Patents

Literature

52results about How to "Good wrinkle effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferrite-based stainless steel plate, steel pipe, and production method therefor

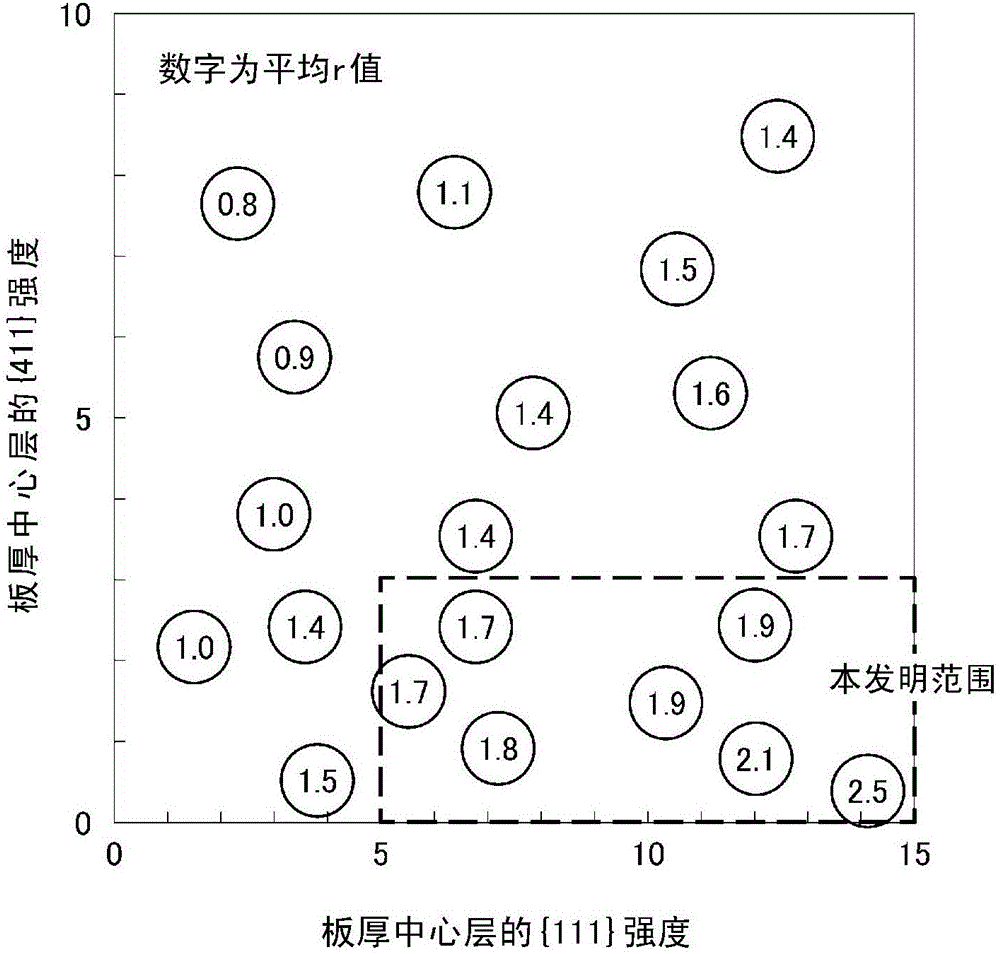

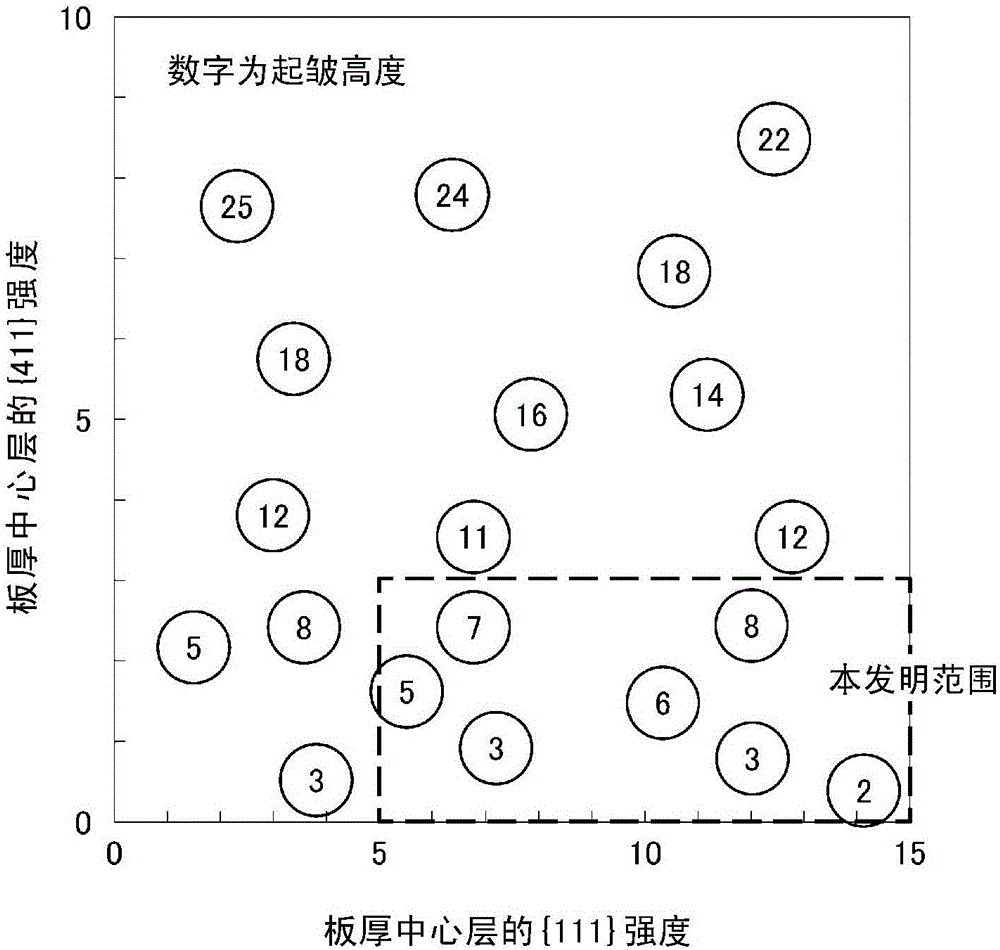

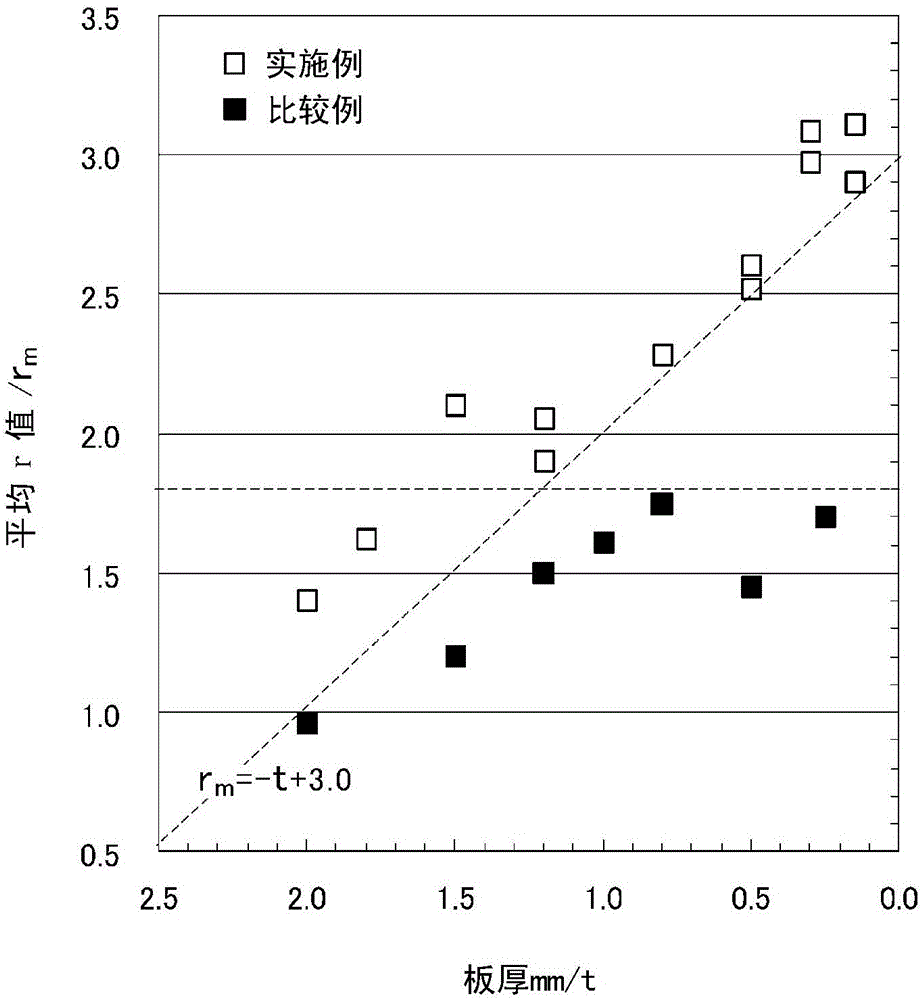

ActiveCN106795608AGood formabilityGood wrinkle effectFurnace typesHeat treatment furnacesSS - Stainless steelPipe

Owner:NIPPON STEEL STAINLESS STEEL CORP

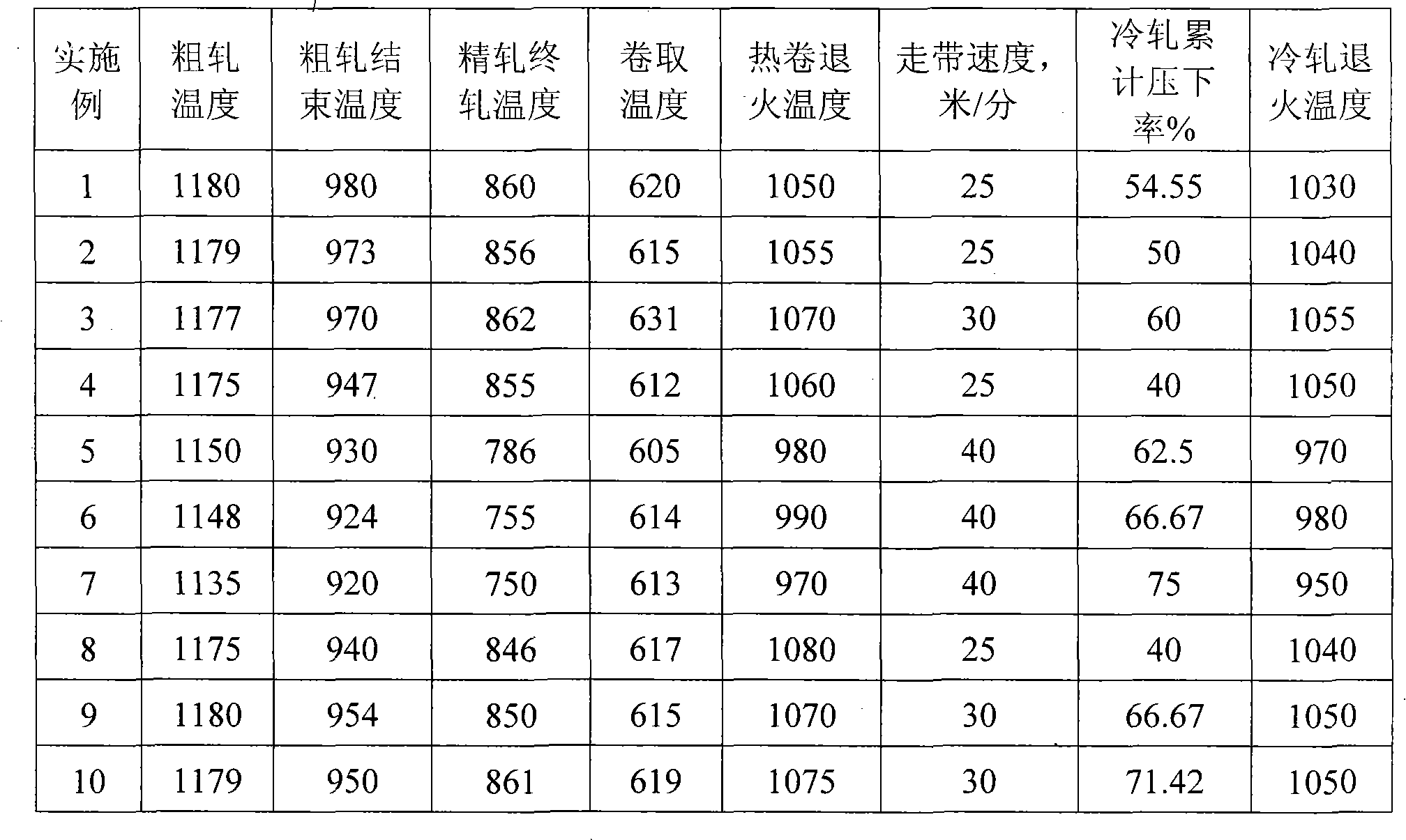

Ferritic stainless steel with good wrinkle resistance and production method thereof

InactiveCN101845595AGood wrinkle effectProduction process is feasibleWrinkle skinTransition temperature

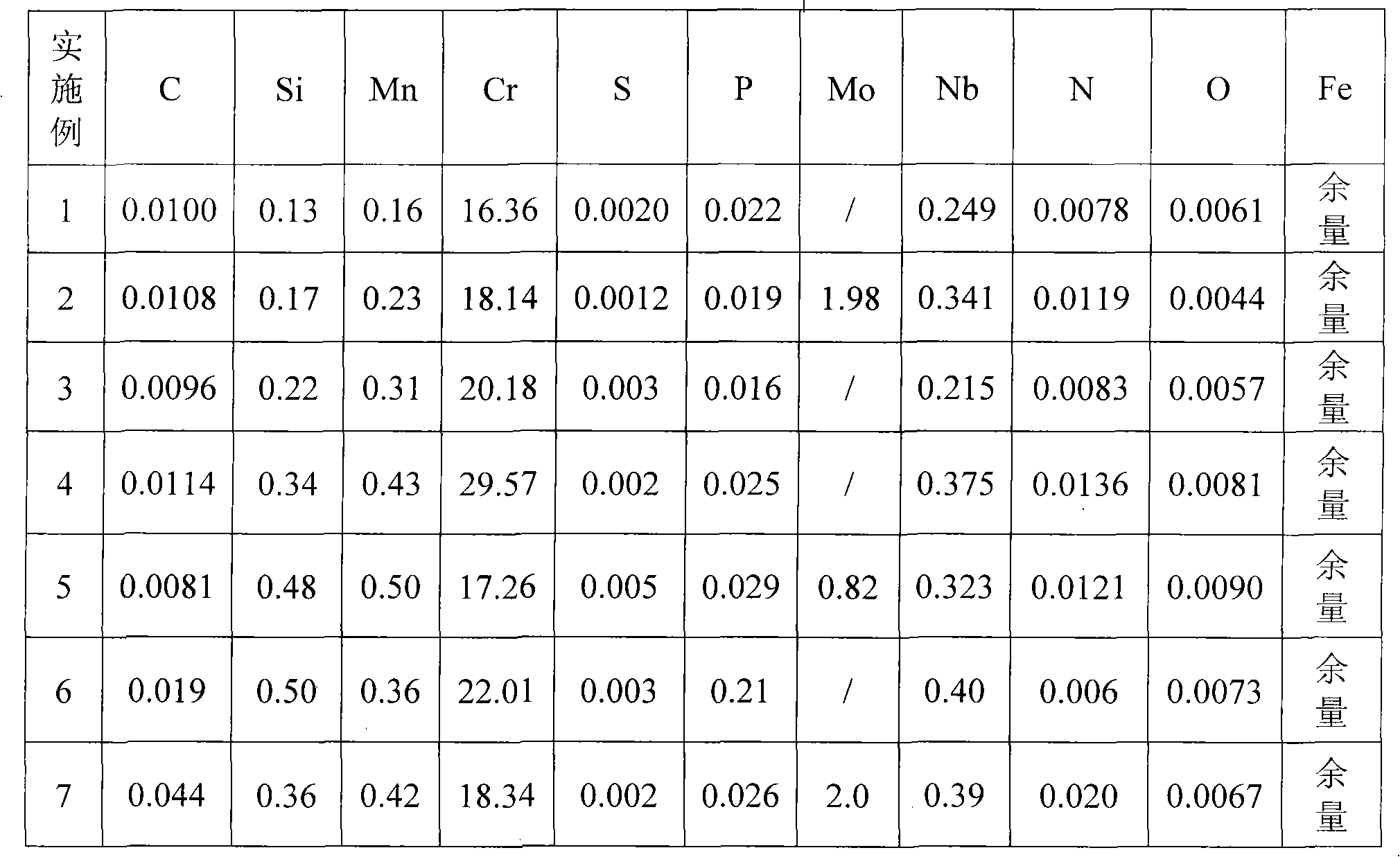

The invention relates to ferritic stainless steel with good wrinkle resistance and a production method thereof. The ferritic stainless steel comprises the following components by weight percentage: less than or equal to 0.02 percent of C, less than or equal to 0.02 percent of N, 0.10-0.50 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 16-30 percent of Cr, less than or equal to 1.00 percent of Ni, 0.15-0.40 percent of Nb, less than or equal to 16 percent of Nb / (C+N), less than or equal to 0.010 percent of O, less than or equal to 1.00 percent of Cu and the rest being Fe and inevitable impurity elements. Since the stabilization element Ti which can damage the surface quality of continuous casting and increase the brittle transition temperature is not added, and only the stabilization element Nb is added, the invention can reduce the quantity of casting blank repair and the strip breakage risk, improve the surface quality and overall performance, eliminate the wrinkle of the surface of the ferriticstainless steel cold-rolled plate with a medium and high Cr content, reduce the wear and repair loss during the production process, and decrease the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Superfine fiber artificial leather

InactiveCN103132344AGood comfortGood creaseSynthetic resin layered productsTextiles and paperChemistrySurface layer

The invention discloses superfine fiber artificial leather which comprises at least three layers, wherein the inner layer is superfine fiber basic material which is a surface formed after polyurethane resin is dipped and provided with microporous, the middle layer is a polyurethane film which contains polyurethane components and fits in with the inner layer, and the surface layer contains an abrasive-resistant polyurethane film. The superfine fiber artificial leather is ageing-resistant. After the superfine fiber artificial leather is used for eight weeks, the wear resistance is above level-4, and the peel intensity is 1.5 kg / cm. After the superfine fiber artificial leather is bent for 100,000 times, the bending resistance is above level-4. Meanwhile, the superfine fiber artificial leather has the advantages of being comfortable, good in crease resistance and wear resistance, and applicable to luggage, clothing, shoes, automotive interior materials or furniture. The superfine fiber artificial leather is high-grade artificial leather which is especially applicable to school bags.

Owner:东丽国际贸易(中国)有限公司

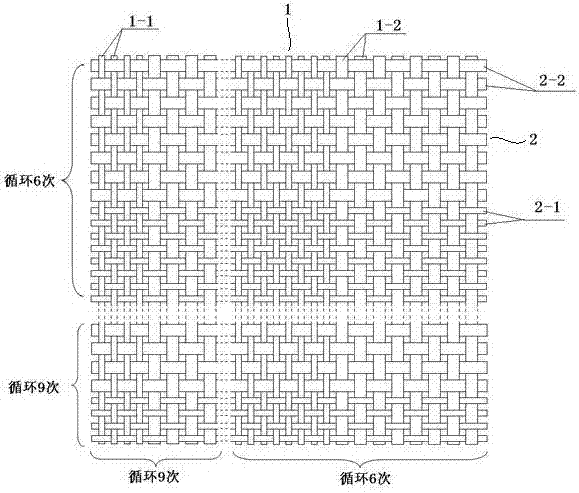

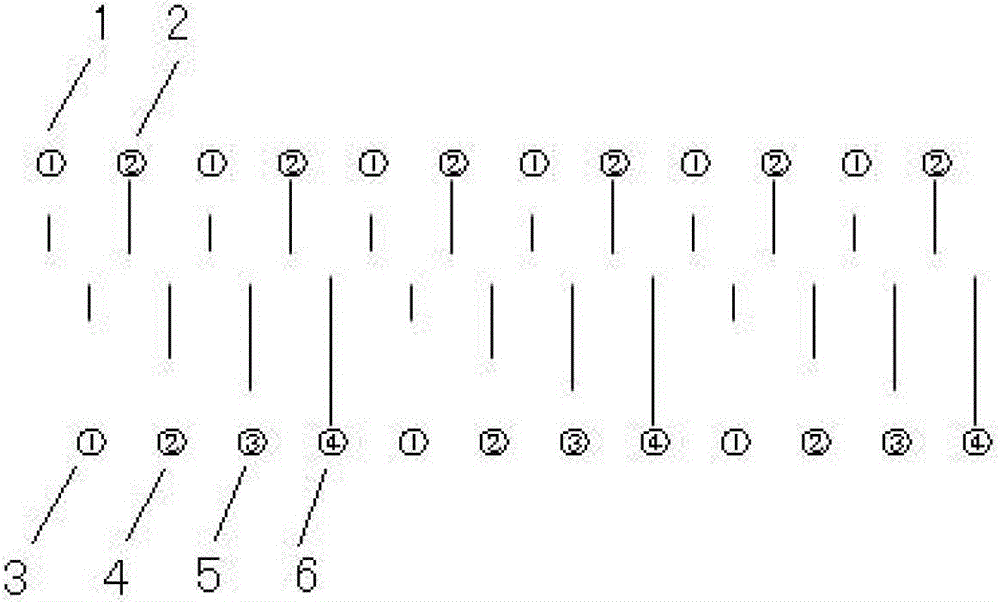

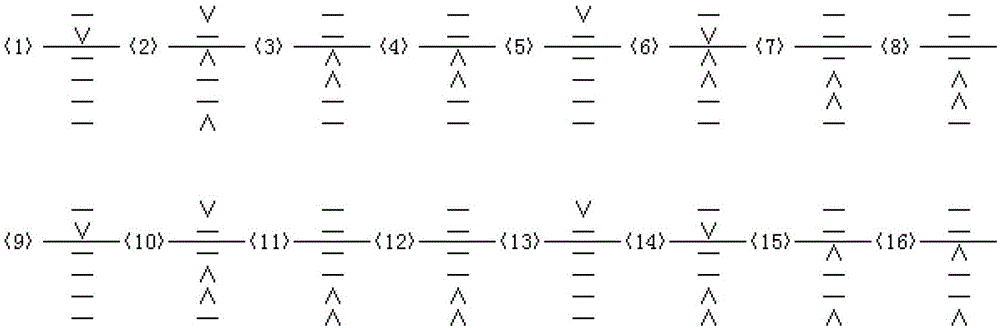

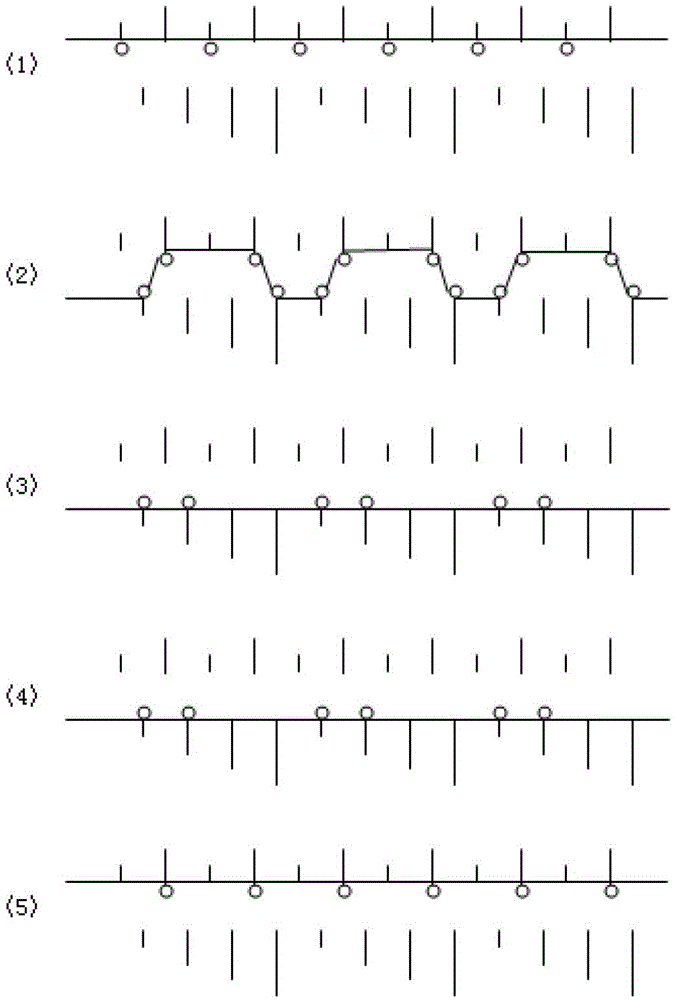

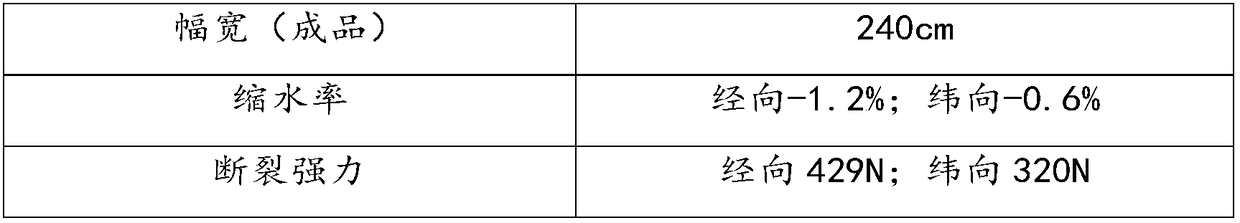

Plisse crepe lattice fabric production technology

ActiveCN107488927ASolve the impossible to weave puzzleReduce weaving costHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringDyeing

The invention discloses a plisse crepe lattice fabric production technology which is characterized by comprising the following steps: evenly winding first warps and second warps on a warp beam through a warping technology, wherein warps include the first warps and the second warps, and the first warps and the second warps have different warp tensions; utilizing a single warp beam weaving technology to weave gray fabric of the plisse crepe lattice fabric; finishing through a later dyeing and finishing technology to enable the shell fabric to not only form grid shape distribution Plisse crepe lattice fabric with a unique style, but also have good all-side stretch touch of shell fabric. According to the seersucker grid shell fabric production technology disclosed by the invention, the technologies of warping, re-beaming, weaving, desizing, scouring, bleaching and the like are innovated, so that the problem that single warp beam weaving cannot weave plisse crepe is solved.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

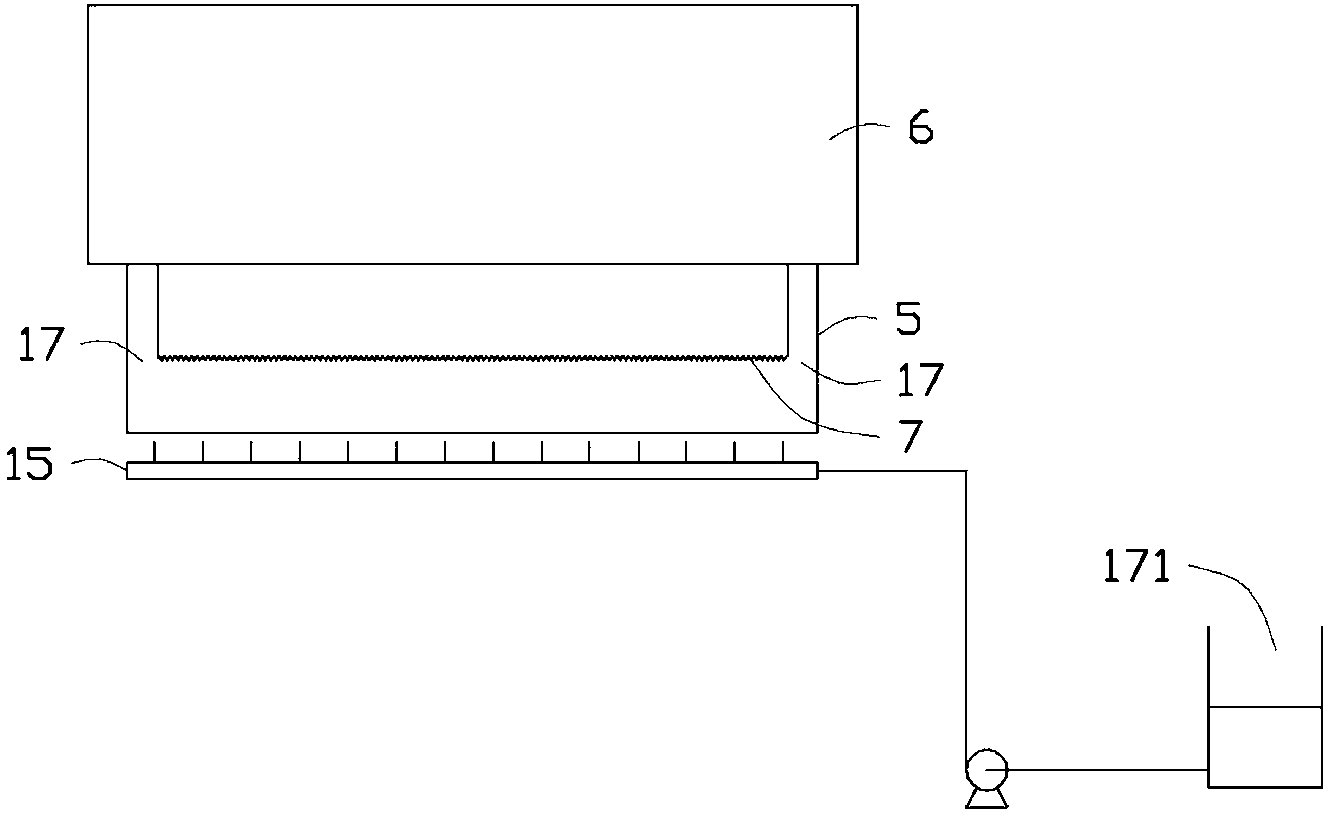

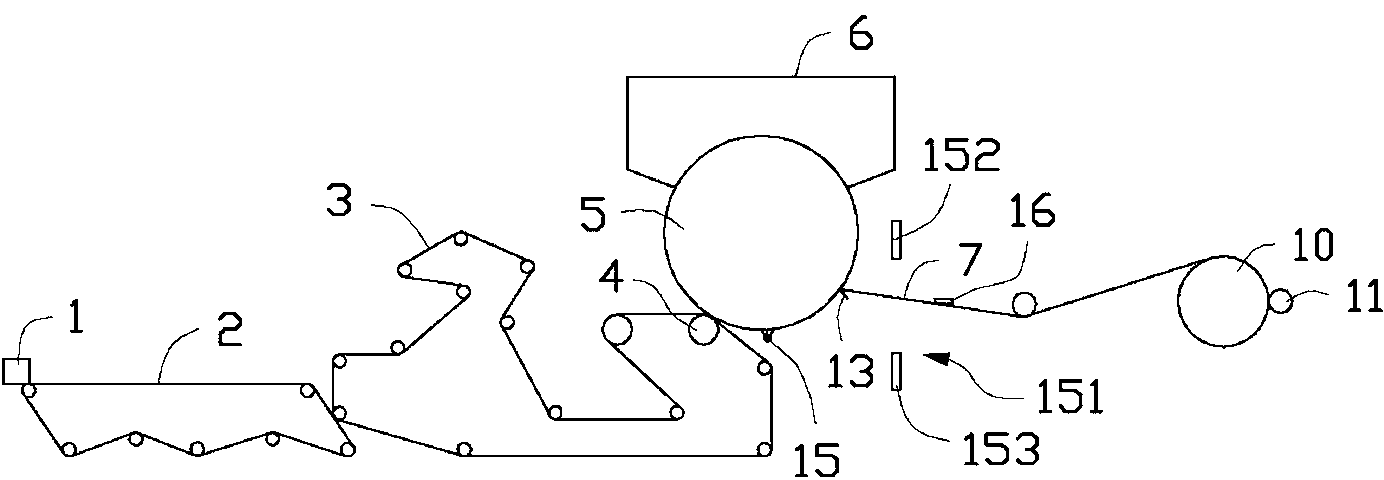

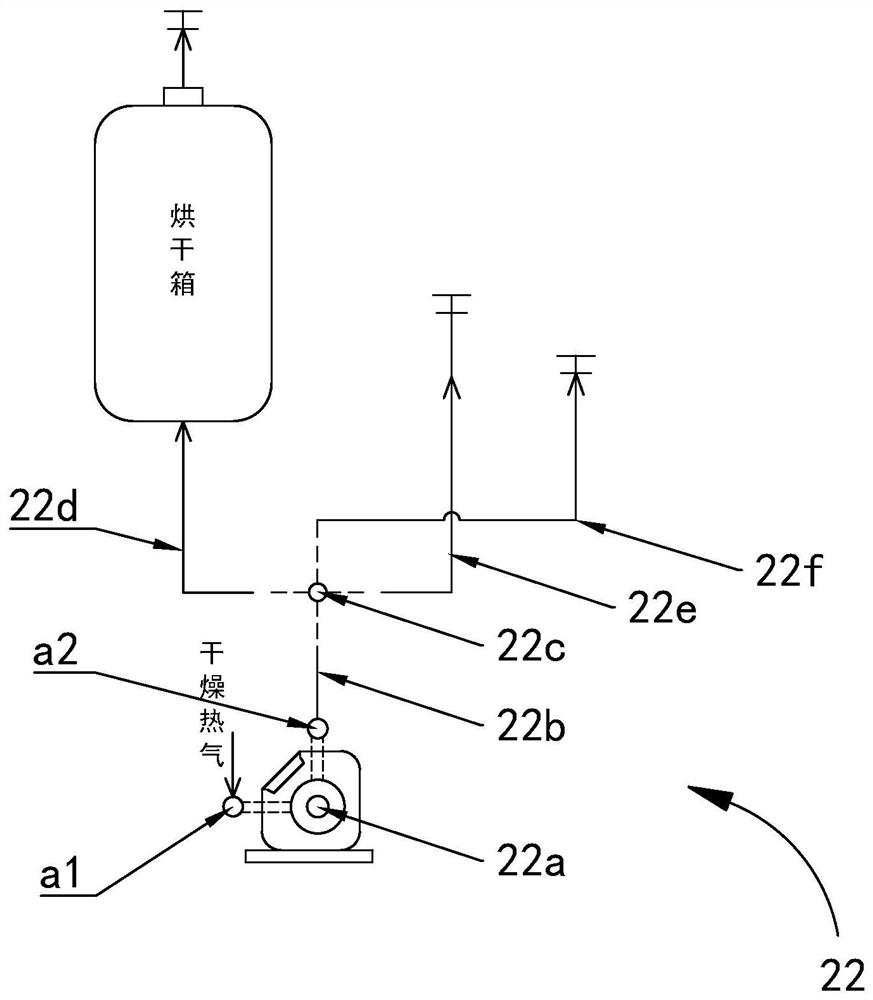

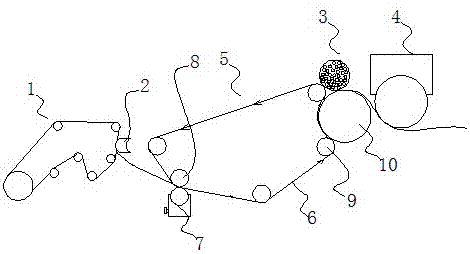

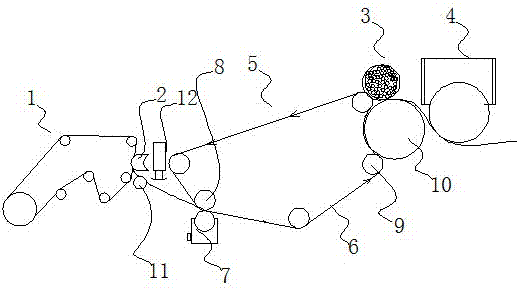

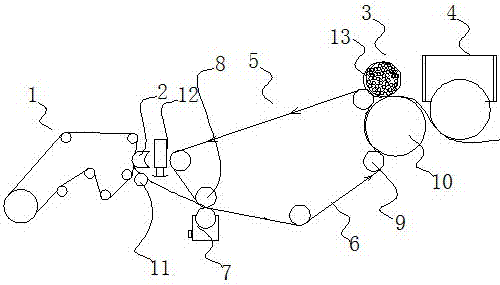

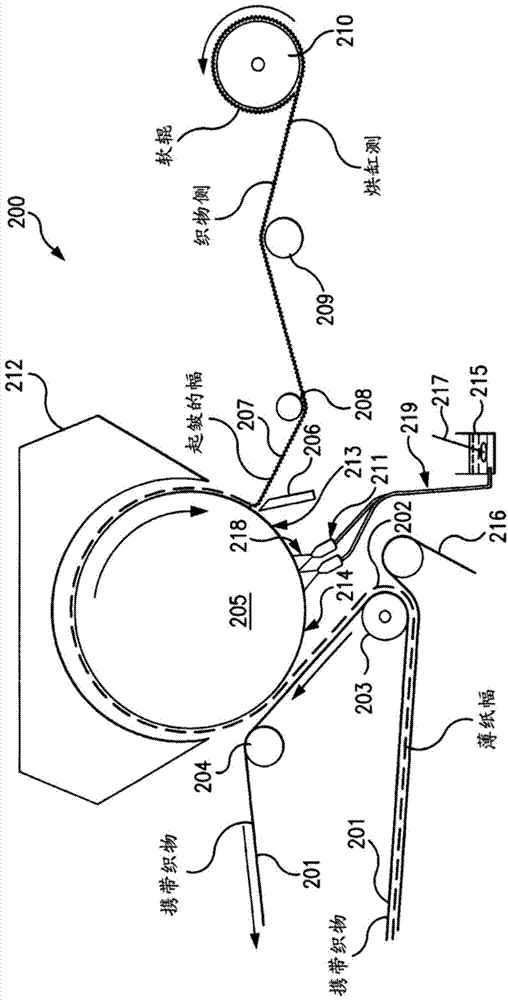

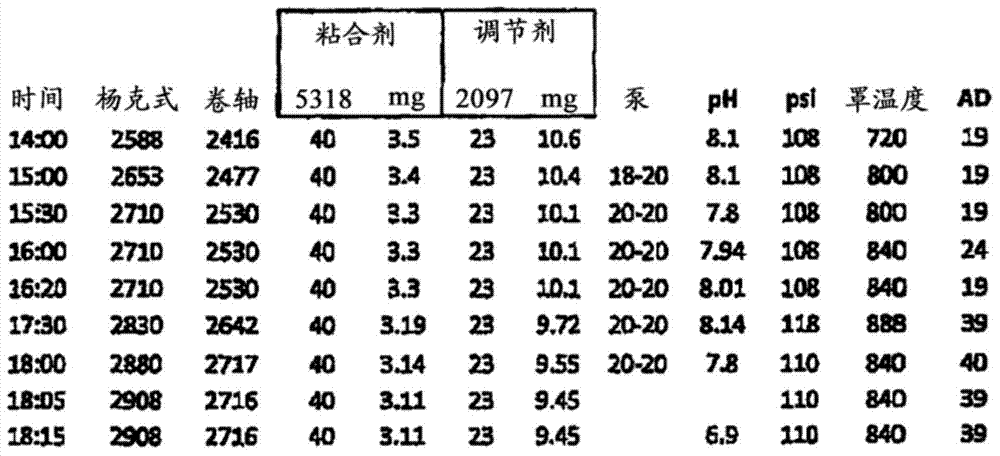

Dryer cylinder coating establishing device and controlling method thereof

ActiveCN103266527AGood wrinkle effectAdjust ingredients in real timeDryer sectionPulp and paper industryRaw material

The invention provides a dryer cylinder coating establishing device and a controlling method of the dryer cylinder coating establishing device. A feedback device for operation states after paper wrinkles is arranged to provide an induction signal for regulating a ratio of raw material content of a coating, so that properties of the coating are regulated in a real-time and dynamic mode, the paper always has a good wrinkling effect, and the situation that fluctuation of various factors which affect the properties of the coating in the actual production process can affect the wrinkling effect is avoided.

Owner:金红叶纸业(湖北)有限公司

Alcohol-acid type wrinkled resin and preparing method

InactiveCN101070376AIncrease productionPromote development and utilizationCoatingsPolymer scienceGlycerol

The present invention discloses a kind of alkyd wrinkles resin. The alkyd wrinkles resin comprises linolenic acid, 95% glycerine, phthalic anhydride, adduct, xylene, and diluted solvent. The present invention also discloses the preparation method of the said alkyd wrinkles resin. The present invention avoids the general existing process of high-temperature refining tung oil and many defects of winkles paint brought by adding tung oil, and makes the process of synthesizing winkles paint resin simply and easy to operate, and also saves energy. The resin-prepared winkles paint synthesized by using the present invention, has no necessary to be diluted with benzene before using, which makes it more secure and more environmentally friendly for the use of winkles paint, and meets the overall trend of current development of paints.

Owner:NANJING CHANGJIANG PAINT

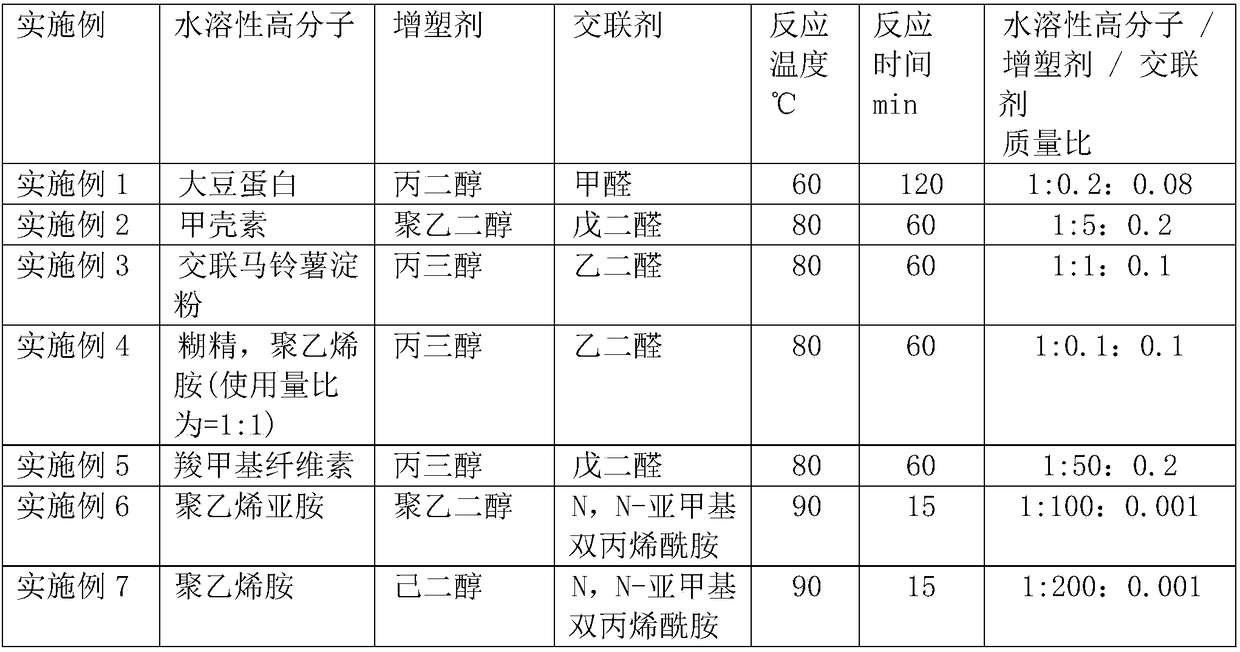

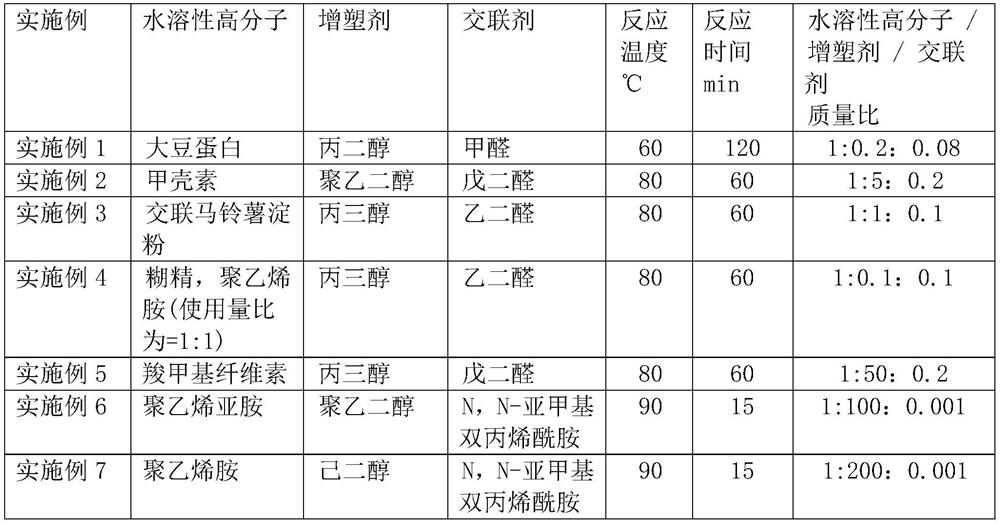

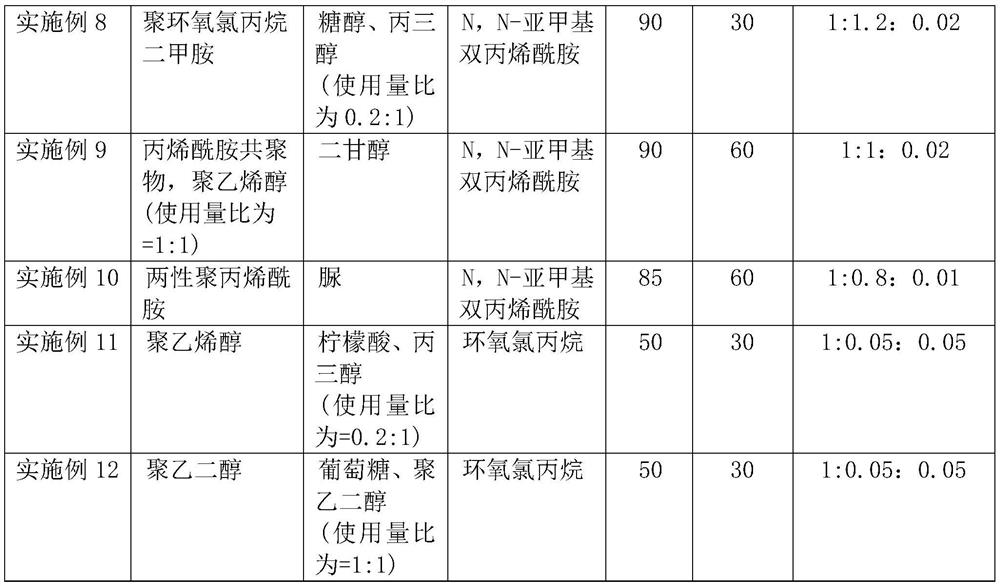

Preparation method of cylinder adhesive for crepe paper

ActiveCN108148502AChange film formationChange the cohesivenessStarch coatingsPolyether coatingsCross-linkPolymer science

The invention relates to a preparation method of cylinder adhesive for crepe paper. The existing cylinder adhesive generally has defects such as poor film forming performance, poor film forming elasticity and poor remoistening performance and the like. By utilizing a water-soluble macromolecular polymer in a water phase, by adding a cross-linking agent and a plasticizer, the cylinder adhesive is prepared by virtue of local cross-linking of macromolecules and the compounding of the plasticizer. The cylinder adhesive prepared by the invention is stable in performance, has good adhesive force andfilm forming performance, can adjust the remoistening performance and softness of a film and can well improve the wrinkling performance of the crepe paper.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Processing method for real silk crepe-de-chine shell fabric

ActiveCN104631005AHigh whitenessImprove shrinkageStretchingLiquid/gas/vapor textile treatmentShrinkage ratePulp and paper industry

The invention provides a processing method for real silk crepe-de-chine shell fabric. The processing method for the real silk crepe-de-chine shell fabric utilizes real silk green body raw materials to serve as raw materials, and the whole processing flow comprises the steps that (1) pre-processing is carried out; (2) degumming and white refining are carried out on the processed green body raw materials; cold water tank soaking is carried out, and the green body raw materials are placed in a cold water tank with the water temperature ranging from 15 DEG C to 30 DEG C and soaked for 40-60 minutes; primary refining process is carried out, 20-25 kg of dispersing agents, 20-25 kg of sodium carbonate, 4-6 kg of sodium silication and 1-1.5 kg of sodium hydrosulfite are added into a primary refined tank containing 5 tons of water, the water temperature rises from 80-85 DEG C to 100 DEG C, and refining is carried out again for 40-50 minutes; secondary refining process is carried out, 8-10 kg of the dispersing agents, 2-2.5 kg of the sodium carbonate, 4-6 kg of the sodium silication and 0.5-1 kg of sodium hydrosulfite are added into a secondary refined tank containing 5 tons of water, the water temperature is kept at 100 DEG C and refining is carried out for 30-40 minutes; (4) coiling is carried out, tension-free coiling is carried out by a loose type coiling machine; (5) arranging is carried out, drying and stretching are carried out by a tension-free carpet machine and a stretching machine, and then the real silk crepe-de-chine shell fabric with the shrinkage rate reaching to 6%-8% is obtained. According to the real silk crepe-de-chine shell fabric obtained by the processing method, the shrinkage rate can reach to 6%-8%, and the whiteness is good.

Owner:ZHEJIANG TONGHUI TEXTILE

Woolen knitting pleat clothing preparation method

The invention relates to a woolen knitting pleat clothing preparation method. The method comprises steps of: (1) preparing a solution, namely preparing the solution which contains 30-50g / L of an antifelting addition agent, 1-3g / L of a wetting agent and 10-20g / L of a reducing agent and has a pH value of 6.5-7.5; (2) soaking woolen knitting clothing into the solution to be completely soaked, and then spinning the clothing to be dry until the liquid content of the clothing is 65-90%; (3) carrying out pleat treatment on the clothing treated in step (2); (4) washing the pleat clothing with water for 5-15 minutes, then soaking the clothing in a solution containing 2.0% of hydrogen peroxide at 40-50 DEG C for 15-25 minutes, and finally, washing and airing the clothing. The preparation method is simple to operate, and the woolen knitting clothing has a good pleat effect.

Owner:上海嘉麟杰纺织科技有限公司

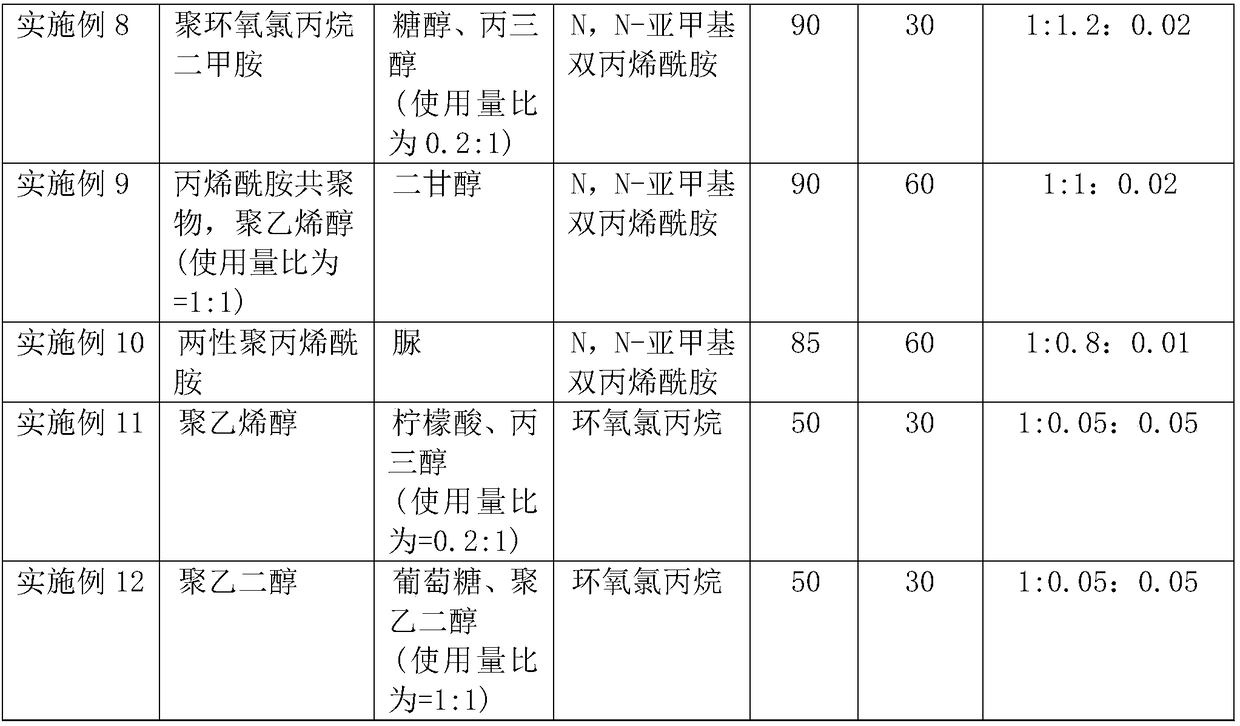

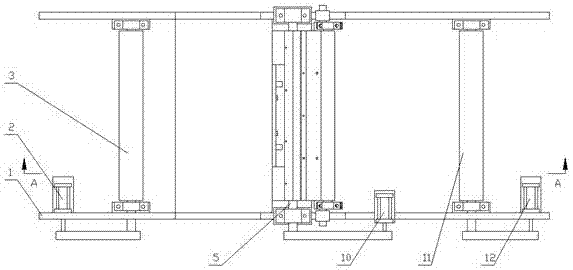

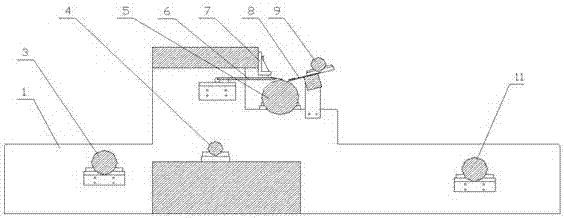

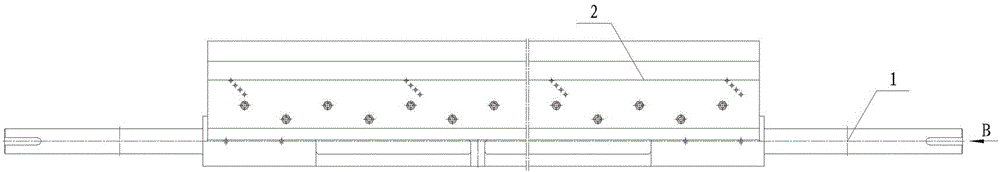

Vibration type wrinkling machine

InactiveCN107009685AGood wrinkle effectIncrease roughnessMechanical working/deformationPattern makingWrinkle skinPiezoelectric actuators

The invention discloses a vibration type wrinkling machine. The vibration type wrinkling machine comprises a machine frame, an unwinding device, a front-end tensioning roller, a conveying device, a material pressing mechanism, a vibrating mechanism, a material lifting mechanism, a rear-end tensioning roller and a winding device, wherein the unwinding device is arranged at the head part of the machine frame, the front-end tensioning roller is arranged on the right side of the unwinding device, the conveying roller is arranged in the middle of the machine frame, the material pressing mechanism, the vibrating mechanism and the material lifting mechanism are sequentially arranged above the conveying roller from left to right, the rear-end tensioning roller is arranged on the right side of the material lifting mechanism, and the winding device is arranged at the tail part of the machine frame. According to the vibration type wrinkling machine, rapid fluctuating pressure is provided for material to be processed through a piezoelectric actuator, compact and complex wrinkles are produced through the caused vibration, the roughness degree of the interior of the material to be processed is improved, the product obtained by processing has stronger adsorbability and ductility, the amplitude and the frequency of the vibration are controlled only by adjusting the input voltage of the piezoelectric actuator, and then the wrinkling effect is controlled. The vibration type wrinkling machine can be used for wrinkling cloth and paper and has a remarkable effect on improving the adsorption performance of the material.

Owner:ZHEJIANG UNIV

Denim antibiosis and crumpling finishing liquid and preparation method thereof

InactiveCN107326666AImprove antibacterial propertiesGood wrinkle effectBiochemical fibre treatmentWrinkle resistant fibresMoisture absorptionAdditional values

The invention provides a denim antibiosis and crumpling finishing liquid, which is characterized by being prepared from the following ingredients in parts by weight: 25-35 parts of crumpling resin, 5-12 parts of stiffening agent, 10-20 parts of plant extracting solution, 4-8 parts of methylcellulose, 2-6 parts of polypropylene glycol, 25-35 parts of water, 1-4 parts of dispersant and 0.5-2 parts of buffer agent. The denim antibiosis and crumpling finishing liquid contains the natural plant extracting solution so as to endow traditional denim garments with dual functions of antibiosis and crumpling, the finished denim garment has the advantages of good antibiosis and crumpling effects and excellent moisture absorption and air permeability. By use of the method, production efficiency is improved, production cost is reduced, and the additional value of the denim garments is improved.

Owner:SUZHOU JINGCUN GARMENT CO LTD

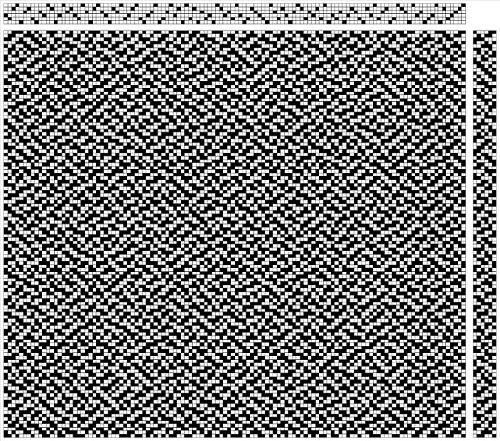

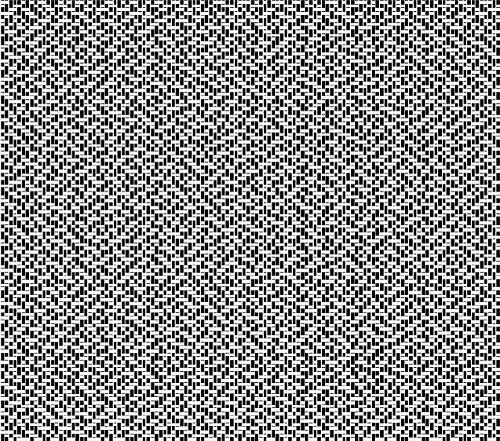

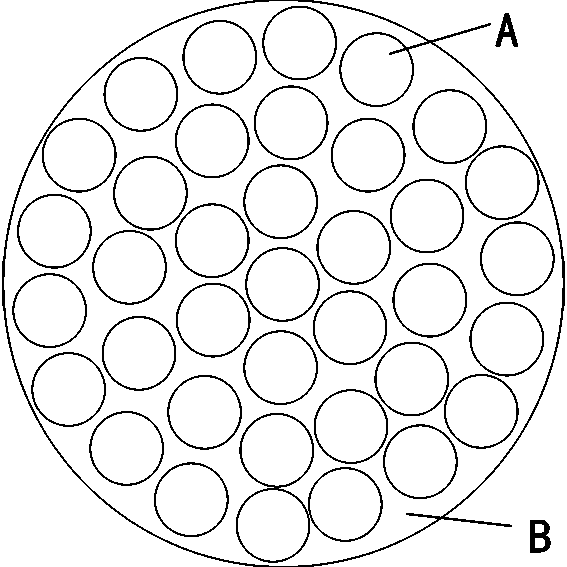

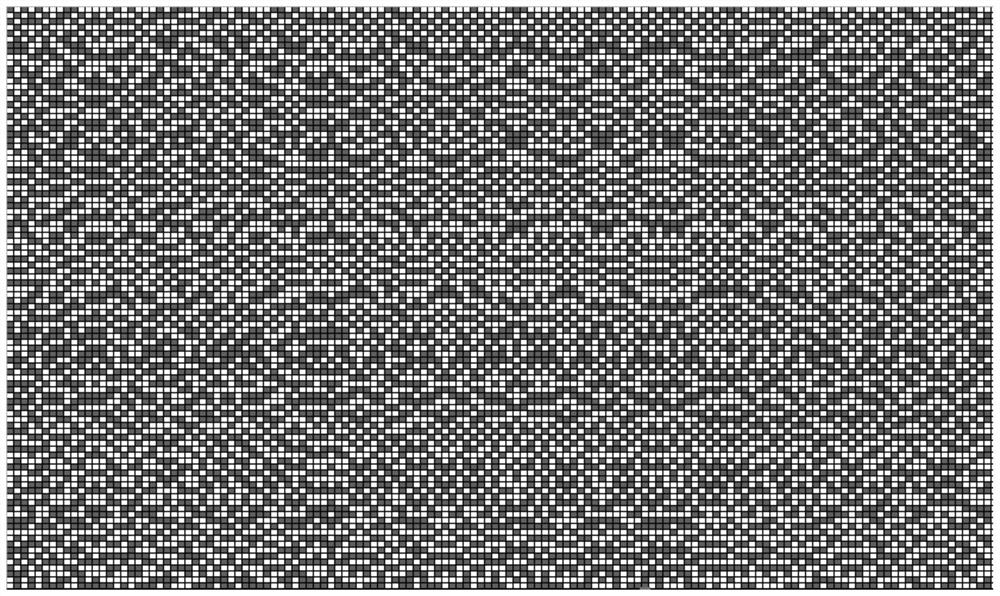

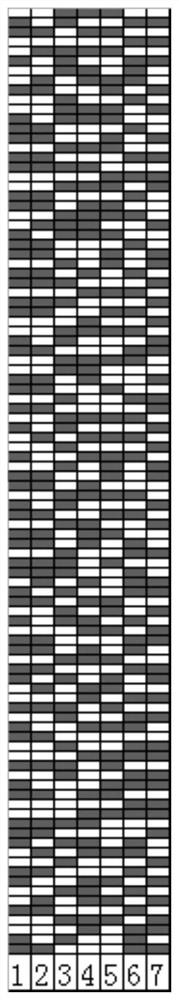

Spunbonded nonwoven fabric and filter using same

ActiveUS9011567B2Improve rigidityGood wrinkle effectCombination devicesDispersed particle filtrationPolyesterEngineering

The purpose of the present invention is to obtain a spunbonded nonwoven fabric, which comprises a single-component polyester-based fibers, having a high basis weight and a high rigidity by embossing, which is difficult to attain in the conventional art. Further, the present invention provides a filter base material having excellent pleatability, pleat retention property and durability, and a filter using thereof. The present spunbonded nonwoven fabric is obtained by subjecting a deposited fiber assembly to a thermocompression bonding by embossing with a pair of an embossing roll and a flat metal roll, and has a basis weight of 150 to 400 g / m2, a longitudinal bending repulsion of 20 to 60 mN and a longitudinal tensile strength of 400 N / 5 cm or more.

Owner:TOYOBO MC CORP

Preparation method of woolen knitted wrinkled clothes

InactiveCN103696238AGood wrinkle effectEasy to operateAnimal fibresTextile shapingSulfite saltGlycerol

The invention discloses a preparation method of woolen knitted wrinkled clothes. The method comprises the following steps: (1) preparing working liquid from 1g / L fatty alcohol-polyoxyethylene ether, an 25g / L anti-felt aid, a 5-6g / L wetting agent, 1g / L hydroxypropyl methyl cellulose, 8-9g / L anhydrous sodium sulfite, 1g / L polyglycerol monostearate and 4-7g / L sodium pyrosulfite, and adding lauric acid for adjusting the pH value to 5.5; (2) soaking woolen knitted clothes into the working liquid under the condition that the bath ratio is 3:25, and drying the clothes by spinning after fully soaking till the liquid content of the clothes is 55 percent; (3) wrinkling, and ironing by adopting an ironing board of which the temperature is 165 DEG C for 20 seconds; and (4) flushing the wrinkled clothes with water for 25 minutes, soaking into a solution of 55 DEG C containing 3 percent of hydrogen peroxide for 35 minutes, washing with water, and airing. The preparation method of the woolen knitted wrinkled clothes, which is disclosed by the invention, is easy to operate, and the woolen knitted clothes has a very good wrinkling effect.

Owner:常熟市凯丽针纺织有限公司

A kind of preparation method of cylinder sticking agent for crepe paper

ActiveCN108148502BChange film formationGood wrinkle effectStarch coatingsPolyether coatingsPolymer sciencePlasticizer

The invention relates to a preparation method of cylinder adhesive for crepe paper. The existing cylinder adhesive generally has defects such as poor film forming performance, poor film forming elasticity and poor remoistening performance and the like. By utilizing a water-soluble macromolecular polymer in a water phase, by adding a cross-linking agent and a plasticizer, the cylinder adhesive is prepared by virtue of local cross-linking of macromolecules and the compounding of the plasticizer. The cylinder adhesive prepared by the invention is stable in performance, has good adhesive force andfilm forming performance, can adjust the remoistening performance and softness of a film and can well improve the wrinkling performance of the crepe paper.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Hygroscopic and sweat releasing knitted fabric with shape memory function and processing method thereof

Owner:SHANGHAI JIALE

Method and application of dyeing and finishing of pure cotton fabrics

ActiveCN108642922ALower pHReduce sheddingDry-cleaning apparatus for textilesGrip property fibresSodium bicarbonateSodium metasilicate

The invention belongs to the technical field of dyeing and finishing of fabrics and relates to a method and application of dyeing and finishing of pure cotton fabrics. The cotton fabric dyeing and finishing method comprises pretreatment, dyeing and post-treatment. The dye used in the dyeing process is an s-triazine-type reactive dye. The post-treatment process orderly comprises sand washing, waterwashing, softening treatment, dehydration and drying. In the sand washing process, a mixture of sodium metasilicate and sodium bicarbonate is used as a sand washing aid, the sand washing operation iscarried out at 95-100 DEG C for 15-25 DEG C, the fabric is cooled to 35-45 DEG C and then is subjected to sand washing for 30-50min, the washing solution is discharged and the fabric is washed by water. The softening treatment process utilizes a softening agent comprising a mixture of polyurethane and epoxy modified silicone resin. The method can improve the production efficiency, reduce the generation of the defective cloth, can also produce soft and fluffy peach skin fuzzy feeling on the cloth surface, and has a natural wrinkle and antique effect.

Owner:新乡橄榄枝纺织化工有限公司

Creping adhesive and process for creping tissue paper

InactiveCN1251149AGood wrinkle effectMechanical working/deformationSpecial paperPolymer scienceAdhesive

An adhesive for applying to a creping surface in the process for dry creping tissue paper is disclosed. The adhesive comprises cationic starch and optionally a polyvinyl alcohol and a water-soluble, thermosetting, cationic polyamide-epihalohydrin resin. The adhesive provides high adhesion and doctorability for dry creping.

Owner:THE PROCTER & GAMBLE COMPANY

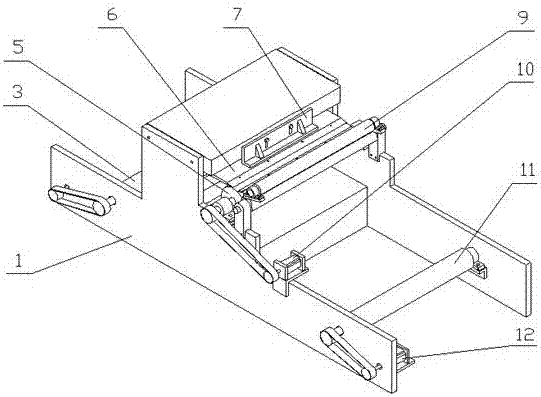

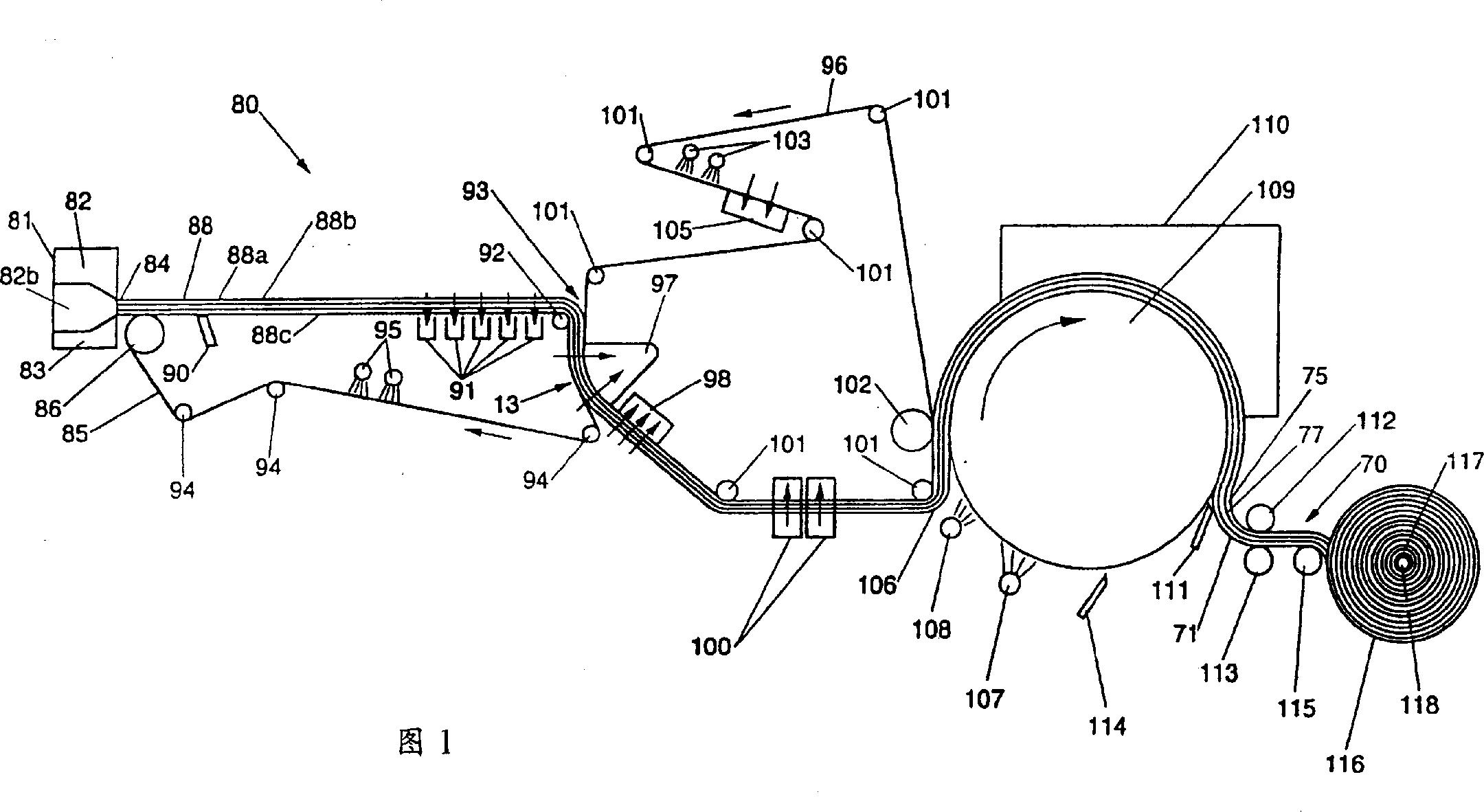

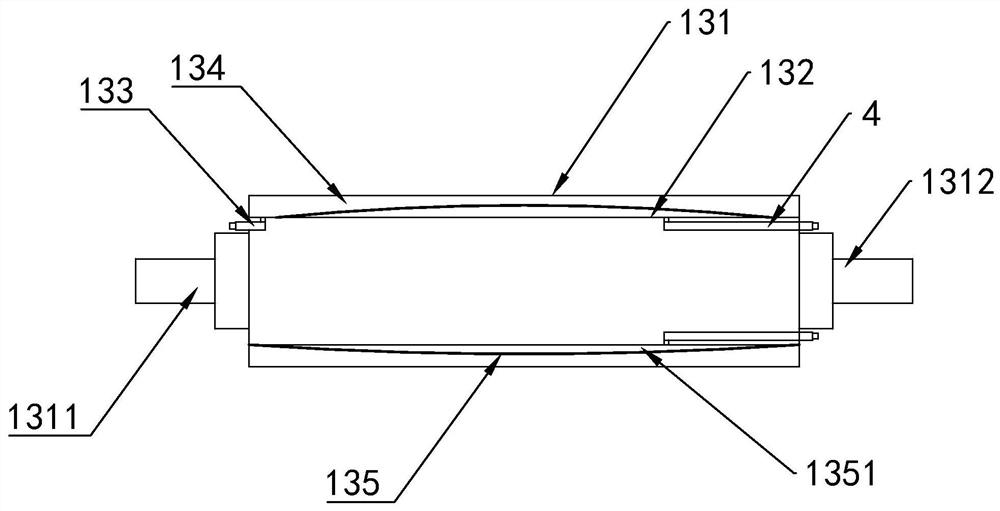

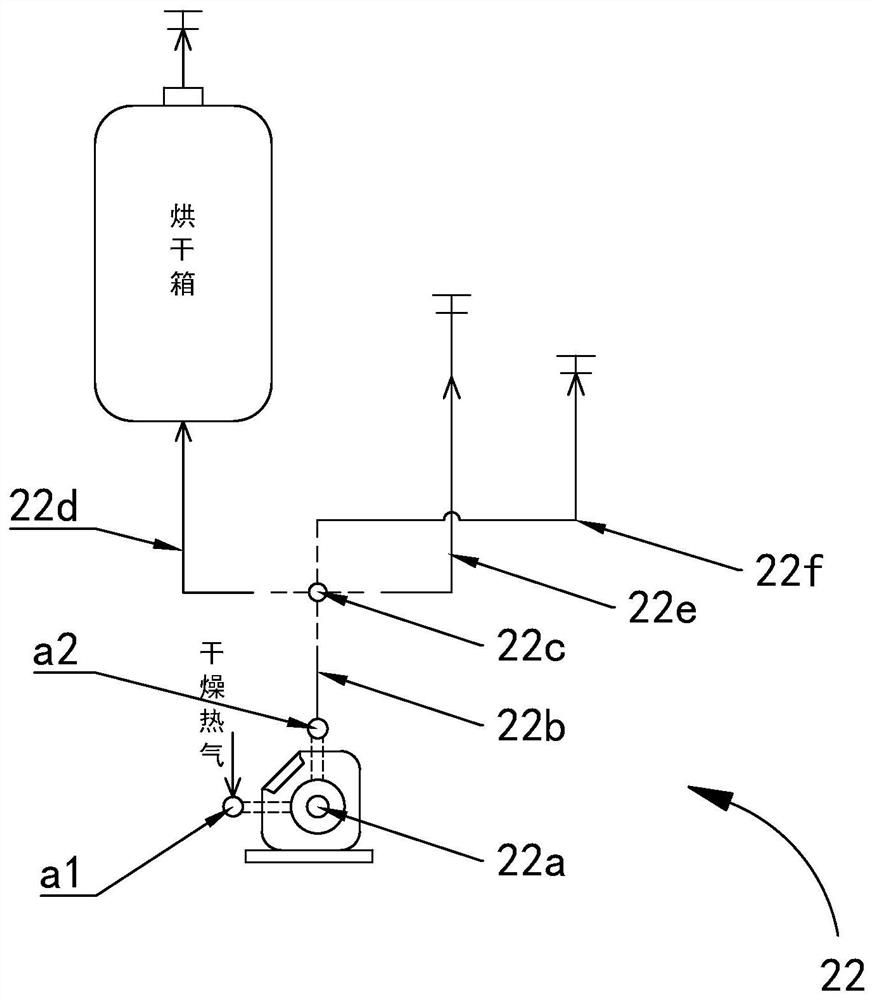

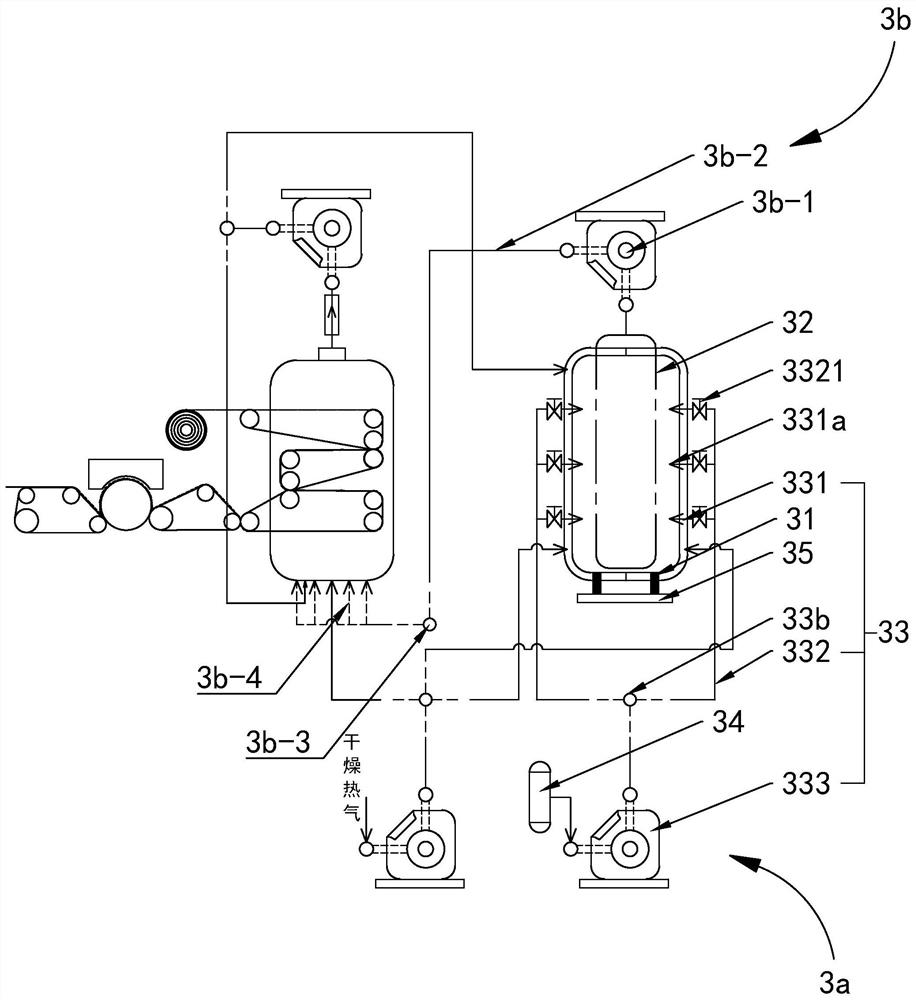

Crepe paper manufacturing system and manufacturing method based on speed difference wrinkling

InactiveCN113584928AIncrease fluffinessHigh strengthDryer sectionPaper/cardboardCrêpe paperManufacturing systems

The invention relates to a crepe paper manufacturing system based on speed difference wrinkling. The crepe paper manufacturing system is characterized by comprising a wrinkling device with a rack; the wrinkling device comprises a paper web input mechanism, a drying cylinder and a vacuum wrinkling roller; the paper web input mechanism, the drying cylinder and the vacuum wrinkling roller are sequentially mounted on the rack; and the vacuum wrinkling roller and the drying cylinder extrude each other, and the rotating speed of the vacuum wrinkling roller is lower than that of the drying cylinder, so that speed difference is generated, and paper wrinkling is achieved. The system is high in practicability and easy to popularize.

Owner:徐岳斌

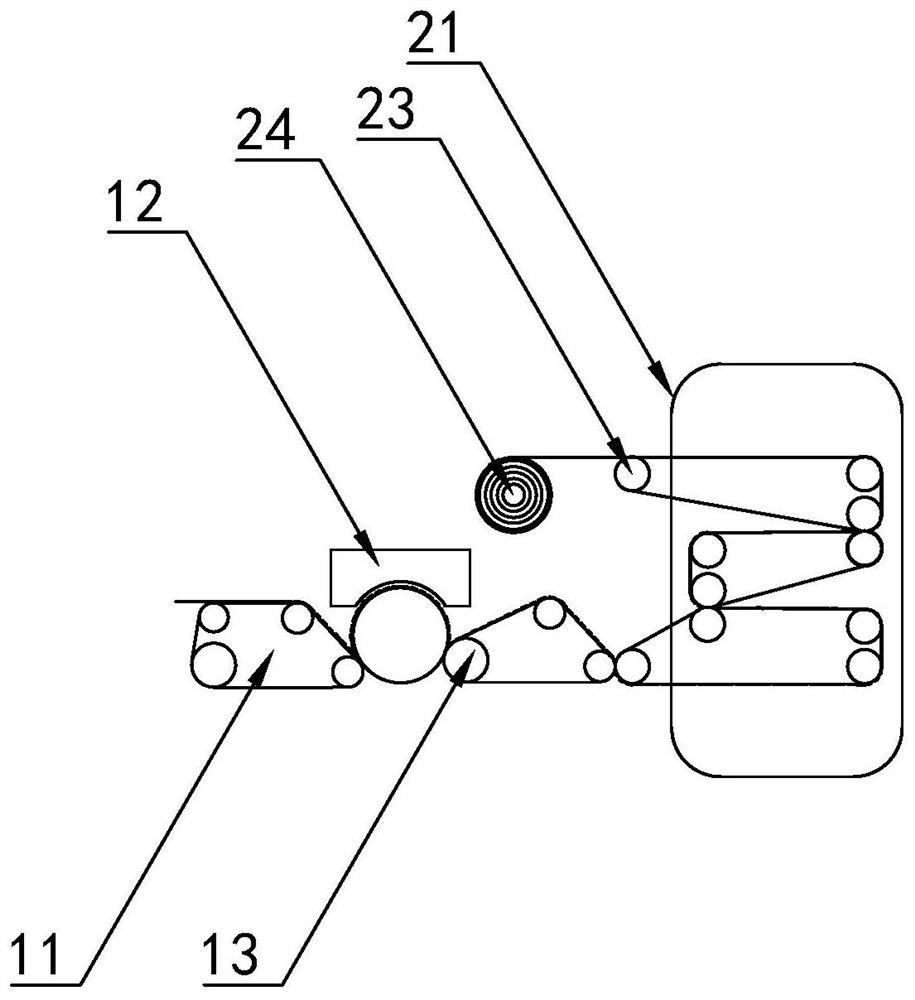

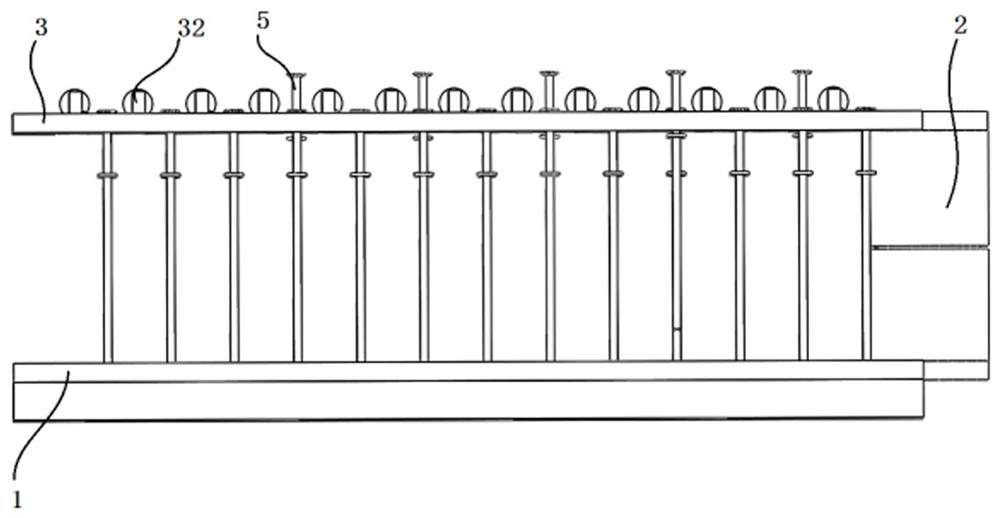

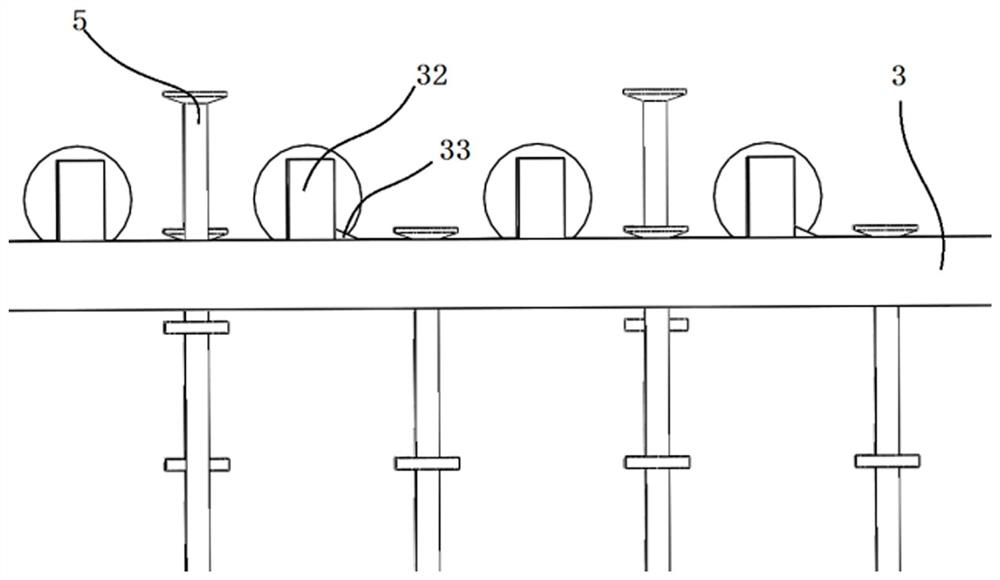

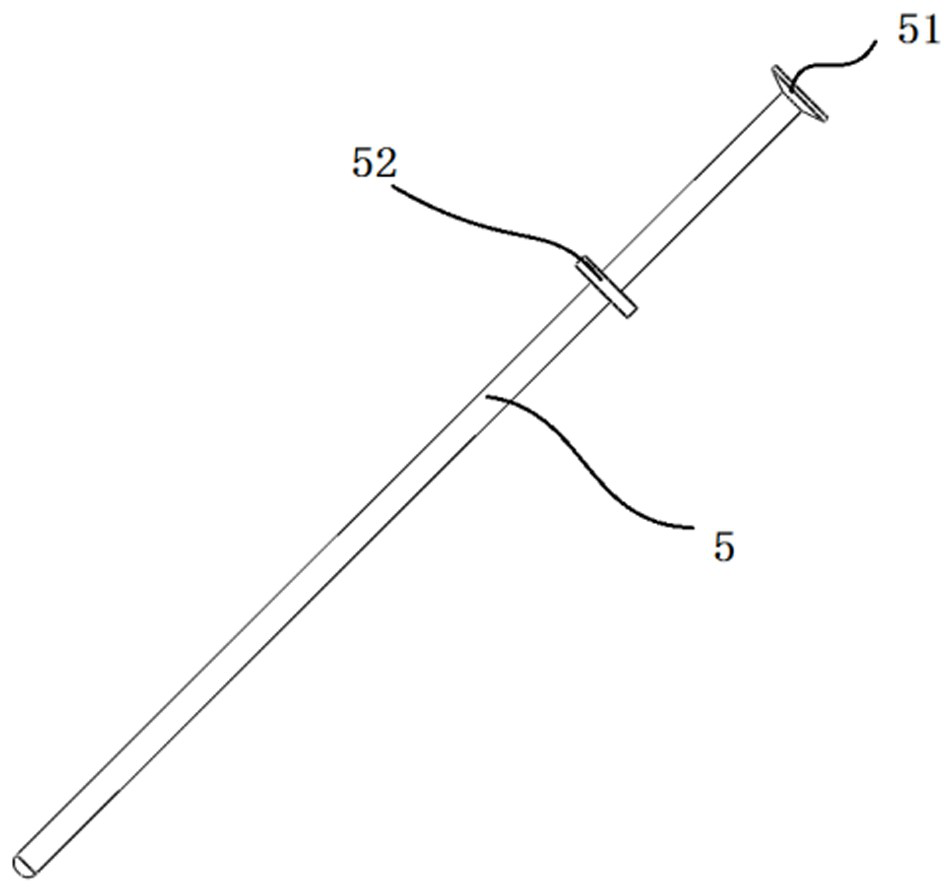

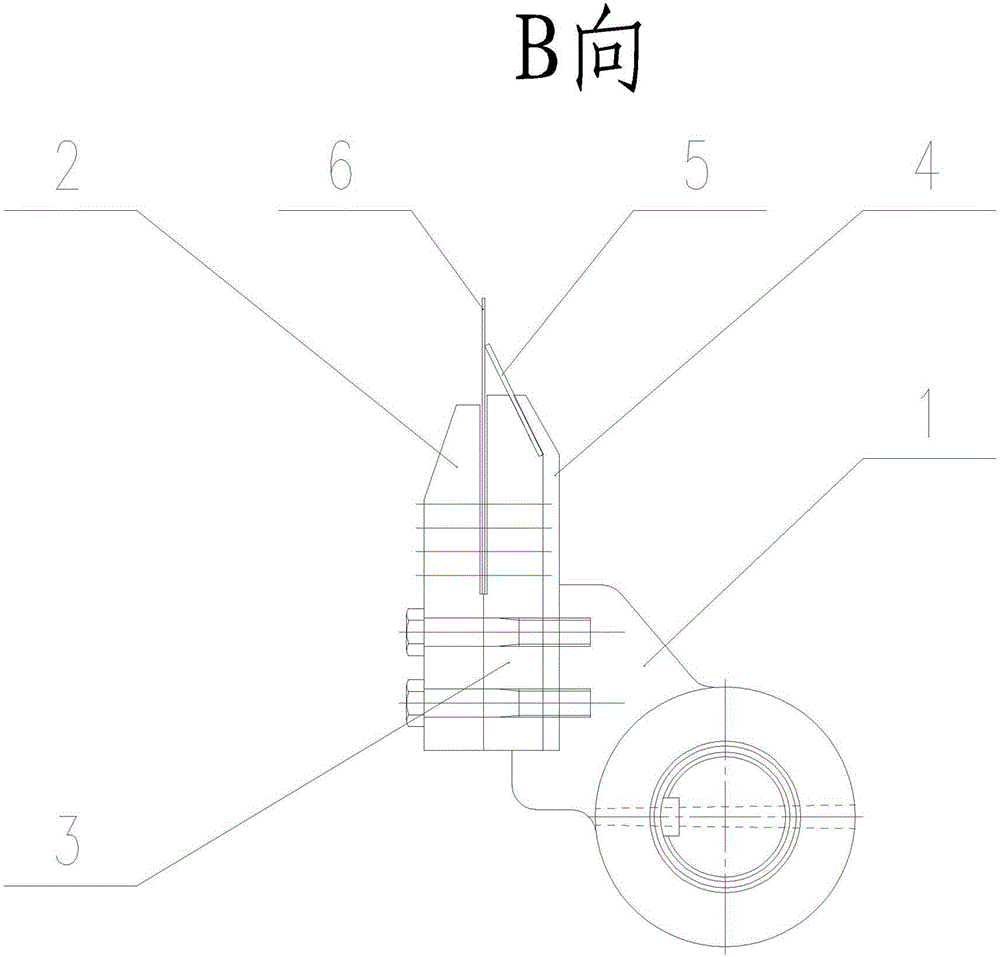

High-degree-of-freedom needle control equipment and use method thereof

InactiveCN112048903AGood wrinkle effectHas a thickness propertyTextile shapingFiberStructural engineering

The invention discloses high-degree-of-freedom needle control equipment and a use method thereof. The high-degree-of-freedom needle control equipment comprises a laying mechanism and a needle controlmechanism arranged at one side of the laying mechanism, wherein the needle control mechanism comprises a limiting plate and non-destructive needles, long-strip holes are densely formed in the limitingplate and distributed in parallel, a plurality of adjusting blocks are arranged on the limiting plate and perpendicular to the long-strip holes, and the adjusting blocks are movably connected with the limiting plate through sliding rails; the widths of the long-strip holes are consistent with the diameters of the non-destructive needles, the plurality of nondestructive needles penetrate through any long-strip hole, the adjusting blocks and the non-destructive needles are arranged at intervals one by one within the range of any long-strip hole, and needle heads of the non-destructive needles face the laying mechanism; and the laying mechanism comprises a material plate and a telescopic column, the two axial ends of the telescopic column are connected with the limiting plate and the material plate respectively, and grooves are densely formed in the material plate. According to the invention, the non-destructive needles are inserted into gaps between cloth fibers, the transverse displacement of the non-destructive needles is adjusted to realize diversified wrinkle treatment on the cloth fibers, use is convenient and fast, and diversified products can be obtained.

Owner:SUZHOU JINGJIEWEI FABRIC TECH CO LTD

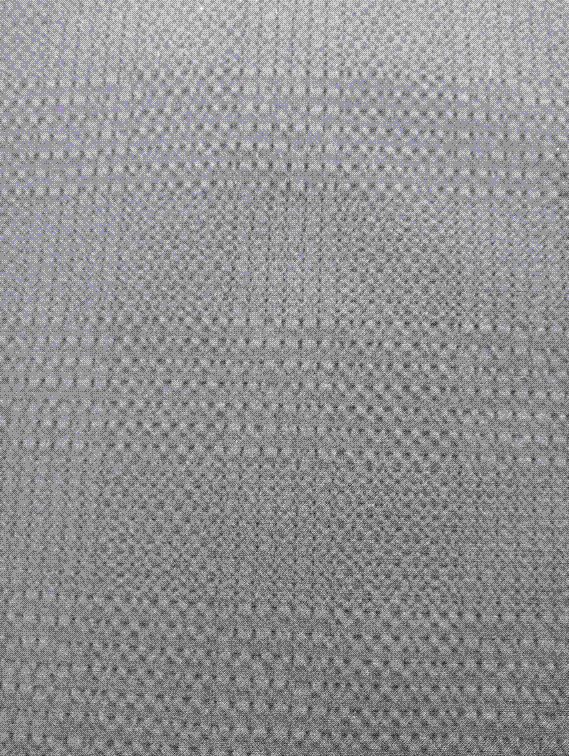

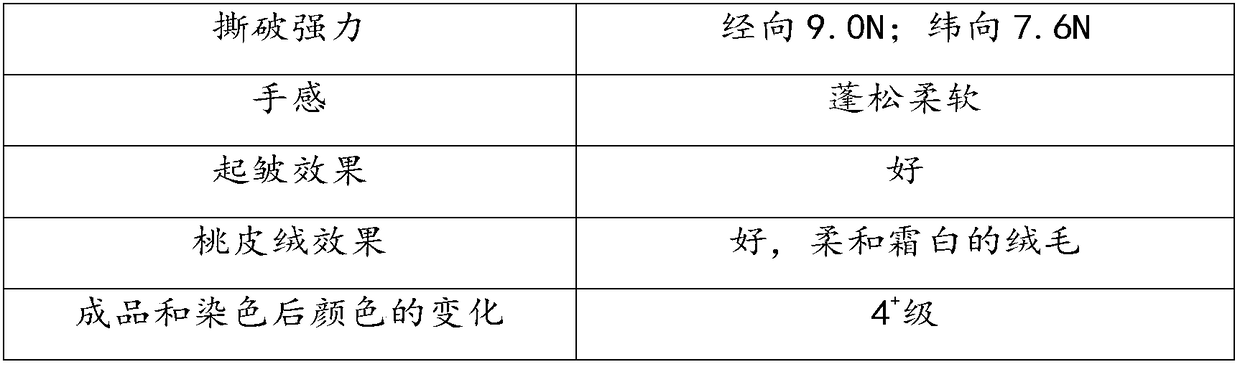

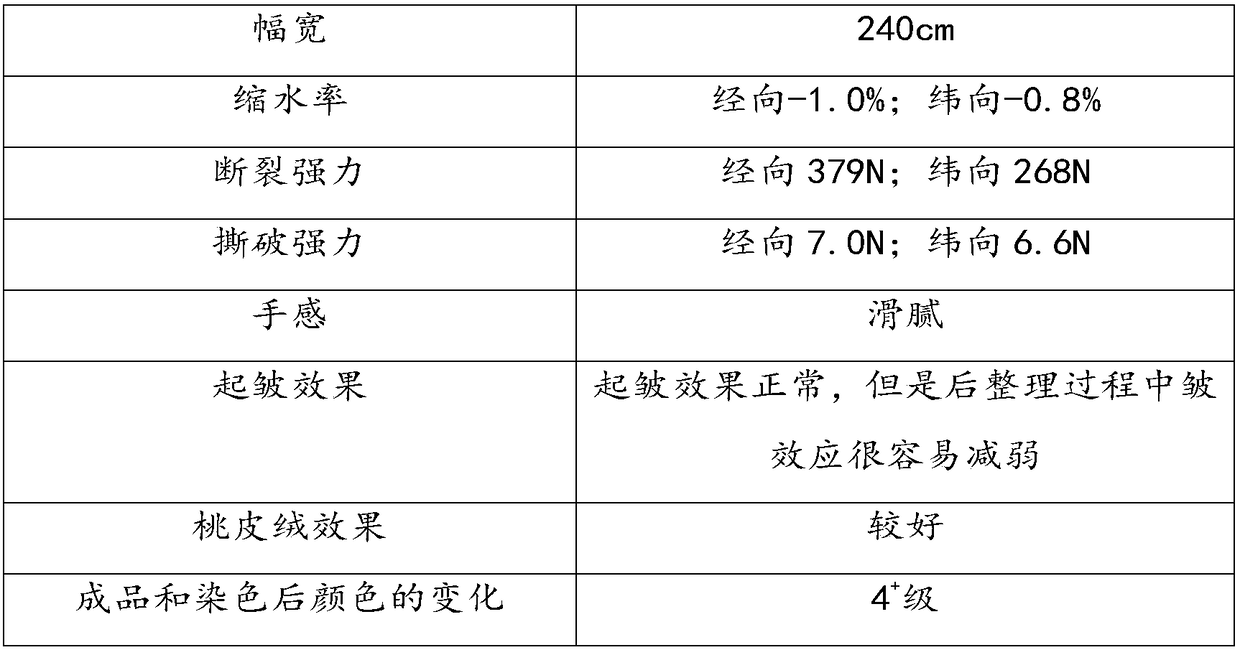

Moisture-absorbing sweat-releasing fine denier polyester shell fabric and preparation method thereof

InactiveCN111441123AReduce rateSmall reduction rateFibre typesHeating/cooling textile fabricsPolyesterPolymer science

The invention discloses a moisture-absorbing sweat-releasing fine denier polyester shell fabric and a preparation method thereof. The moisture-absorbing sweat-releasing fine denier polyester shell fabric is prepared by the steps of performing spooling, texturing, double twisting, sectional warping, and weaving on a loom on fine denier polyester filaments, performing weaving with a water-jet loom,and sequentially carrying out preshrinking refining, decrement splitting, dyeing, and shaping after finishing. The moisture-absorbing sweat-releasing fine denier polyester shell fabric is characterized in that the fine denier polyester filaments are sea-island type bi-component composite polyester filaments of 50-75D / 24-36F / 24-37 i, the composite ratio of island phase to sea phase is 75: 25-80: 20, the fine denier polyester filaments are processed on a one-step texturing two-for-one twister for later use, the density of warp yarns for weaving on the loom is 58-72 n / cm, the density of weft yarns on the loom is 33-40 n / cm, a 6-16-heald multi-arm water-jet loom is adopted to weave according to a coplanar moss crepe texture, and a slight alkali decrement incomplete splitting treatment mode isadopted for the decrement splitting. The moisture-absorbing sweat-releasing fine denier polyester shell fabric has an obvious crepe effect and has the functions of moisture absorption and sweat releasing.

Owner:徐州荣盛达纤维制品科技有限公司

Anti-ultraviolet fabric, finishing method thereof, and anti-ultraviolet fabric product

InactiveCN107190505AImproves UV resistanceImprove mechanical propertiesLight resistant fibresWrinkle resistant fibresUltravioletEngineering

The invention discloses an anti-ultraviolet fabric, a finishing method thereof, and an anti-ultraviolet fabric product, and belongs to the technical field of industrial fabric treatment. The finishing method comprises following steps: a mixed solution composed of chitosan, a dispersant, and attapulgite is subjected to polymerization, and then ultrasonic treatment is carried out so as to obtain an attapulgite-chitosan microcapsule solution; fabric to be modify is immersed in the attapulgite-chitosan microcapsule solution, and then is taken out from the attapulgite-chitosan microcapsule solution, and is dried so as to form a capsule structure with a capsule wall and a capsule core. The multiple effects of attapulgite can be achieved fully, and fabric ultraviolet resistance is improved obviously; the finishing method is capable of improving fabric comprehensive performance; the anti-ultraviolet fabric product is obtained via finishing of the anti-ultraviolet fabric via the finishing method, and is excellent in ultraviolet resistance.

Owner:YANCHENG INST OF IND TECH

PTT (poly(trimethylene terephthalate)) memory fabric production process

InactiveCN101736487BSoft touchShinyWarping machinesHeating/cooling textile fabricsFiberPolyethylene terephthalate

The invention relates to a PTT (poly(trimethylene terephthalate)) memory fabric, in particular to a PTT memory fabric production process. The production process comprises the following steps of: batch warping, starching, shaft combining, leasing, looming healding, weaving, pretreatment of dying and finishing, alkali quantity decreasing, dying, waterproof processing and thermal forming. The fabrichas unique memory function and comfortable hand feel, the performance of smoothing by touching the fabric enables the product to achieve an effect of totally ironing free, and favorable draping effect and recovery capability enable the fabric to become one of fashionable functional fabrics. Fibers of the fabric are completely biodegradable under certain condition and the fabric is an environmental-protection and green product.

Owner:杭州宏峰纺织集团有限公司

Crepe paper manufacturing system and manufacturing method based on speed difference wrinkling

InactiveCN113584927AIncrease fluffinessGood strengthDryer sectionPaper/cardboardPaper sheetCrêpe paper

The invention relates to a crepe paper manufacturing system based on speed difference wrinkling, wherein the system is characterized by comprising a wrinkling device with a rack, and the wrinkling device comprises a paper web input mechanism, a drying cylinder and a vacuum wrinkling roller; the paper web input mechanism, the drying cylinder and the vacuum wrinkling roller are sequentially mounted on the rack; and the vacuum wrinkling roller and the drying cylinder extrude each other, and the rotating speed of the vacuum wrinkling roller is lower than that of the drying cylinder, so that speed difference is generated, and paper wrinkling forming is achieved. The system is high in practicability and easy to popularize.

Owner:徐岳斌

Creping scraper for paper machine

The invention discloses a creping scraper for a paper machine, and belongs to the technical field of paper machines. The creping scraper for the paper machine comprises a knife rest and a blade, wherein the knife rest is connected with a front blade clamping block and a rear blade clamping block; the blade is placed between the front blade clamping block and the rear blade clamping block; and the front blade clamping block and the rear blade clamping block are matched with each other to clamp the blade. The creping scraper for the paper machine is simple in structure, easy to operate, convenient to use, low in cost, quite wide in using range and suitable to be popularized and used; and moreover, the creping effect is quite high, the length of the blade can be adjusted according to actual needs, and the creping scraper can be used for paper machines in various models and crepe paper.

Owner:SICHUAN JINGYAN COUNTY DURING THE LIGHT IND MACHINERY FACTORY

Household paper making machine

The invention discloses a household paper making machine. The household paper making machine comprises a formation part, a conveying part, a drying part and a curling part which are arranged in sequence, and a model tape part is arranged between the conveying part and the drying part. The model tape part comprises an automatic power model tape; a shoe pressure roller is installed on the bottom of the input end of the automatic power model tape; a counter-pressure roller is installed at the position, directly facing the shoe pressure roller, on the inner side of the automatic power model tape; the drying mechanism is composed of a Yankee dryer; a smoothly conveying press roller is installed at the end, directly facing the Yankee dryer, of the inner side of the automatic power model tape. According to the household paper making machine, paper first passes a vacuum dehydration roller and then is combined with the model tape at the shoe pressure position; paper web is conveyed into the Yankee dryer through the smoothly conveying press roller, and the main squeezing process is conducted at the shoe pressure position; the bulk is higher, more fibers are saved, the processing process is more saved, and the softness, the bulk and the water absorption performance of the paper are good.

Owner:徐州泰丰泵业有限公司

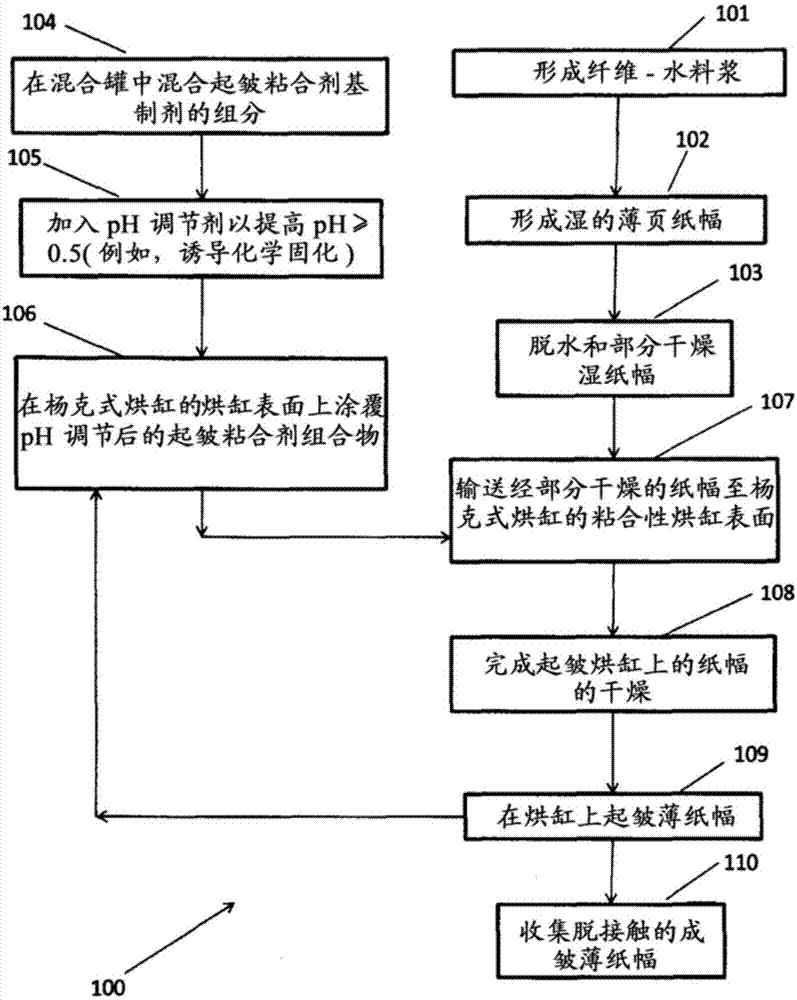

Creping methods using ph-modified creping adhesive compositions

InactiveCN103842589ARelieve pressureReduce dwell timeCreping adhesives additionPaper coatingFiberPolymer

A method for manufacturing a creped fiber web is provided and includes providing a rotating cylindrical dryer surface, providing a creping adhesive composition or coating package having a pH boosted at least 0.5 pH units relative to its original base formulation pH in the range of from about 4.5 to about 9, for chemically setting a crosslinkable polymer component at least in part before applying the creping adhesive composition to the rotating cylindrical dryer surface to provide an adhesive dryer surface on which a fiber web can be transferred, dried, and creped.

Owner:BUCKMAN LAB INT INC

Treatment process of pleating fabric of knitted sweater

The invention discloses a treatment process of pleating fabric of a knitted sweater. The treatment process comprises steps as follows: 1) solution preparation: 1-3 g / L fatty alcohol polyoxyethylene ether, a 15-25 g / L shrink-proofing aid, a 3-5 g / L wetting agent, 1 g / L hydroxypropyl methyl cellulose, 1 g / L oligomer polyols, 4-7 g / L bisulfite and a 4-5 g / L crosslinking agent are prepared, and lauricacid is added to adjust the pH value to be 5.5-6.5; 2) knitted sweater clothing is soaked in the solution and spin-dried until the take-up rate of the clothing is 60% after being sufficiently soaked;3) the treated clothing is subjected to pleating finishing; 4) the clothing subjected to pleating finishing is washed with water for 5-15 min, 2%-4% (o.w.f) of a penetrant is added, the knitted sweater clothing is soaked at the temperature of 30-40 DEG C for 20-40 min, and finally, water washing and airing are performed. By means of the process, the knitted sweater clothing has a good pleating effect.

Owner:HUIZHOU NANXUAN KNITWEAR FACTORY CO LTD

Weaving process of slightly-elastic crape

InactiveCN113463250ADifferent wrinkle linesGood wrinkle effectWoven fabricsChemical treatmentPolyester

The invention discloses a weaving process of a slightly-elastic crape, and relates to the technical field of textile. The specific preparation process of the crape comprises the following steps of (1) a warping process; (2) a sizing process; (3) a denting process; and (4) a weaving process. According to the crape weaving process, fine denier polyester / Tanboocel (50 / 50) 60 compact is adopted as warp yarn, fine denier polyester / Tanboocel (50 / 50) 60 + 30D is adopted as weft yarn, the crape is woven through selection of the warp yarn and the weft yarn and reasonable matching of textures, meanwhile, the woven crape has the characteristic of micro-elasticity by means of micro-elasticity of the weft yarn, the cloth cover has different wrinkles, the wrinkling effect is good, and the crape is rich in elasticity and high in comfort; and the crape woven through the weaving technology does not need chemical treatment, is safe, environmentally friendly and free of pollution, and solves the problems that in the prior art, the crepe wrinkling appearance effect is single, a chemical treatment method is adopted for post-treatment of the crape, and the environment is polluted.

Owner:JIHUA 3542 TEXTILE CO LTD

Woolen knitting pleat clothing preparation method

The invention relates to a woolen knitting pleat clothing preparation method. The method comprises steps of: (1) preparing a solution, namely preparing the solution which contains 30-50g / L of an antifelting addition agent, 1-3g / L of a wetting agent and 10-20g / L of a reducing agent and has a pH value of 6.5-7.5; (2) soaking woolen knitting clothing into the solution to be completely soaked, and then spinning the clothing to be dry until the liquid content of the clothing is 65-90%; (3) carrying out pleat treatment on the clothing treated in step (2); (4) washing the pleat clothing with water for 5-15 minutes, then soaking the clothing in a solution containing 2.0% of hydrogen peroxide at 40-50 DEG C for 15-25 minutes, and finally, washing and airing the clothing. The preparation method is simple to operate, and the woolen knitting clothing has a good pleat effect.

Owner:上海嘉麟杰纺织科技有限公司

A kind of processing method of silk double-sided crepe fabric

ActiveCN104631005BHigh whitenessImprove shrinkageStretchingLiquid/gas/vapor textile treatmentShrinkage rateWater temperature

The invention provides a processing method for real silk crepe-de-chine shell fabric. The processing method for the real silk crepe-de-chine shell fabric utilizes real silk green body raw materials to serve as raw materials, and the whole processing flow comprises the steps that (1) pre-processing is carried out; (2) degumming and white refining are carried out on the processed green body raw materials; cold water tank soaking is carried out, and the green body raw materials are placed in a cold water tank with the water temperature ranging from 15 DEG C to 30 DEG C and soaked for 40-60 minutes; primary refining process is carried out, 20-25 kg of dispersing agents, 20-25 kg of sodium carbonate, 4-6 kg of sodium silication and 1-1.5 kg of sodium hydrosulfite are added into a primary refined tank containing 5 tons of water, the water temperature rises from 80-85 DEG C to 100 DEG C, and refining is carried out again for 40-50 minutes; secondary refining process is carried out, 8-10 kg of the dispersing agents, 2-2.5 kg of the sodium carbonate, 4-6 kg of the sodium silication and 0.5-1 kg of sodium hydrosulfite are added into a secondary refined tank containing 5 tons of water, the water temperature is kept at 100 DEG C and refining is carried out for 30-40 minutes; (4) coiling is carried out, tension-free coiling is carried out by a loose type coiling machine; (5) arranging is carried out, drying and stretching are carried out by a tension-free carpet machine and a stretching machine, and then the real silk crepe-de-chine shell fabric with the shrinkage rate reaching to 6%-8% is obtained. According to the real silk crepe-de-chine shell fabric obtained by the processing method, the shrinkage rate can reach to 6%-8%, and the whiteness is good.

Owner:ZHEJIANG TONGHUI TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com