An intumescent aviation fireproof composite material and its manufacturing method

A composite material and intumescent technology, which is applied in the direction of fireproof coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc., can solve the problems of aviation fireproof coating construction difficulties, affecting the normal use of aircraft, and long removal and recoating cycles , to achieve the effect of shortening the aircraft production and maintenance cycle, increasing material costs, and isolating flames and heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

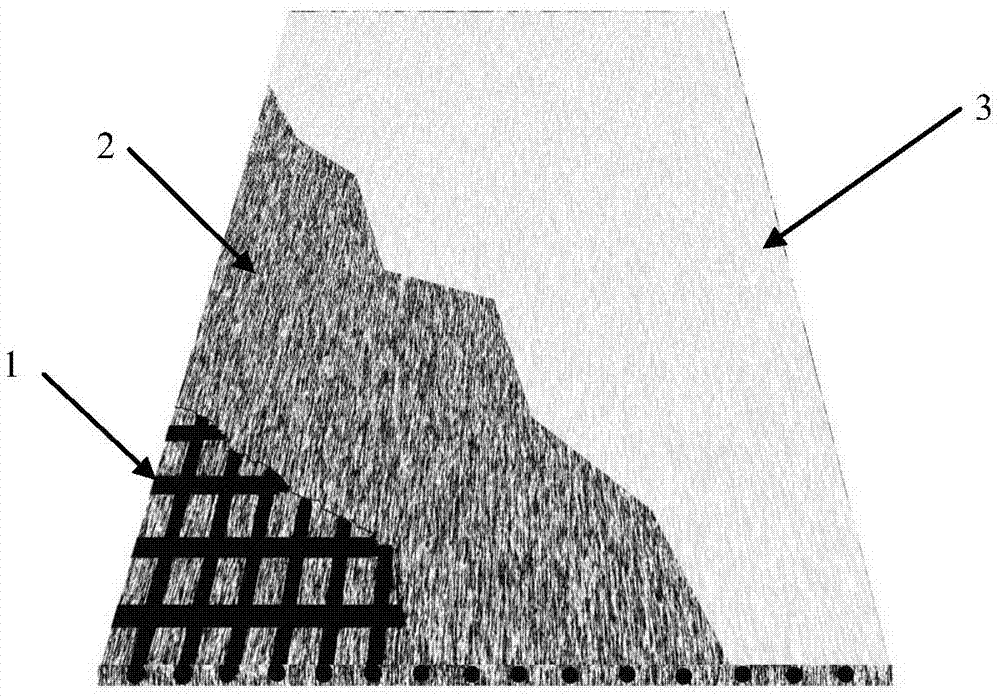

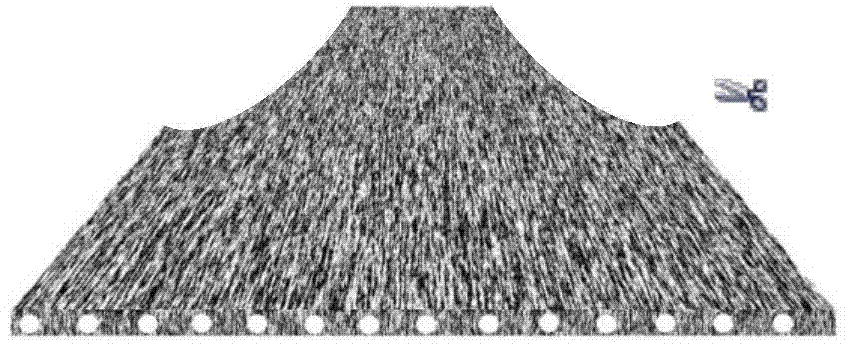

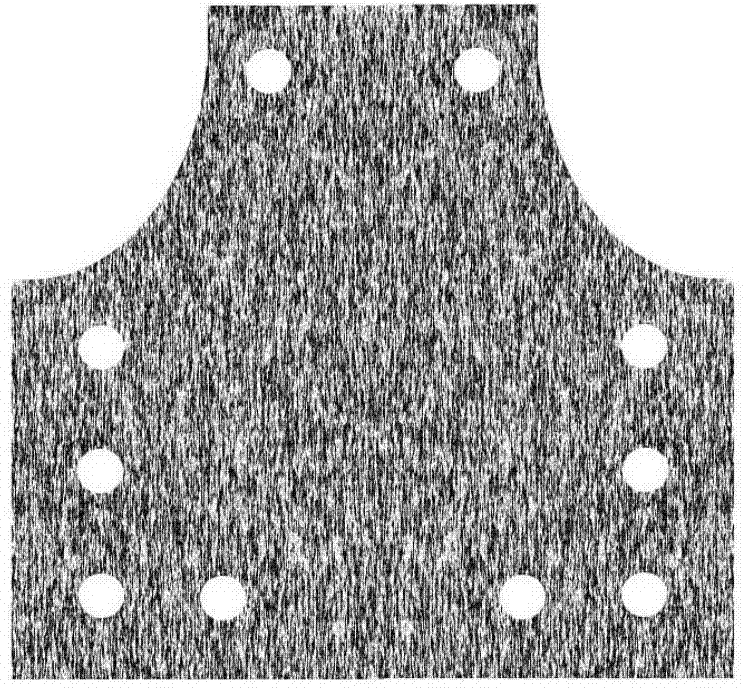

Image

Examples

Embodiment

[0018] Selection of required materials:

[0019] The thin wire mesh is selected from steel or stainless steel thin mesh that meets the requirements of HB1862-1993. In order to ensure the adhesion and fireproof effect, the basic size of the thin mesh mesh should not be larger than the thickness of the fireproof coating. Suggested preferred dimensions are as follows:

[0020]

[0021] Choose fire-resistant coatings and paints:

[0022] As the matrix resin of intumescent aviation fireproof composite material, the fireproof coating has good flexibility, adhesion and antirust ability, and the protective topcoat has good environment resistance and medium resistance ability. The main components of the fire retardant coating are high temperature resistant acrylic silicone resin, P-C-N intumescent flame retardant and asbestos chopped fiber, the ratio is about 3:5:1, and the main component of the protective topcoat is flame retardant modified acrylic polyurethane. At present, fire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com