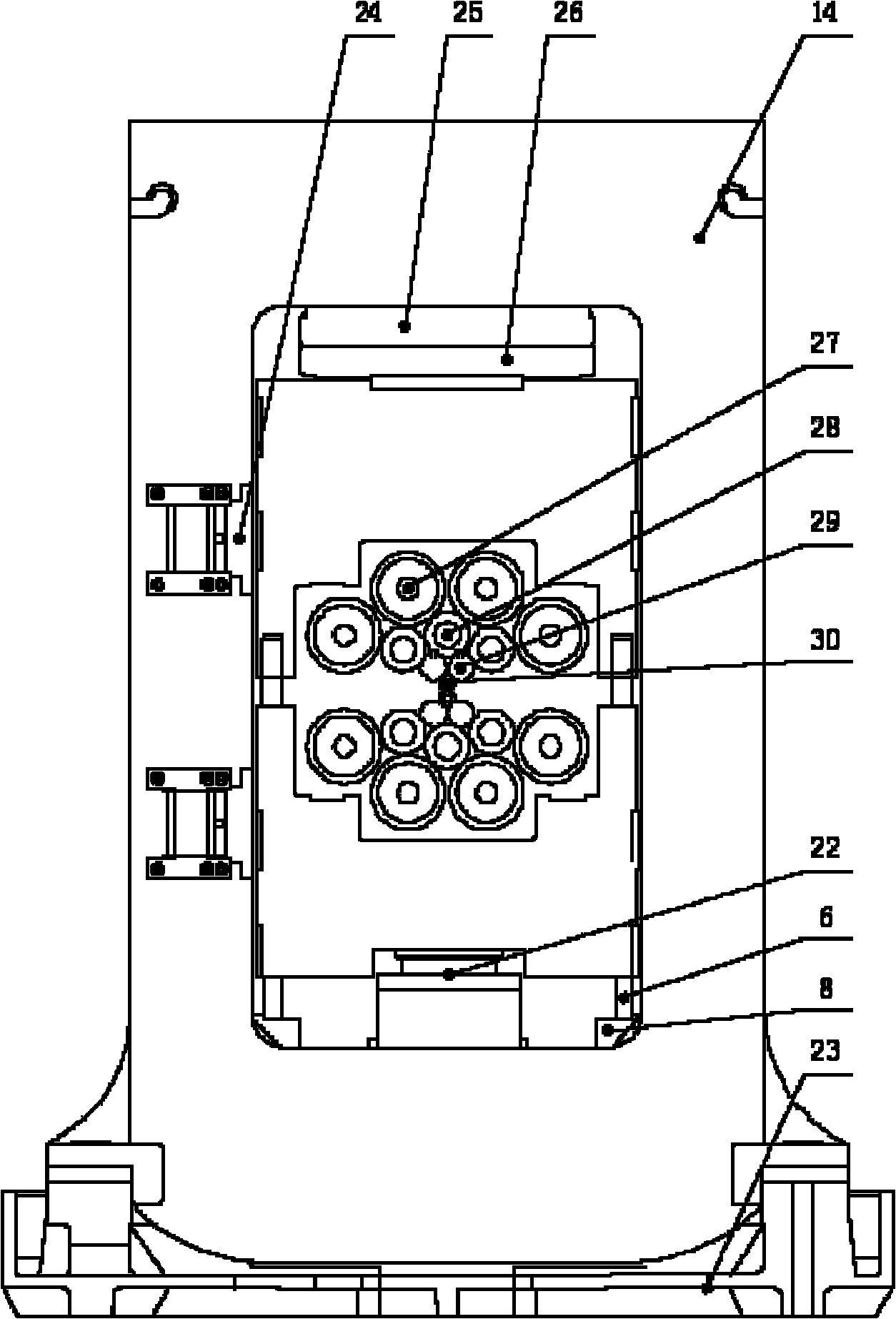

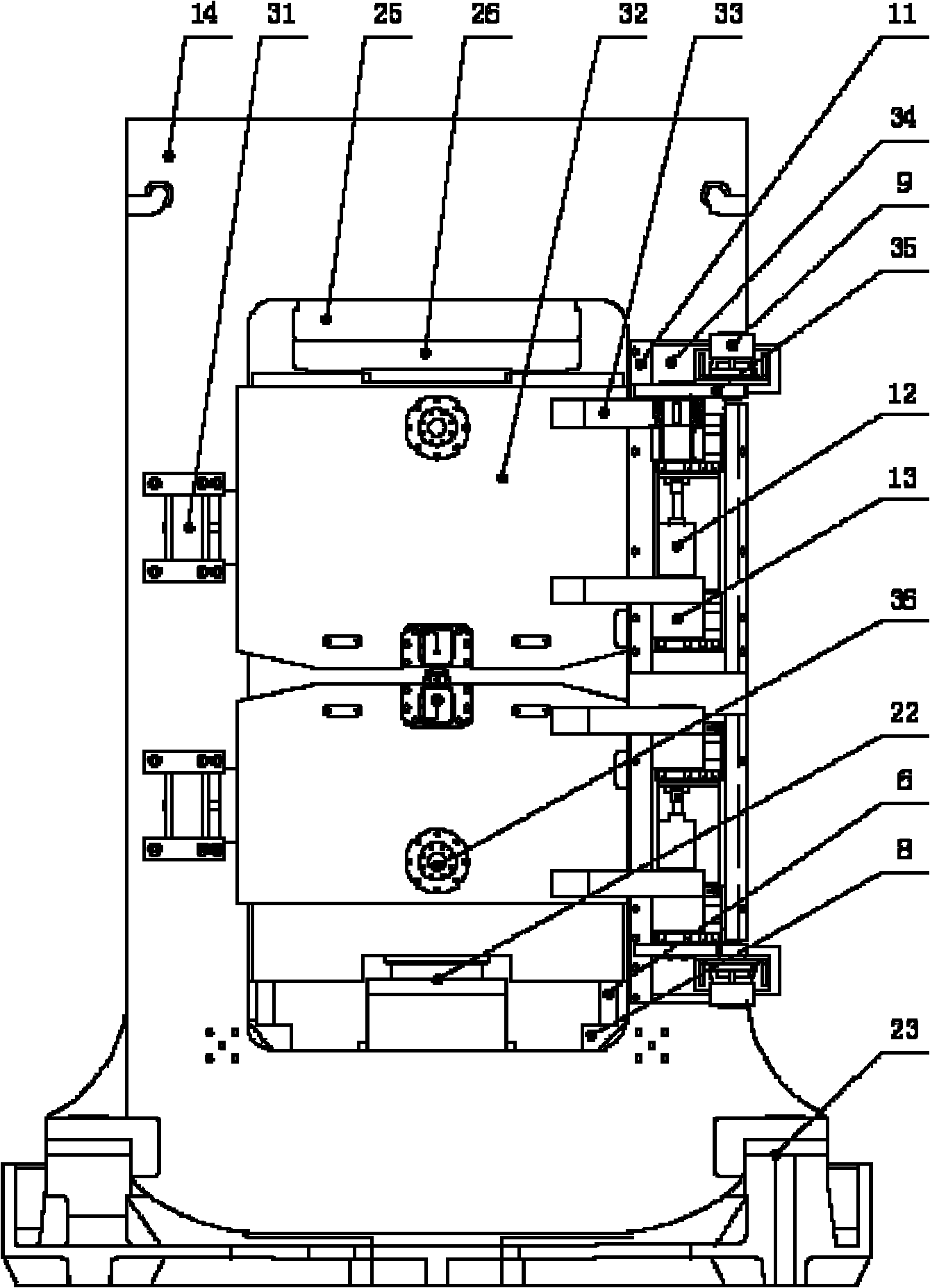

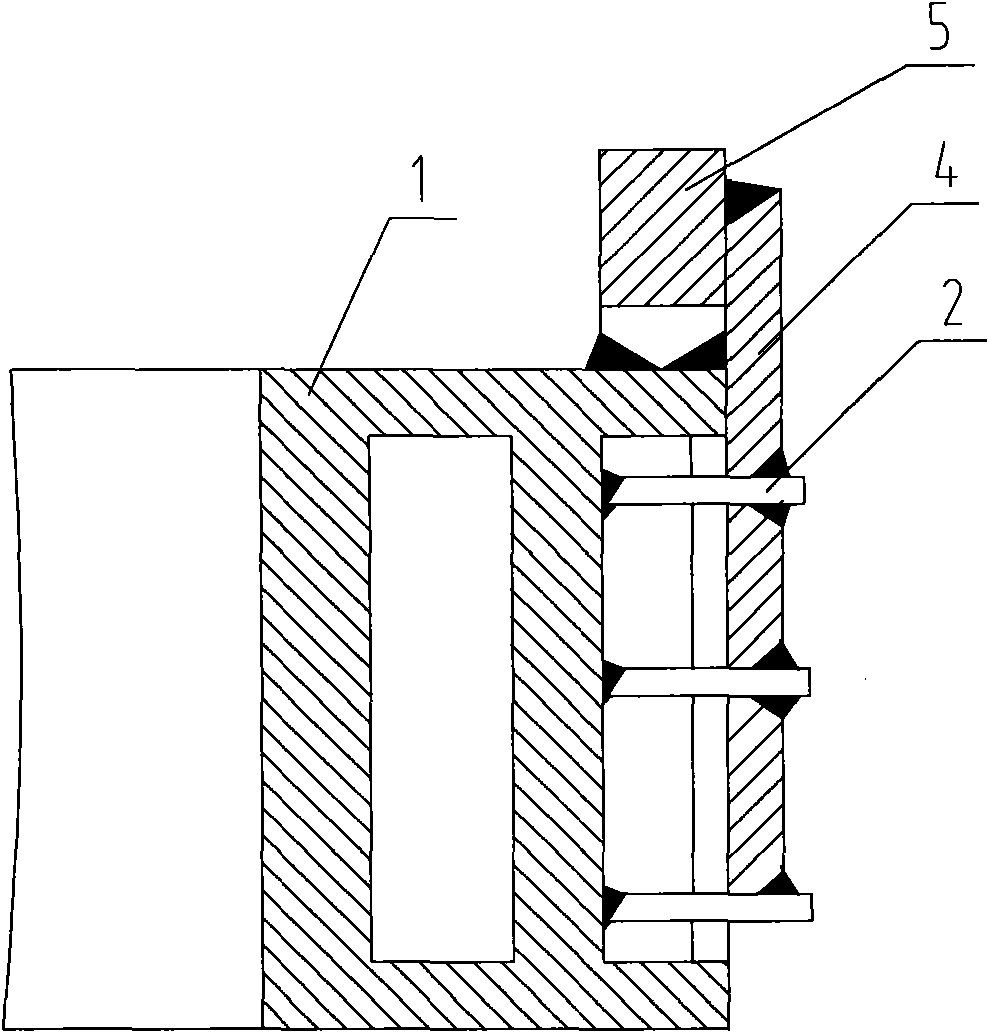

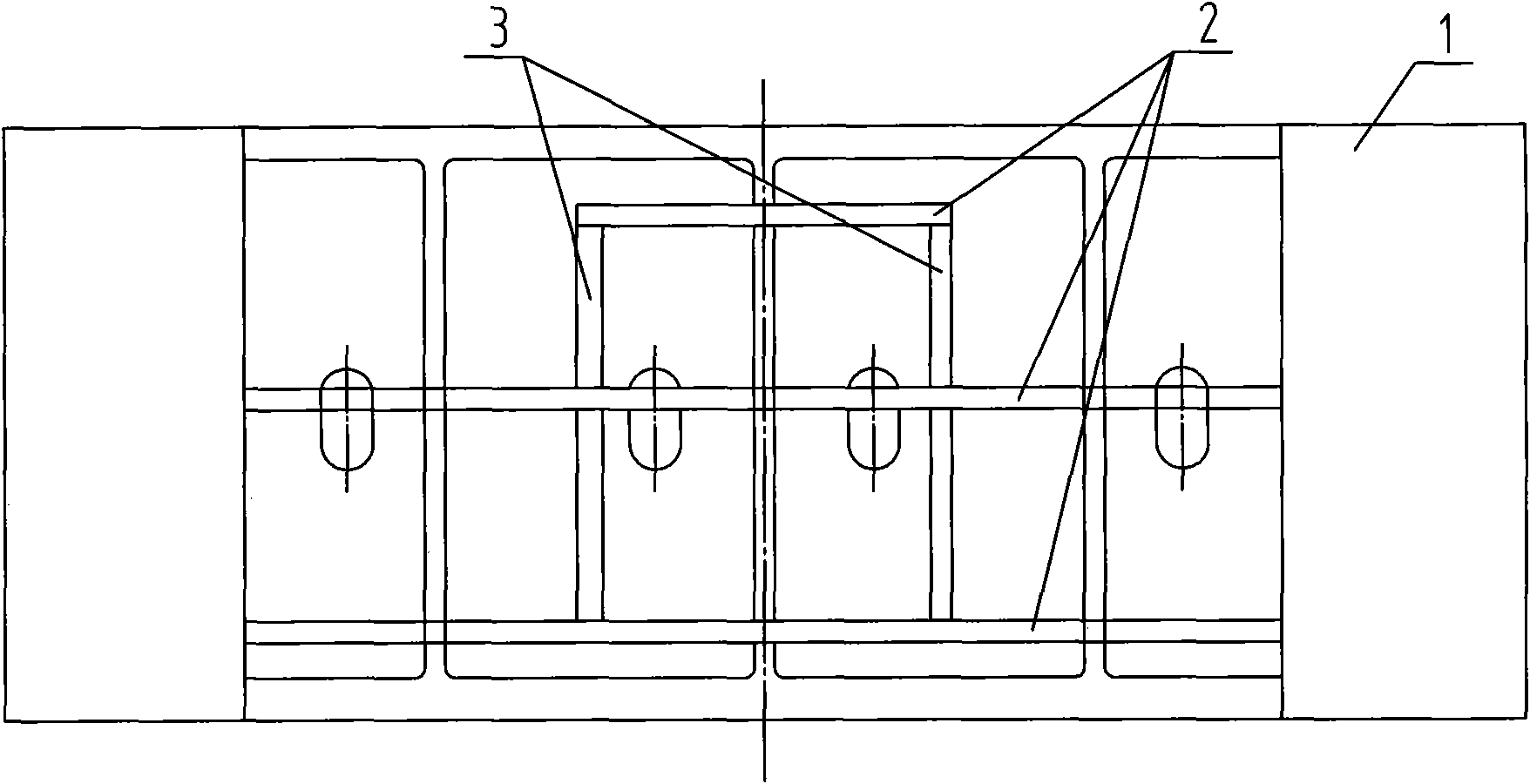

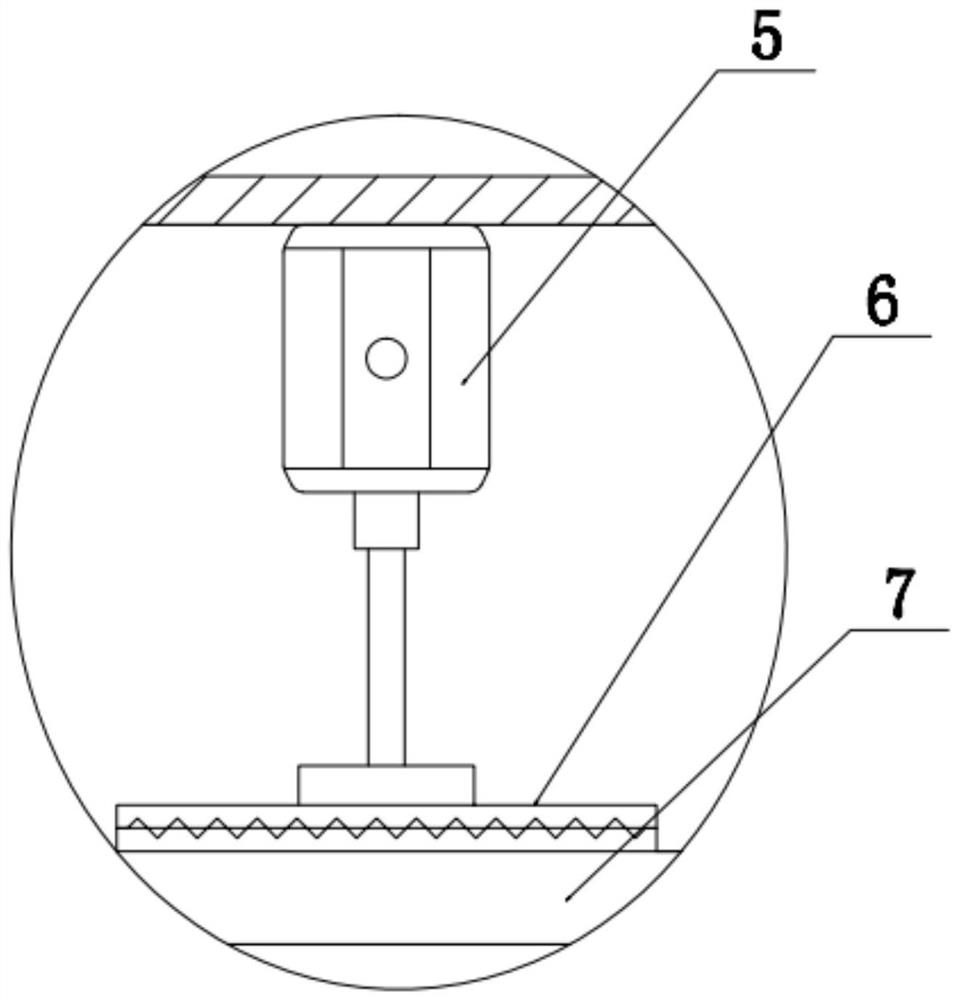

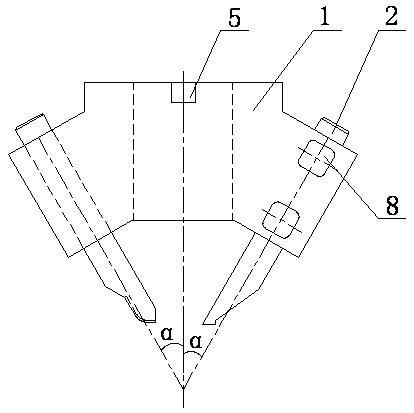

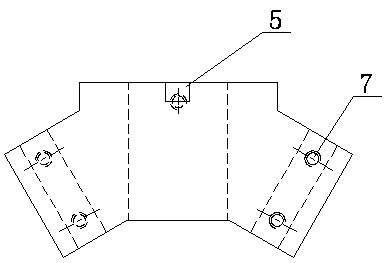

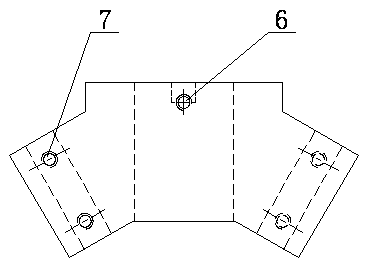

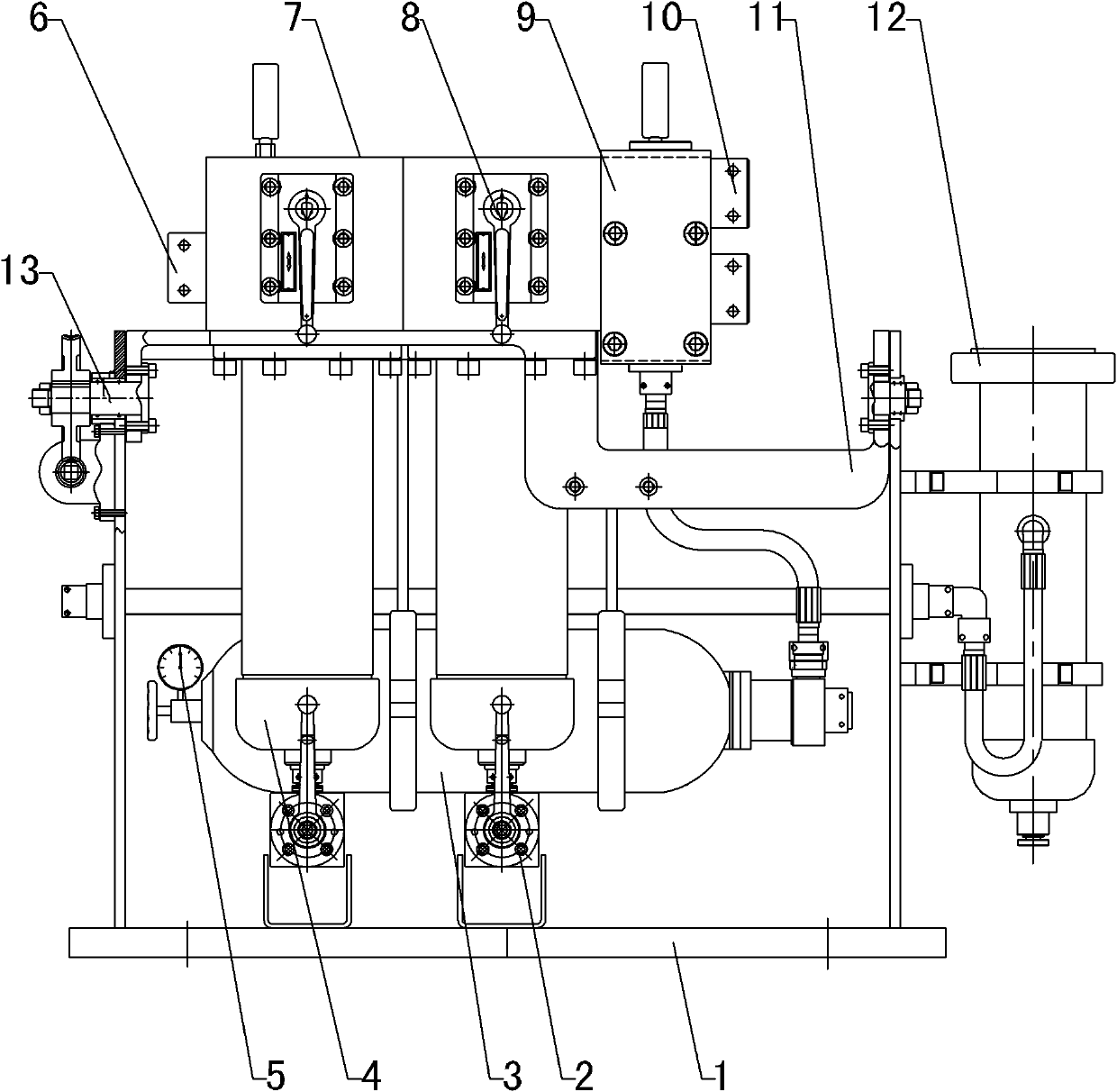

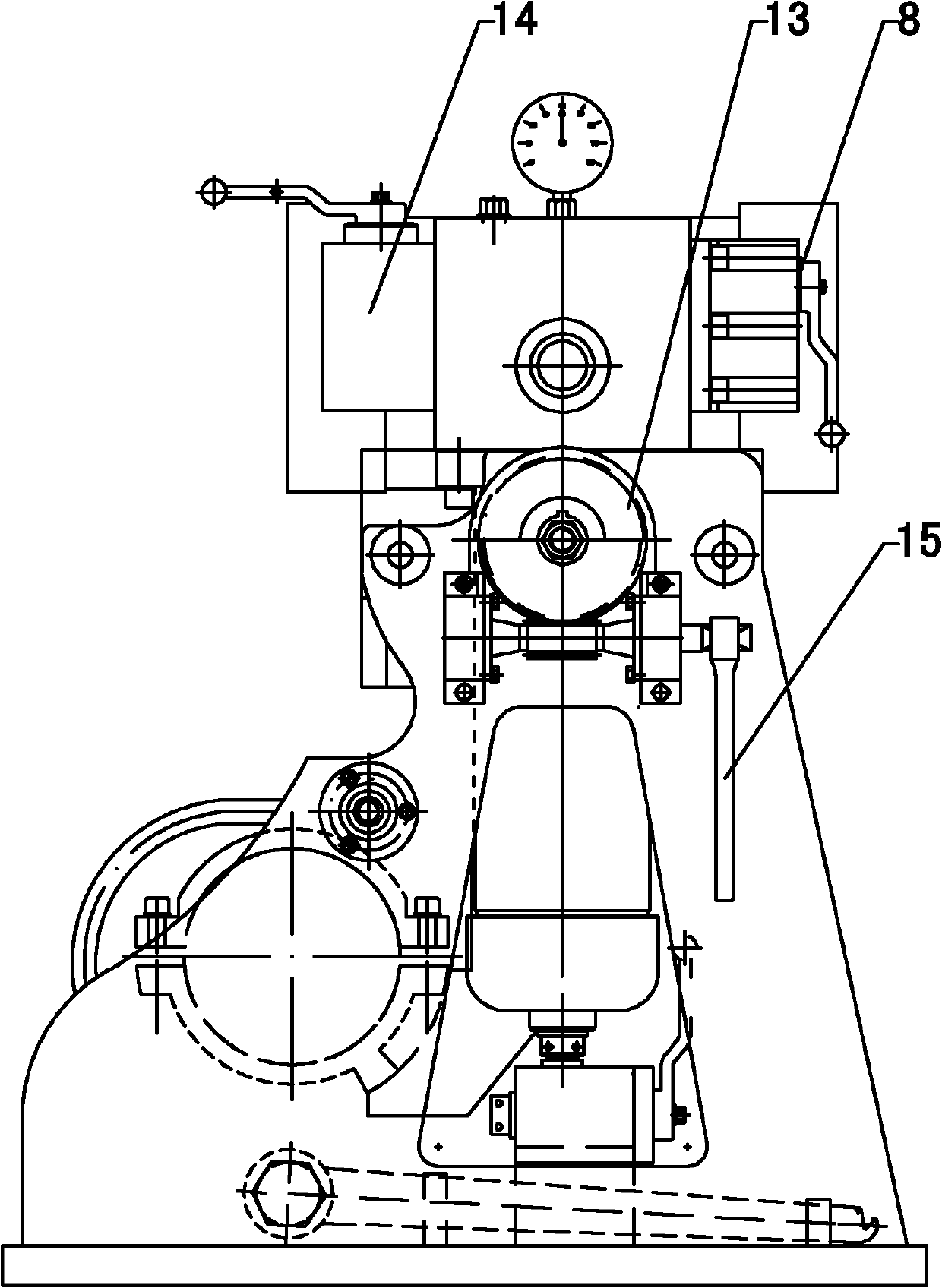

Novel twenty-roller cold-rolling mill

InactiveCN102228904AAvoid deformationLarge openingMetal rolling stand detailsWork treatment devicesProduction scheduleHydraulic cylinder

The invention relates to a novel twenty-roller cold-rolling mill which comprises an upper roller box and a lower roller box, wherein the upper roller box and the lower roller box are internally and symmetrically provided with two groups of roller systems and are both arranged in a frame-type stand, the lower roller box is arranged on a base of the stand, a jacking hydraulic cylinder used for jacking the lower roller box is arranged on the base of the stand, the upper roller box is arranged on the upper ends of supporting guide columns arranged on four corners of the upper end of the lower roller box, and the upper end of the upper roller box is pressed on the bottom surface of an upper rolling line regulating device arranged at the upper end of the stand. The roller boxes in the novel twenty-roller cold-rolling mill can vertically move to precisely complete the rolling of sheets, and can freely move out from the stand, and when rollers are changed or the roller boxes are maintained, a new roller box can directly slide into the stand without influencing a production schedule; and two sets of convexity regulating devices are arranged on the stand, the novel twenty-roller cold-rolling mill has high regulating precision, and is very convenient for disassembly and assembly and use.

Owner:天津冶金规划设计院

Vibration welding technology

InactiveCN1943968AConvenient welding operationGood welding performanceWelding/cutting auxillary devicesAuxillary welding devicesPower flowEngineering

The vibration welding technology of the present invention includes: 1. connecting a vibration exciter rigidly to the welded part or a vibration table with the welded part, and regulating the exciting force of the vibration exciter in resonant state to make the welded part obtain required amplitude; 2. maintaining the welded part in resonant state and in stable amplitude; 3. selecting one relatively low work frequency in resonant state and with amplitude not greater than one third of the resonant amplitude; 4. picking up the vibration with one acceleration sensor fixed in certain distance to the welding seam and shifting with the welder for tracking and monitoring the vibration parameters; etc. The present invention has convenient welding operation, high welding effect and high welding speed, and is suitable for welding different kinds of member.

Owner:黎凡七

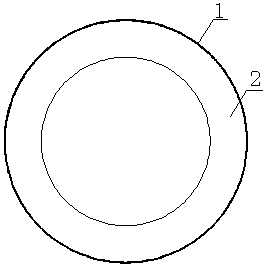

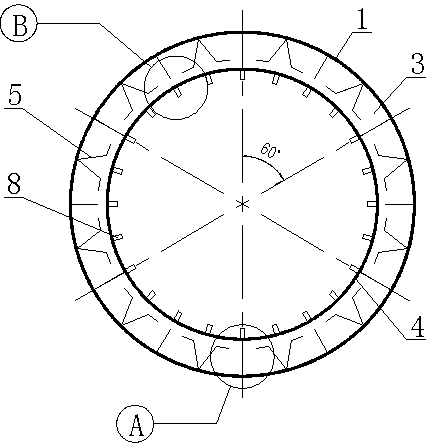

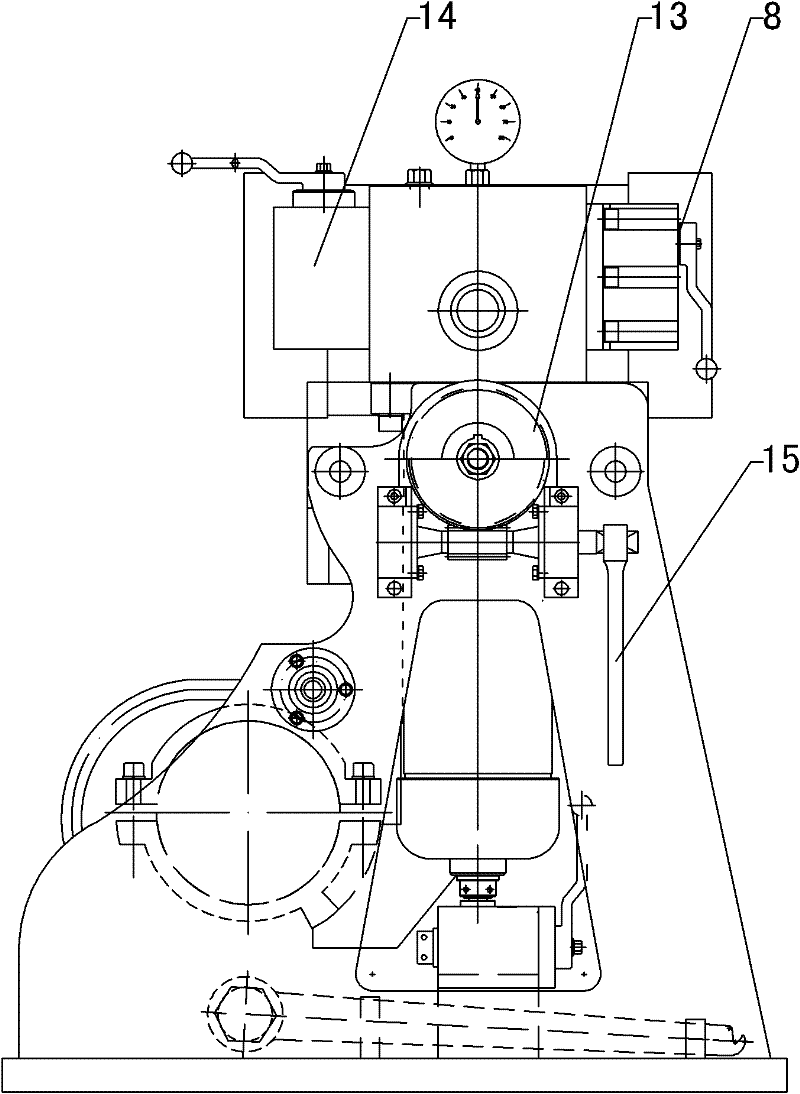

Rotary kiln applied to ferronickel reduction production technology and construction method thereof

The invention discloses a rotary kiln applied to ferronickel reduction production technology and a construction method thereof. The rotary kiln comprises a rotary kiln casing and fire-proof materials bricked in the rotary kiln casing. The rotary kiln is characterized in that a heat-resistant alloy steel cylinder with the same coaxiality as the rotary kiln casing is fixed on the surface of the fire-proof materials. According to the invention, the production efficiency for directly reducing and smelting ferronickel by the rotary kiln is improved, the production cost is reduced, formed rings in the rotary kiln can be processed effectively and timely under the condition that operation of the rotary kiln is not stopped, and the service life of the fire-proof materials used in the reduction concentration phase is prolonged.

Owner:王景军

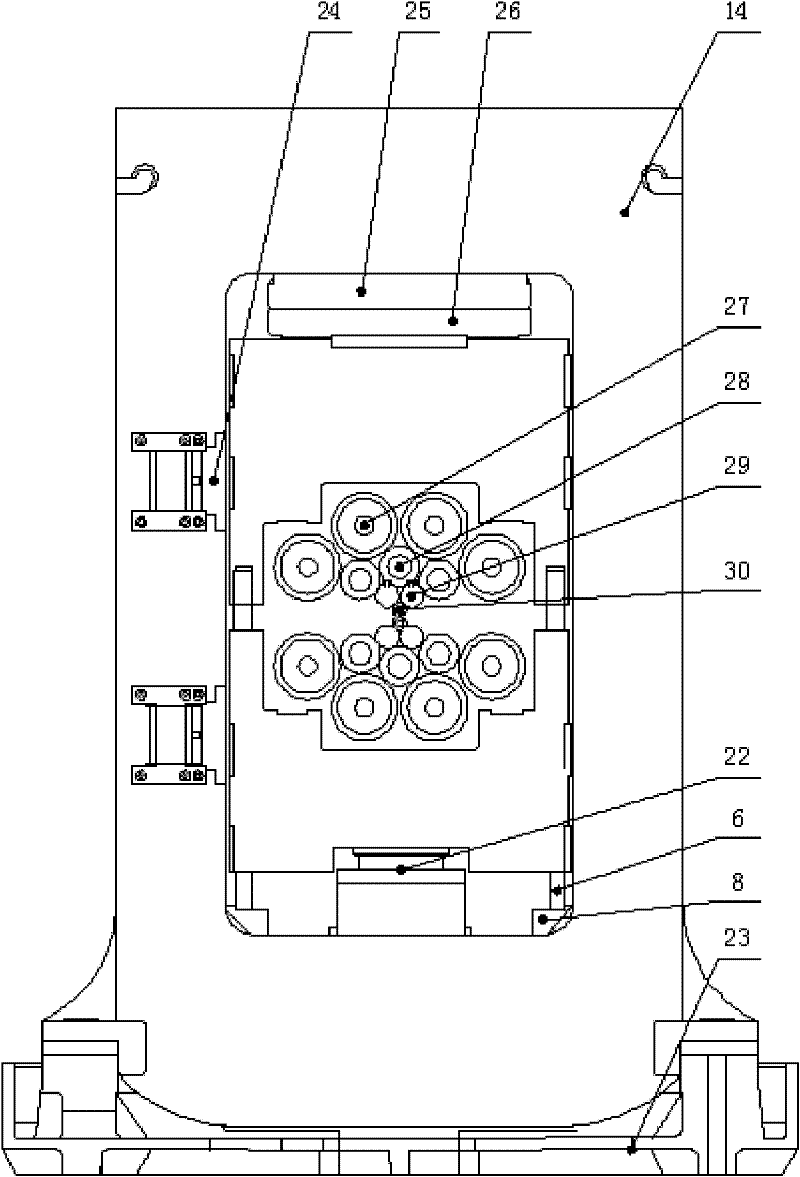

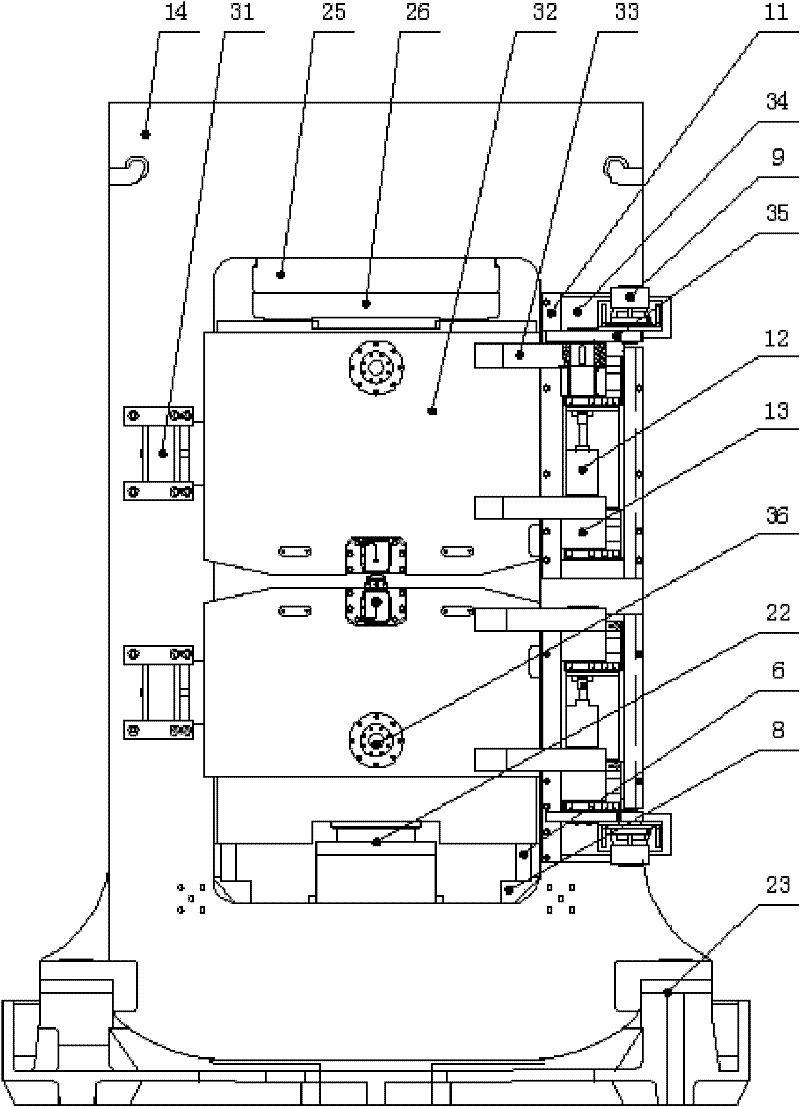

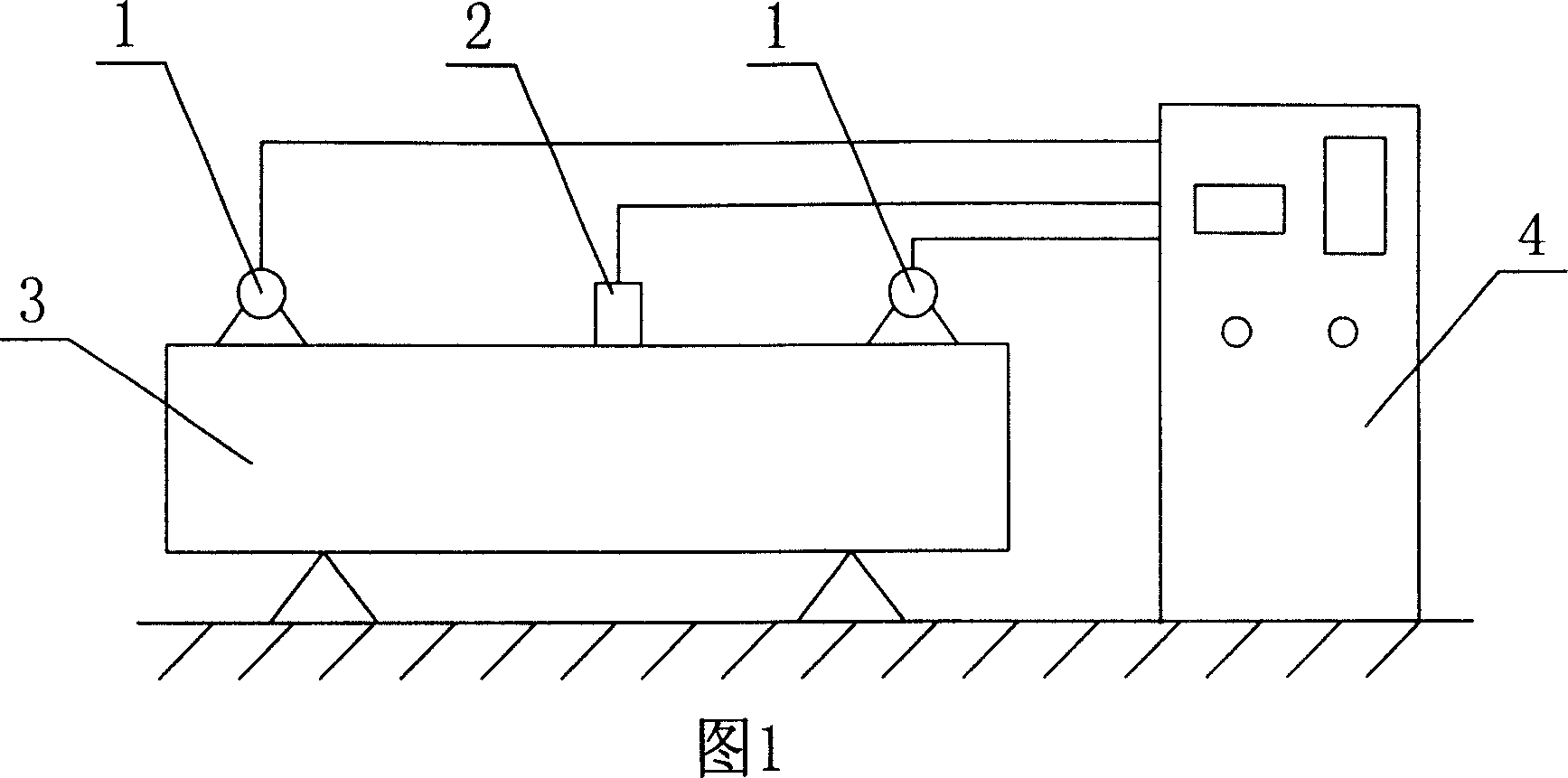

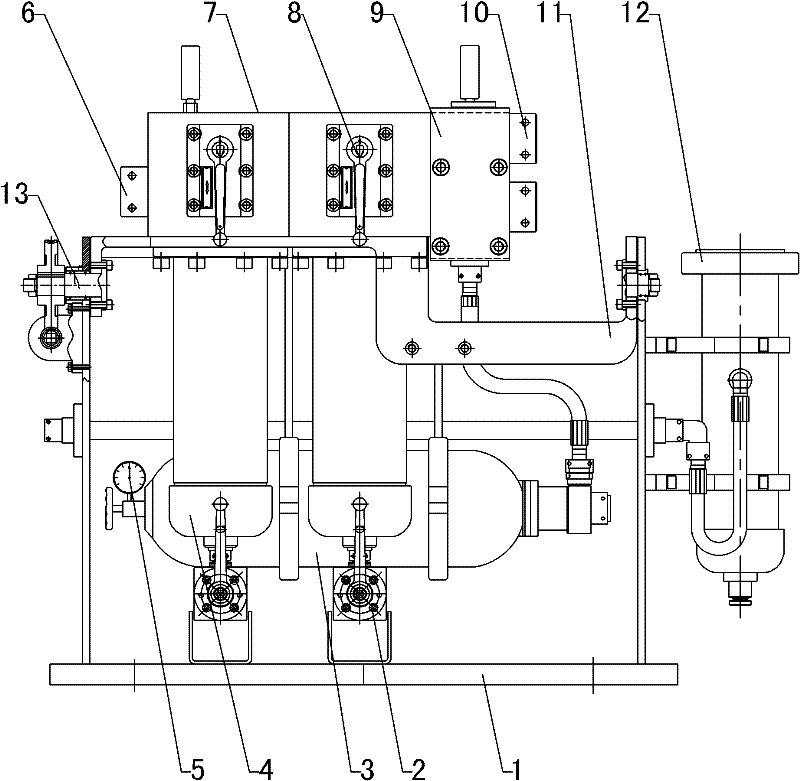

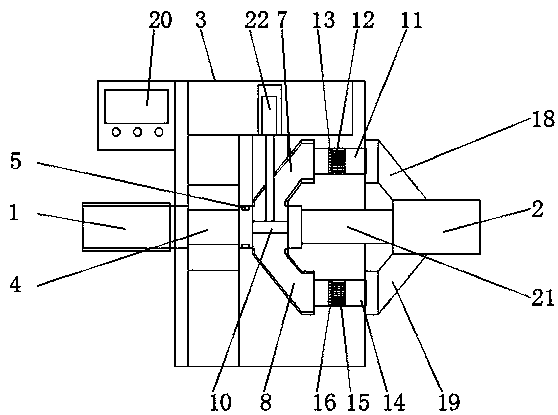

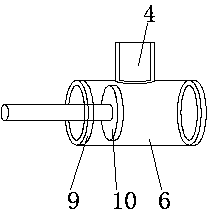

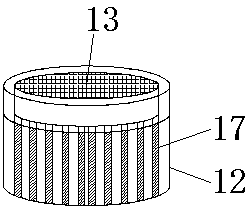

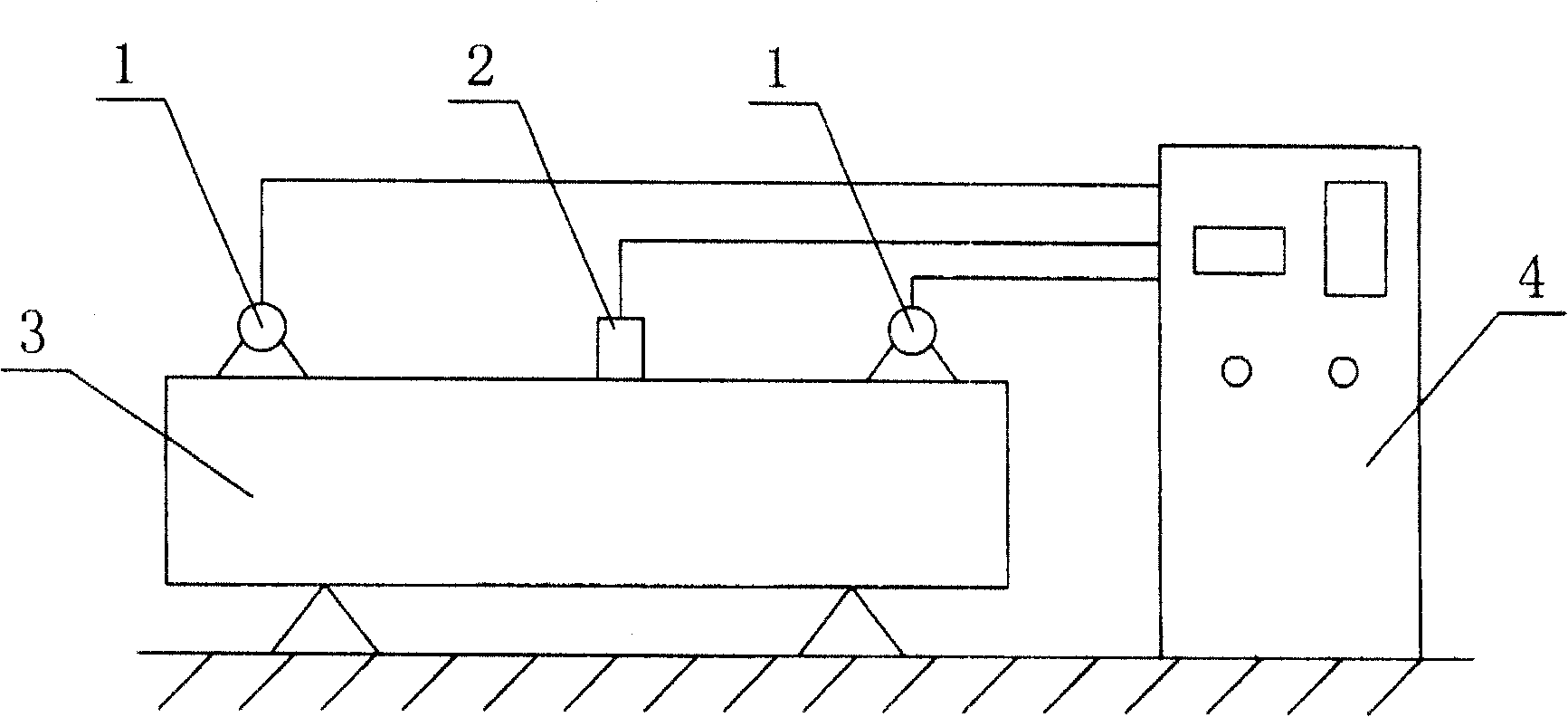

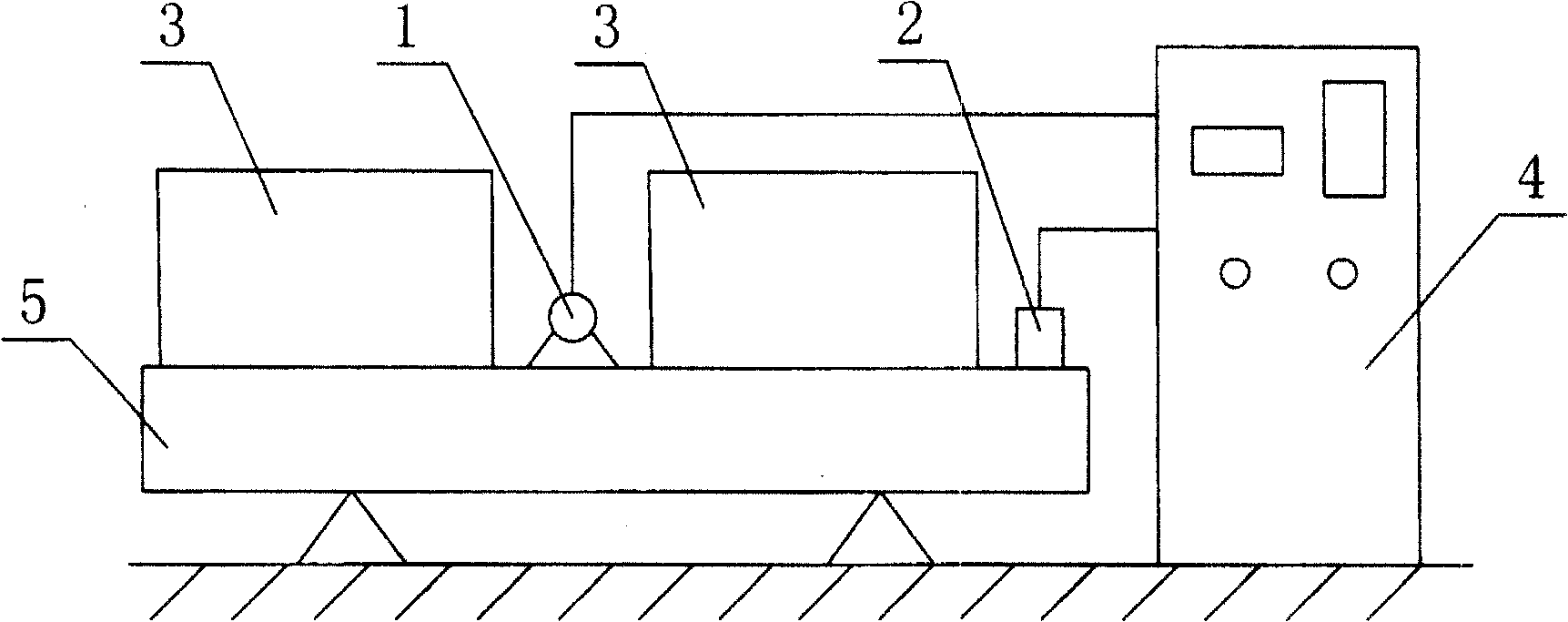

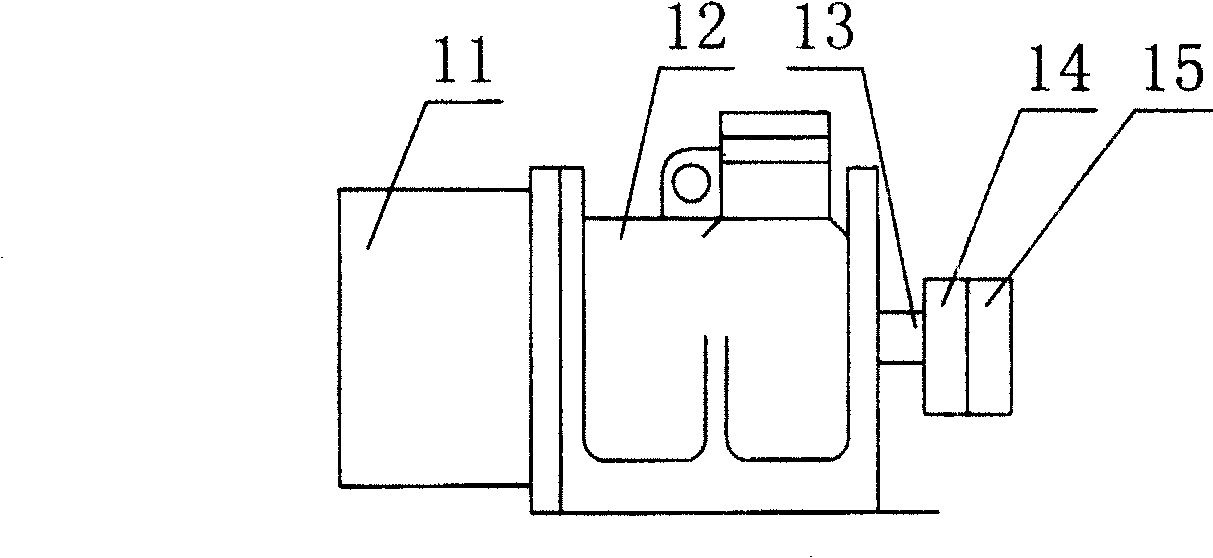

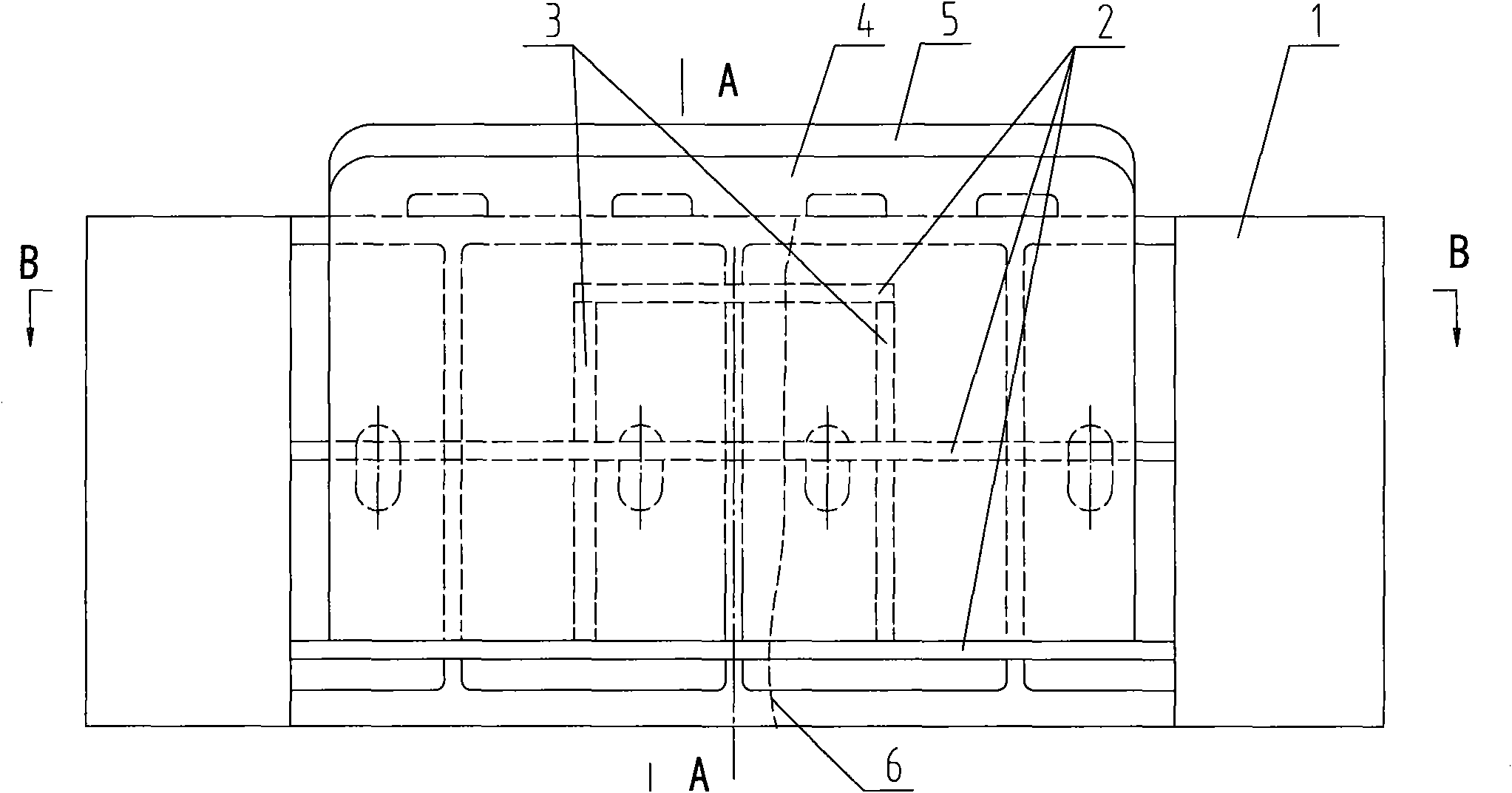

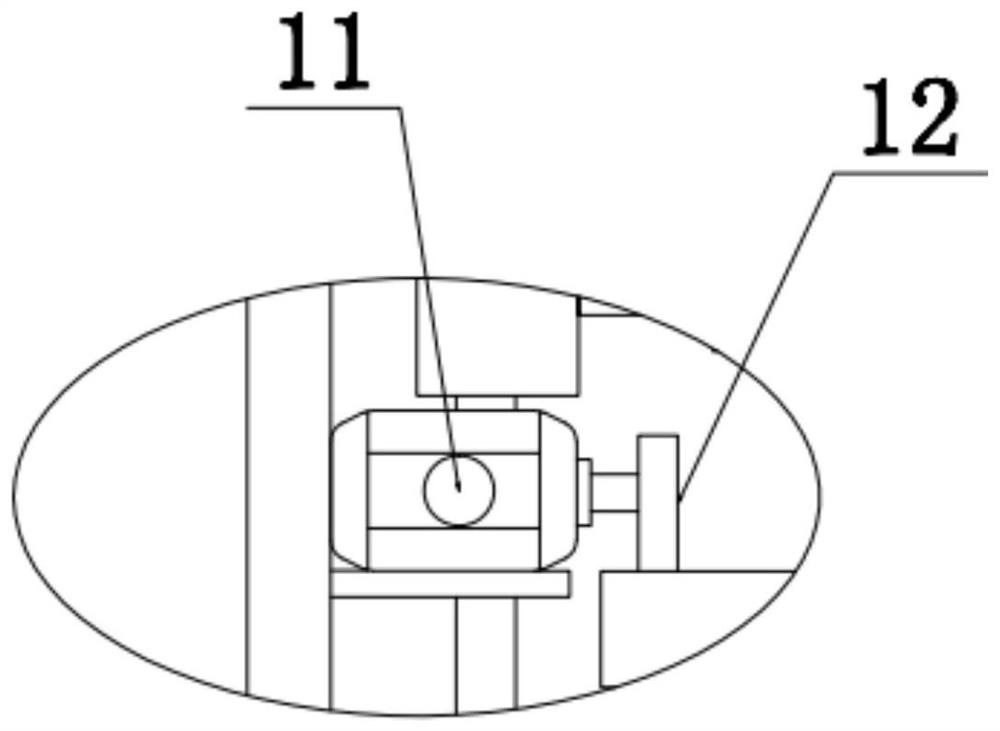

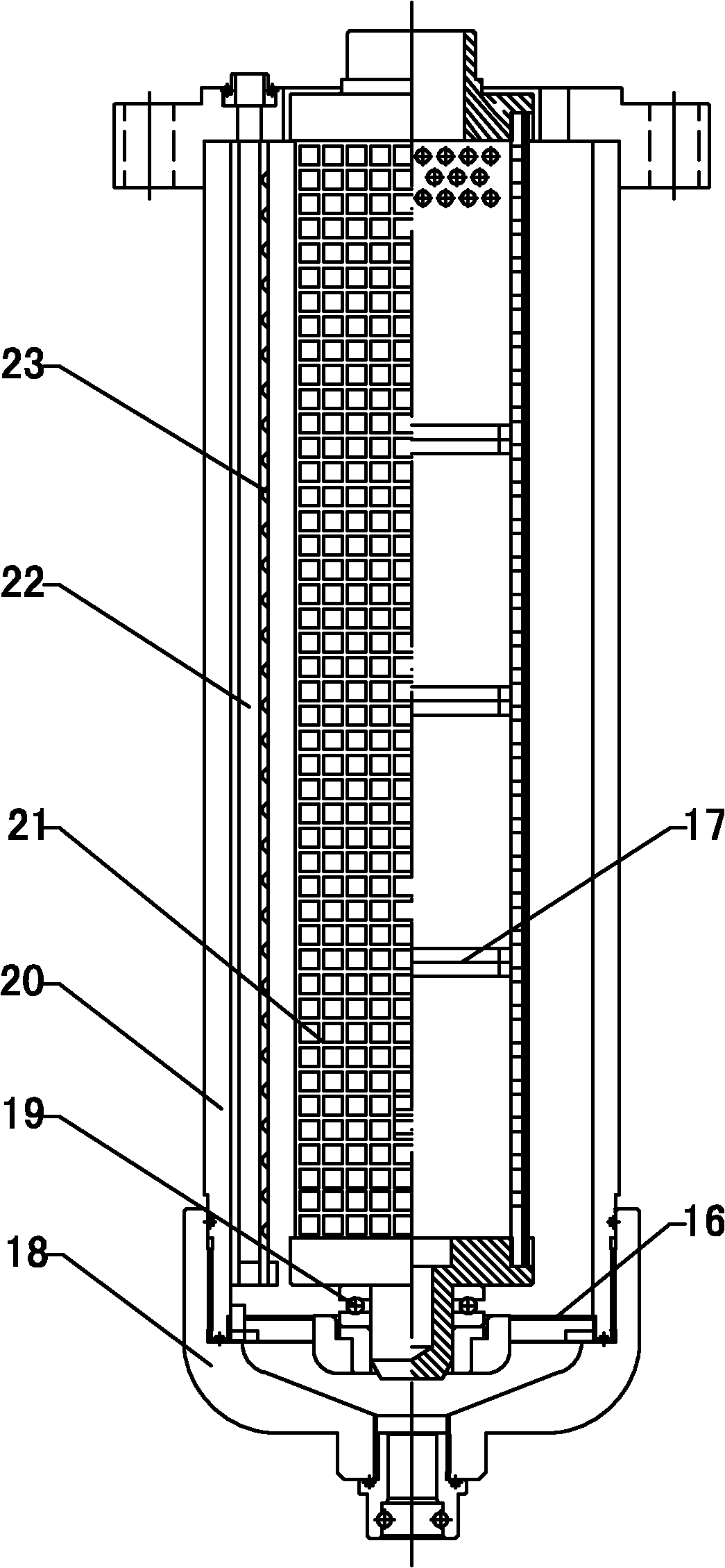

Backwash high pressure filter station

ActiveCN102258910ARealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsEngineeringHigh pressure

The invention discloses a backwashing high-pressure filter station, which belongs to the field of backwashing high-pressure filter devices for hydraulic systems of underground comprehensive mining hydraulic brackets. The backwashing high-pressure filter station comprises a machine seat (1) and a high-pressure filter (4), and is characterized in that: a rotating machine seat (11) is arranged on the upper part of the machine seat (1); an integrated valve seat device (7) is mounted through the rotating machine seat (11); the bottom of the integrated valve seat device (7) is connected with the high-pressure filter (4) and an energy storage device (3); the lower part of the high-pressure filter (4) is connected with a draining valve (2); and a waste liquid recovering device on the lower part of the draining valve (2) is connected with a recovery filter (12). The backwashing high-pressure filter station has the advantages of large flow, high precision, capability of on-line washing, obviouswashing effect, capability of recycling backwashing liquid and the like; and when the backwashing high-pressure filter station is used, the continuous production operation can be ensured, energy conservation and environment protection can be ensured and the cleanness of the working medium can be ensured effectively.

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

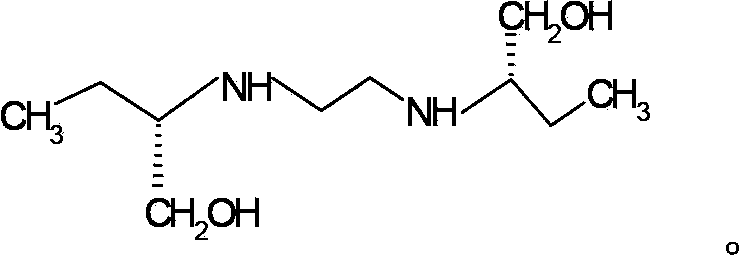

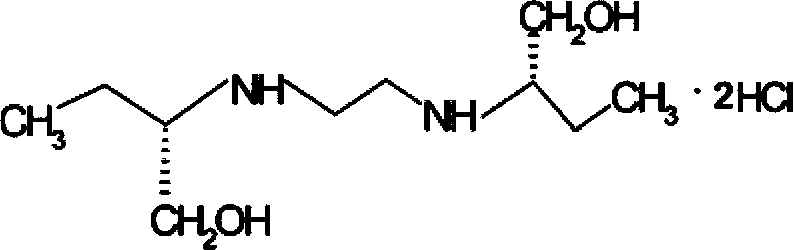

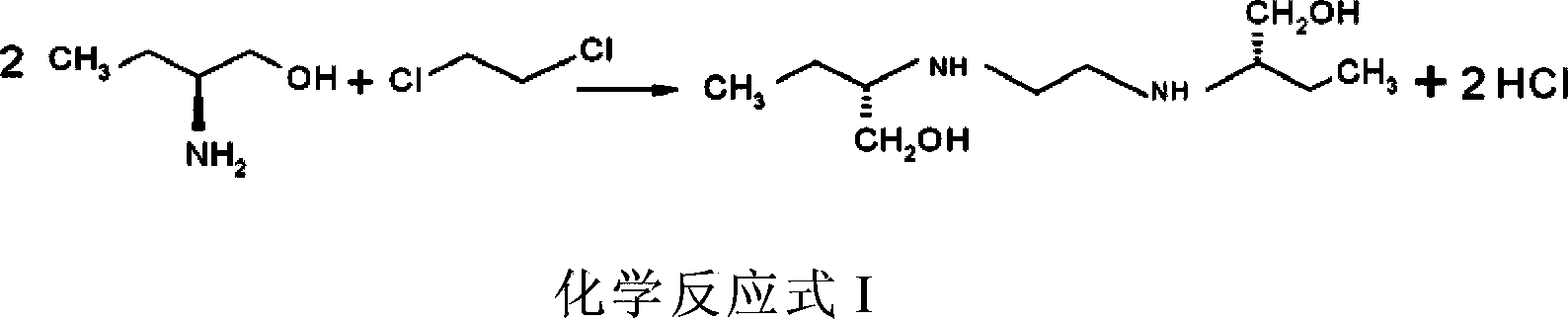

Methods for preparing ethambutol and ethambutol hydrochloride

ActiveCN103772214AEasy to recycleHigh recovery rateOrganic compound preparationAmino-hyroxy compound preparationOrganic solventBoiling point

The invention provides methods for preparing ethambutol and ethambutol hydrochloride. The method for preparing the ethambutol comprises the step of utilizing (S)-2-aminobutanol and 1,2-dichloroethane to perform condensation reaction to prepare the ethambutol, wherein the condensation reaction is carried out in a low-boiling organic solvent, and HCl produced in the ammonia gas neutralization reaction process is utilized. Through the utilization of the method, the ethambutol of which the yield coefficient is improved can be obtained, so that the ethambutol hydrochloride of which the yield coefficient is improved can be obtained. Besides, the methods are simple in technology, safe, stable, low in cost and super-high in practical value in the industry.

Owner:NEW FOUNDER HLDG DEV LLC +2

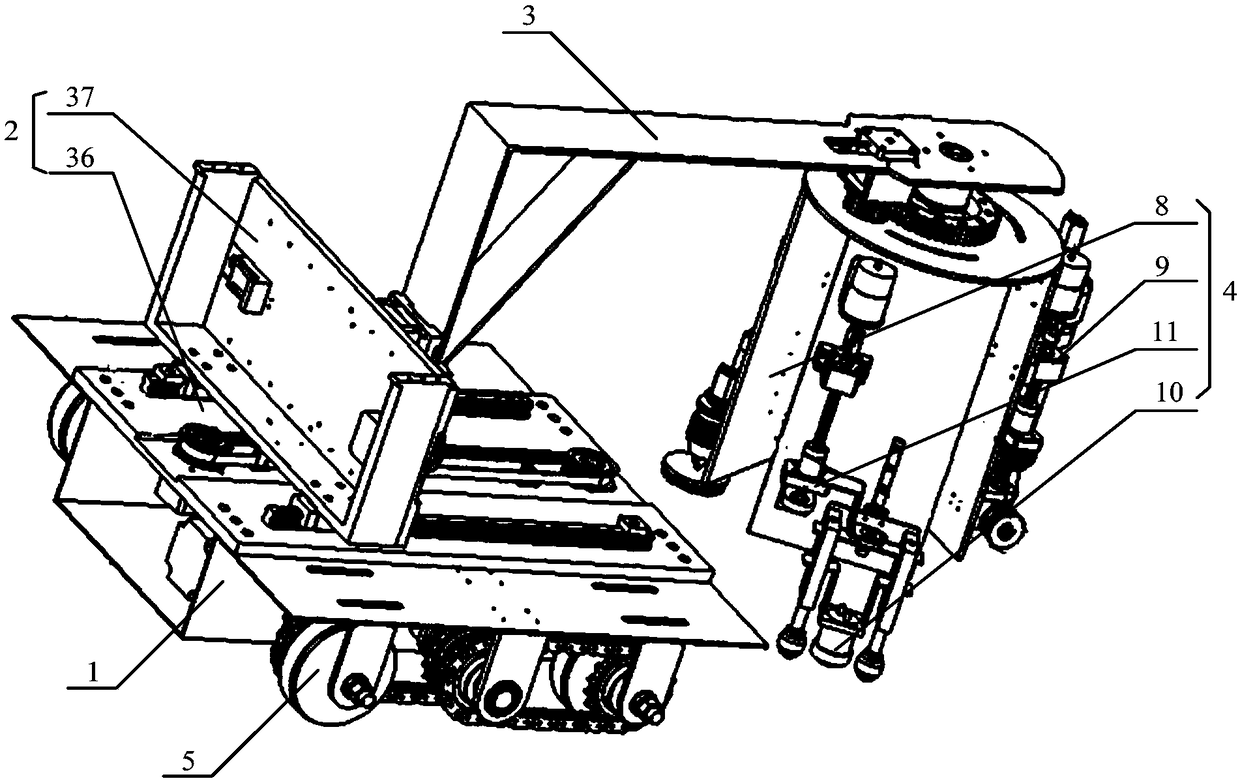

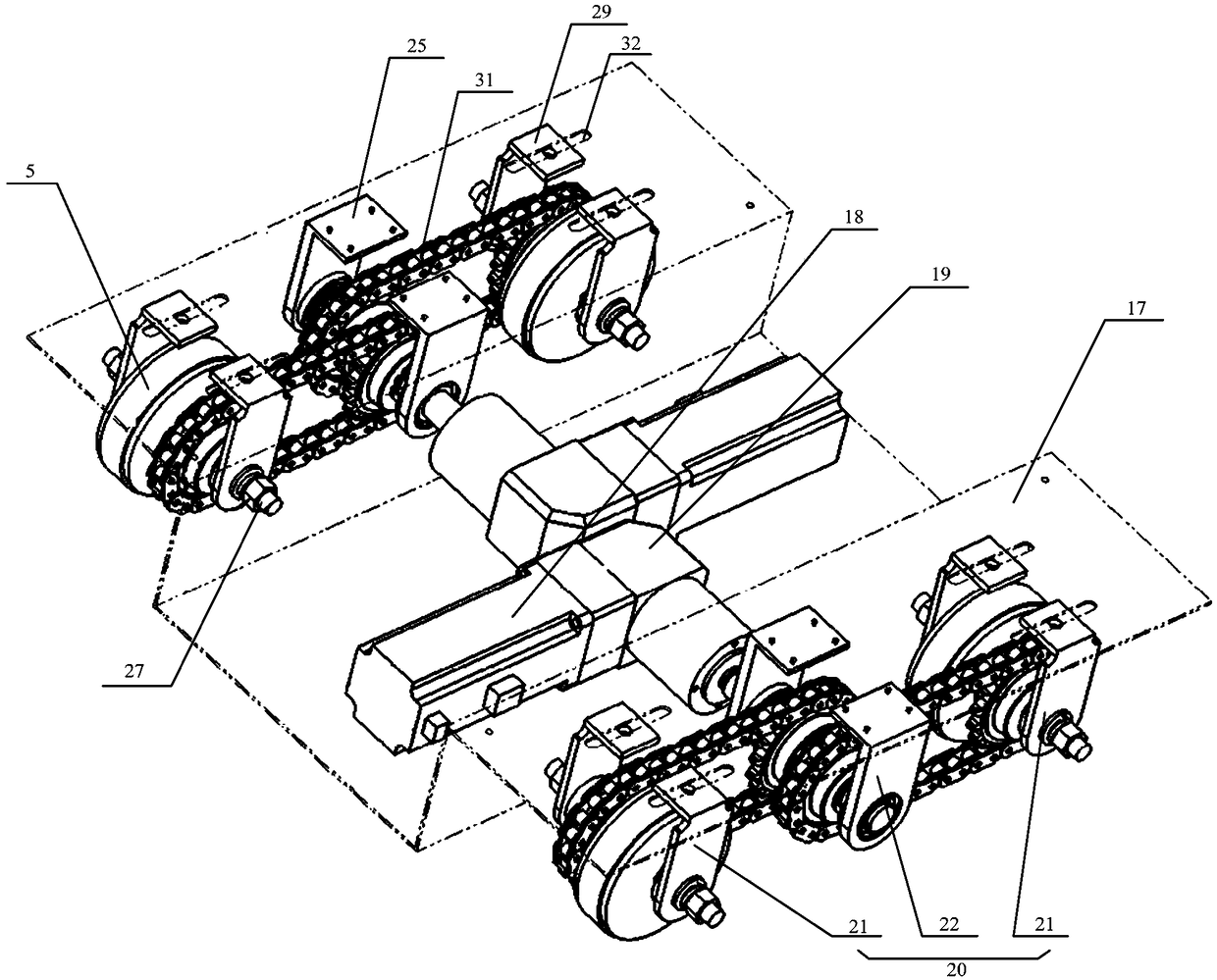

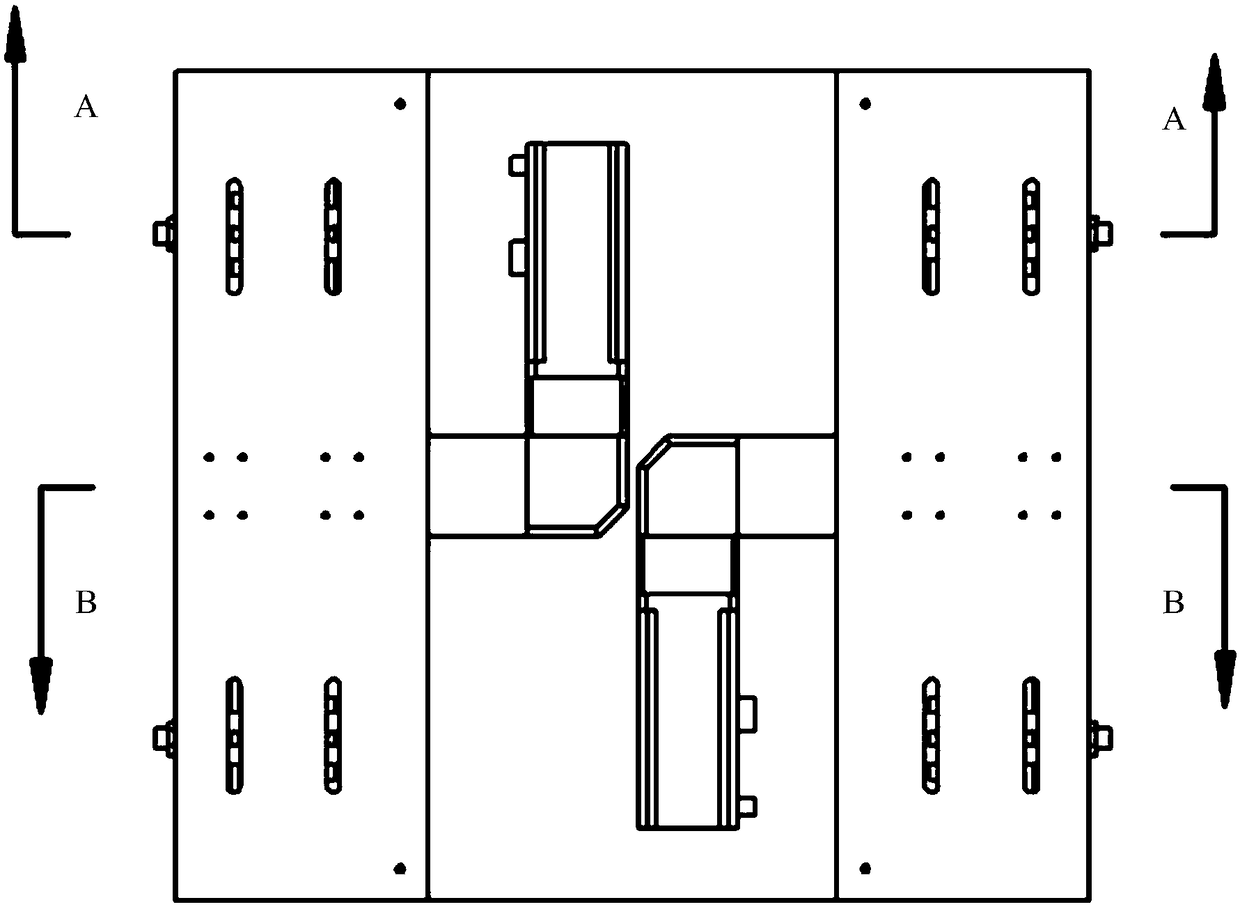

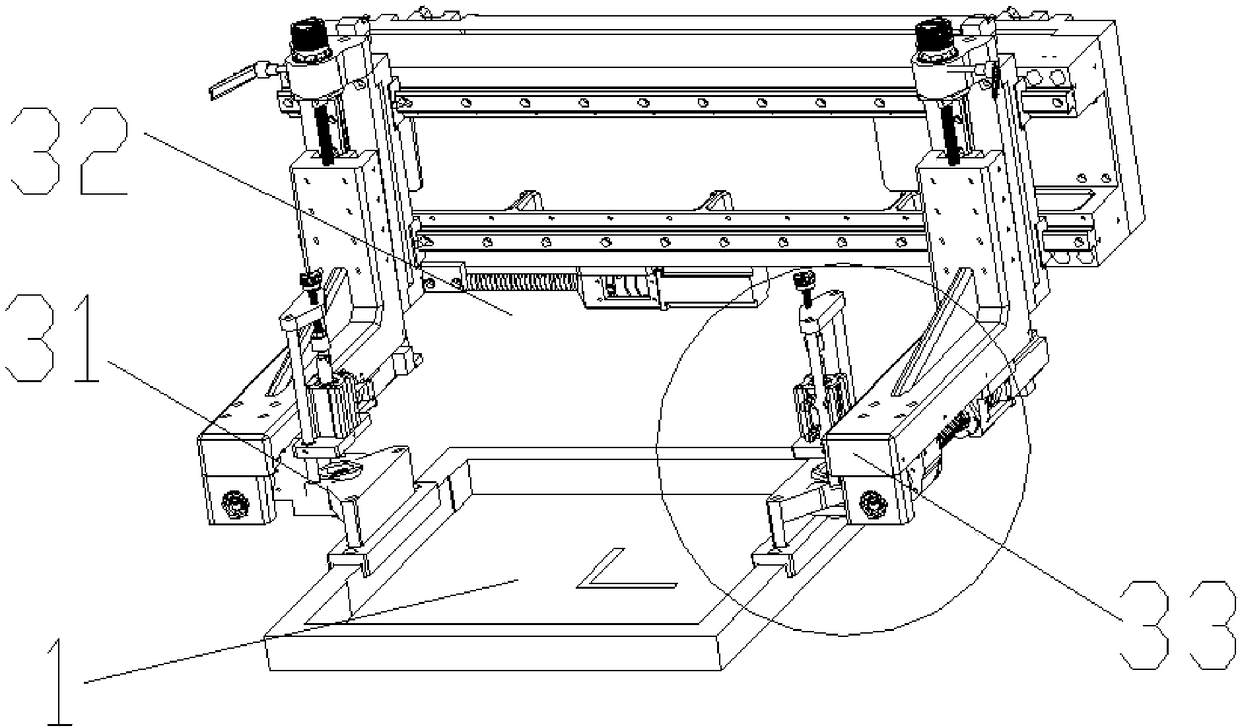

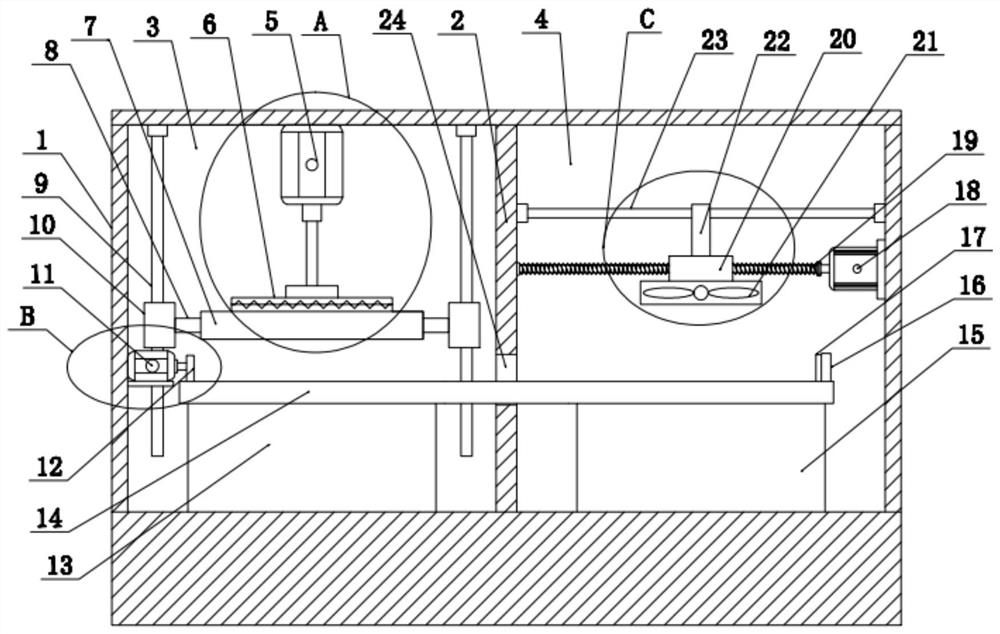

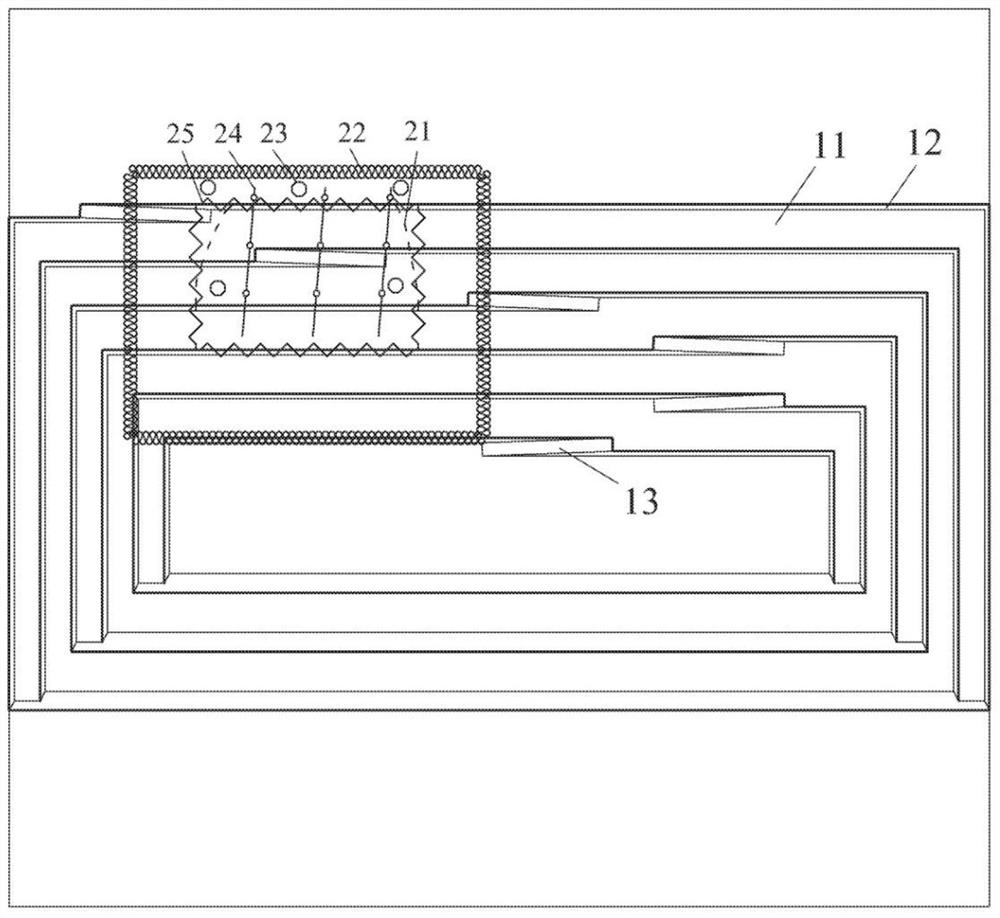

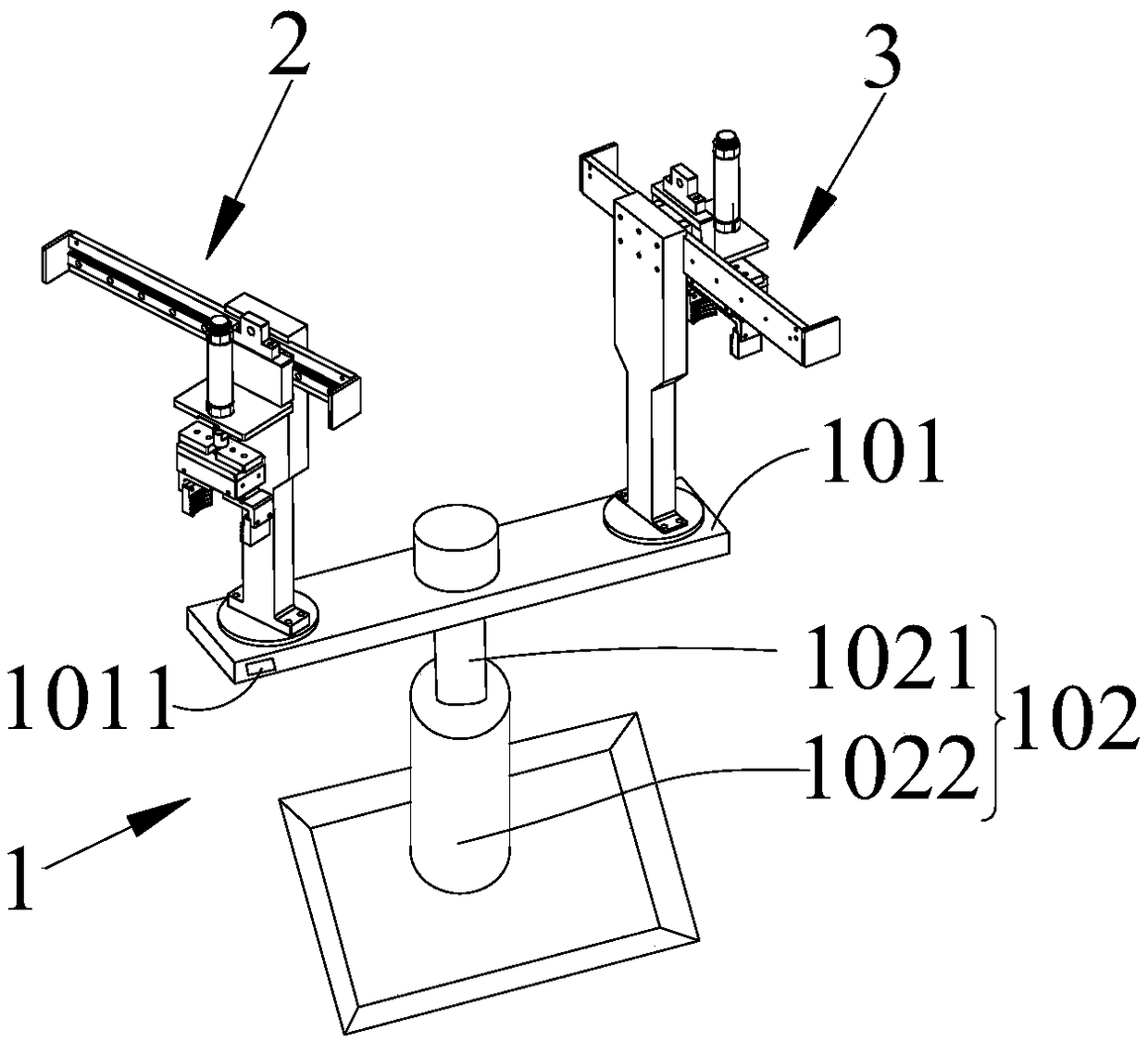

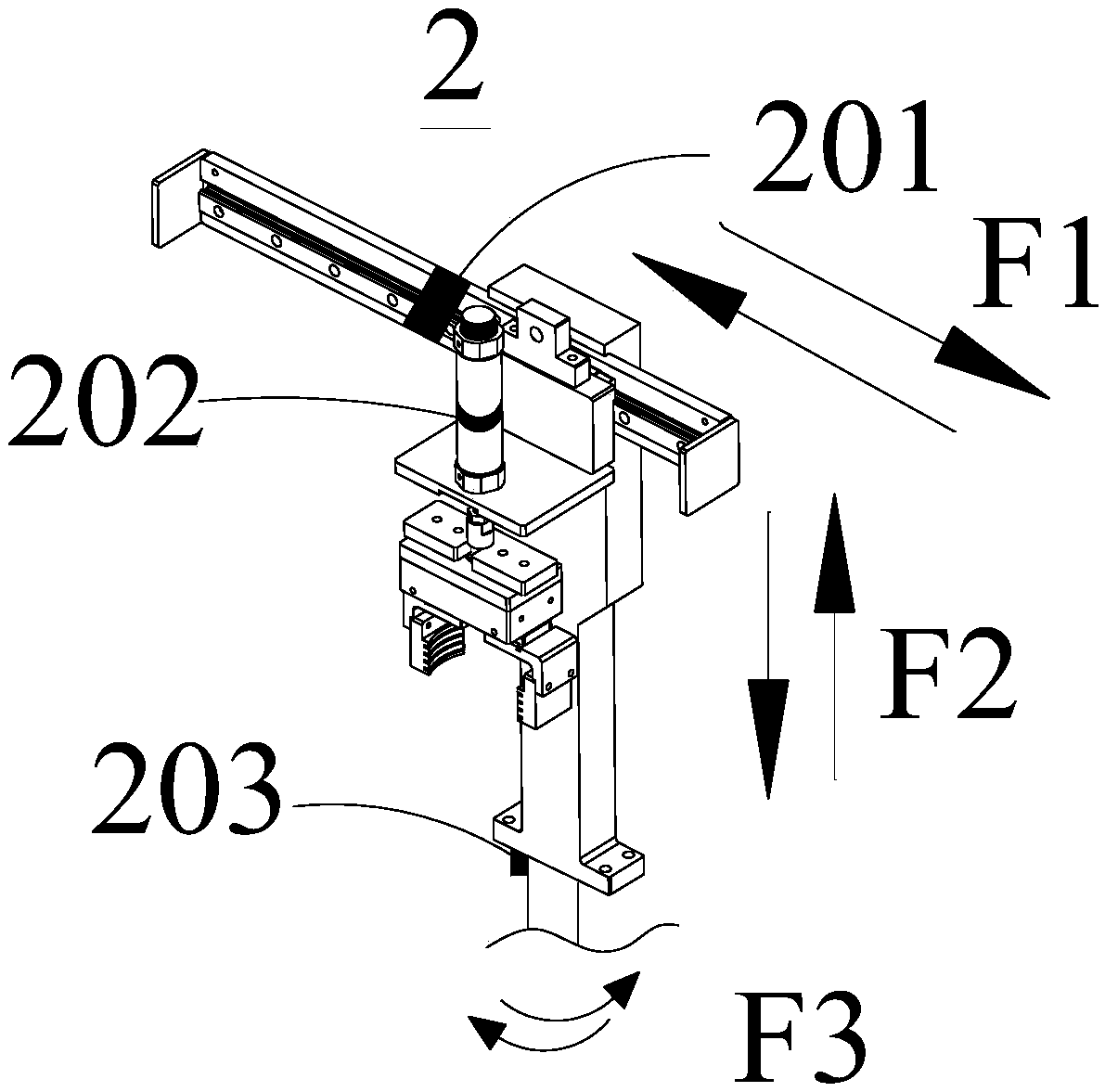

Thickness detection device applied to surface of large-sized metal tank body

ActiveCN108759737ALess amount of smearEnhanced couplingUsing subsonic/sonic/ultrasonic vibration meansEngineeringMetal

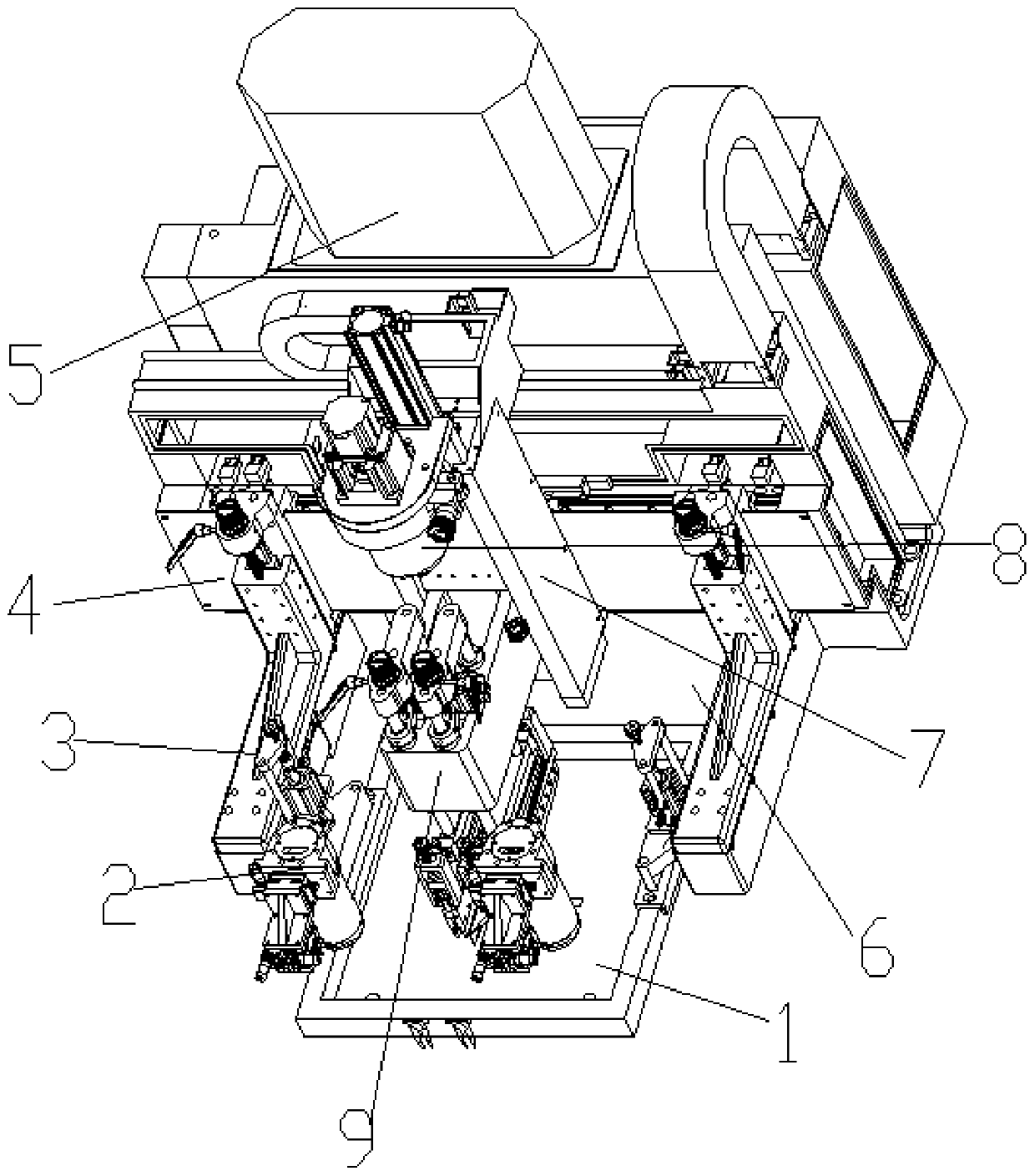

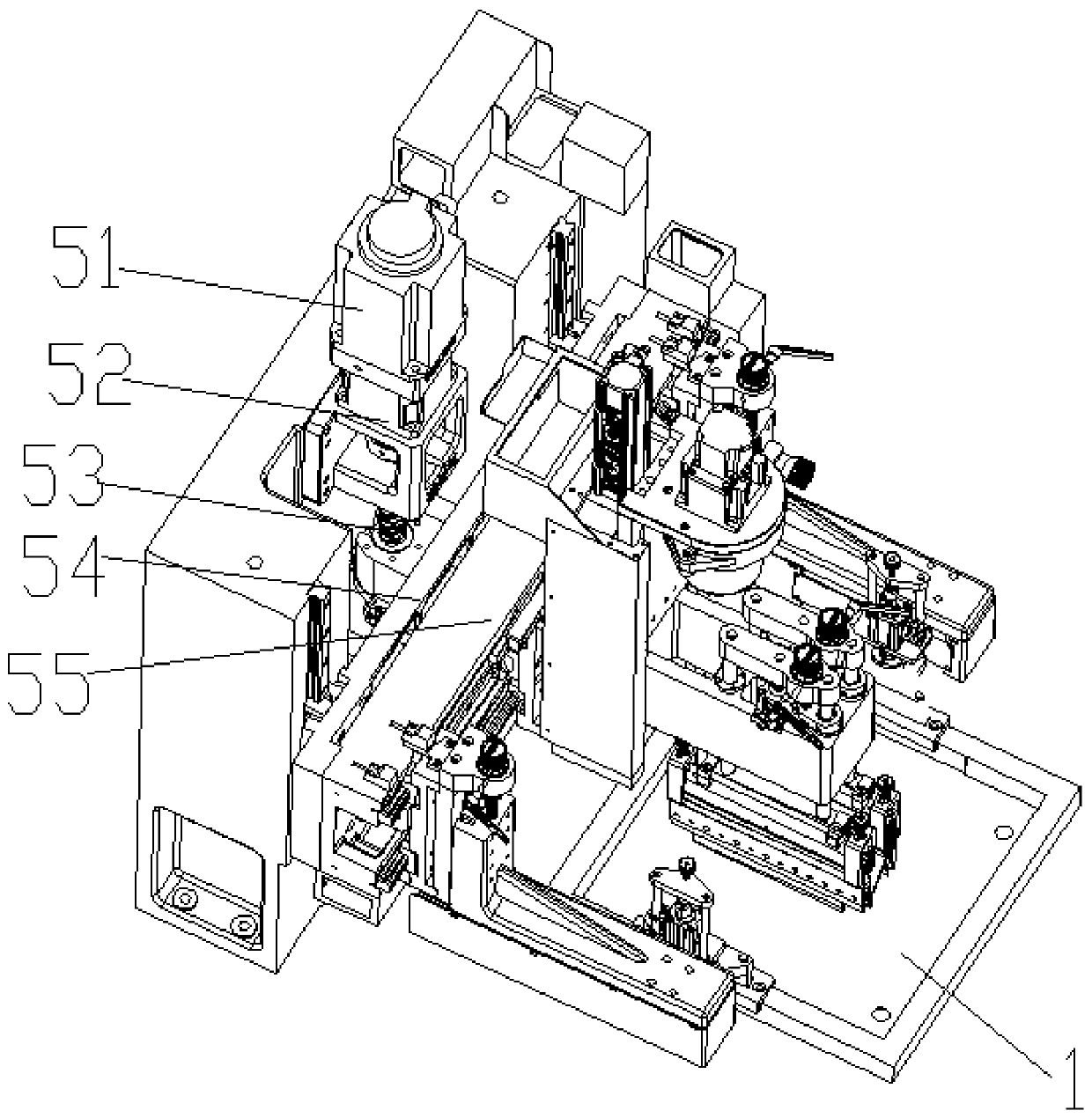

The invention relates to a thickness detection device applied to the surface of a large-sized metal tank body and belongs to the equipment intelligent detection technological field. The thickness detection device applied to the surface of the large-sized metal tank body comprises a device body, an XY direction motion module, a supporting turntable module, a Z direction working module and a controller; the device body is provided with a driving mechanism A and a magnetic wheel; the XY direction motion module is mounted on the device body; the supporting turntable module comprises a supporting frame, a driving mechanism B and a connecting disc, wherein the supporting frame is connected with the XY direction motion module, and the driving mechanism B is mounted on the supporting frame and connected with the connecting disc; the Z direction working module comprises a sweeping module, a couplant applying module, a thickness detecting module and three telescopic mechanisms, wherein the threetelescopic mechanisms are a telescopic mechanism A, a telescopic mechanism B and a telescopic mechanism C respectively, wherein the telescopic mechanism A is connected with the sweeping module, the telescopic mechanism B is connected with the couplant applying module, and the telescopic mechanism C is connected with the thickness detecting module. The device can replace manual operation to detectthe thickness of the metal tank body.

Owner:SOUTHEAST UNIV

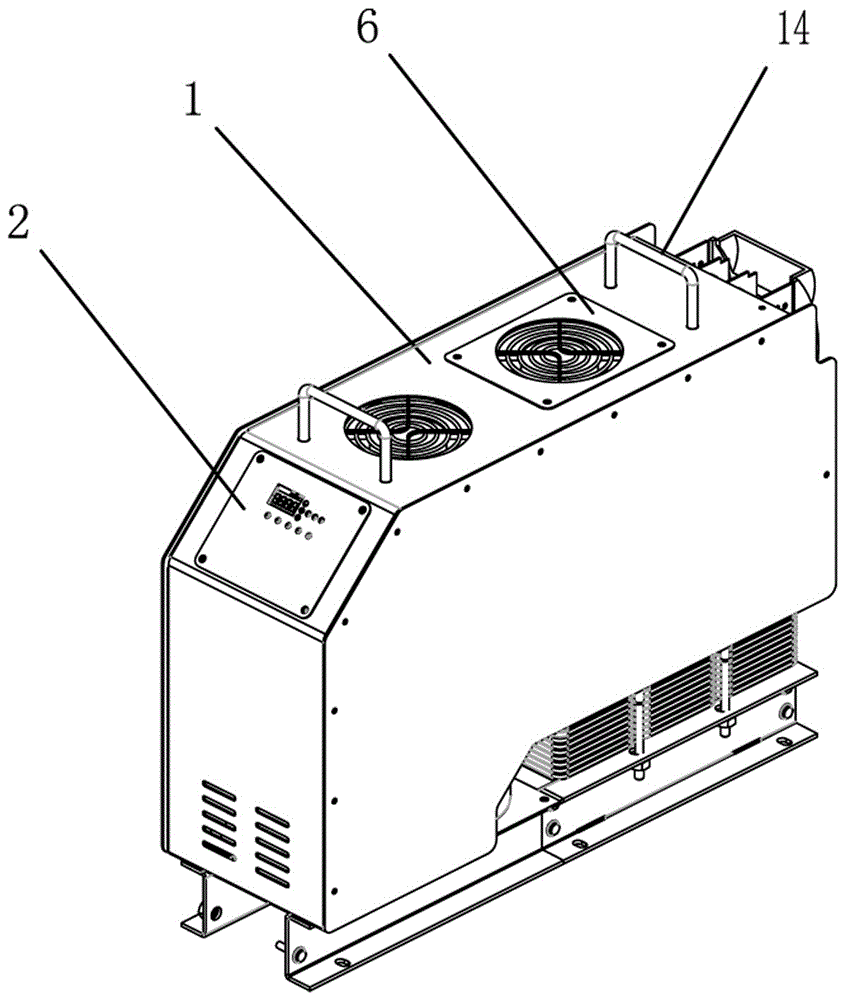

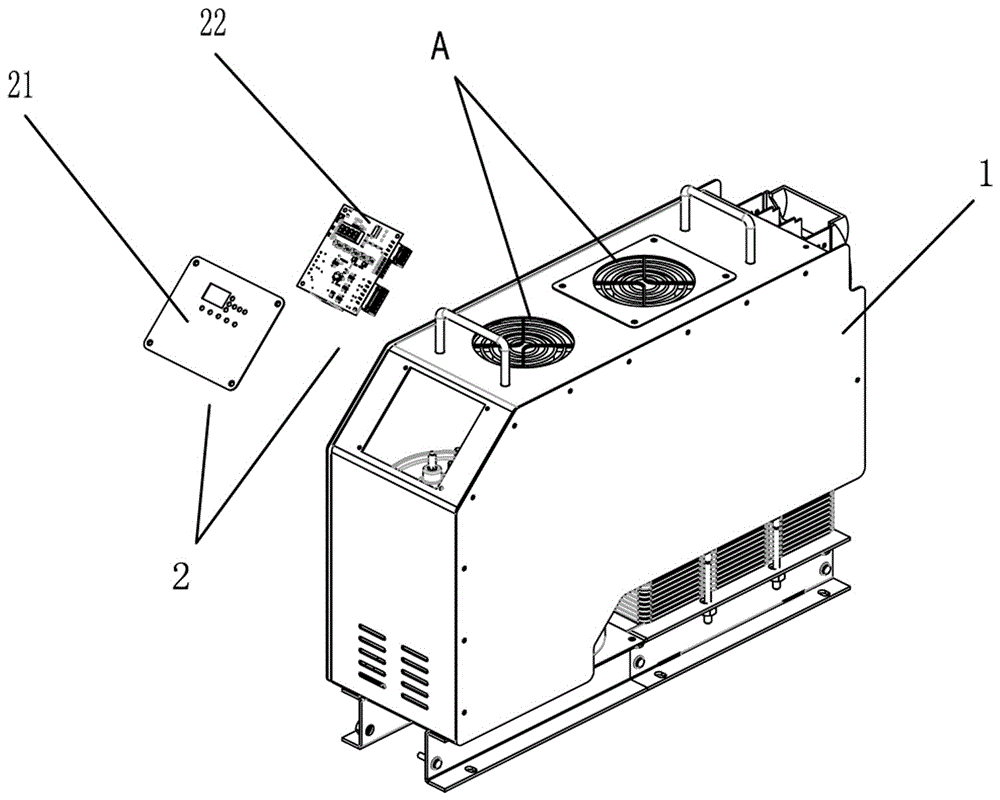

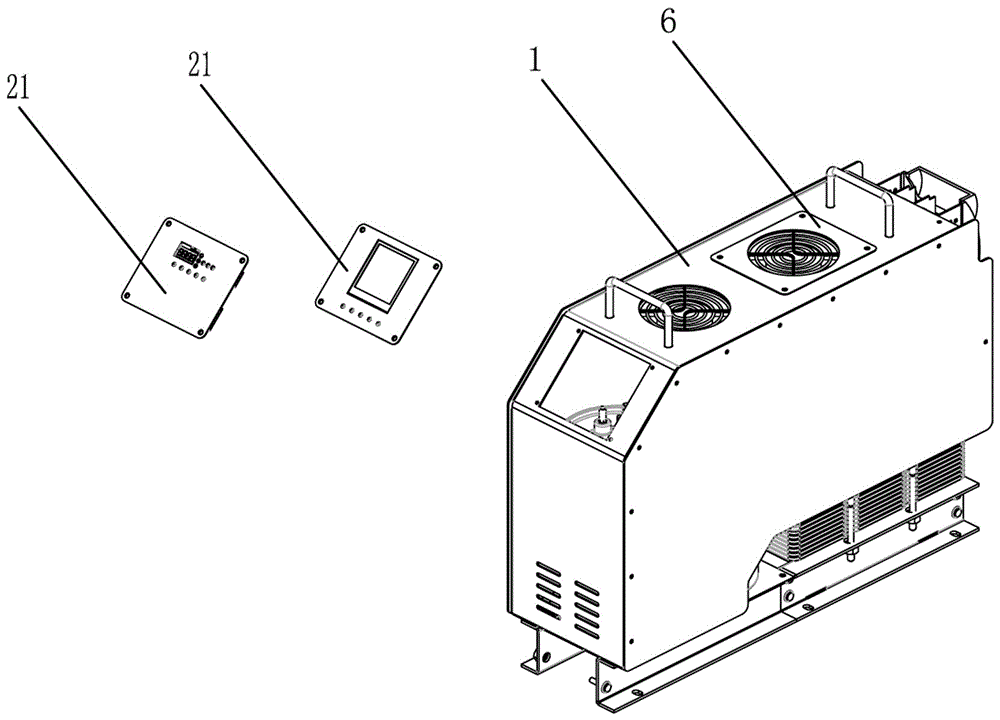

Smart filtering compensation module structure

InactiveCN105896321AFulfil requirementsReduce procurement costsSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement boards/panels/desksSilicon-controlled rectifierComputer module

The invention discloses a smart filtering compensation module structure. The structure comprises an enclosure, and a capacitor, an electric reactor, a silicon controlled rectifier and a fuse knife switch arranged in the enclosure. The structure is characterized in also comprising a main control unit, a fan assembly and a fuse knife switch panel. A triggering board and the fuse knife switch are fixed on the enclosure by the fuse knife switch panel. The fan assembly is mounted on the surface of the enclosure. The electric reactor and the silicon controlled rectifier are electrically connected by a copper bar. The main control unit is electrically connected with the fuse knife switch, the silicon controlled rectifier, the triggering board, the electric reactor and the capacitor. According to the smart filtering compensation module structure, the electric reactor and the silicon controlled rectifier are electrically connected by the copper bar, therefore, the stress of the wiring terminal of the silicon controlled rectifier is reduced, the conductive contact area is increased, and the potential safety hazards are eliminated. Moreover, the triggering board and the fuse knife switch are fixed on the enclosure by the fuse knife switch panel, therefore, replacement or overhaul can be carried out only by disassembling the fuse knife switch panel, the replacement and overhaul of the triggering board and the fuse knife switch are very convenient, and the integral structure is reasonable.

Owner:GUANGDONG GUANGDA ELECTRICAL

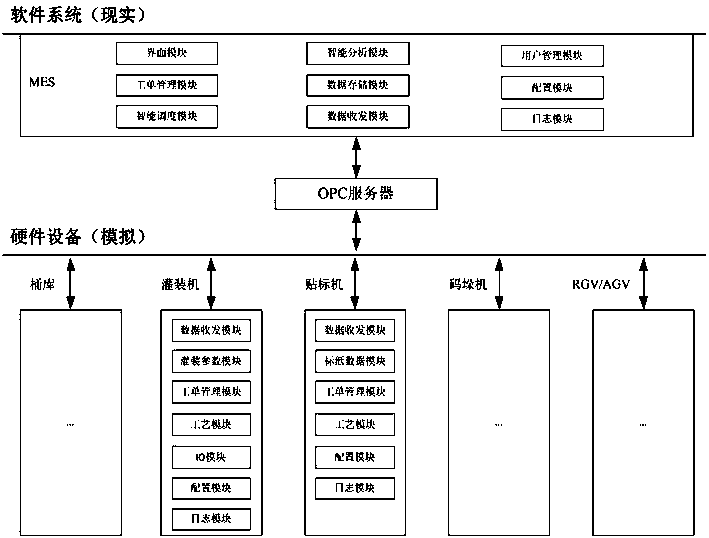

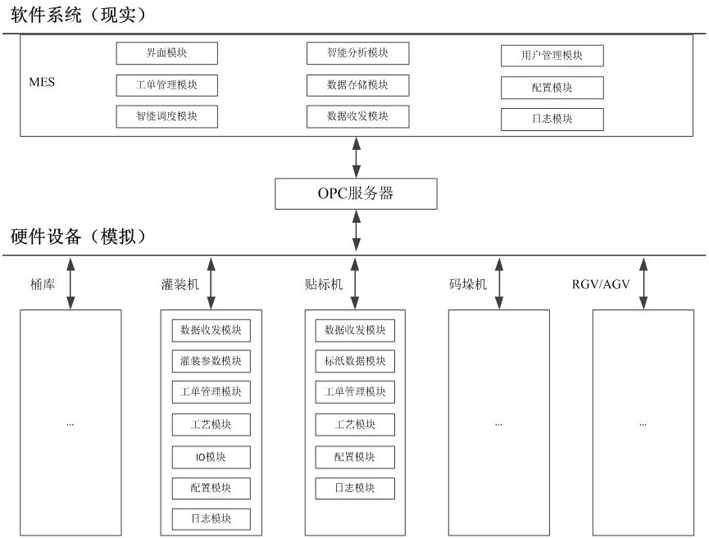

Data simulation method based on OPC intelligent chemical equipment

ActiveCN110347136ADoes not affect production progressSpeed up productionTotal factory controlProgramme total factory controlData simulationSoftware system

The invention relates to a data simulation method based on OPC intelligent chemical equipment, and relates to the technical field of industrial production process control and manufacturing executive management. Software simulation on the whole equipment is carried out by a software system and simulation hardware equipment: on the basis of an MES system, the software system and the simulation hardware equipment are deployed; relevant initial parameters of the system are set; work order data is set in a reality software system; the reality software system sends the work order data to the simulation hardware equipment through an OPC server, and records related operation data; the simulation hardware equipment is started, so that the whole equipment environment is simulated; the simulation hardware equipment receives the work order data sent by the software system, and analyzes the work order; the simulation hardware equipment performs production according to the work order, simulates therelated data running by the equipment, and sends the related data of the equipment to the reality software system; and the software system analyzes the running condition of the simulation chemical equipment in real time. The data simulation method based on the OPC intelligent chemical equipment in the invention simulates each hardware component through software, is independent of the hardware environment, and can independently run and debugg the software system.

Owner:CHANGCHUN BEIFANG INSTR EQUIP +1

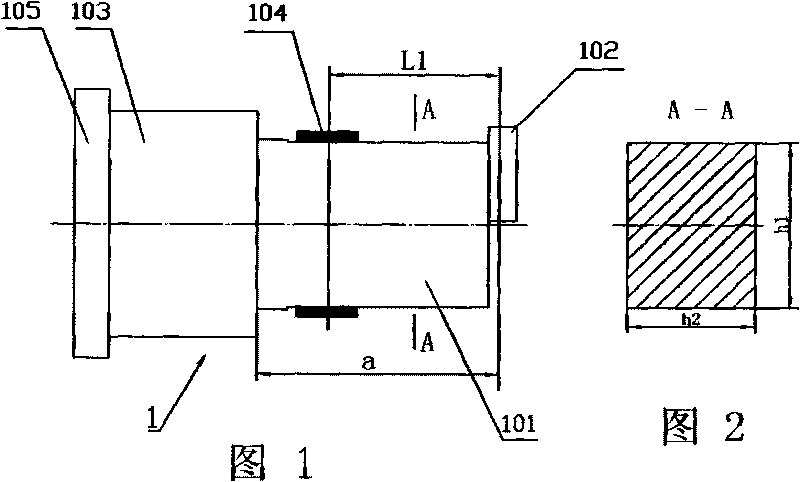

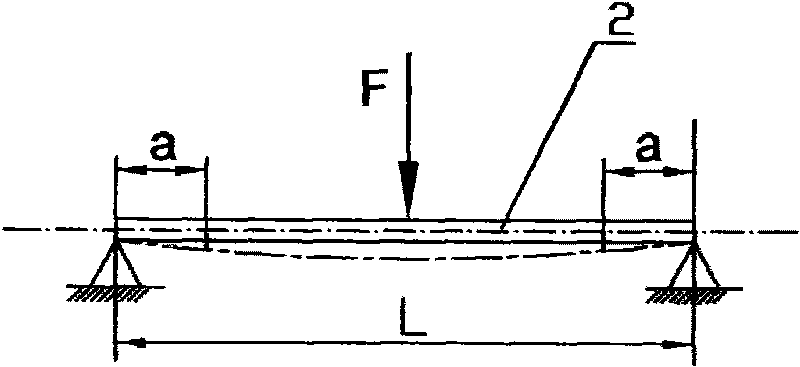

Small measuring range force transducer and method thereof for indirect measuring axle load

The invention is a small measuring range force transducer and a method thereof for indirectly measuring axle load. Two ends of a loaded axle are respectively provided with a small measuring range force transducer provided with a strain beam for sensing bent normal stress. The invention uses the principle that under the action of loading, the deflection of some point of the loaded axle is equal to that of the point of the small measuring range force transducer, adopts the small measuring range force transducer to sense the deflection generated by stress of the loaded axle, determines the measuring range of the transducer and parameters of a stress region by the design specification of the deflection and stress transducer, and manufactures the transducers suitable for the above indirect measurement. The invention completely avoids the traditional design thought directly measuring the axle load, changes the direct measurement of the axle load into indirect deflection measurement, reduces the measurement range and volume of the transducer greatly, and achieves the special skillfully deflected effect.

Owner:西安航天三沃机电设备有限责任公司

Method for rapidly recycling condensates in electron beam cooling bed furnace smelting chamber

The invention discloses a method for rapidly recycling condensates in an electron beam cooling bed furnace. The method comprises the following steps: after completion of cast ingot smelting in the furnace, decreasing the final cast ingot to the station of an ingot puller of the electron beam cooling bed furnace, turning off the isolating valve of a smelting chamber and an ingot pulling chamber, the isolating valve of a vibrating feeding hole and the smelting chamber, the lift valve of a diffusion pump unit, a booster pump and a holding pump bypass-valve to enable the entire smelting chamber to be in the isolated seal state; then, filling argon in the smelting chamber until the air pressure in the smelting chamber to be consistent with the barometric pressure; connecting a refrigerating machine with the smelting chamber, starting the refrigerating machine to cool the indoor temperature, after cooling, turning off the refrigerating machine and the valve of the refrigerating machine and the smelting chamber; finally, loosening the furnace door bolt of the smelting chamber, opening the furnace lid of the smelting chamber, and starting an axial draught fan to blow argon in the smelting chamber out so as to recycle the condensates. With adoption of the method, temperature in the furnace hearth can be rapidly decreased to the required temperature, and the condensates in the furnace can be rapidly recycled without affecting the production cycle.

Owner:YUNNAN TITANIUM IND

Device for producing anesthesia breathing mask

InactiveCN109248362ASimple structureEasy to operateRespiratory masksMedical devicesProduction scheduleEngineering

The invention discloses a device for producing an anesthesia breathing mask. The device comprises a fixed cavity arranged between a material discharge end of a screw extruder and a material inlet endof a die head, the material discharge end of the screw extruder penetrates through one side wall of the fixed cavity to be connected with a transition pipe, pressure sensors are arranged on the innerwall of the end opening of the transition pipe, a main pipe is connected to the end part of the transition pipe, two ends of the main pipe are connected with a first branch pipe and a second branch pipe, an annular baffle ring is arranged on the inner wall of each of two ends of the main pipe, an oil cylinder is arranged on the top of the main pipe, a piston rod of the oil cylinder penetrates through the first branch pipe to be fixedly connected with a baffle plate, a first material delivery pipe is connected to the end part of the first branch pipe, a first filtering block is arranged insidethe first material delivery pipe, a first filtering net is mounted on one side, close to the first branch pipe, of the first filtering block in an embedding manner, the pressure sensors are electrically connected with the input end of a controller, and the output end of the controller is electrically connected with the oil cylinder. For the device provided by the invention, the work efficiency isgreatly improved under the condition that the production schedule is not influenced.

Owner:湖南利德森医疗器械有限公司

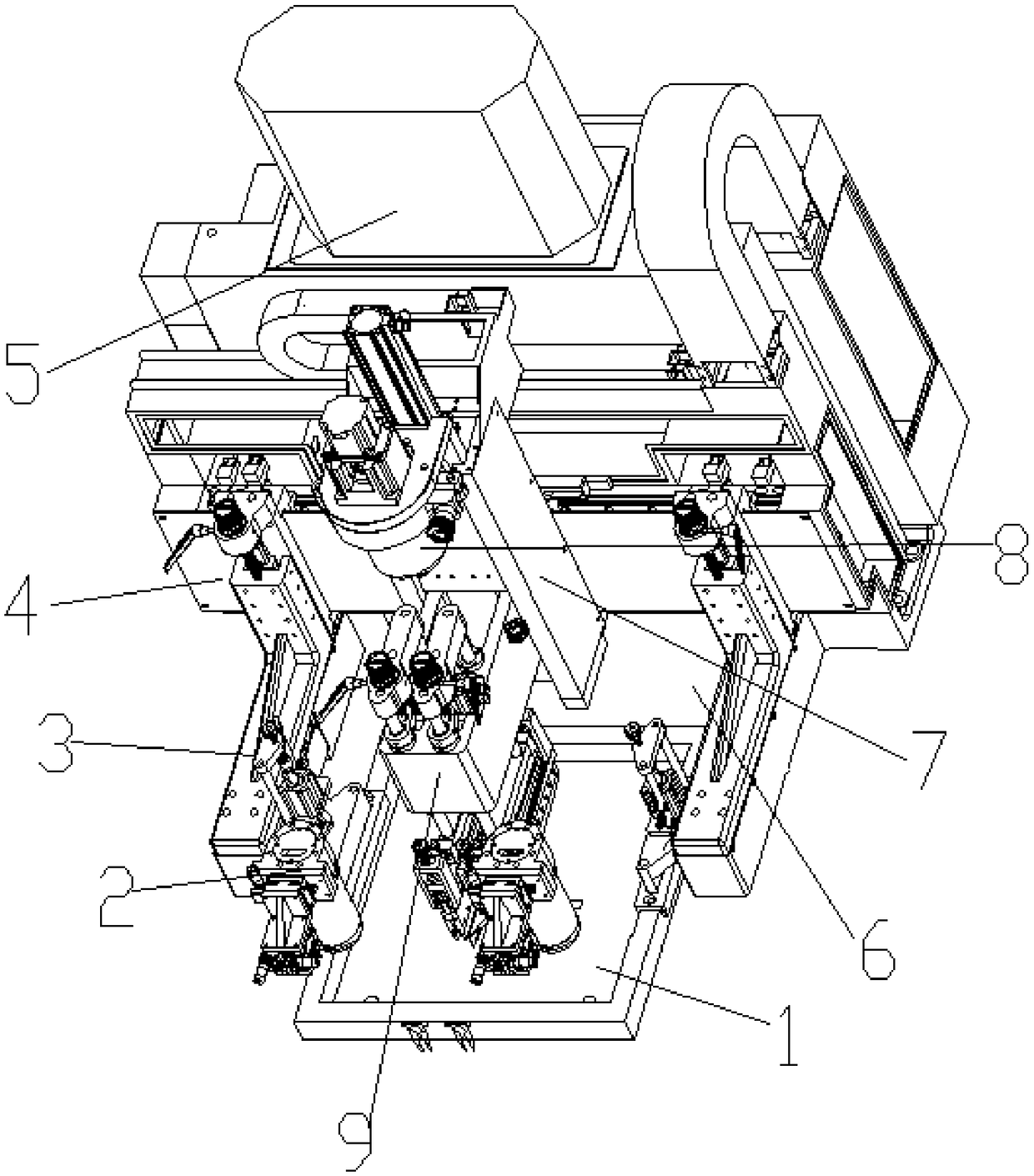

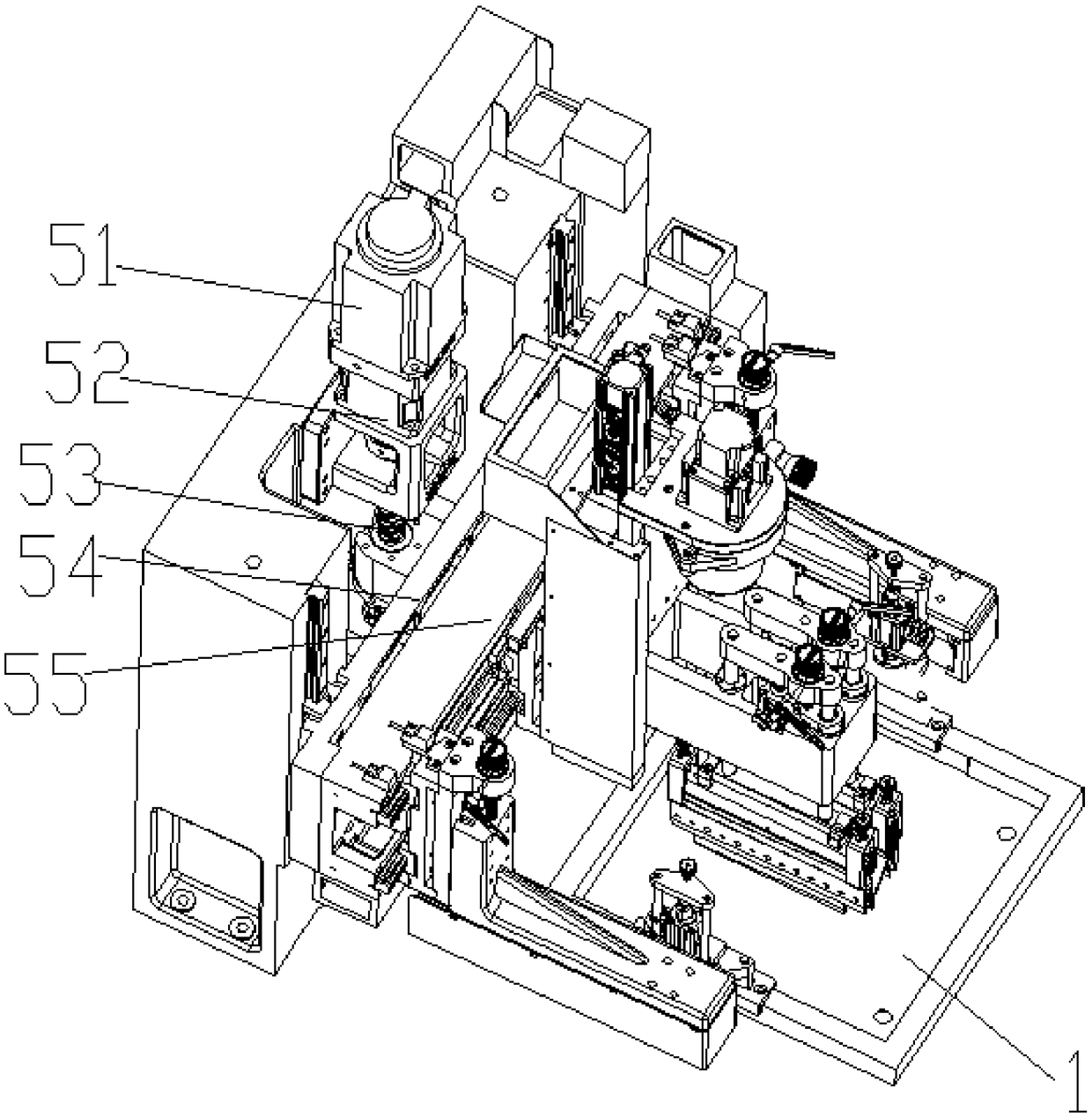

Screen printing machine for printing mobile phone touch screen

ActiveCN108248202AStrong flexibilityThe stirring blade is reasonableScreen printersOther printing apparatusSlide plateMobile phone

The invention discloses a screen printing machine for printing a mobile phone touch screen. The screen printing machine comprises a screen printing main machine lifting platform, a base, a screen printing screen plate, a screen plate fine adjustment platform and a screen printing main machine, wherein the screen printing screen plate, the screen plate fine adjustment platform and the screen printing main machine are arranged on the base, the screen printing screen plate is fixedly arranged in the screen plate fine adjustment platform, the screen printing main machine is installed above the screen printing screen plate, and the screen printing main machine lifting platform is connected with the base and drives the base to complete lifting action; and the screen printing main machine liftingplatform comprises a servo motor, a planetary reducer, a ball screw rod, a guide rail and a lifting sliding plate, the guide rail is arranged in the vertical direction, one side of the lifting sliding plate is fixed to the base, the other side of the lifting sliding plate is connected with the guide rail in a sliding mode, the ball screw rod is connected with the output end of the servo motor through the planetary reducer, and the lifting sliding plate is driven by the ball screw rod.

Owner:广州泰行智能科技有限公司

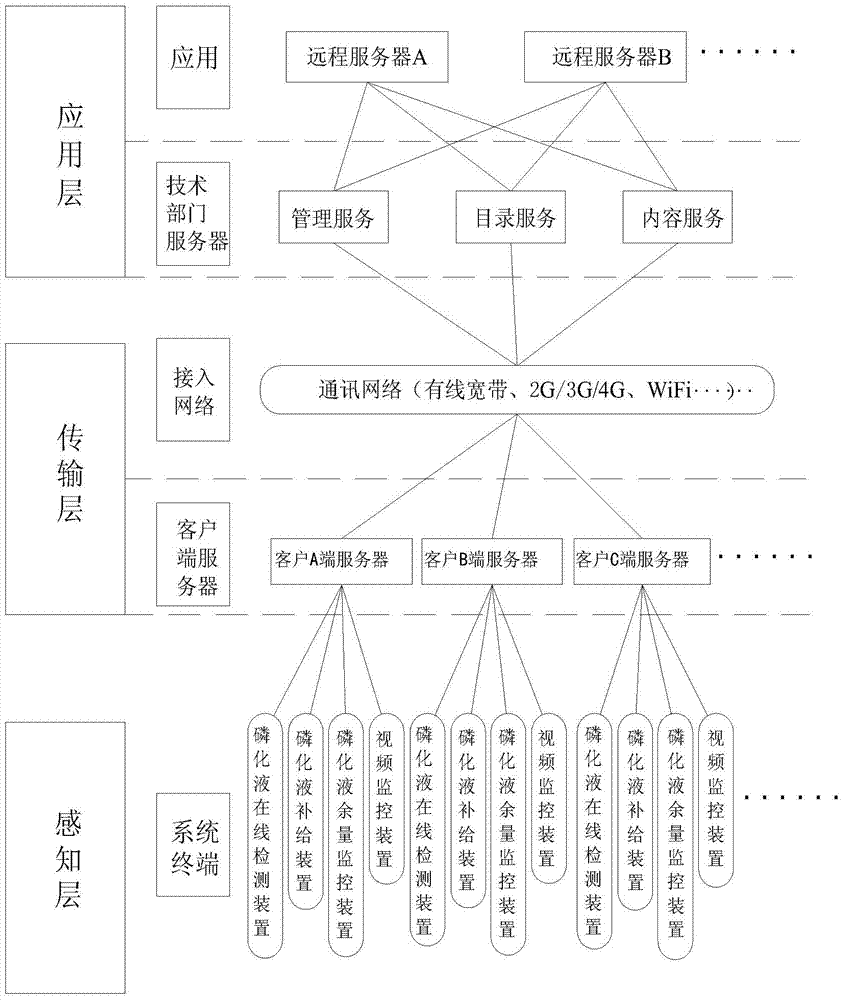

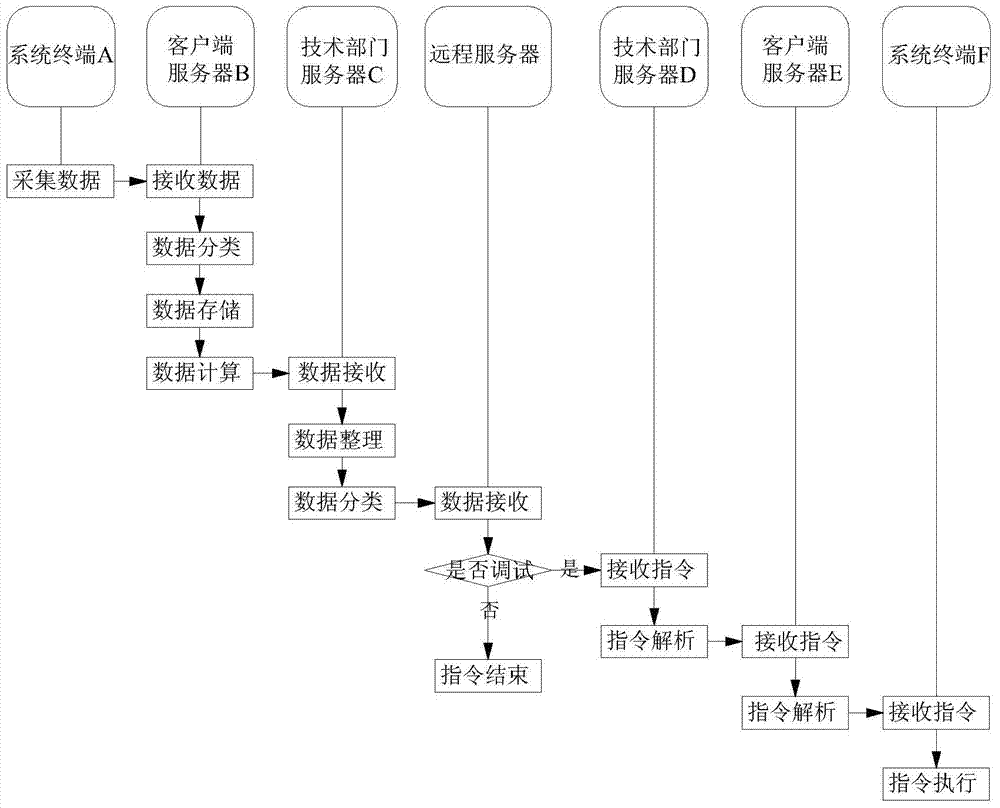

Internet of things technology based phosphating liquid automatic maintenance system and method

InactiveCN104233279AReal-time monitoringEnsure balanceMetallic material coating processesMaintenance managementThe Internet

The invention discloses an Internet of things technology based phosphating liquid automatic maintenance system and method. The Internet of things technology based phosphating liquid automatic maintenance system comprises a system terminal, a client server, a technical department server and a remote server; the system terminal is used for collecting field data; the client server is used for receiving the data returned from the system terminal; the technical department server is connected with the client server through a communication network and used for receiving, classifying and sorting the data collected through the system terminal; the remote server is used for performing remote debugging according to the received data. According to the Internet of things technology based phosphating liquid automatic maintenance system and method, the system terminal serves as a sensing layer, detection, debugging and monitoring functions are achieved, the automatic maintenance management can be achieved through the client server and the system terminal under the condition that the phosphating liquid indicator is stable, a warning is sent to the remote server after the phosphating liquid indicator exceeds a system set value, the remote debugging is performed by the remote technical service personnel, and accordingly the automation and the informationization of the phosphating liquid maintenance treatment are achieved, the production process is not affected, the balance of yin and yang ions in the phosphating liquid is effectively ensured, and the optimum effect of the phosphating liquid is achieved.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

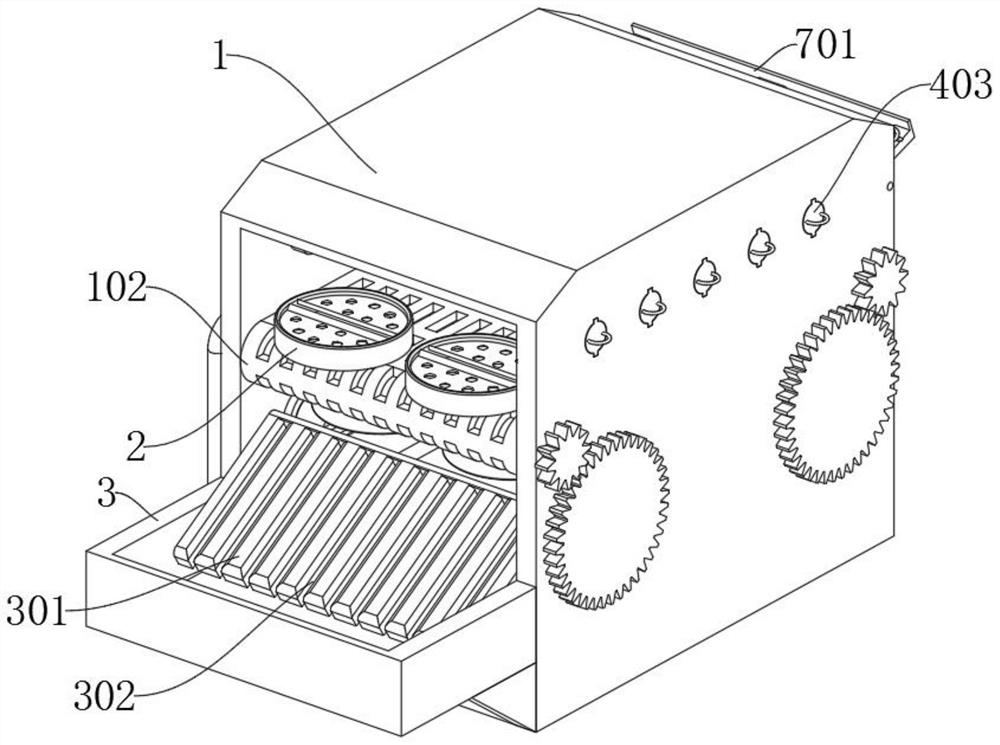

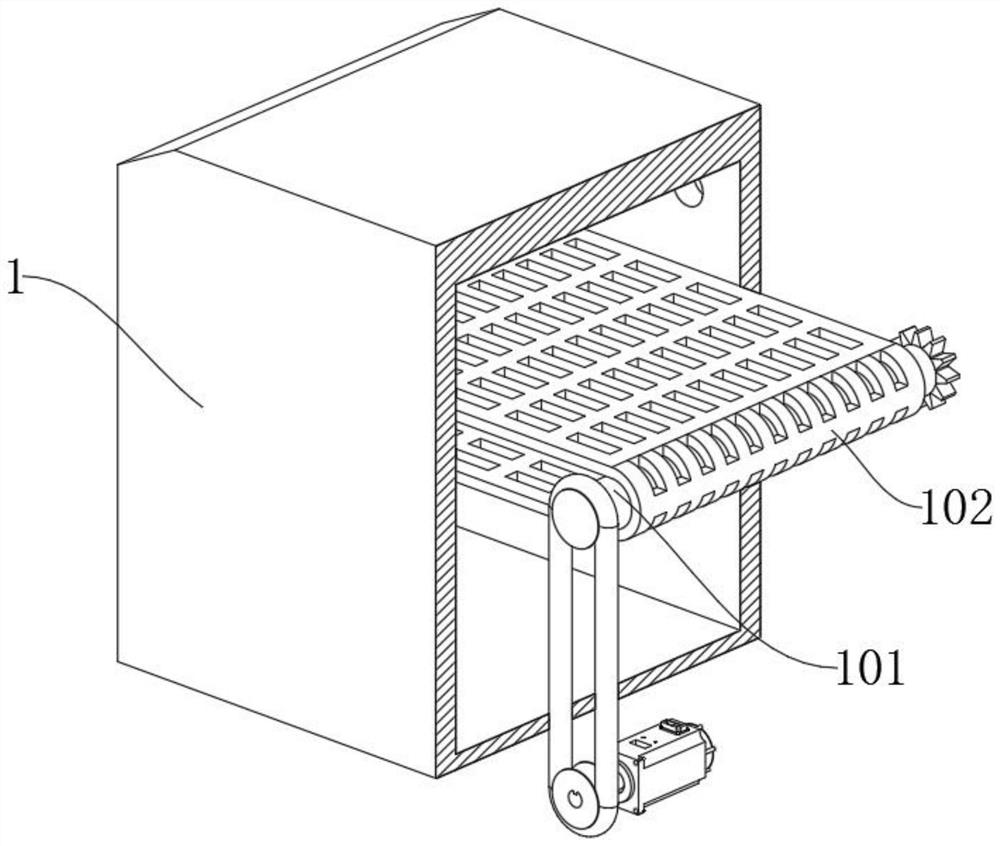

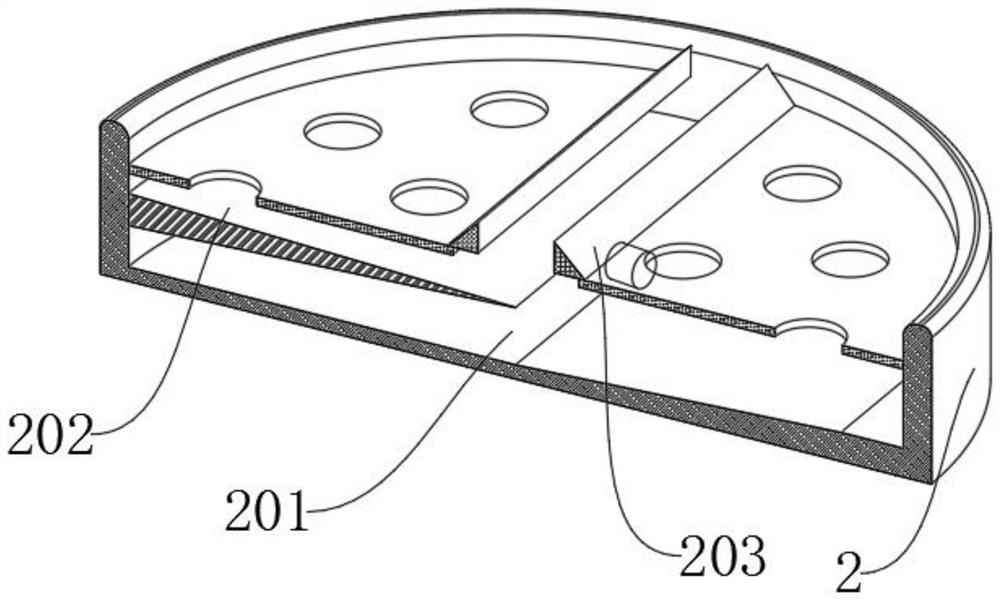

Baking device for food processing

InactiveCN112493263AAvoid pollutionAvoid stickingBaking ovenSpecial goods bakingBiotechnologyEngineering

The invention provides a baking device for food processing, and relates to the technical field of food processing and production. The problem that when an existing baking device is used, grease generated by meat product processing falls into a baking tray, part of grease is prone to falling onto food, and food pollution is caused is solved. The baking device comprises a body, a tray and a heatingpiece. A guide plate at the top of a box is arranged on the inner side of the body; a water tank is formed in the bottom of the inner side of the body; a gear at the outer end of a rotating plate on the outer side of a rotating piece meshes with a gear at the outer end of a rotating rod; a sliding plate is mounted on the inner side of the body through a rotating shaft, and the top of the sliding plate is connected with the inner top of the body through a spring; a filter plate is arranged at the top of the tray, and the tray is mounted on the outer side of the transmission part; and the heating piece is arranged on the inner side of the body, and a pull plate on the outer side of the heating piece is mounted on the side face of the body. The grease is prevented from polluting the processedfood through the tray, and the grease is cleaned through a scraping plate on the heating piece.

Owner:高颖

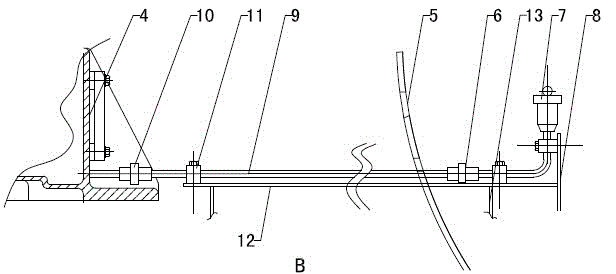

Oil level monitoring and oil recharging device for gear box of cooling tower

InactiveCN103335096ALubrication and maintenance work is safe and convenientIngenious designGear lubrication/coolingLubrication elementsProduction scheduleCounter flow

The invention discloses an oil level monitoring and oil recharging device for a gear box of a cooling tower, belongs to the field of common large cooling tower equipment, and specifically relates to an oil level monitoring and oil recharging device of a cooling fan gear box for a large counter flow cooling tower. The oil level monitoring and oil recharging device is characterized in that the oil level monitoring and oil recharging device is mounted in an inspection channel at the top of the cooling tower and comprises an oil pipe (9), an oil cup (7) and a fixing bracket (8), wherein the oil cup (7) and the oil pipe (9) are mounted through the fixing bracket (8); and one end of the oil pipe (9) is communicated with an oil outlet of the oil cup (7), while the other end of the oil pipe (9) is communicated with an oil drain hole (403) of the gear box (4) of the cooling tower. The principle that liquid levels of two communicated appliances are equal is ingeniously utilized, a maintenance worker can judge the height of the liquid level of an operating oil level in the gear box by observing the liquid level of the oil level in the oil cup and can safely and conveniently lubricate and maintain the gear box, the gear box is not required to halt no matter whether monitoring or oil recharging is performed, the normal operation of the device is not influenced, and the production efficiency and the production schedule are not influenced.

Owner:SHANDONG DONGHUA TECH CO LTD

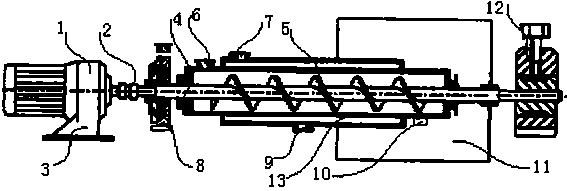

Material spiral conveying device

InactiveCN108792463AWon't clogDoes not affect normal operationConveyorsCleaningDrive shaftEngineering

The invention discloses a material spiral conveying device. A rolling bearing sleeves the front end of a conveying transmission shaft; one end of a conveying device body is arranged in a roller screen; a slide bearing is arranged at the outer end of the roller screen; a rolling bearing and the slide bearing are arranged at two ends of a transmission shaft, and are arranged at the external of the spiral conveying machine body for isolation from materials, so that the temperatures of the bearings are not influenced by the temperature of the materials, the bearings cannot be blocked by the materials and dust, the normal operation of the spiral conveying device is not influenced, the maintenance is convenient, the production progress is not influenced, and the cost is saved; a water cooling inlet is formed in the upper opening end of the conveying device body; a water cooling outlet is formed in the bottom end of the conveying device body; when the device operation is stopped, the materialspiral conveying device is cooled by the water cooling inlet and the water cooling outlet, and the spiral conveying device can be cleaned; one end of the conveying device body is arranged in the roller screen; the materials are screened by adopting the roller screen; the materials are screened to meet requirements; and material particles are nonuniformly removed.

Owner:泰州市科美伦机电有限公司

Multiple train unit intelligent maintenance system, and multiple train unit intelligent maintenance system control method

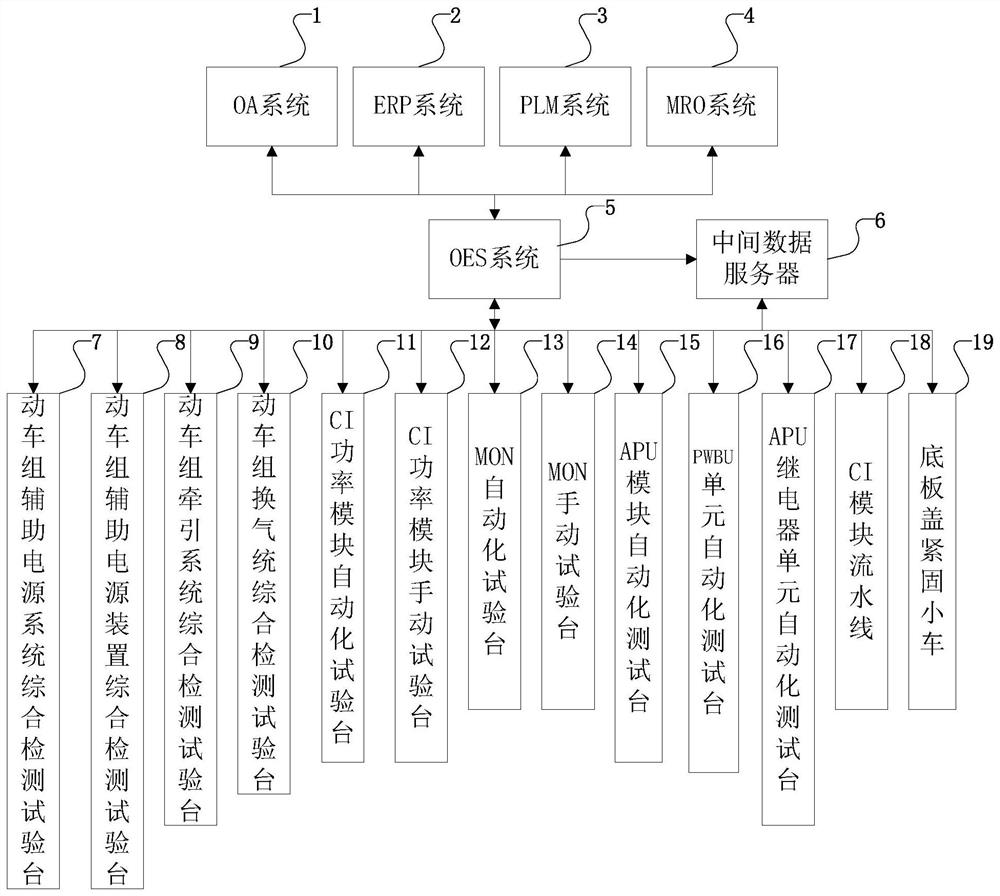

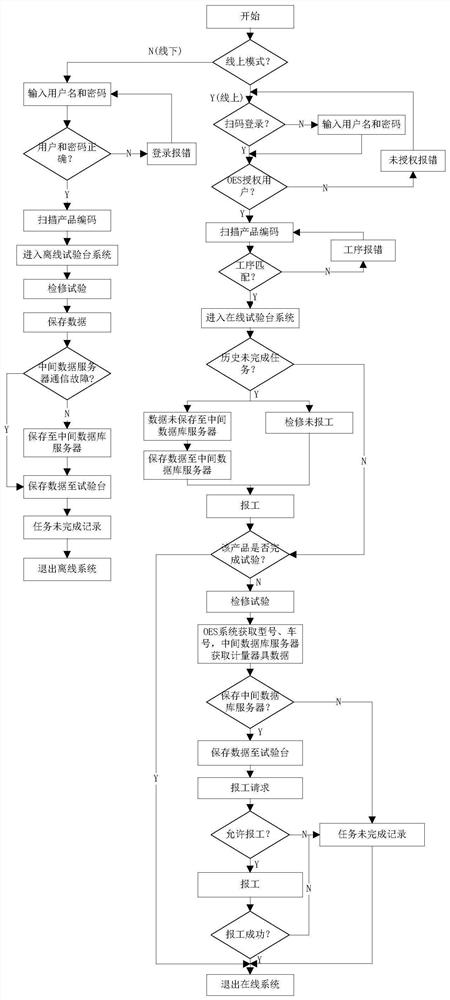

PendingCN114077902AEnsure safety and traceabilityReduce maintenance costsResourcesData informationIntelligent maintenance system

The invention discloses a multiple train unit intelligent maintenance system, and a multiple train unit intelligent maintenance system control method. The maintenance system comprises: a plurality of test stands, a CI module flow line, an intermediate database server, an OES system, an OA system, a PLM system, an ERP system, and an MRO system. Each test stand is connected with the intermediate database server and the OES system; the CI module flow line comprises a plurality of stations for completing different procedures; the intermediate database server is used for storing data information of each test stand; the OES system is respectively connected with the OA system, the PLM system, the ERP system and the MRO system; the OA system is used for querying data analysis reports in the OES system; the PLM system is used for providing basic information configuration; the ERP system is used for providing reference information and product performance inspection and analysis information; the MRO system is used for providing material management data. The system has the advantages of unified management, centralized control, energy conservation, environmental protection, low maintenance cost, high maintenance efficiency and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

A screen printing machine for mobile phone touch screen printing

ActiveCN108248202BPrevent solidification and agglomerationIncrease flexibilityScreen printersOther printing apparatusScreen printingTouchscreen

The invention discloses a screen printing machine for printing a mobile phone touch screen. The screen printing machine comprises a screen printing main machine lifting platform, a base, a screen printing screen plate, a screen plate fine adjustment platform and a screen printing main machine, wherein the screen printing screen plate, the screen plate fine adjustment platform and the screen printing main machine are arranged on the base, the screen printing screen plate is fixedly arranged in the screen plate fine adjustment platform, the screen printing main machine is installed above the screen printing screen plate, and the screen printing main machine lifting platform is connected with the base and drives the base to complete lifting action; and the screen printing main machine liftingplatform comprises a servo motor, a planetary reducer, a ball screw rod, a guide rail and a lifting sliding plate, the guide rail is arranged in the vertical direction, one side of the lifting sliding plate is fixed to the base, the other side of the lifting sliding plate is connected with the guide rail in a sliding mode, the ball screw rod is connected with the output end of the servo motor through the planetary reducer, and the lifting sliding plate is driven by the ball screw rod.

Owner:广州泰行智能科技有限公司

Vibration welding technology

InactiveCN100457377CDoes not affect production progressLow costWelding/cutting auxillary devicesAuxillary welding devicesPower flowWeld seam

The vibration welding technology of the present invention includes: 1. connecting a vibration exciter rigidly to the welded part or a vibration table with the welded part, and regulating the exciting force of the vibration exciter in resonant state to make the welded part obtain required amplitude; 2. maintaining the welded part in resonant state and in stable amplitude; 3. selecting one relatively low work frequency in resonant state and with amplitude not greater than one third of the resonant amplitude; 4. picking up the vibration with one acceleration sensor fixed in certain distance to the welding seam and shifting with the welder for tracking and monitoring the vibration parameters; etc. The present invention has convenient welding operation, high welding effect and high welding speed, and is suitable for welding different kinds of member.

Owner:黎凡七

Novel twenty-roller cold-rolling mill

InactiveCN102228904BAvoid deformationLarge openingMetal rolling stand detailsWork treatment devicesHydraulic cylinderEngineering

Owner:天津冶金规划设计院

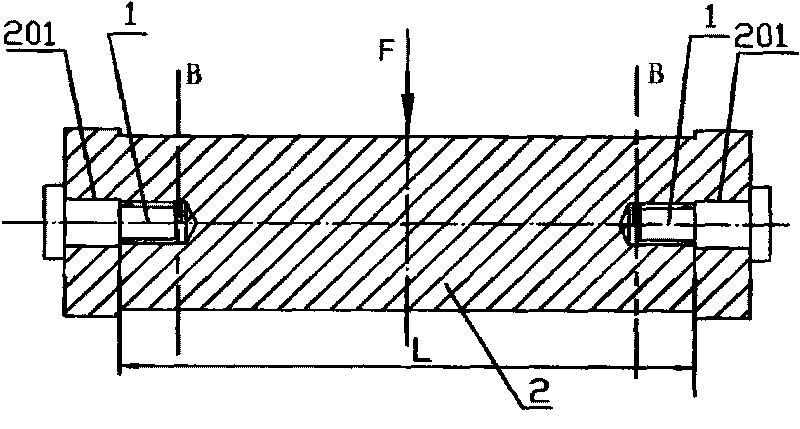

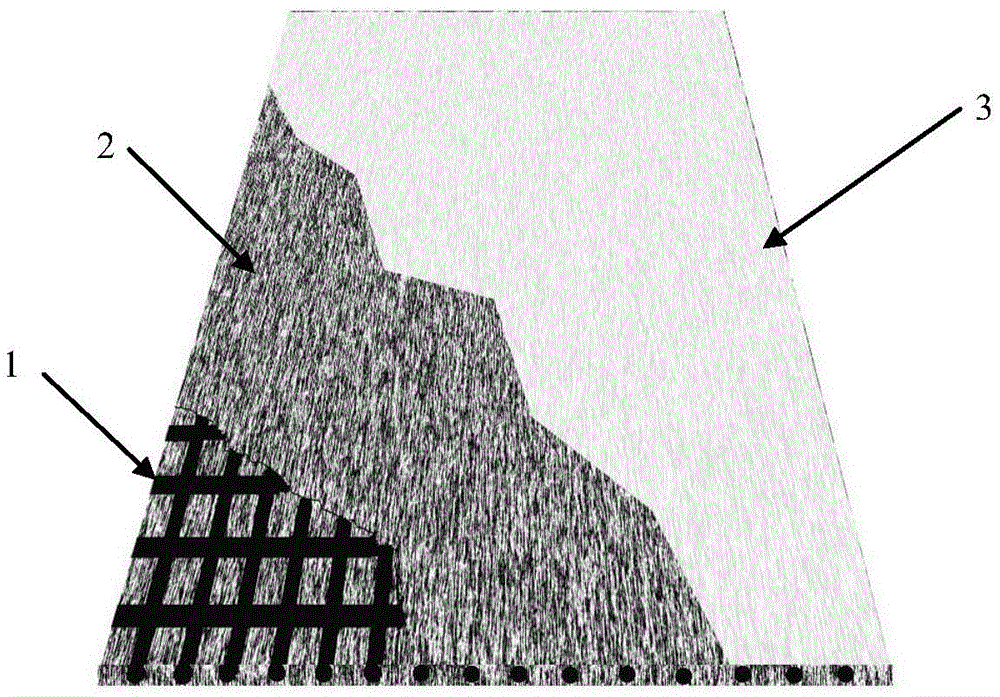

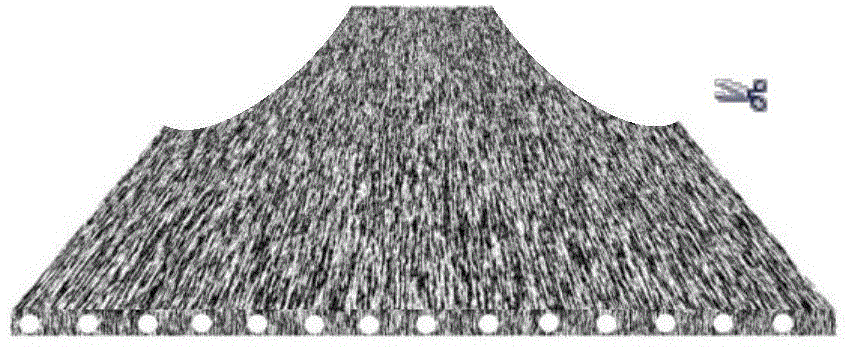

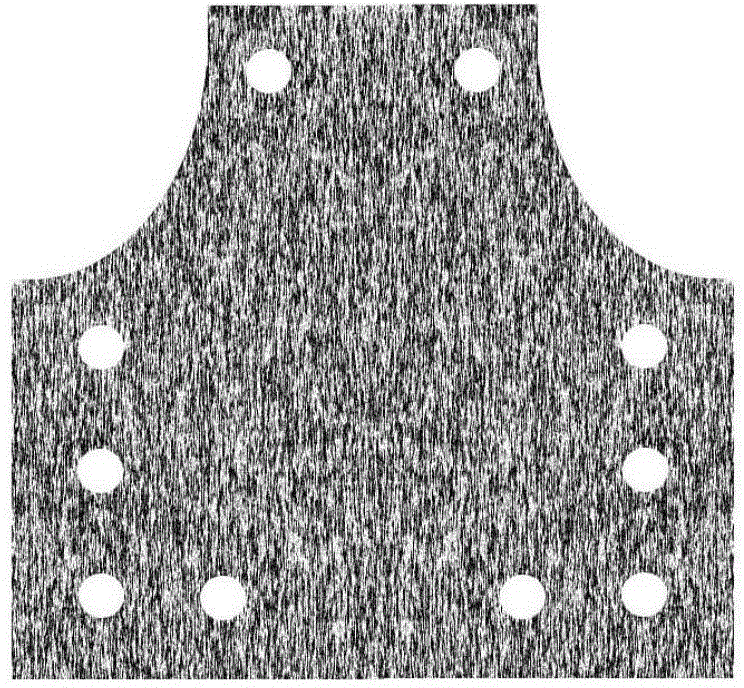

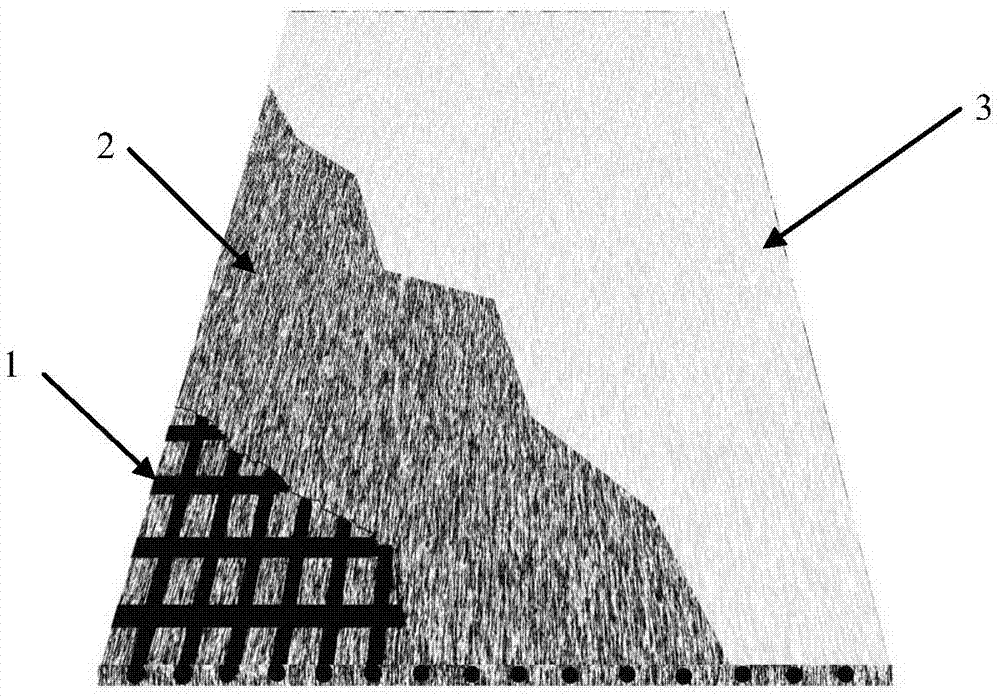

On-line repairing method for fractured upper beam for hydraulic press casting and structure reinforcing device

ActiveCN102267012BImprove structural strengthExtended service lifeForging/hammering/pressing machinesWelding/soldering/cutting articlesEngineeringUltimate tensile strength

The invention relates to an on-line repairing method for a fractured upper beam for hydraulic press casting and a structure reinforcing device. The on-line repairing method is characterized in that the fractured upper beam is reset, a pressure stress weld joint is formed at the position of a crack, a box-shaped structure reinforcing device is arranged in a force-loaded area of the upper beam, the structural strength of the upper beam is promoted and the on-line repairing is realized. The on-line repairing method comprises the following steps: 1) resetting; 2) processing a groove; 3) preheating and welding in sections; 4) performing heat treatment; 5) welding cracks on an outer wall; and 6) arranging the box-shaped structure reinforcing device. The structure reinforcing device is characterized in that two vertical tendons are arranged on the two sides of the crack; 3-4 transverse bars are arranged on the vertical tendons; cover plates are arranged between the transverse bars, thereby forming a box-shaped structure; and an upper lacing bar is arranged on the upper beam. The on-line repairing method has the advantages that the fractured crack is welded and the box-shaped structure reinforcing device is arranged in the force-loaded area of the upper beam, thereby realizing the on-line repairing of the fractured upper beam for a hydraulic press and promoting the structural strength of the upper beam.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

A data simulation method based on opc intelligent chemical equipment

ActiveCN110347136BDoes not affect production progressSpeed up productionTotal factory controlProgramme total factory controlData simulationSoftware system

Owner:CHANGCHUN BEIFANG INSTR EQUIP +1

Full-automatic hot pressing device for liquid crystal display screen production

PendingCN114265217AHigh degree of automationImprove practicalityNon-linear opticsLiquid-crystal displayEngineering

A full-automatic hot-pressing device for liquid crystal display screen production relates to the technical field of hot-pressing devices and comprises a machine body, a partition plate is vertically arranged in the machine body and divides the machine body into a hot-pressing space and a heat dissipation space, and a hot-pressing device for hot-pressing a liquid crystal display screen is arranged in the hot-pressing space. A heat dissipation device for conducting active air cooling heat dissipation on the liquid crystal display screen subjected to hot pressing is arranged in the heat dissipation space, and the liquid crystal display screen hot pressing device further comprises a driving device for conveying the liquid crystal display screen located in the hot pressing space into the heat dissipation space. And equivalently, the working efficiency is improved, the production schedule is not affected, practicability is high, and the device is worthy of application and popularization.

Owner:深超光电技术(河源)有限公司

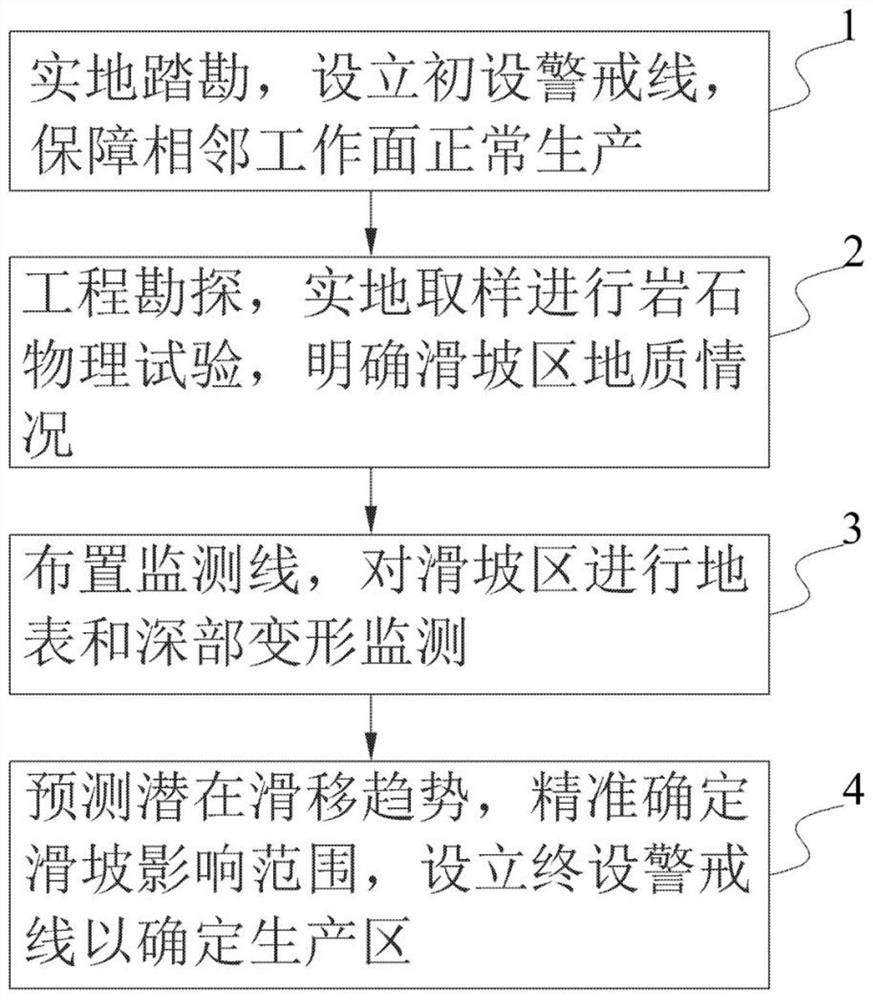

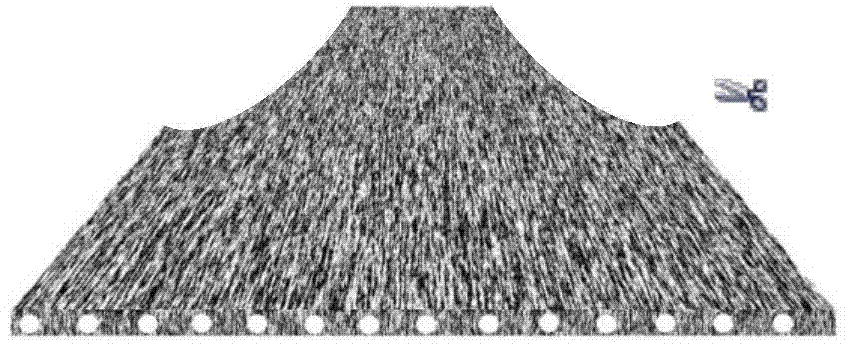

Opencast coal mine working side landslide treatment method based on reduction of production influence degree

PendingCN112132311AGood effectAccurately determineFoundation testingForecastingMining engineeringDeformation monitoring

The invention provides an opencast coal mine working slope landslide treatment method based on reduction of production influence degree, which comprises the following steps: S1, on-site reconnaissance: setting an initial warning line according to the on-site reconnaissance situation to ensure normal production of adjacent working faces without influencing the production schedule; s2, performing engineering exploration, performing on-site sampling to perform a rock physical experiment, and determining the geological condition of a landslide area; s3, arranging monitoring lines in the landslidearea, and conducting ground surface and deep deformation monitoring on the landslide area; s4, predicting a potential slip trend to determine a landslide influence range, and setting a warning area again for the landslide influence range to determine a production area; by accurately determining the minimum range of the landslide influence, the strippable area of the working side is maximized, theinfluence time and influence range of the landslide are minimized, and on the premise of safety, normal stripping operation is not influenced, the coal exposing speed is increased, the coal mining amount is guaranteed, the production task is completed, and the emergency disposal capacity of enterprises is improved. The influence degree of working side landslide on production is reduced.

Owner:CCTEG CHINA COAL RES INST +1

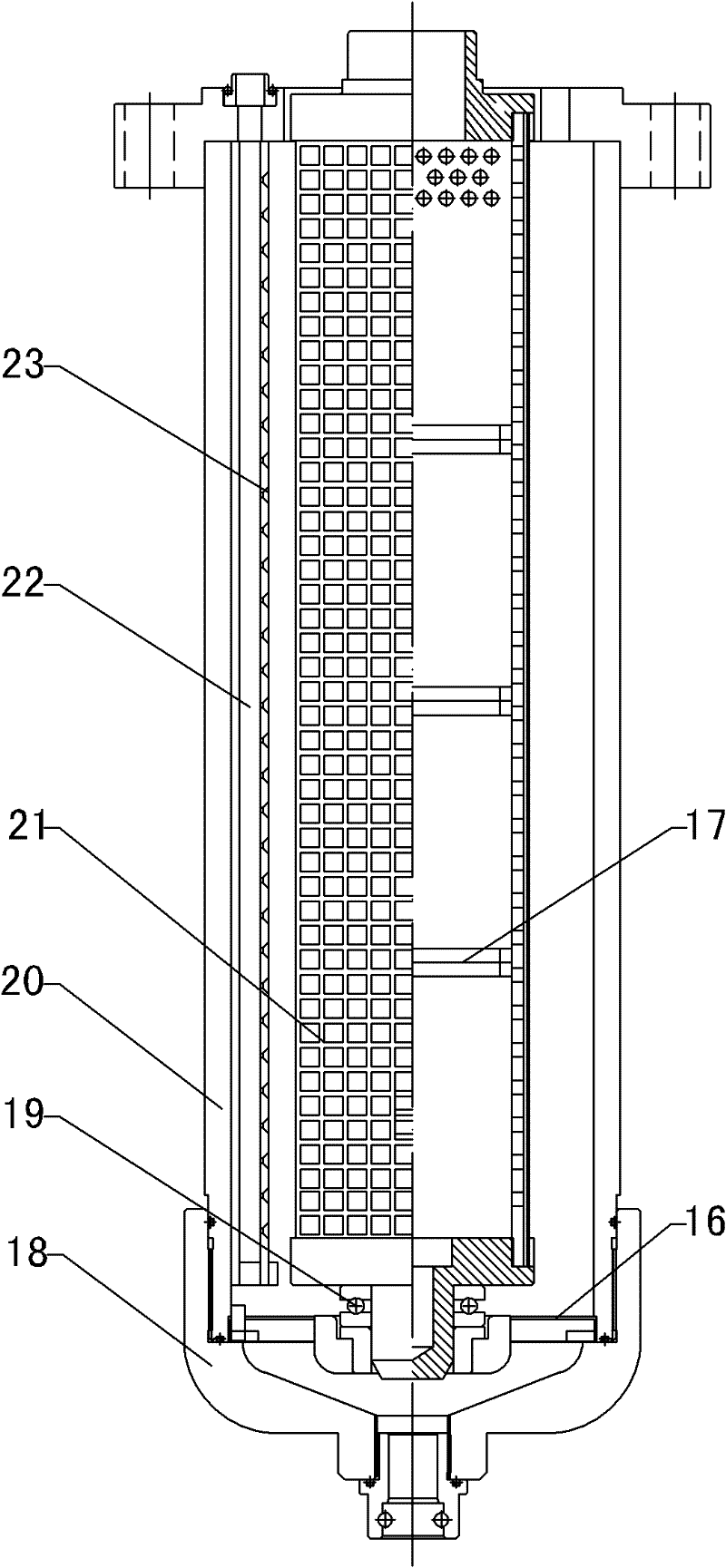

A countersink tool with quick adjustment and positioning

ActiveCN106583807BEasy to assemble and disassembleReduce maintenance costsTransportation and packagingTrepanning drillsEngineeringMachining

The invention relates to the field of machining knife tools and discloses a novel countersink tool. The novel countersink tool comprises knife-containing blocks, knife tools used for machining are removably mounted on the knife-containing blocks correspondingly, and the knife-containing blocks are removably mounted on a main drilling shaft and rotate with the main drilling shaft. Each knife-containing block is designed in a briefs shape, a knife-containing block installing hole is formed in the central position of each knife-containing block, the knife-containing blocks are mounted on the main drilling shaft through the knife-containing block installing holes, two knife tool installing holes are formed in the two ends of each knife-containing block symmetrically, and knife tools are mounted in the knife-containing blocks through the knife tool installing holes correspondingly. Installation and operation are easy, maintenance, dismounting and assembly are convenient, cost is low, universality is good, and the labor strength of a worker is greatly reduced.

Owner:SICHUAN CHUANGUO BOILER

Redundant mechanical gripper system for automatic production line and working method thereof

PendingCN109352659AIncrease productivityDoes not affect production progressProgramme-controlled manipulatorManipulatorManufacturing engineering

The invention relates to the field of mechanical production, in particular to a redundant mechanical gripper system and a working method thereof. The redundant mechanical gripper system comprises a main manipulator and an auxiliary manipulator rotating through a rotating device, and a detection device for detecting the working state of the main manipulator, wherein the rotating device and the detection device are electrically connected with a main control module; and after the fault of the main manipulator is determined, the main control module is suitable for controlling the rotating device to rotate, so that the auxiliary manipulator rotates to the working position of the main manipulator so as to replace the main manipulator to work. When the main manipulator is failed, the production of the production line can be continuously accomplished, so that the production progress is not influenced, the production efficiency is improved, and all-weather production is realized.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Expansive type aviation fireproof composite material and manufacture method thereof

ActiveCN103552310ADoes not affect production progressShorten the production cycleFireproof paintsPolyurea/polyurethane coatingsAirplaneRadiation

The invention belongs to the fireproof material technology, and relates to an expansive type aviation fireproof composite material for fire-preventing of an airplane structure, and a manufacture method of a fireproof composite material. The fireproof composite material can be singly manufactured or purchased in a finished product form, the mounting and replacement are relatively simple, and the required period is only 1 / 100 of the period for coating fireproof paint, the production period and maintenance period of the airplane are greatly shortened. The materials for manufacturing the fireproof composite material are materials in existence, so that the material cost cannot be greatly increased. The fireproof composite material is capable of expanding and foaming to isolate the flame and heat radiation when the airplane is on fire, and meanwhile the fixed shape can be maintained. When the thickness is 0.8mm, the fireproof composite material can be used for preventing fire for 15min and more at 1093 DEG C, and when the thickness is 0.5mm, the fireproof composite material can be used for preventing fire for 5min and more.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

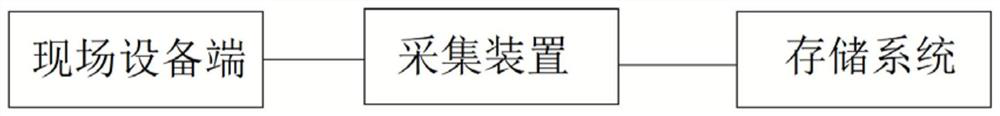

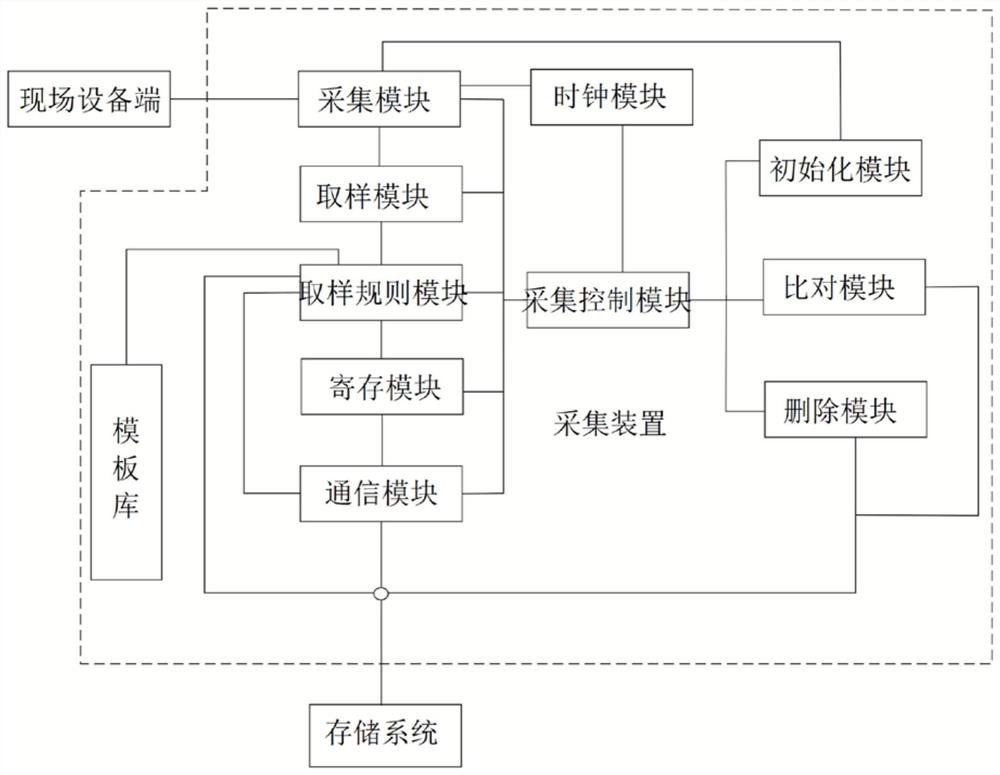

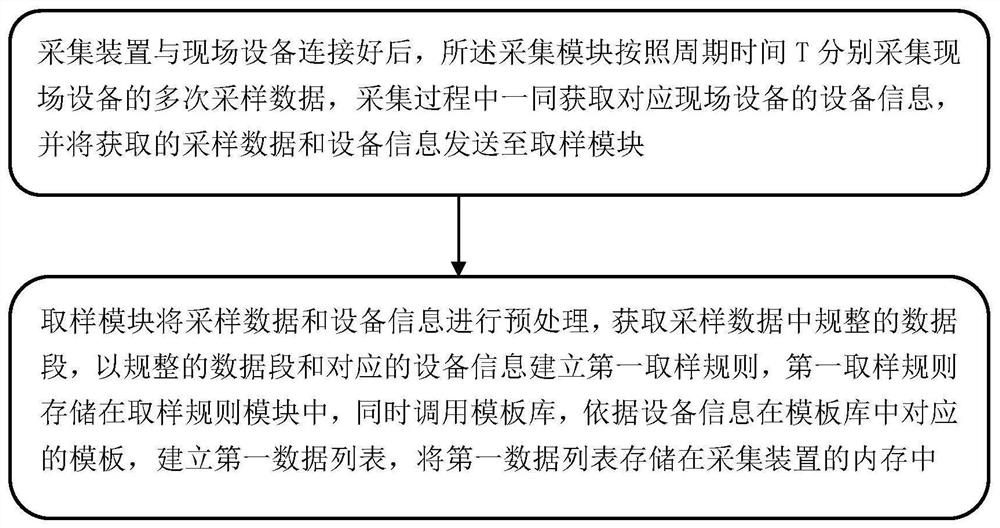

A special operation process data acquisition system and storage system

ActiveCN113449013BDoes not affect production progressWith early warning functionText processingRelational databasesSoftware engineeringData acquisition

The invention provides a special operation process data acquisition system and storage system, which includes a field equipment end, a collection device connected with the field equipment end, and a storage system connected with the collection device. The invention can automatically call the template library through the sampling module and the established sampling rules, and establish the first data list according to the template corresponding to the device information in the template library. The template corresponding to the basic information of the device can complete the establishment of the link. If the front-end equipment is upgraded or the monitoring equipment is updated, it is only necessary to set the template corresponding to the basic information of the field equipment in the template library, and then initialize the system through the initialization module to complete the link update without redesigning the link. There is no need for debugging, and the renovation can be completed without affecting the production progress.

Owner:北京思路智园科技有限公司

Backwashing high-pressure filter station

ActiveCN102258910BRealize online recoilDoes not affect production progressFiltration circuitsFluid-pressure actuator componentsHigh pressureMechanical engineering

Owner:SHANDONG MINGDUN EXPLOSION PROOF EQUIP TECH CO LTD

An intumescent aviation fireproof composite material and its manufacturing method

ActiveCN103552310BDoes not affect production progressShorten the production cycleFireproof paintsPolyurea/polyurethane coatingsAviationJet aeroplane

The invention belongs to the fireproof material technology, and relates to an expansive type aviation fireproof composite material for fire-preventing of an airplane structure, and a manufacture method of a fireproof composite material. The fireproof composite material can be singly manufactured or purchased in a finished product form, the mounting and replacement are relatively simple, and the required period is only 1 / 100 of the period for coating fireproof paint, the production period and maintenance period of the airplane are greatly shortened. The materials for manufacturing the fireproof composite material are materials in existence, so that the material cost cannot be greatly increased. The fireproof composite material is capable of expanding and foaming to isolate the flame and heat radiation when the airplane is on fire, and meanwhile the fixed shape can be maintained. When the thickness is 0.8mm, the fireproof composite material can be used for preventing fire for 15min and more at 1093 DEG C, and when the thickness is 0.5mm, the fireproof composite material can be used for preventing fire for 5min and more.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com