Asphalt road based on thermal power plant existing road and construction method thereof

A construction method and technology for thermal power plants, which are applied to roads, roads, and on-site coagulation pavements, etc., can solve problems such as increased construction period and cost, cracked cement pavement, and non-conforming road elevations, and reduce the amount of renovation works. and cost, prolong the service life and reduce the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

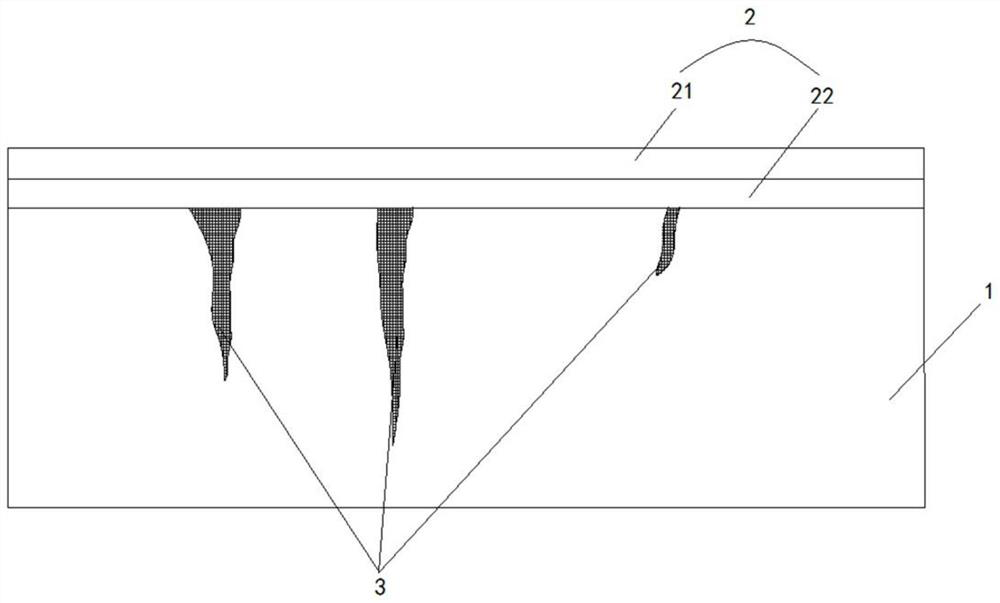

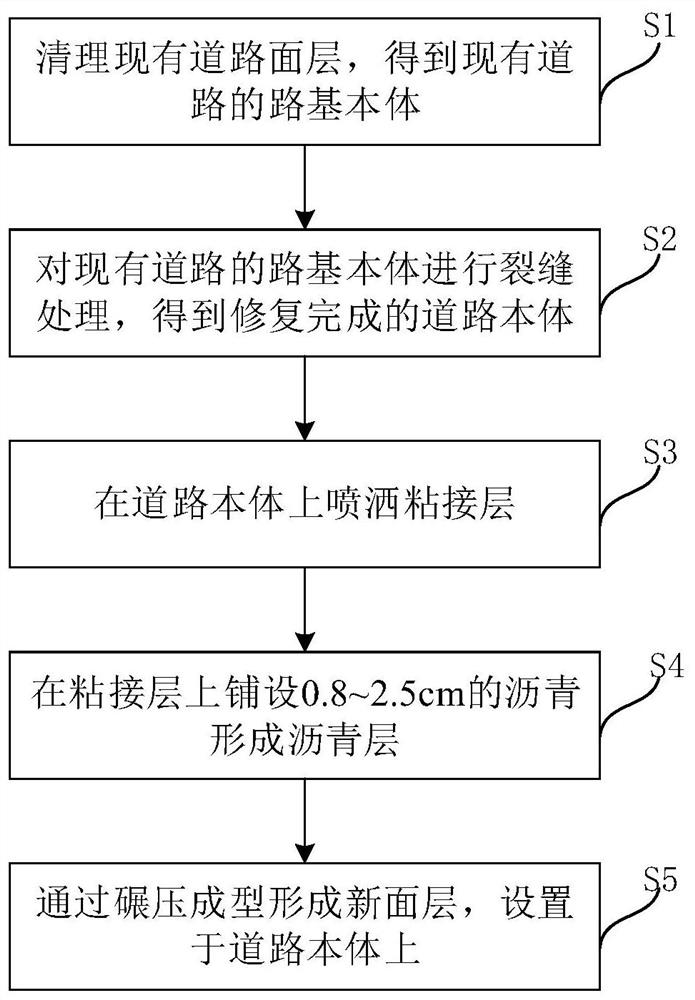

[0029] like figure 1 As shown, the present invention provides a kind of asphalt road based on the existing roads of thermal power plants, which can be used for the existing fixed roads and temporary roads of power plants, including adhesive 3 and road body 1 and road surface layer arranged in sequence from bottom to top 2. The road body 1 is the road base body of the existing road of the thermal power plant. The road surface layer 2 includes an adhesive layer 21 and an asphalt layer 22 arranged on the road body 1 in sequence from bottom to top. The thickness of the asphalt layer 22 ranges from 0.8 to 2.5 cm, in this embodiment, is preferably set to 2 cm. The asphalt layer 22 is made of high-performance asphalt, which has good high-temperature stability, low-temperature crack resistance, fatigue crack resistance, anti-reflection crack and anti-loosening ability. It is combined with the existing road of the power plant and the temporary construction road, and some ratios are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com