Small measuring range force transducer and method thereof for indirect measuring axle load

A load cell and small-range technology, which is applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of inconvenient sensor replacement, no installation space, large sensor size, etc., to achieve small size and short replacement period , range and volume reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

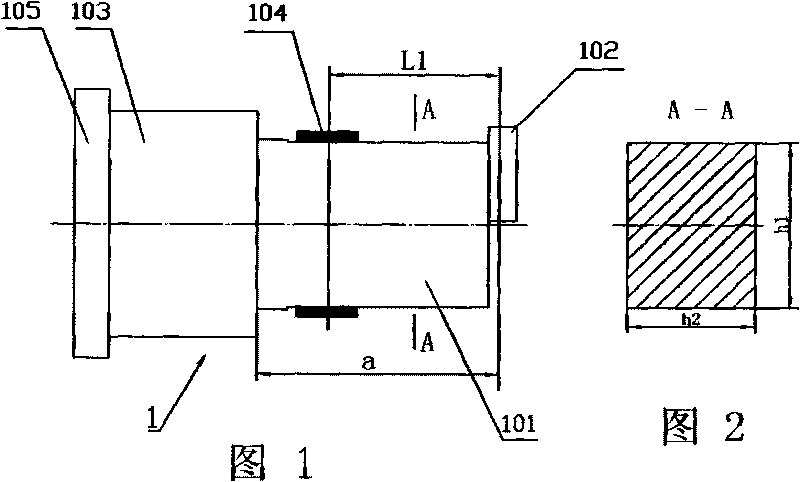

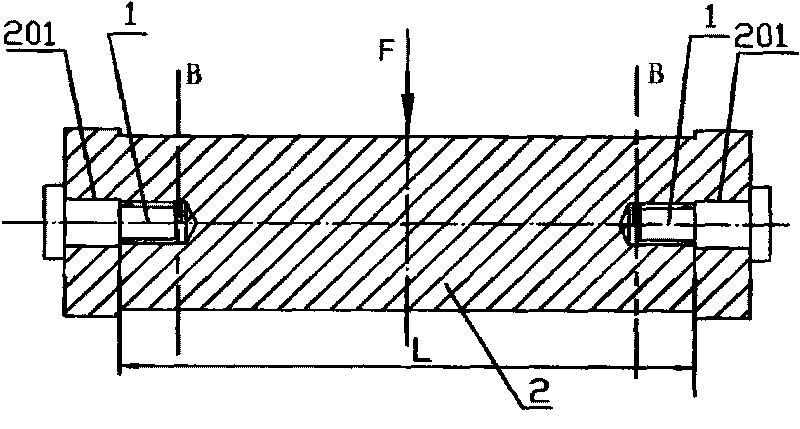

[0041] see figure 1 , 2 3. The small-range load cell 1 has a strain beam 101 that feels the bending normal stress, a small semi-cylindrical bearing head 102 with an enlarged diameter extends from the front end of the strain beam, and a diameter-expanded small bearing head 102 extends from the rear end of the strain beam. A cylindrical fixed seat 103, and a stopper 105 with an enlarged diameter extends from the tail end of the cylindrical fixed seat 103. The small-range load cell strain beam 101 can adopt a conventional rectangular cantilever beam structure, That is, the loading surface of the strain beam 101 is rectangular, and the strain gauge 104 is attached to the strain beam 101 . In order to facilitate installation and replacement, the diameter of the small semi-cylindrical carrying head 102 is preferably smaller than the diameter of the fixing seat 103 .

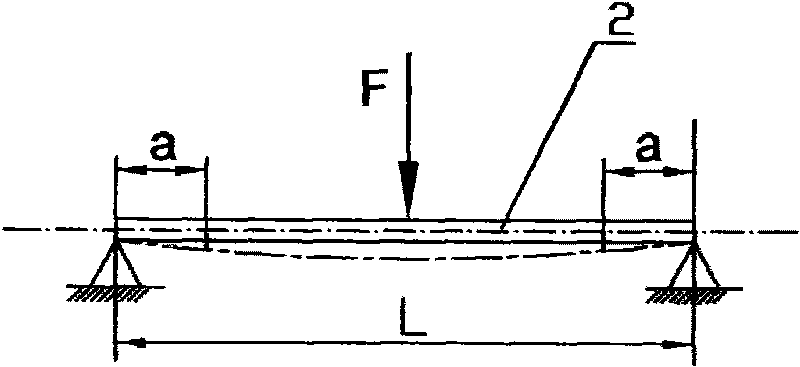

[0042] The steps of the indirect measurement shaft load measurement method using the above-mentioned small-range l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com