Novel twenty-roller cold-rolling mill

A 20-high, cold rolling mill technology, applied in metal rolling stands, metal rolling mill stands, driving devices for metal rolling mills, etc., can solve the problem that the crown adjustment device cannot be found and the adjustment accuracy of the roll system cannot be guaranteed. , the upper frame cannot be balanced in motion, etc., to avoid uneven rolling force, large opening and uniform pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

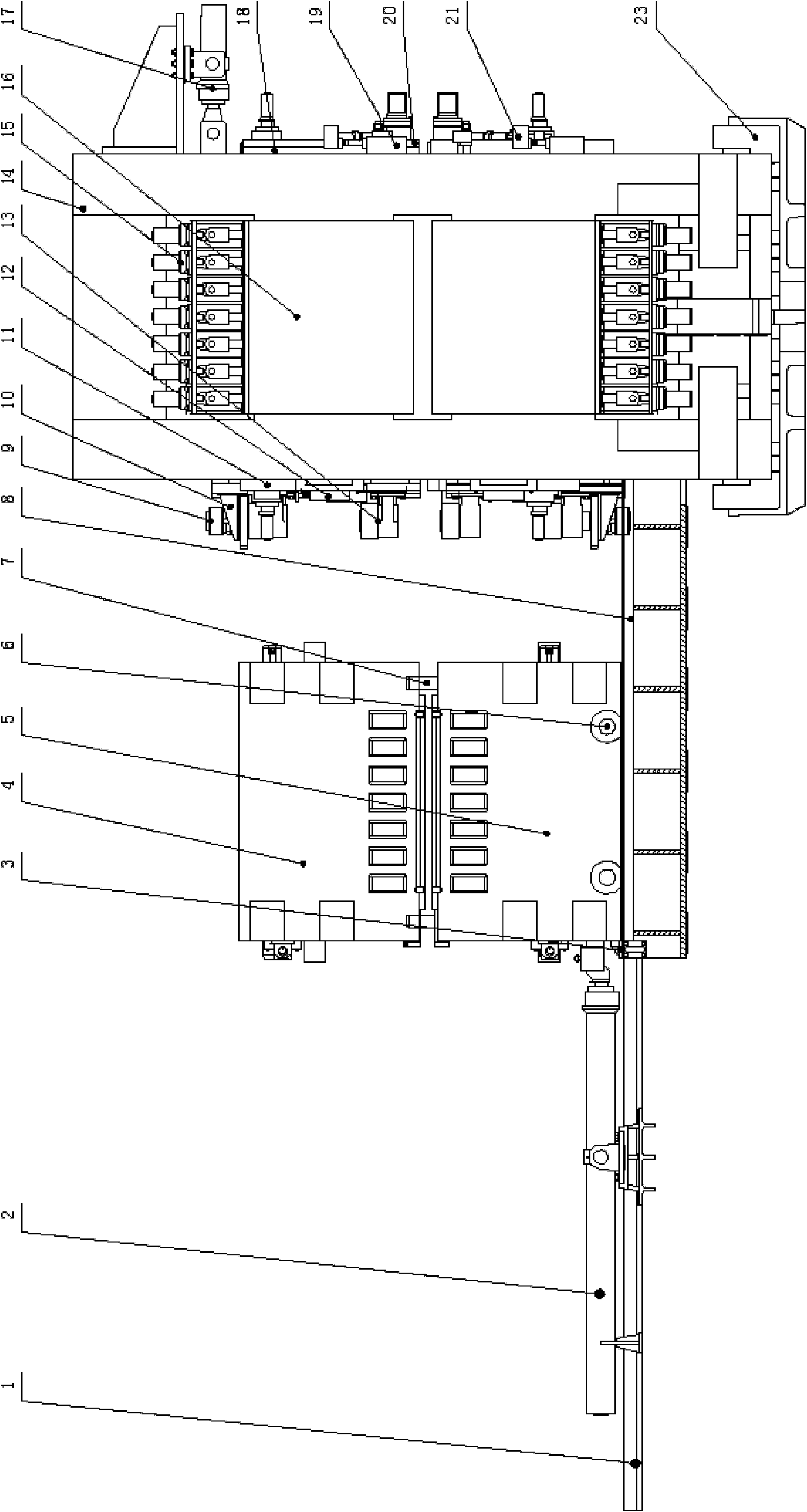

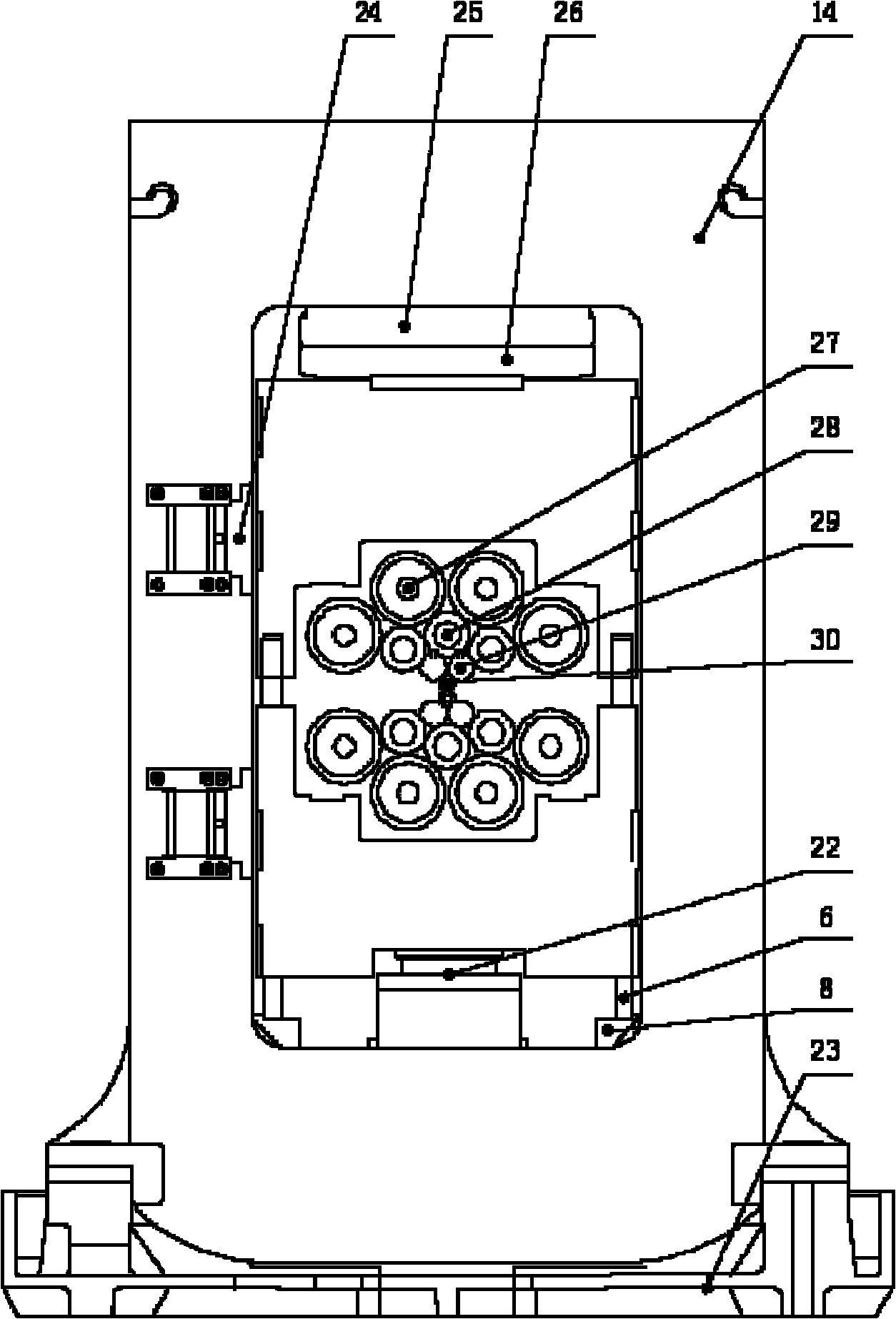

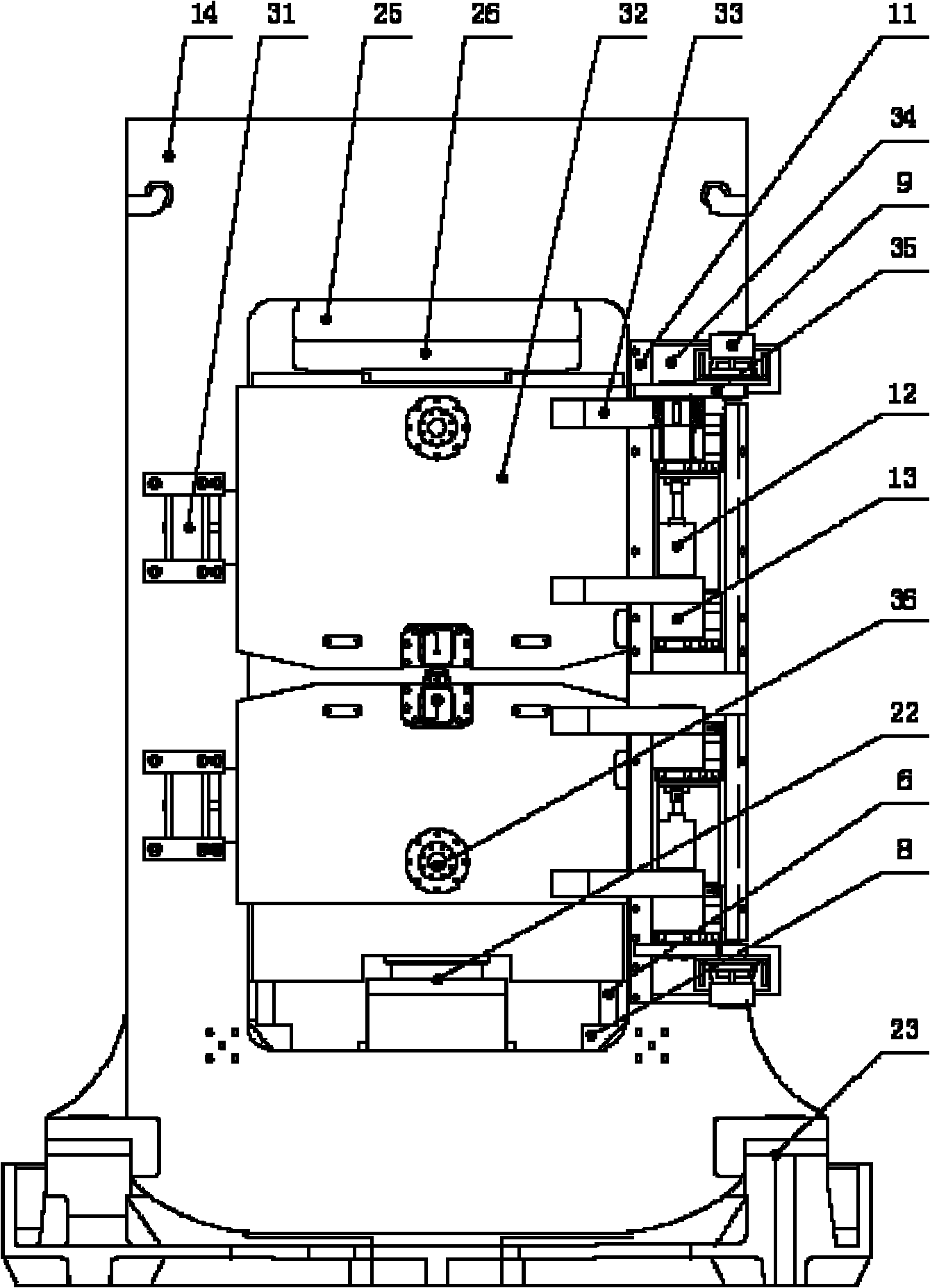

[0042] A new twenty-high cold rolling mill, such as Figure 1-14As shown, including upper roll box 4 and lower roll box 5, two sets of roller systems are installed symmetrically in the upper roll box and the lower roll box. Four support rolls 27, three second intermediate rolls 28, two first intermediate rolls 29 and one work roll 30 constitute the first layer. The innovation of the present invention is that the upper roll box and the lower roll box are stacked and installed on a frame In the frame 14 of type, the lower roller box is installed on the base 23 of the frame, and a jacking hydraulic cylinder 22 for supporting the lower roller box is installed in the base, and the supporting guide columns 7 installed at the four corners of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com