A countersink tool with quick adjustment and positioning

A technology for adjusting positioning and countersinking, applied in the field of machining tools, can solve problems such as increasing tool cost, tool damage, affecting production progress, etc., and achieves the effect of reducing chip removal resistance, tool cost, and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

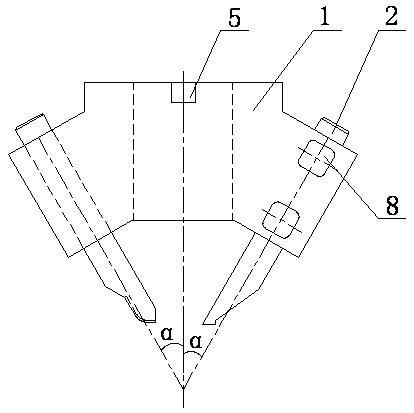

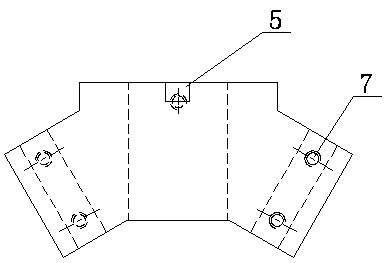

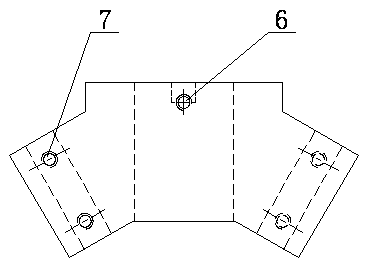

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as Figures 1 to 4 As shown, a countersink tool that can be quickly adjusted and positioned includes a tool block 1 on which a tool 2 for processing is detachably installed, and the tool block 1 is detachably mounted on On the main drilling shaft (not shown in the figure), and rotate together with the main drilling shaft. The knife-mounting block 1 is designed as a pants type, and a knife-mounting block mounting hole 3 is arranged at the center of the knife-mounting block 1, and the knife-mounting block 1 is installed on the main drilling shaft through the knife-mounting block mounting hole 3, Two cutter mounting holes 4 are arranged symmetrically at both ends of the cutter block 1, where the cutter mounting holes 4 are square, and the cutter 2 is installed in the cutter mounting block 1 through the cutter mounting holes 4, and the two symmetrical cutters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com