Vibration welding technology

A vibration welding and technology technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of affecting welding progress, increasing labor intensity, difficult amplitude, etc., to achieve good welding effect, improve welding speed and efficiency, The effect of convenient welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

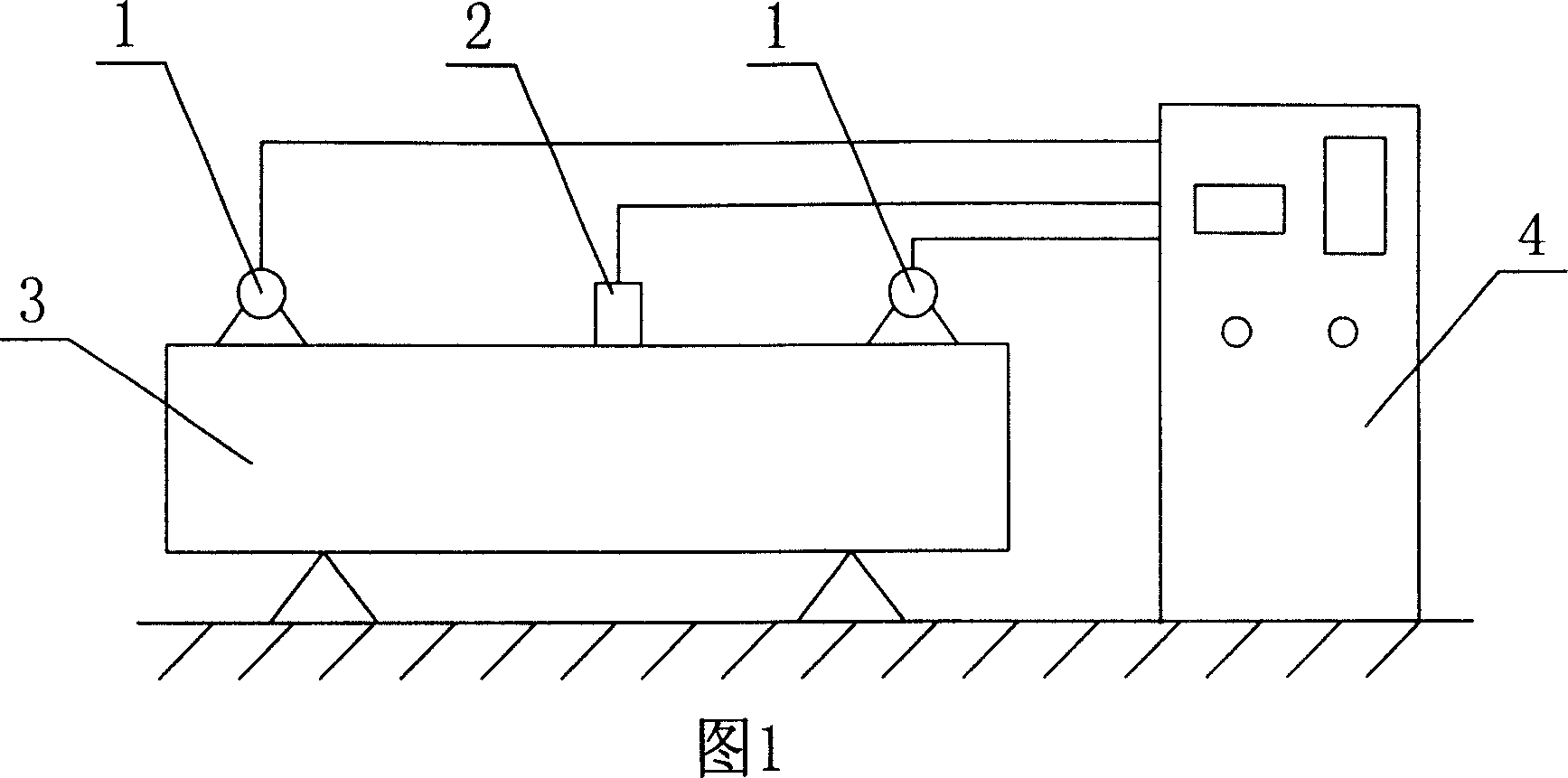

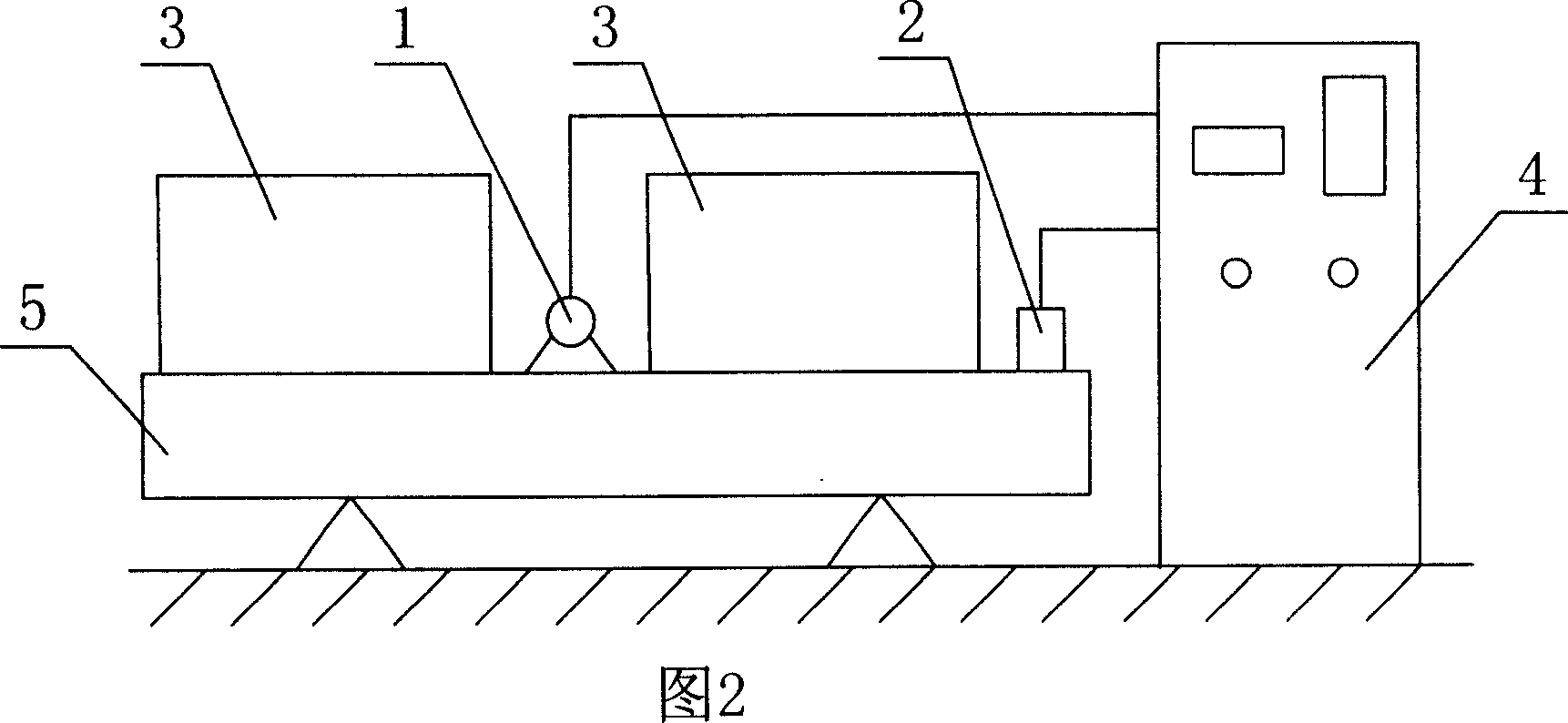

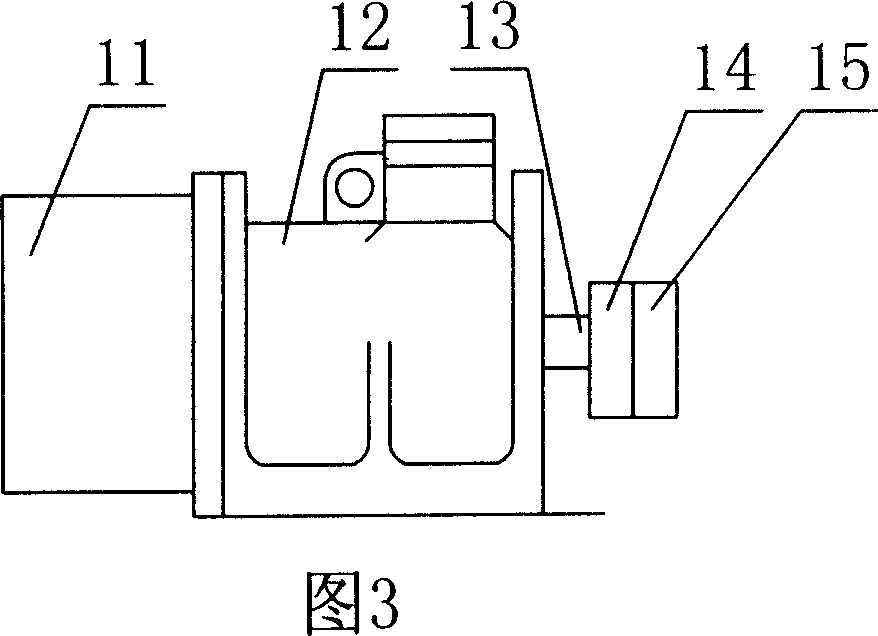

[0040] 1. After the welded components are assembled and welded according to the welding process, they are supported stably with rubber or wood. The support method varies according to different types of components.

[0041] a. For beam-shaped members, the support position is 2 / 9L from both ends of the weldment (L is the length of the weldment), and the exciter is fixed at the center or one side of the center or at the end.

[0042] b. For circular workpieces, support them at four or three points, and the vibrator is fixed between two points.

[0043] c. For plate-shaped workpieces, the support is arranged along the length direction, the fulcrum is 1 / 3L or 2 / 3L away from the end, and the exciter is clamped at the middle position.

[0044] d. For welded components with a ratio of length, width, and height close to 1, select a place with low rigidity in the three directions to support four points, the fulcrum is 1 / 3L or 2 / 3L from the end, and the exciter is fixed on both sides or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com