Inoculant for ferritic nodular cast iron and preparation method of inoculant

A nodular cast iron and inoculant technology, which is applied in the field of ferritic nodular cast iron inoculants and its preparation, can solve the problems of scrapped castings and unstable inoculation effects, and achieve low usage and good inoculation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

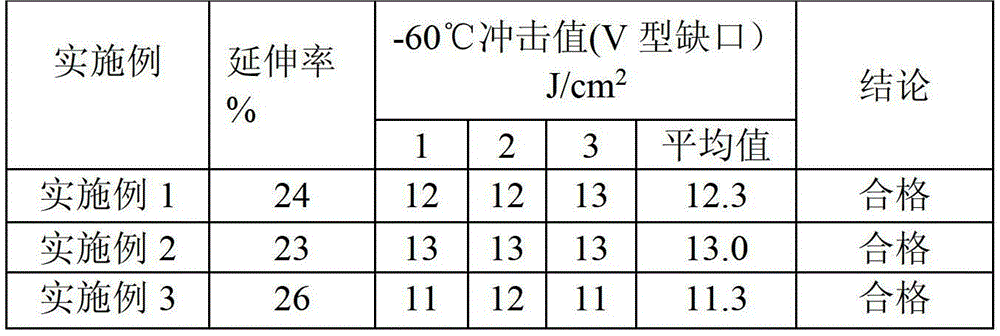

Examples

preparation example Construction

[0021] A method for preparing an inoculant for ferritic nodular cast iron. According to the chemical composition and mass percentage of the above-mentioned inoculant for ferritic nodular cast iron, corresponding raw materials are prepared for deployment, and then the prepared raw materials are put into a crucible to melt and refine , and finally pouring, cooling, and crushing and granulation.

[0022] A method for using an inoculant for ferritic nodular cast iron, using two inoculation treatments: one inoculation at the bottom of the bag to cover the surface of the nodulizer with the inoculant, the addition of the above-mentioned inoculant for ferritic nodular cast iron is 0.10- 0.15wt%; the top is covered with a steel plate; the secondary inoculation adopts flow inoculation, and the above-mentioned inoculant for ferritic ductile iron is added in an amount of 0.80-0.85wt%.

Embodiment 1

[0023] Example 1 Formula: The mass percent of the inoculant for ferritic ductile iron is: Si: 65%, Bi: 5.0%, Ca: 4.0%, Ba: 2.9%, Al<0.5%, Ti<0.05%, Mn <0.4%, S<0.02%, P<0.05%, the balance is iron.

Embodiment 2

[0024] Example 2 Formula: The mass percentage of the inoculant for ferritic ductile iron is: Si: 70%, Bi: 4.0%, Ca: 2.0%, Ba: 1.0%, Al<0.5%, Ti<0.05%, Mn< 0.4%, S<0.02%, P<0.05%, the balance is iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com