Universal negative type combined model used in production of diesel engine flywheel with iron mold coated sand

A technology of sand-coated iron molds and combined molds, applied in the field of casting molds, can solve the problems of high cost of tens of thousands to hundreds of thousands and high cost of flywheels, improve management, solve special and general problems, and reduce the cost of saving tooling and molds. troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

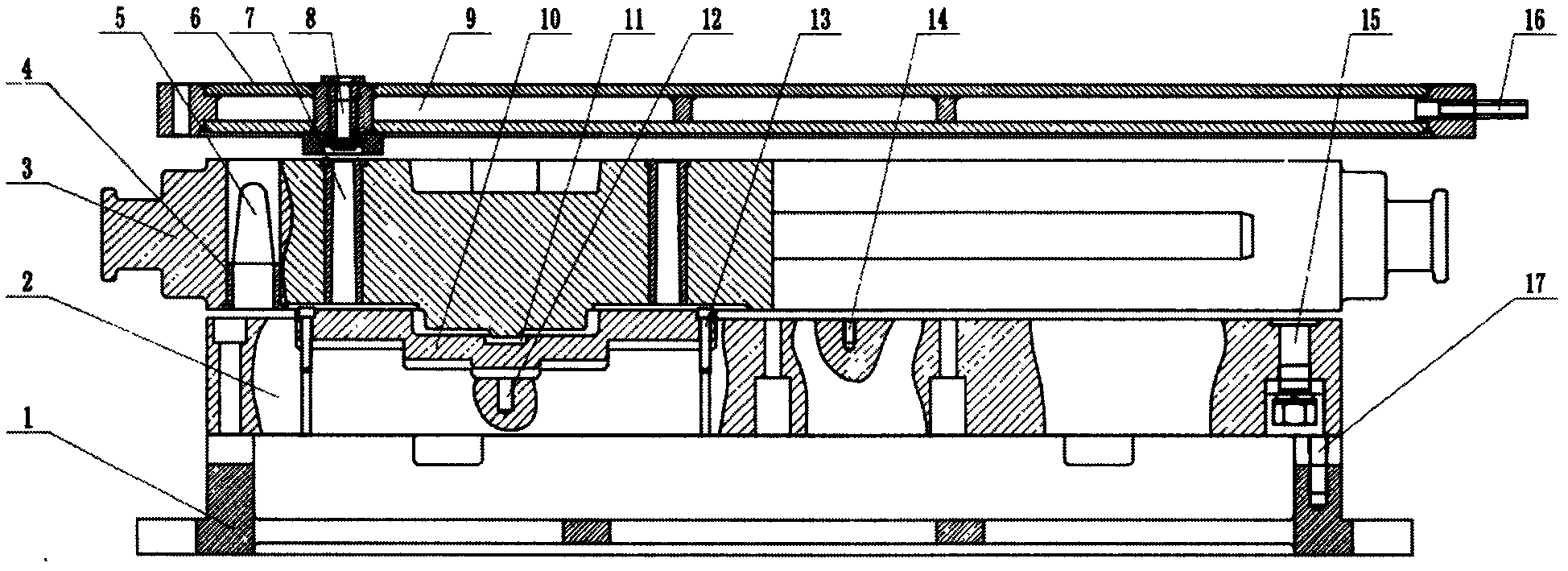

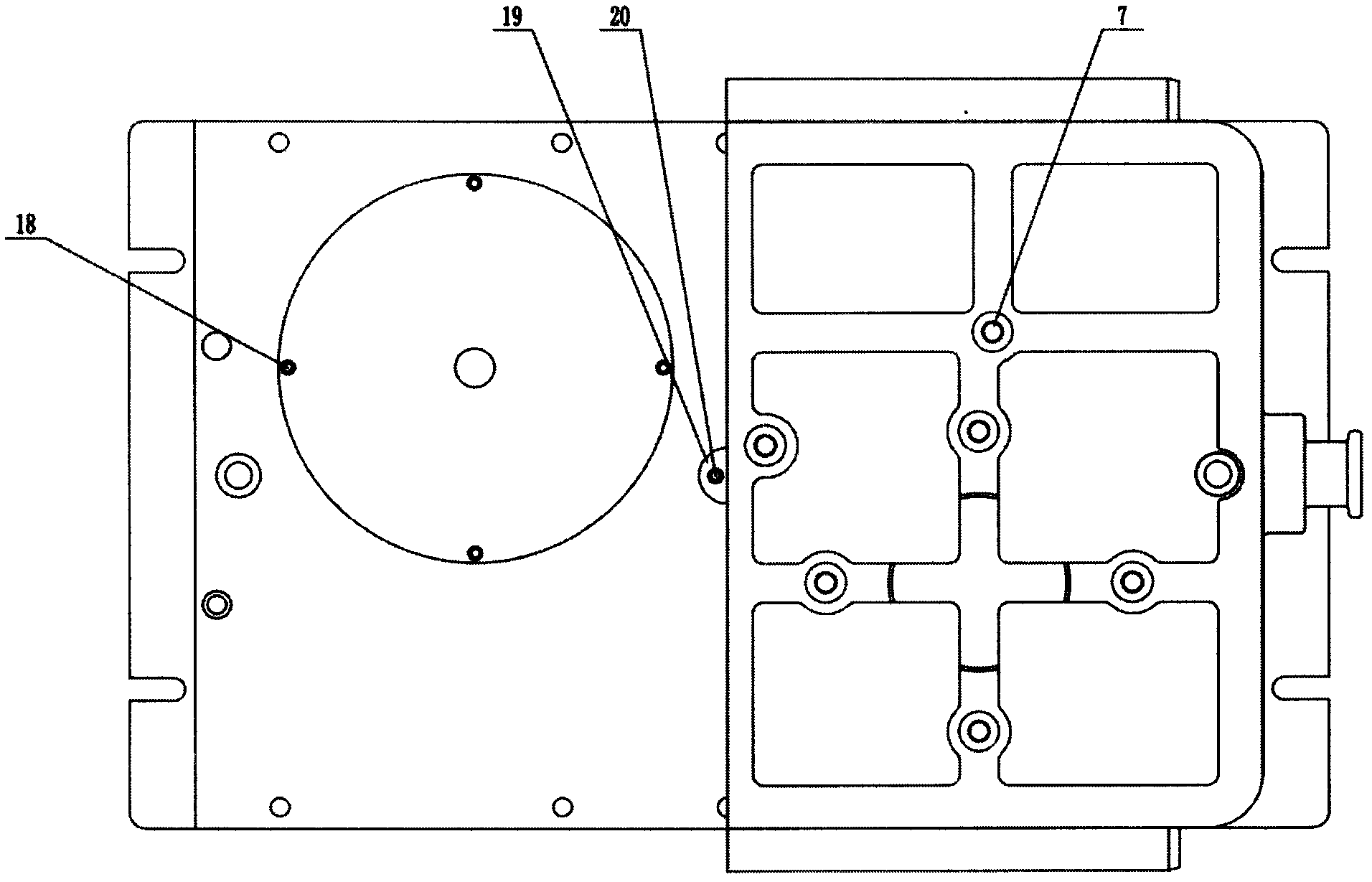

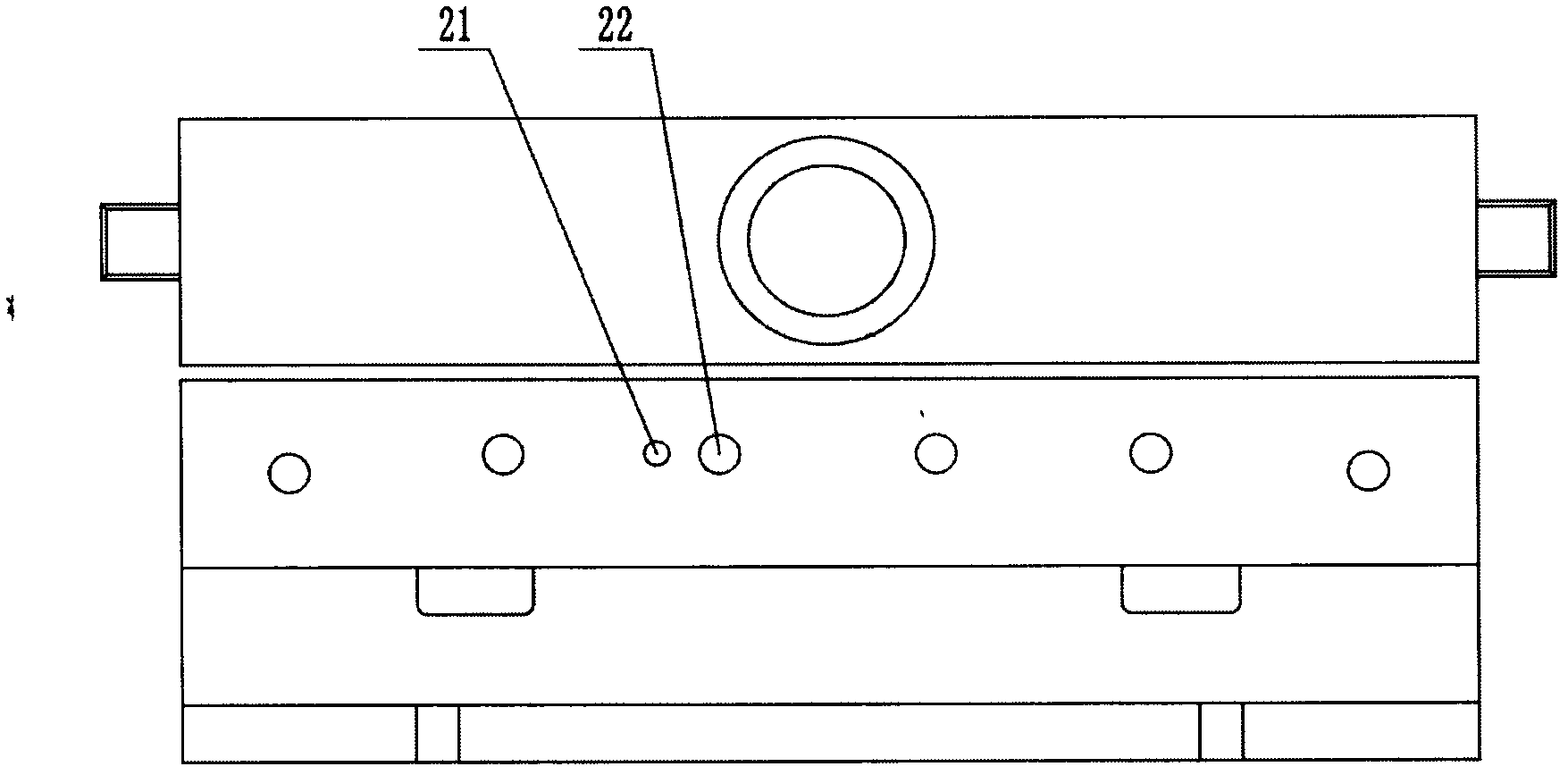

[0017] The preferred embodiment of the present invention is like this, with reference to Figure 1 to Figure 10 As shown, the common lower template features of all different types of products (mainly including similarity in outer contour size and similarity in appearance) are summarized, and then the products with common features are collected and classified, and then the products with common features The lower templates are all attached to a virtual shape, and then the minimum processing contour is taken (the upper template is the largest, and the lower template is the negative shape, the smallest), so as to design a public virtual shape of the lower shape. Taking this as the design goal, a negative general-purpose module with a standard interface is designed. In the mode of clearance fit, the bottom plate of the lower mold is connected to the bottom plate of the lower mold through top-mounted hexagon socket screws. Specifically: it includes the flywheel standard formwork bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com