Redundant mechanical gripper system for automatic production line and working method thereof

A working method and the technology of mechanical claws, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as shutdown of unmanned factories and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

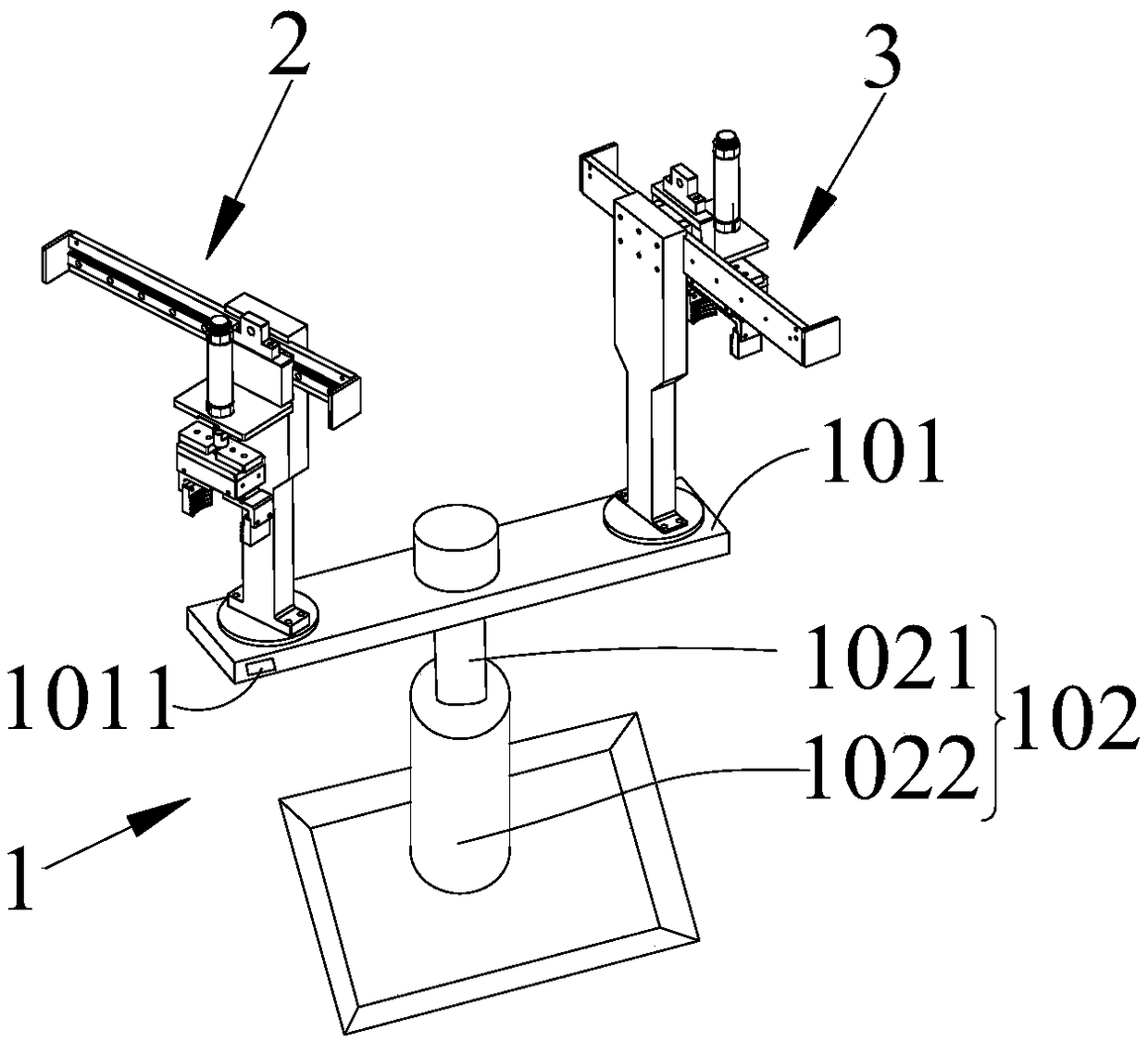

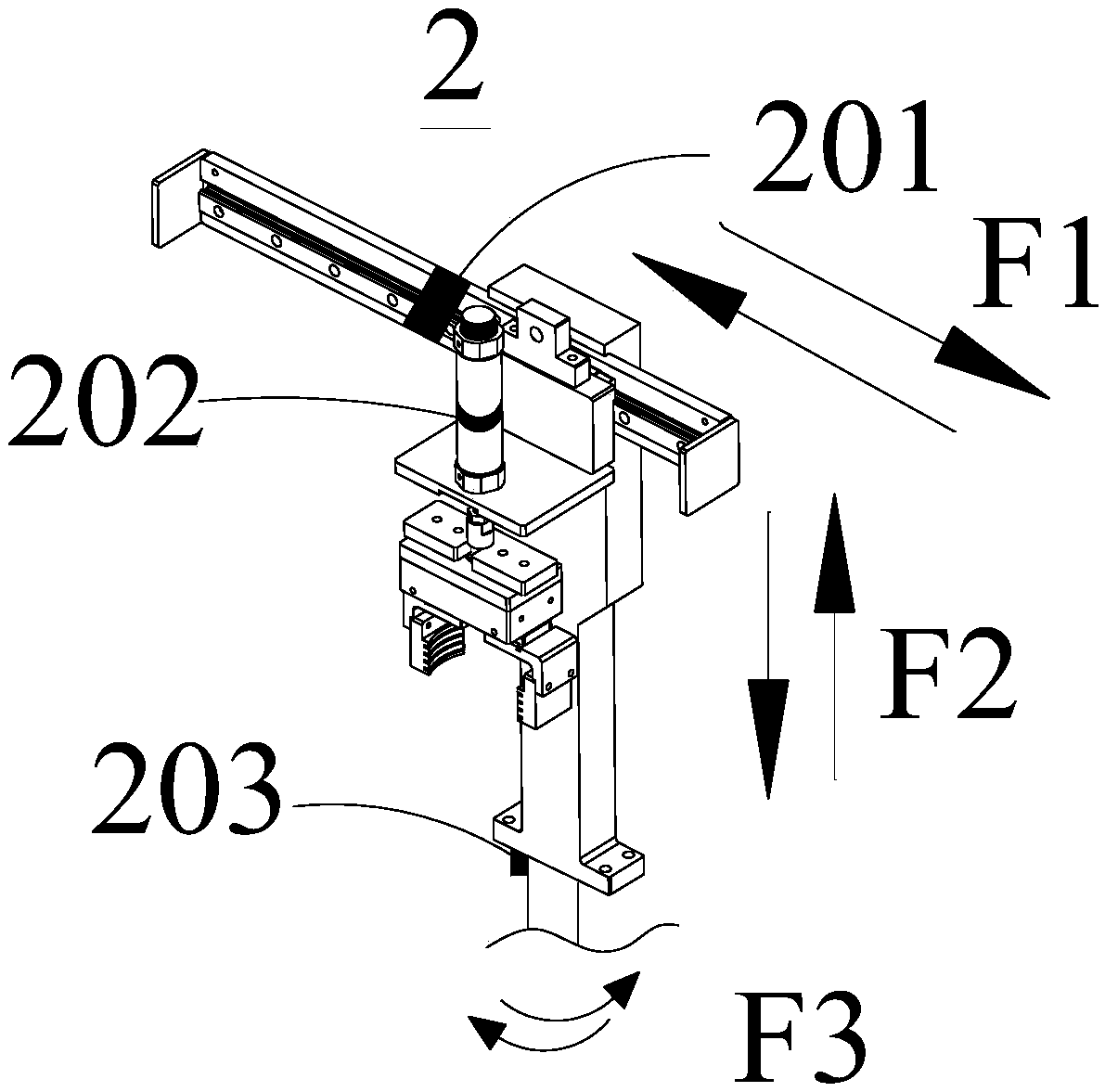

[0023] figure 1 It is a structural diagram of the redundant mechanical claw system of the present invention;

[0024] Such as figure 1 As shown, the present invention provides a redundant mechanical gripper system, a main manipulator 2 and a secondary manipulator 3 rotated by a rotating device 1, and a detection device for detecting the working state of the main manipulator; wherein the rotating device and the detection device are both It is electrically connected with the main control module; after judging that the main manipulator is faulty, the main control module is suitable for controlling the rotation of the rotating device 1, that is, the auxiliary manipulator 2 is rotated to the working position of the main manipulator 3 to work instead of the main manipulator 2; by rotating The device 1 rotates the auxiliary manipulator 3 to the working position of the main manipulator 2 to realize the normal production of the unmanned factory when the main manipulator 2 fails.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com